Complex-wave type harmonic drive speed reducer

A technology of harmonic drive and reducer, applied in the direction of transmission, transmission parts, gear transmission, etc., to achieve the effect of large transmission ratio, compact structure and small outline size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

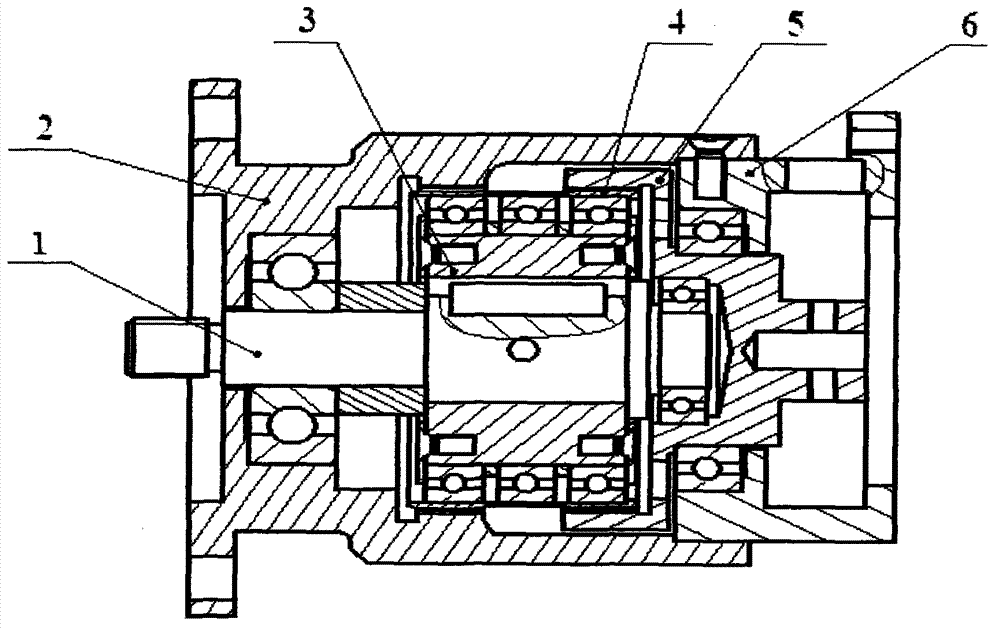

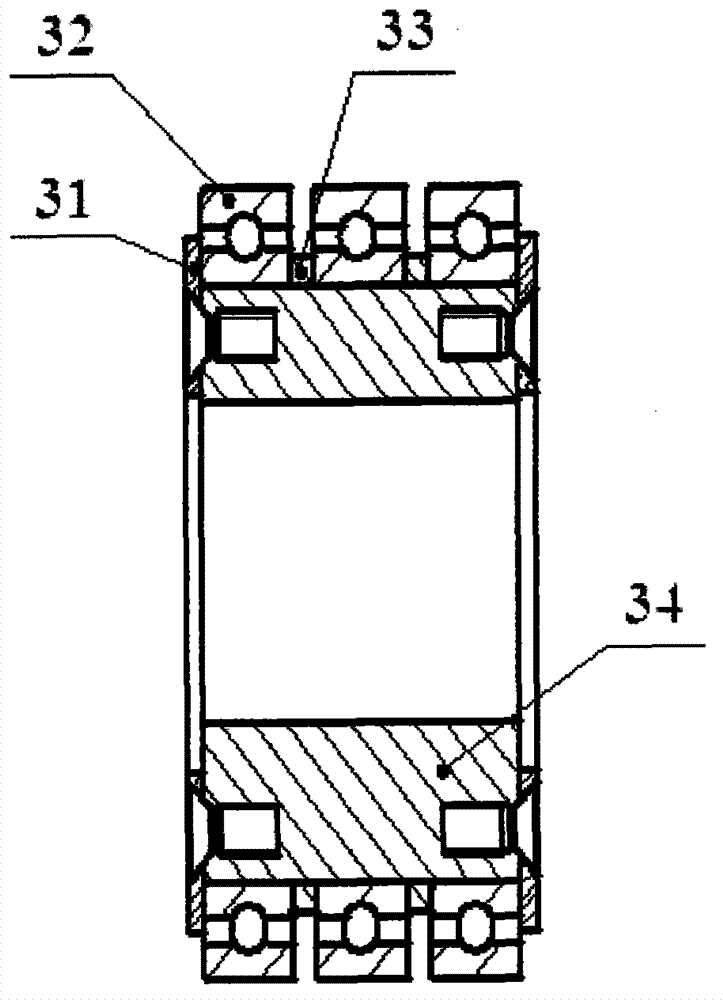

[0013] Such as figure 1 As shown, the compound wave harmonic transmission reducer of the present invention includes an input shaft 1, a fixed rigid wheel (ie, a housing) 2, a wave generator 3, a double flexible wheel 4, an output rigid wheel 5, and an end cover 6. Among them, the wave generator 3 and the input shaft 1 are tightly connected by keys and cylindrical pins, and the output steel wheel 5 is integrated with the output part, and the torque is transmitted in the form of a shaft, and the deceleration is realized. The motor drives the input shaft 1 to rotate at a high speed, and the input shaft 1 drives the wave generator 3 to rotate, causing controllable deformation to the flex spline 4. The external gear at one end of the flex spline 4 meshes with the internal gear of the fixed rigid spline 2, resulting in a tooth-staggered movement. The first-or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com