Pipeline centring method

A pipeline and centering device technology, which is applied to tubular objects, auxiliary devices, applications, etc., can solve the problems of poor centrality control, affecting the quality and volume of pipeline installation in the tunnel, and achieve the effect of convenient pipeline centering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

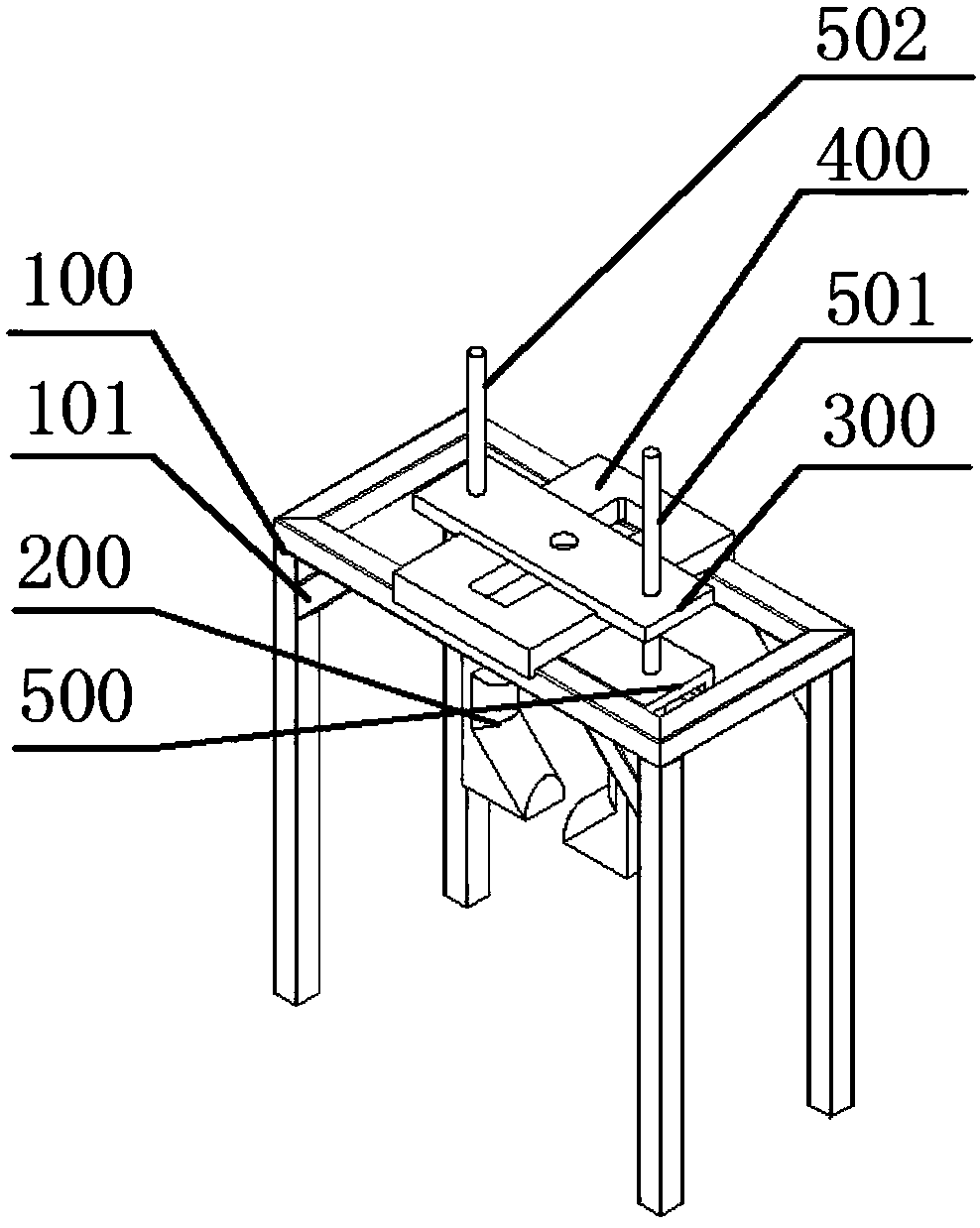

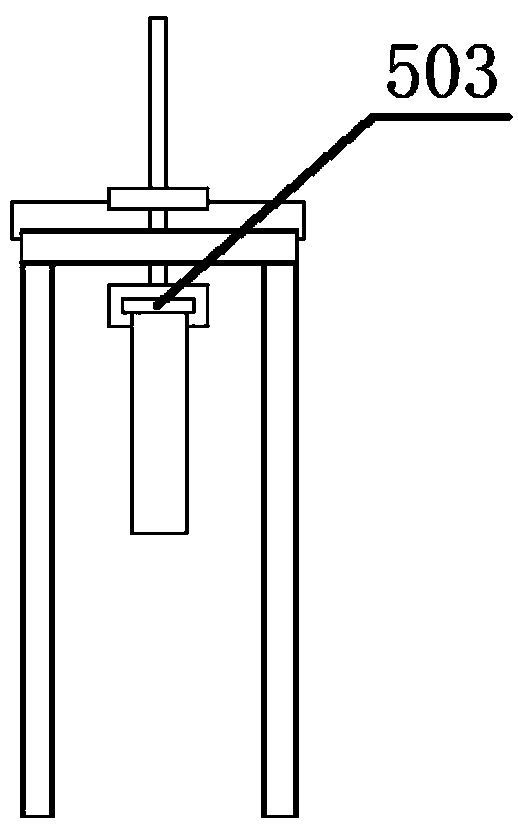

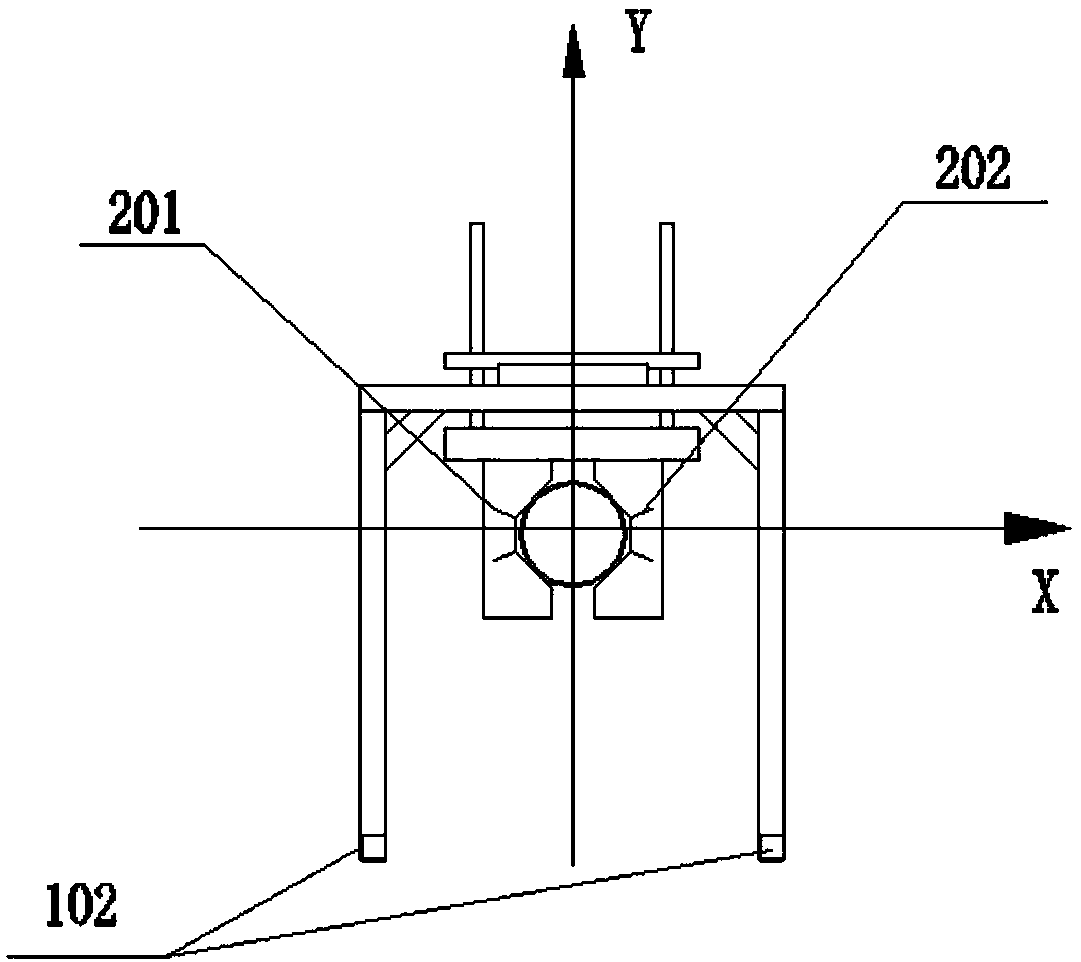

[0022] Such as figure 1 A pipeline centering device shown includes a bracket 100, a Z-axis moving table 300, a Y-axis moving table 500, an X-axis moving table 400, and a clamping mechanism 200. The clamping mechanism 200 includes a first clamp 201 and a second clamp 202, the Y-axis mobile platform 500 includes a lower slideway 503 and an upper guide column 501, the first clamp 201 and the second clamp 202 are connected to the Y-axis mobile platform 500 through the slideway 503, and the X-axis mobile platform 400 is placed on the bracket On the upper end of 100, the Z-axis mobile platform 300 is placed above the X-axis mobile platform 400, and the guide column 501 passes through the X-axis mobile platform 400, and can slide up and down within the length of the guide column 501, such as image 3 The shown first clamp 201 and the second clamp 202 have the same structure, and are vertically placed in a "concave" shape, and the concave openings are opposite to each other for placin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com