High precision gyro motor bearing loading method

A high-precision, motor-based technology, applied to measuring devices, instruments, etc., can solve problems such as large influence, low precision, and large bearing preload, and achieve the effects of eliminating errors, improving displacement measurement accuracy, and improving loading accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

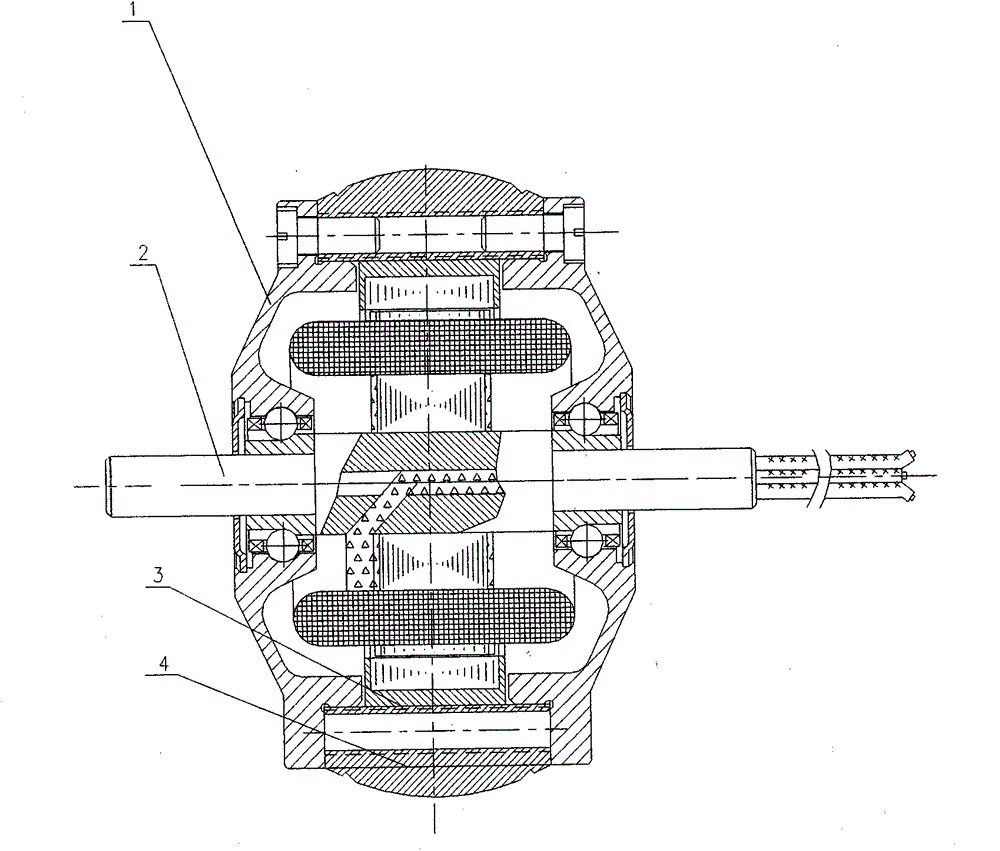

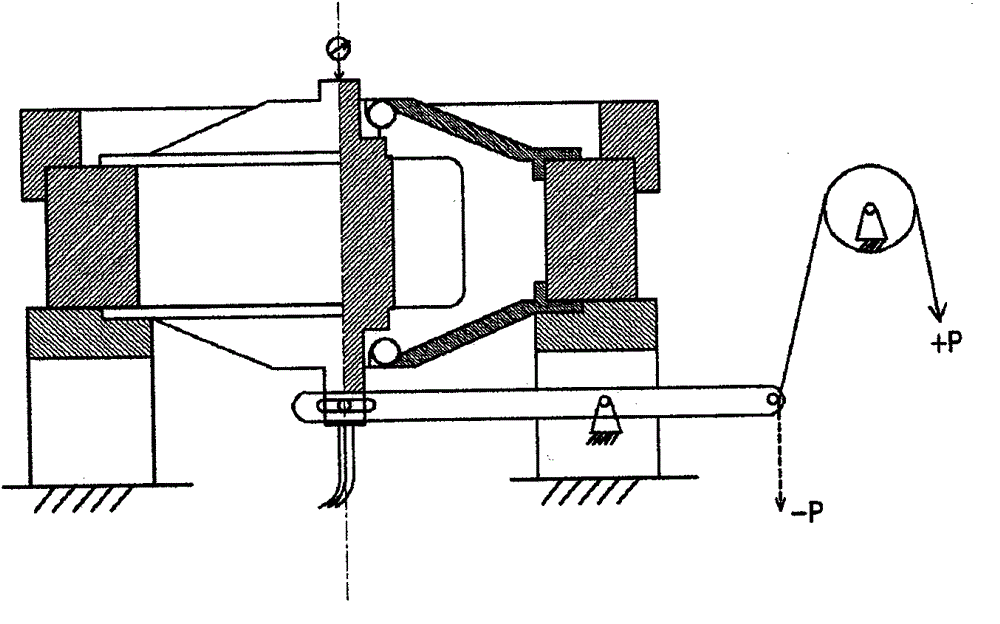

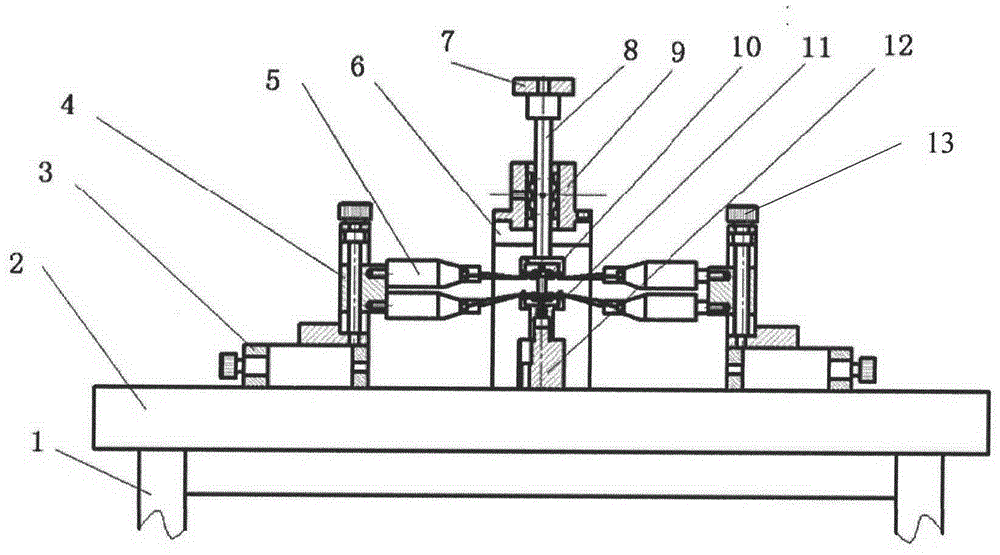

[0066] Take the bearing loading of 32TZW431D hysteresis gyro motor as an example. The 32TZW431D hysteresis gyro motor adopts the end cover type C906073A2 bearing. The axial stiffness of the bearing is 200g-250g / μm, and the axial stiffness after pairing is half of the stiffness of a single set of bearings, which is 100g-125g / μm. The loading accuracy of the bearing is required to be ±50g.

[0067] During the loading process, the air bearing is used as the guiding system of the loading system, and the coaxiality between the air main shaft and the centering base is guaranteed to be less than 0.005 μm and the air pressure is not lower than 4.6 MPa through assembly. The displacement sensor adopts the GT31 high-precision inductive displacement sensor produced by Swiss TESA company. Its measurement repetition error is 0.1 μm. The parallelism of the two shaft shoulders of the standard motor is better than 1 μm, and the distance is the same as the nominal distance of the motor rotor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com