Patents

Literature

51results about How to "Improve displacement measurement accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

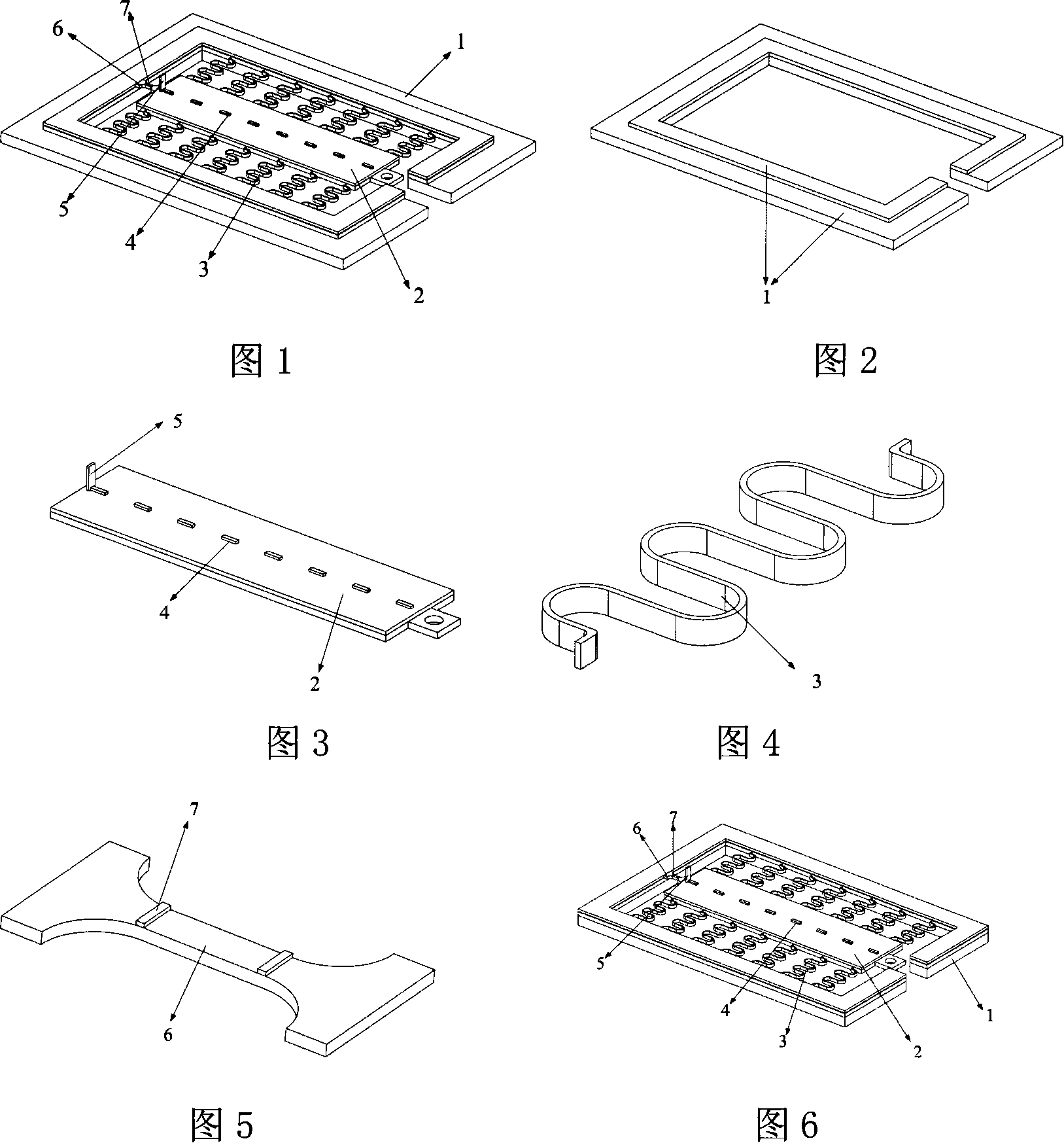

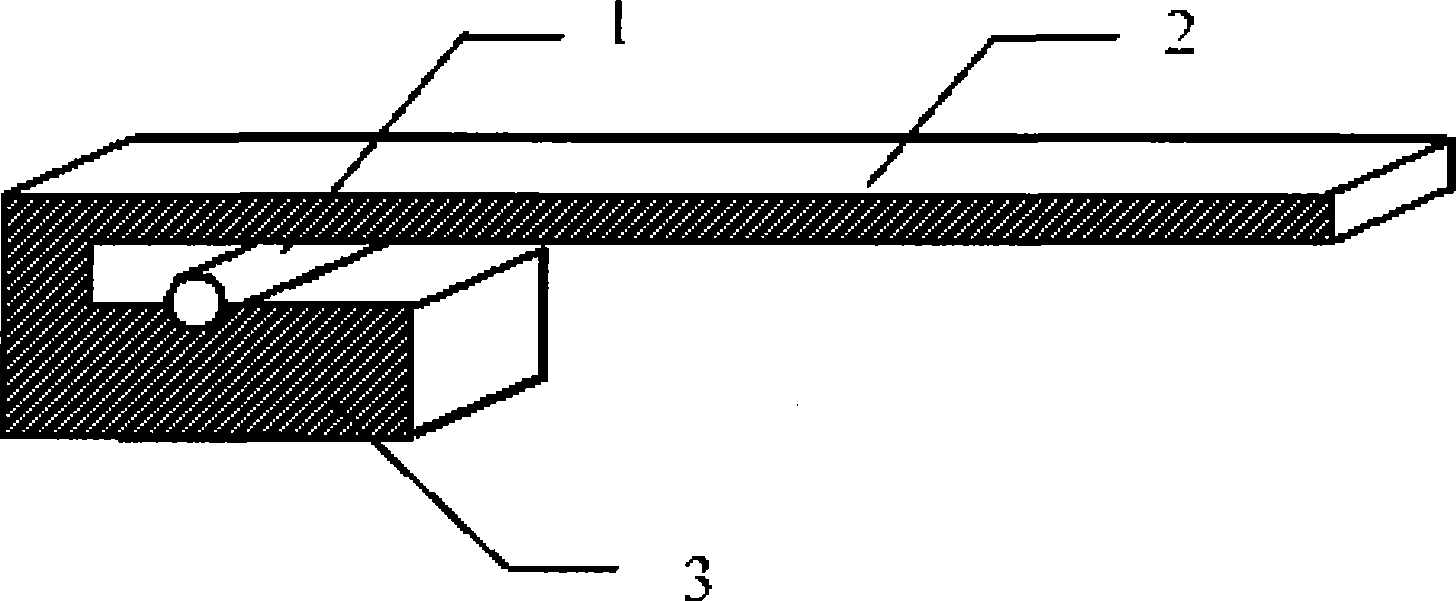

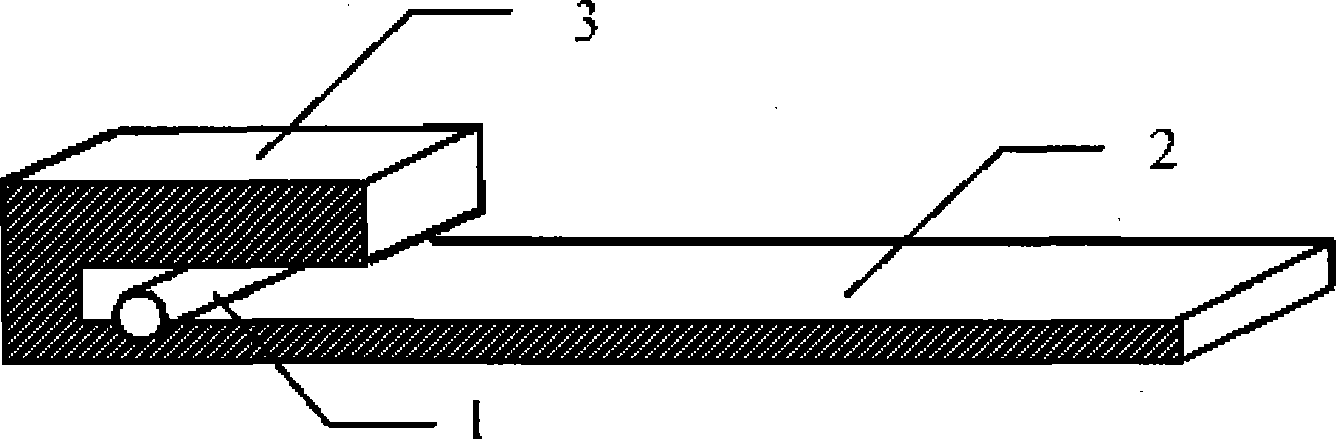

Uniaxial micro-tensile test piece for thin film mechanical performance test

InactiveCN101149317AEasy assemblyImprove verticalitySurface/boundary effectStrength propertiesEngineeringPlastic property

The single -shaft micro tensile test piece to test the film dynamic performance includes the U shpe supporting platform, movable platform, the snake supporting spring, centring marker, displacement marker. The snake supporting spring is connected with the U shape supporting platform and movable platform; the U shape supporting platform and movable platform are connected with two suspended ends of the film sample; the centring marker is on the top of the movable platform; the displacement marker is pasted to the tail to movable platform and near to the film sample. Compared to the present test piece, the process is available, it has good repeatability and high yield; also it has avoided the test error generated by the supporting girder deformation in tension process. The test piece of invention is proper for the film micro dynamic performance test of single metal, alloy and compound material.

Owner:SHANGHAI JIAO TONG UNIV

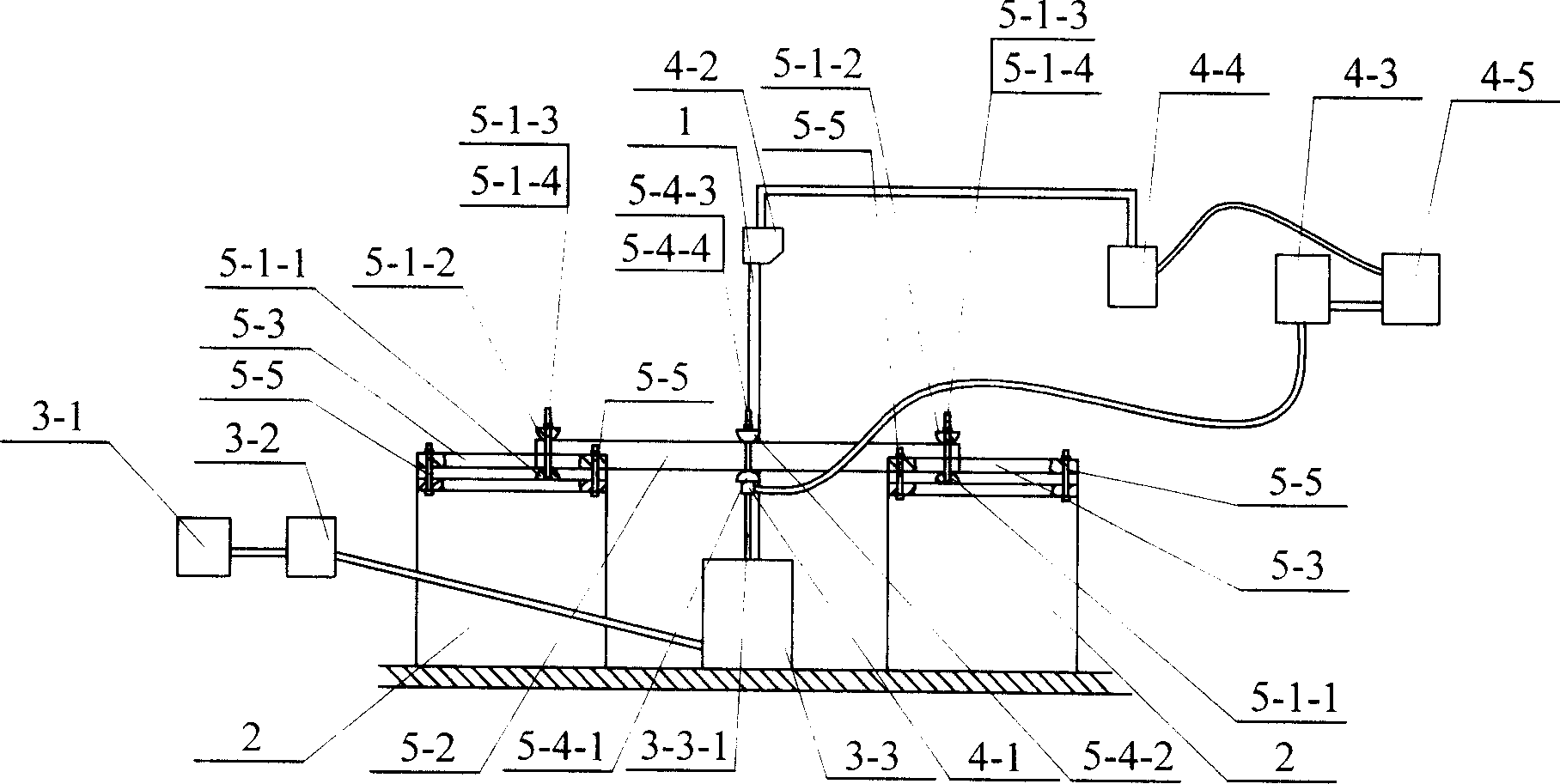

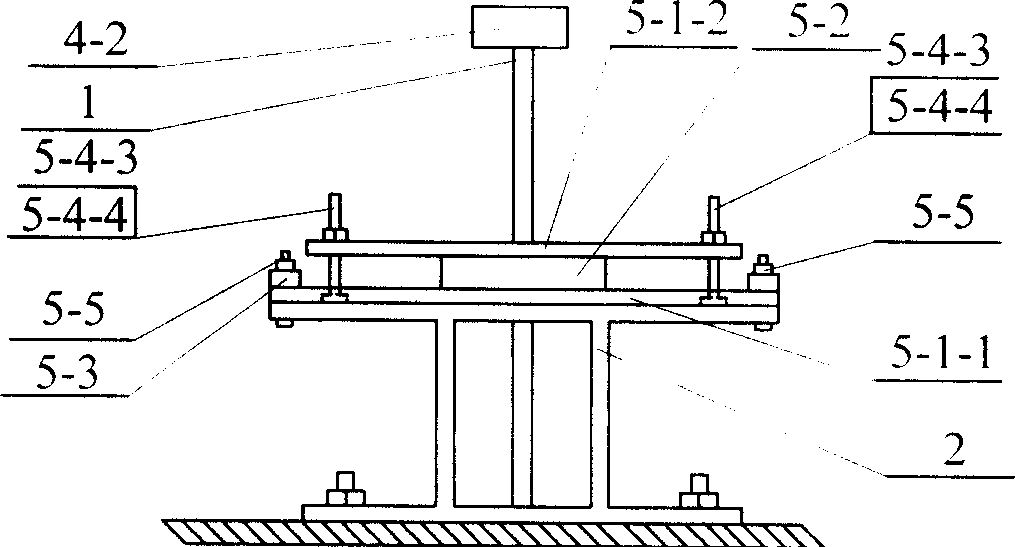

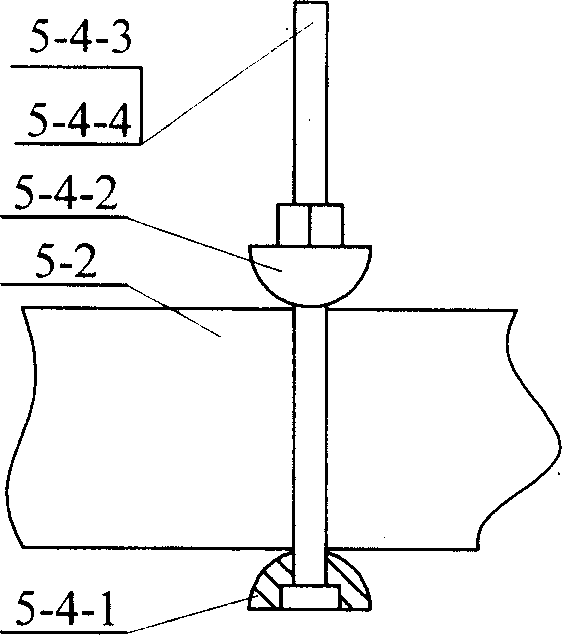

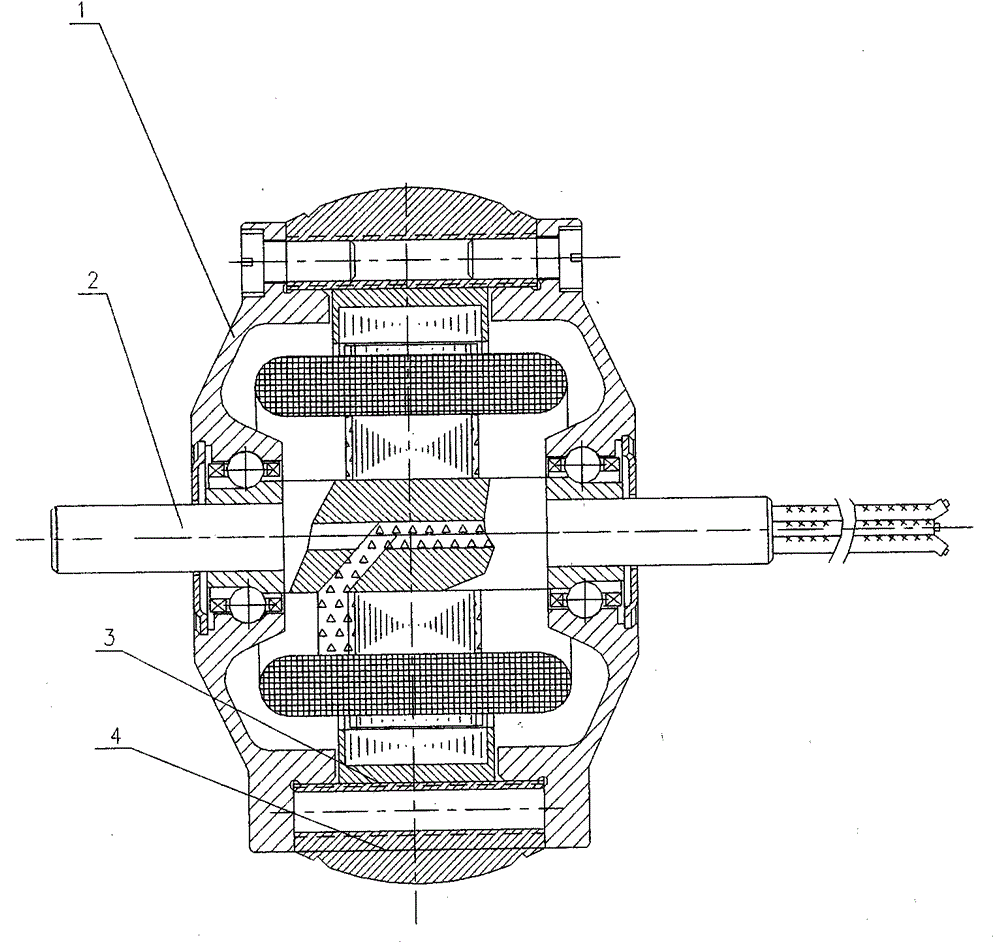

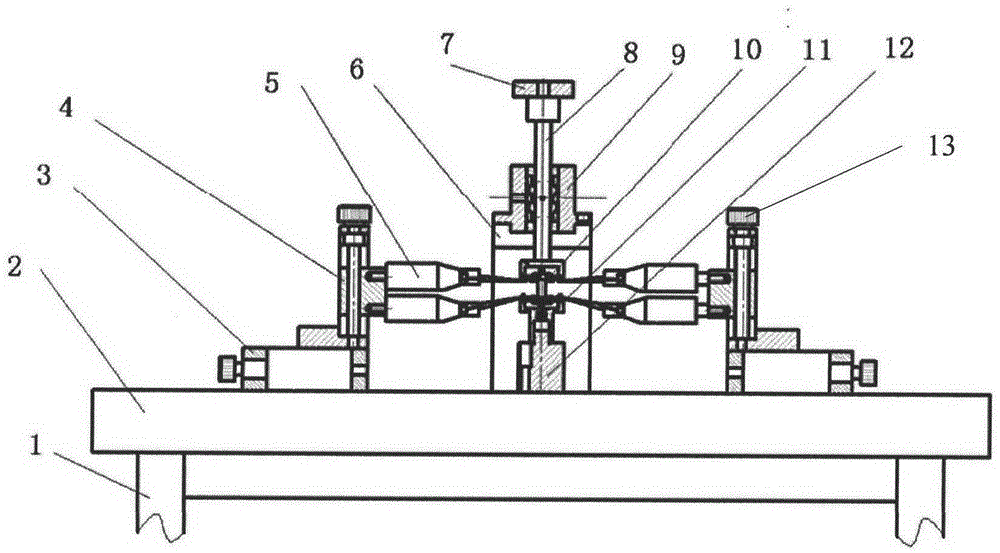

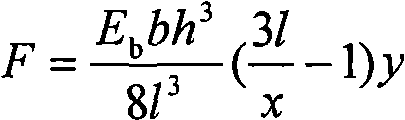

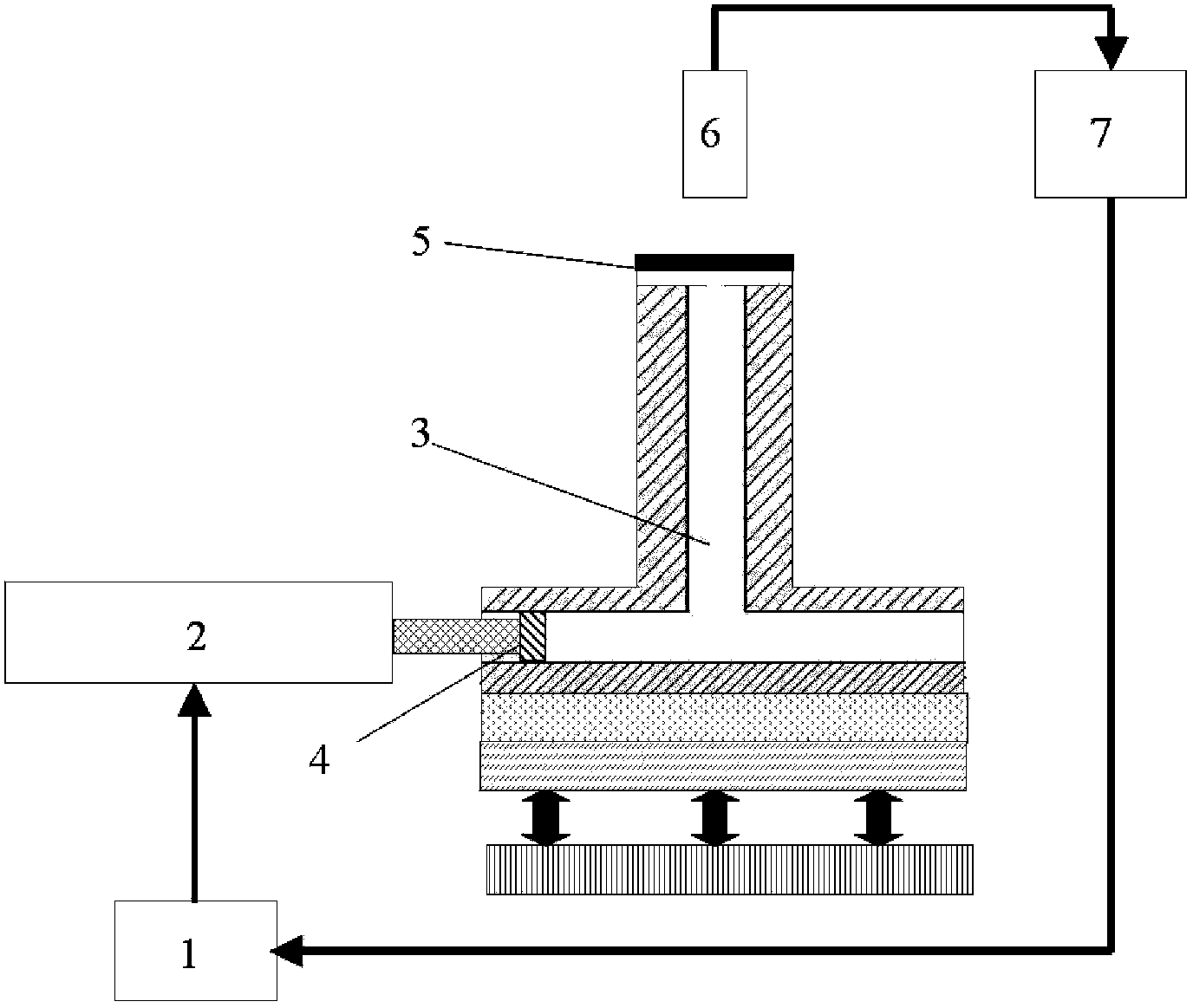

Three-point bending beam type apparatus for big size material damping test

InactiveCN1844887ARealize data collectionImprove displacement measurement accuracyMaterial strength using repeated/pulsating forcesElasticity measurementData acquisitionEngineering

The invention relates to a damping tester of three-point bended beam large-scale material, which can solve the problem of present device that can not test the damping property of large-scale material. Wherein, two ends of three-point bended beam (5-2) are fixed on each hinge base of base; each hinge base is vertically fixed via press beam (5-3); the middle part of three-point bended beam (5-2) is fixed with a load head; the force sensor (4-1) is connected to the load head, the actuator (3-3) and the charge amplifier (4-3); the power amplifier (3-2) is connected to the actuator (3-3) and the signal generator (3-1); the displacement sensor (4-2) is connected to the voltage amplifier (4-4); the charge amplifier (4-3) and the voltage amplifier (4-4) are connected to the data collector (4-5). The invention can complete the damping test of large-scale material.

Owner:欧进萍

Displacement gauge and displacement measuring method

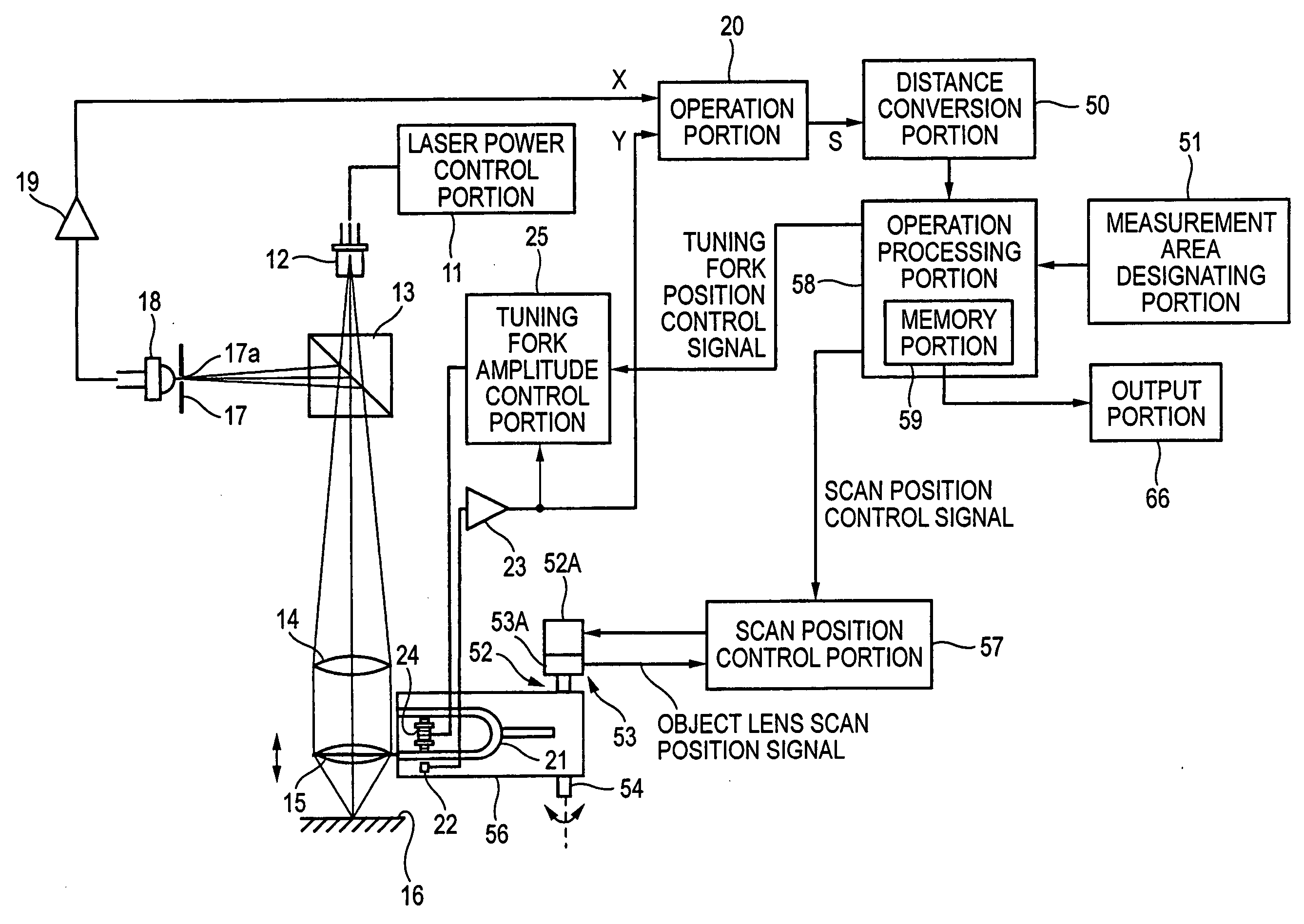

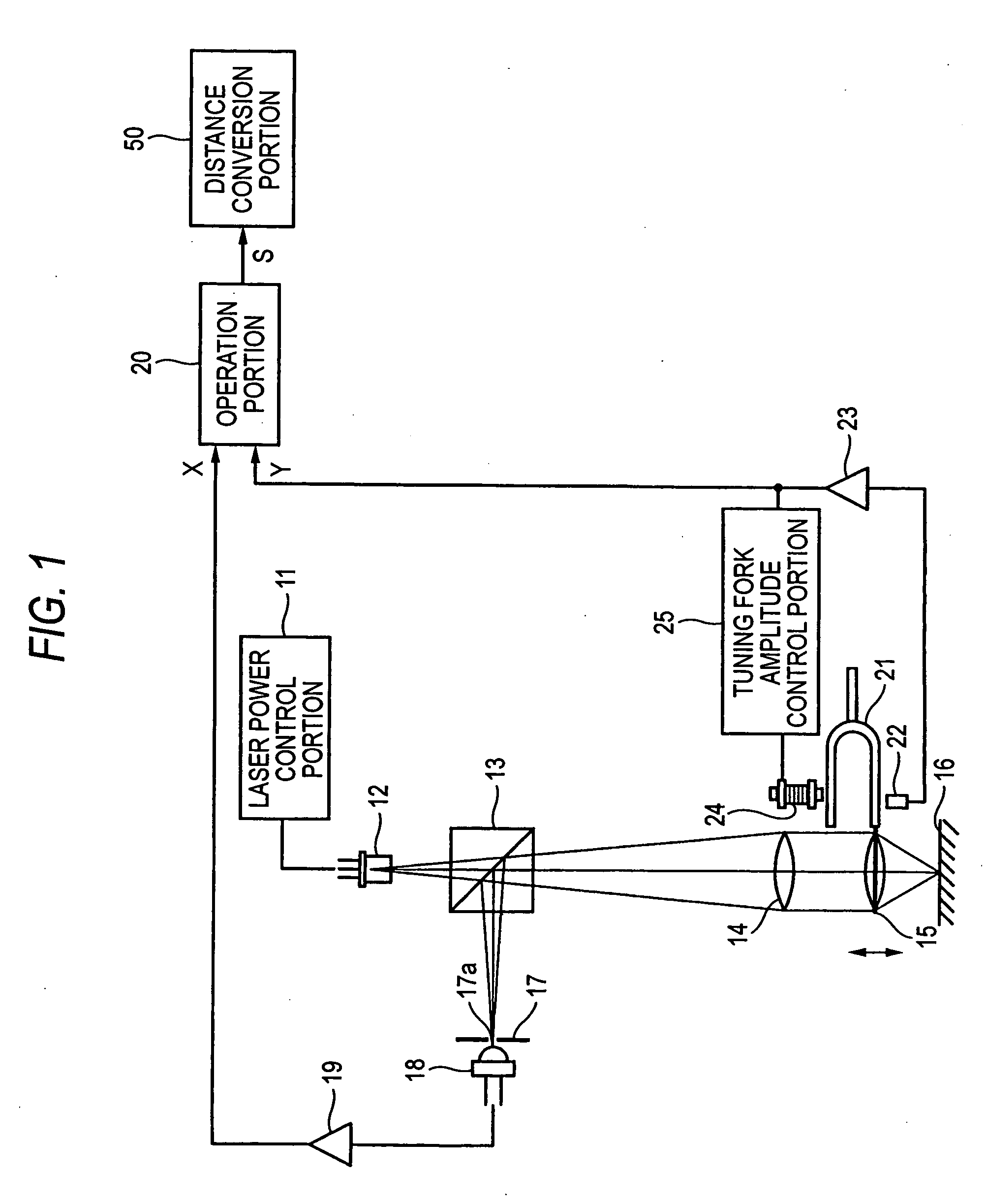

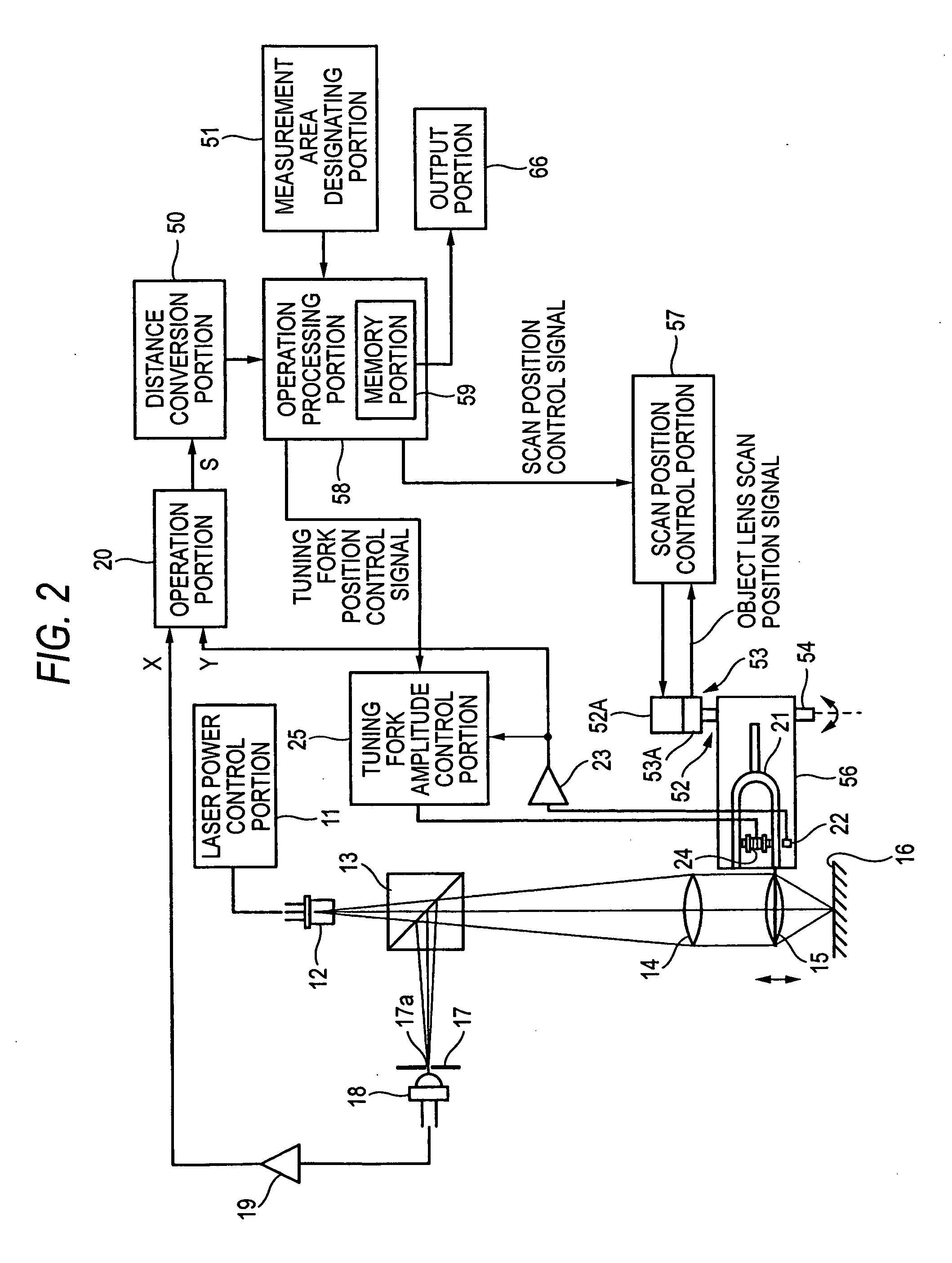

InactiveUS20050030553A1Improve displacement measurement accuracyReduced measurement timeElectric discharge tubesUsing optical meansPhysicsOptical axis

A displacement gauge comprises an objective lens 15 that projects light onto a measurement subject 16, an exciting portion that vibrates the objective lens 15 at a preset amplitude along an optical axis direction of light passing through the objective lens 15, a position detector for detecting the position of the objective lens 15, an objective lens scan portion 52 for scanning the objective lens 15 along a plane orthogonal to the optical axis direction, an objective lens movement detecting portion 53 for detecting the moved position of the objective lens 15, an operation processing portion 58 for calculating a distribution of displacement amount within a measuring area, based on the positional information of the objective lens 15 within the measuring area detected by the objective lens movement detecting portion 53, and the displacement amounts measured at plural measuring points, and an output portion 66 for outputting the result of calculation by the operation processing portion 58.

Owner:KEYENCE

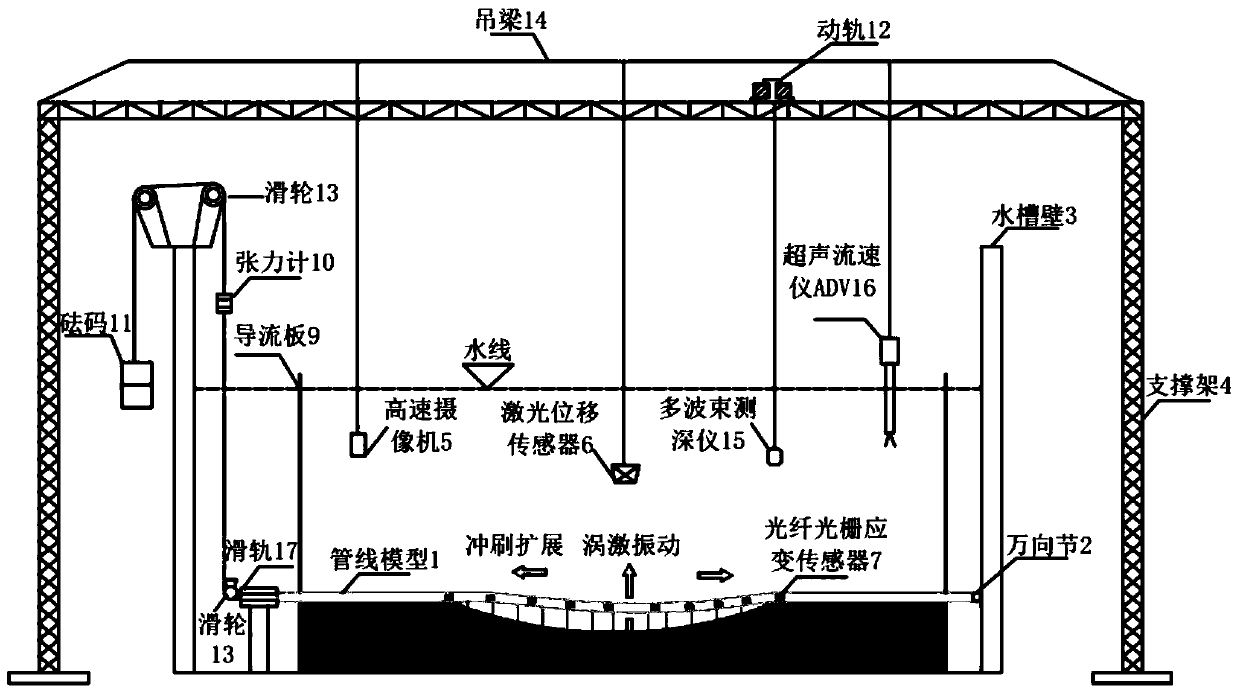

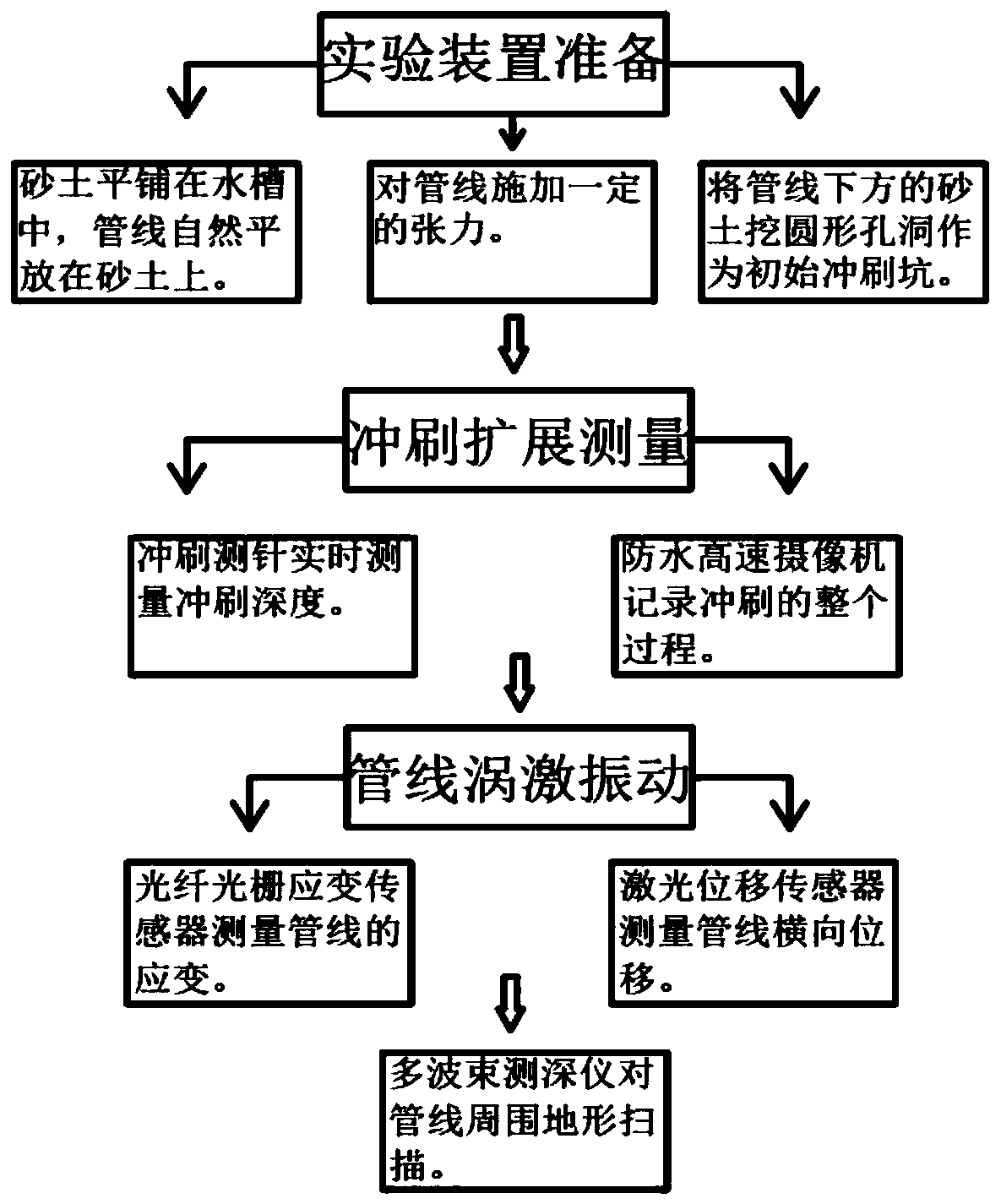

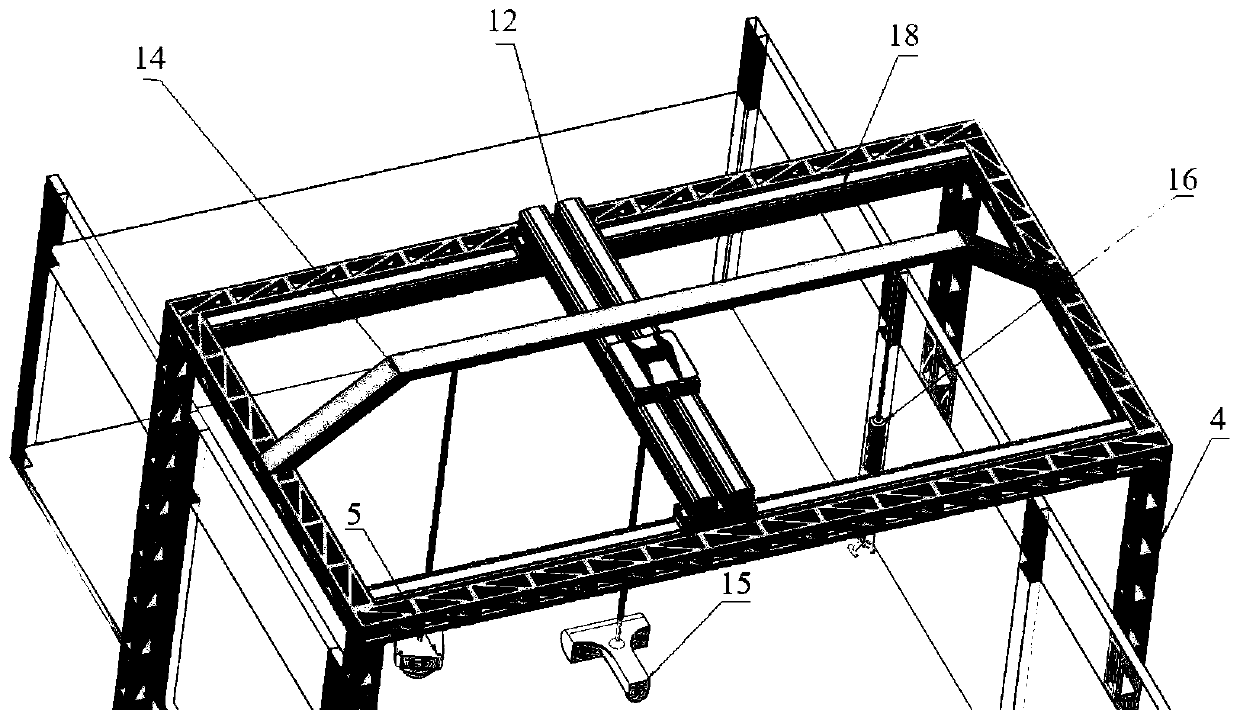

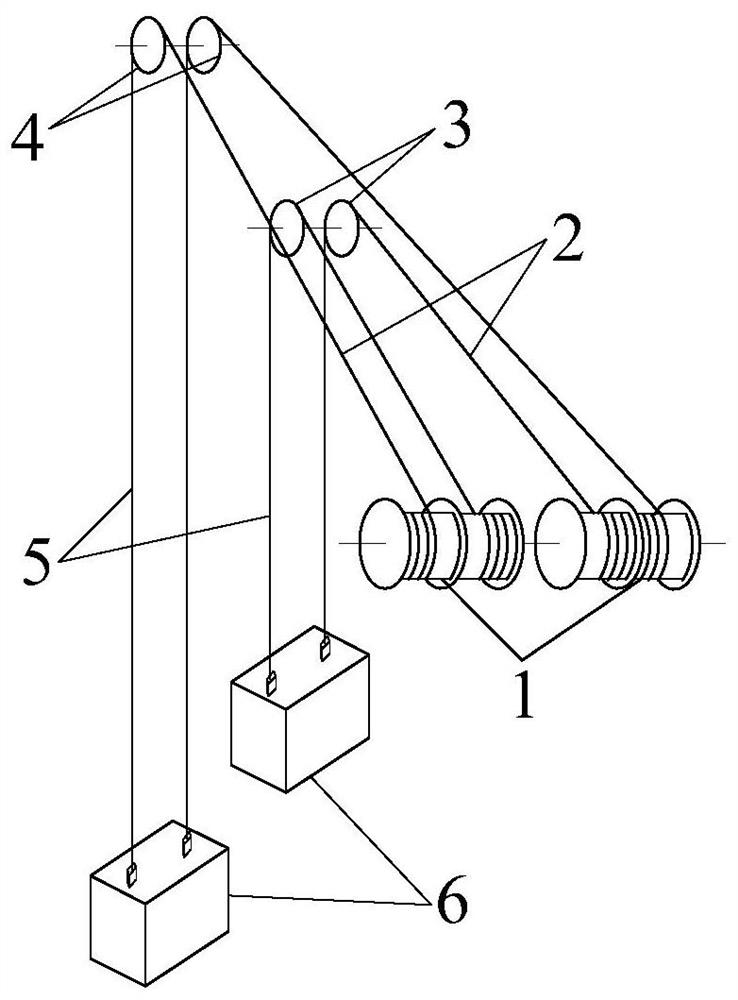

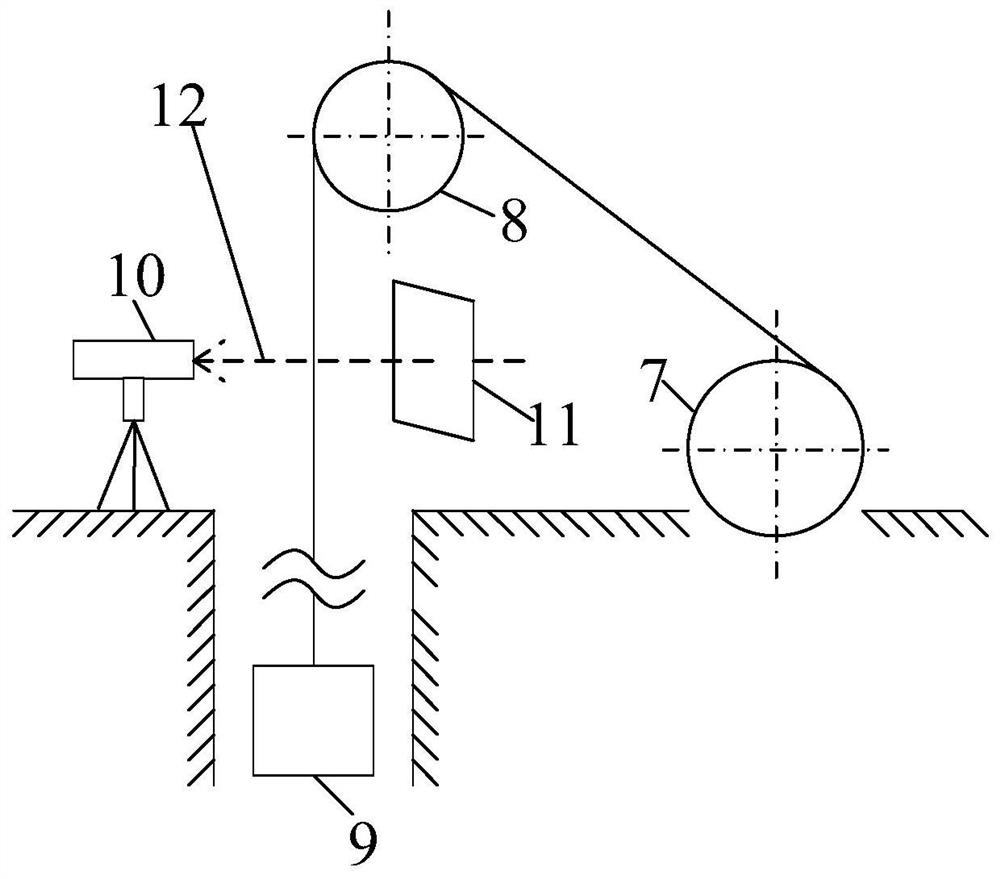

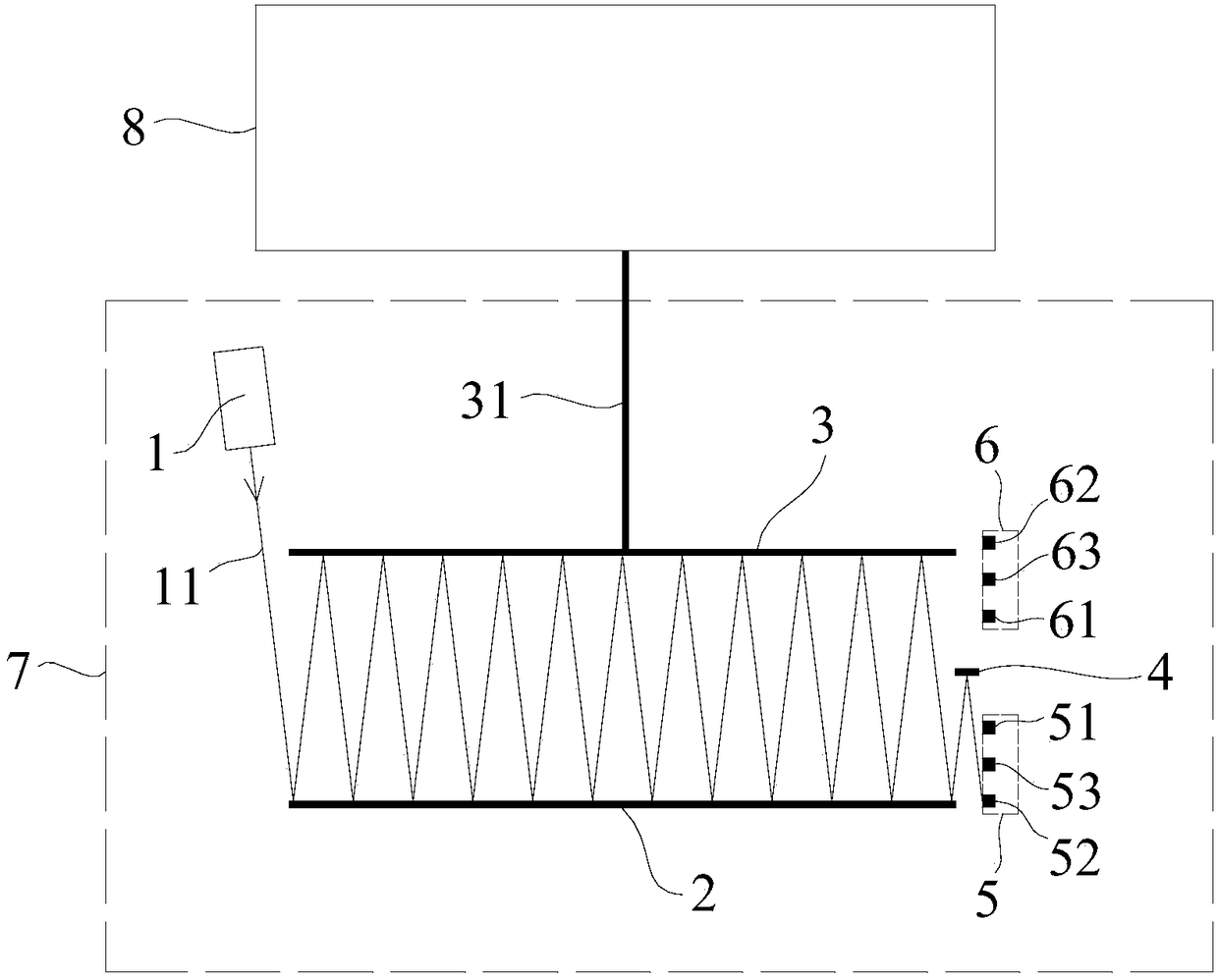

Experimental device and method for simulating scouring and vortex-induced vibration of flexible pipeline

PendingCN109975156AEasy to operateEliminate traditional measurement blind spotsMaterial strength using repeated/pulsating forcesVibration testingFiberGrating

The invention relates to an experimental device and method for simulating scouring and vortex-induced vibration of a flexible pipeline. The experimental device comprises a circulating water tank, a support frame, a pipeline model, a universal joint, a water tank wall, a high-speed camera, a laser displacement sensor, fiber bragg grating strain sensors, measuring probes, a guide plate, a tension meter, weights, a moving rail, pulleys, a hanging beam, a multi-beam echosounder, an ultrasonic current meter ADV, a sliding rail and a fixed rail; a plurality of measuring probes are installed at the bottom of the pipeline model, strain measuring points are determined on the surface of the pipeline model at equal intervals along the axial direction, each strain measuring point is equipped with a left fiber bragg grating strain sensor and a right fiber bragg grating strain sensor in the circulating water tank along the water flow direction, and the left and right fiber bragg grating strain sensors are symmetrically arranged on the horizontal outer surface of the pipeline model; one end of the sliding rail is connected with the pipeline model, the other end of the sliding rail is connected with a steel wire rope, and the sliding rail can slide back and forth relative to the support. The device and the method can be used for research of the flexible pipeline and local scouring extension and measurement of the vortex-induced vibration frequency, the amplitude and the pipeline strain.

Owner:HEBEI UNIV OF TECH

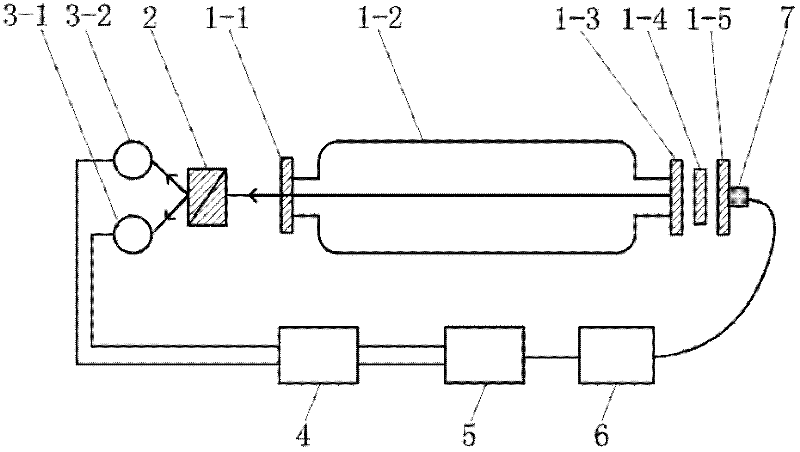

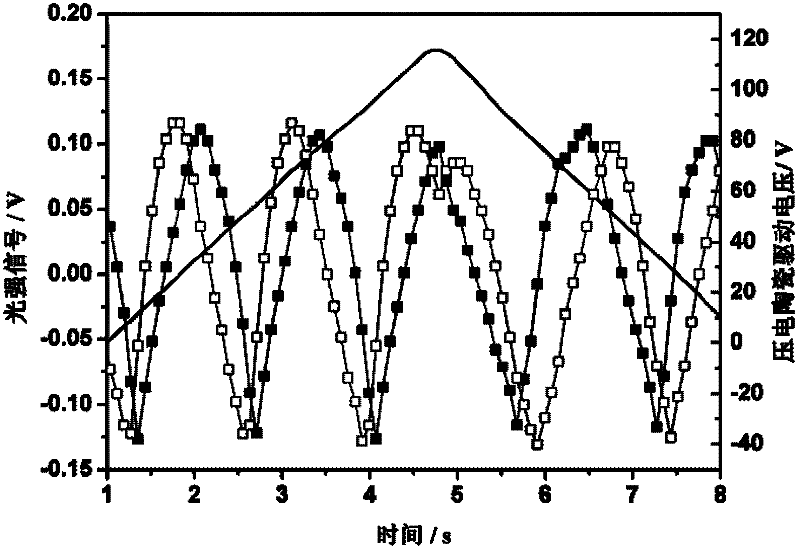

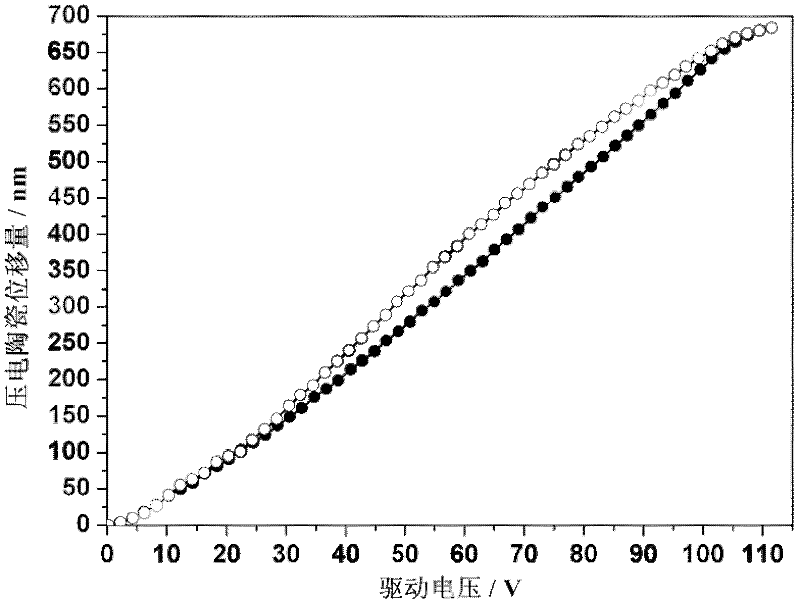

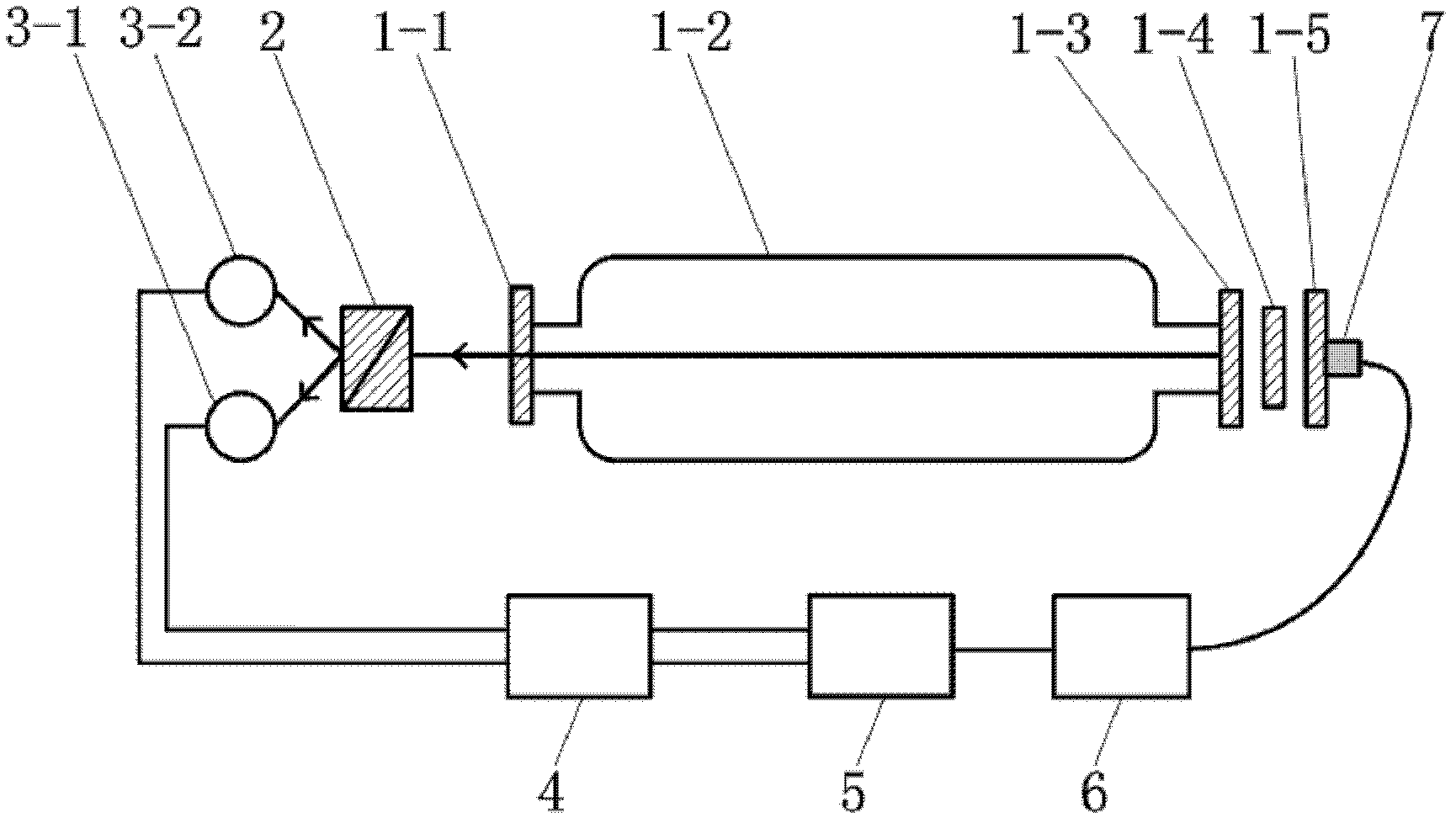

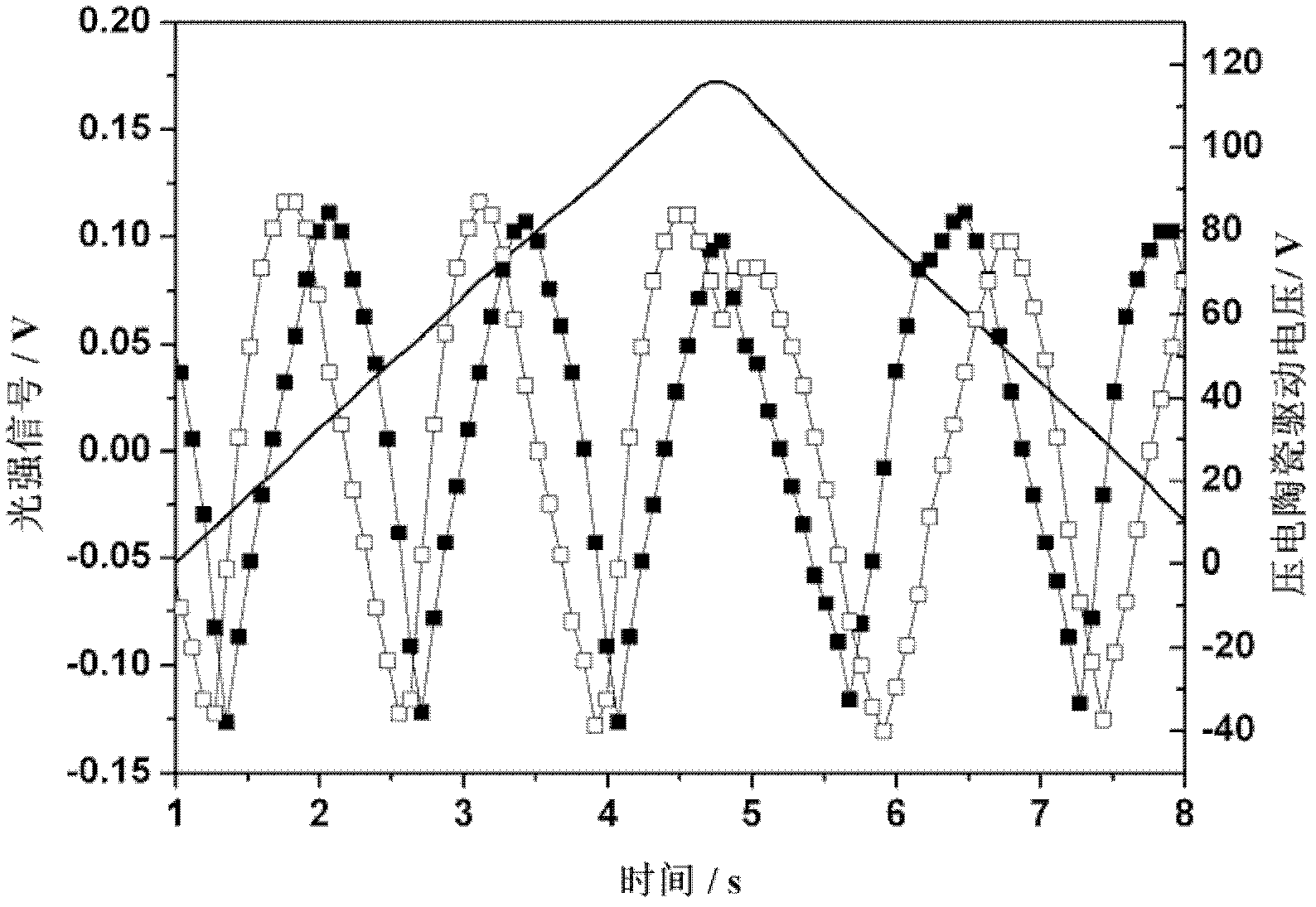

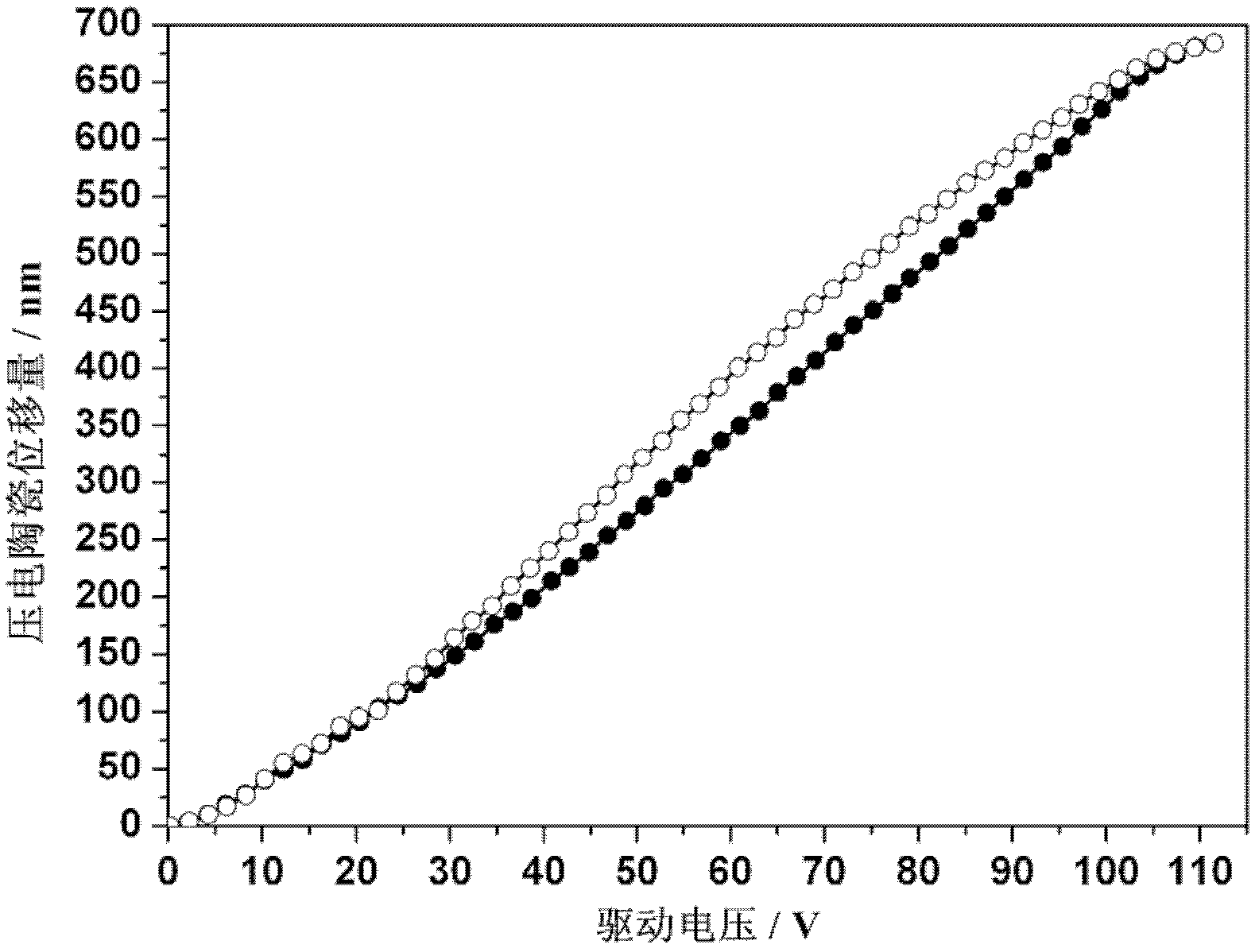

Displacement measurement method based on piezoelectric ceramic open-loop modulation

InactiveCN102506685AImprove hysteresisAdd nonlinearityUsing electrical meansUsing optical meansHysteresisElectricity

The invention provides a displacement measurement method based on piezoelectric ceramic open-loop modulation, belonging to the technical field of measurement. The displacement measurement method provided by the invention is characterized by comprising the following steps of: applying a periodic triangular wave driving voltage to piezoelectric ceramic to enable the piezoelectric ceramic to reciprocate; respectively finding out reference positions corresponding to a certain length of the piezoelectric ceramic in opposite movement directions and obtaining driving voltages corresponding to the reference positions; and calculating an average value of the driving voltages; and calculating a displacement amount to be detected by multiplying the change of the average value by gradients of middle section areas, which are close to be linear, in an average value curve of a displacement-driving voltage curve in the process of raising the driving voltages and a displacement-driving voltage curve in the process of decreasing the driving voltages under the driving of the periodic triangular wave driving voltage. The method provided by the invention has the advantages of effectively improving the hysteresis and the non-linearity of the piezoelectric ceramic and improving the precision of the displacement measurement; the displacement measurement can be realized by only carrying out open-loop control on the piezoelectric ceramic, so that the system complexity and the cost are not increased, the method is convenient to combine with other displacement measurement methods and the large-scale high-precision displacement measurement can be realized.

Owner:TSINGHUA UNIV

Displacement or acceleration sensor

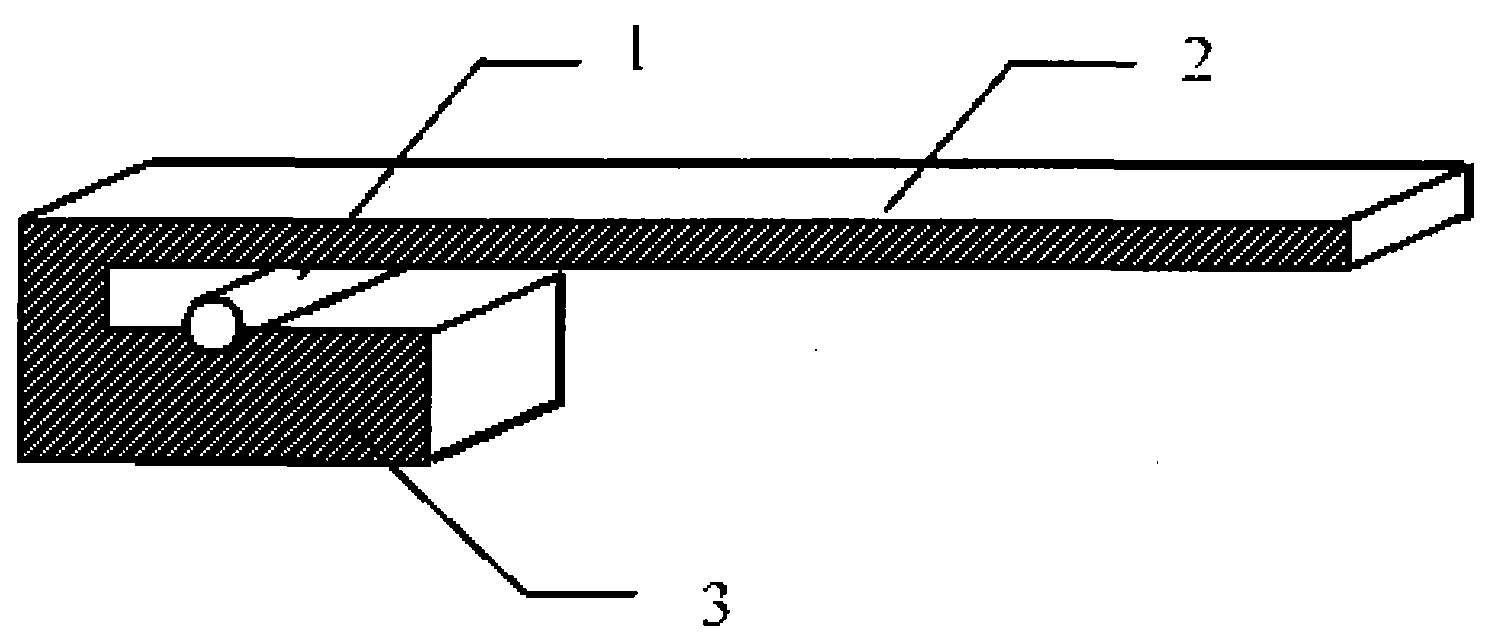

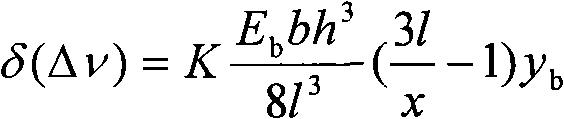

InactiveCN101464138AImmune to electromagnetic interferenceHigh sensitivityAcceleration measurement using interia forcesUsing optical means

The invention discloses a displacement sensor or an acceleration sensor, belongs to the technical field of fiber sensors, and is characterized in that the displacement sensor or the acceleration sensor comprises a first fiber laser, a cantilever beam and a first platform, wherein, the first fiber laser is clamped between the surfaces of the cantilever beam and the first platform; the first fiber laser and the first platform are arranged below or above the cantilever beam; and the deformation generated by the cantilever beam generates acting force to the first fiber laser. The invention has the effects and benefits that the sensor overcomes the defect that the conventional electrical sensor is liable to electromagnetic interference; and the invention provides the fiber displacement sensor or the fiber acceleration sensor having the advantages of high sensitivity, large measurement range, simple structure, low demodulation cost and better signal-to-noise ratio.

Owner:DALIAN UNIV OF TECH

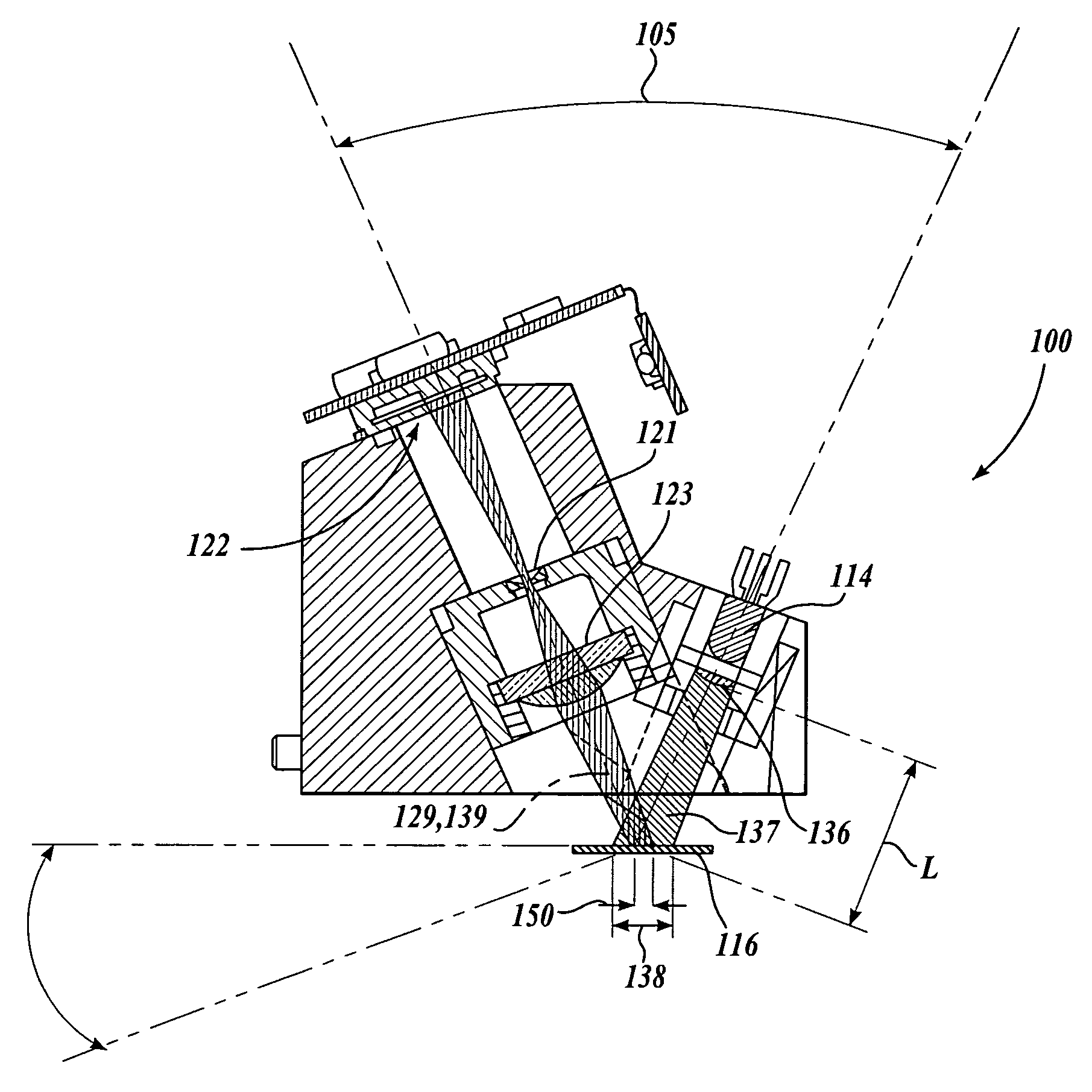

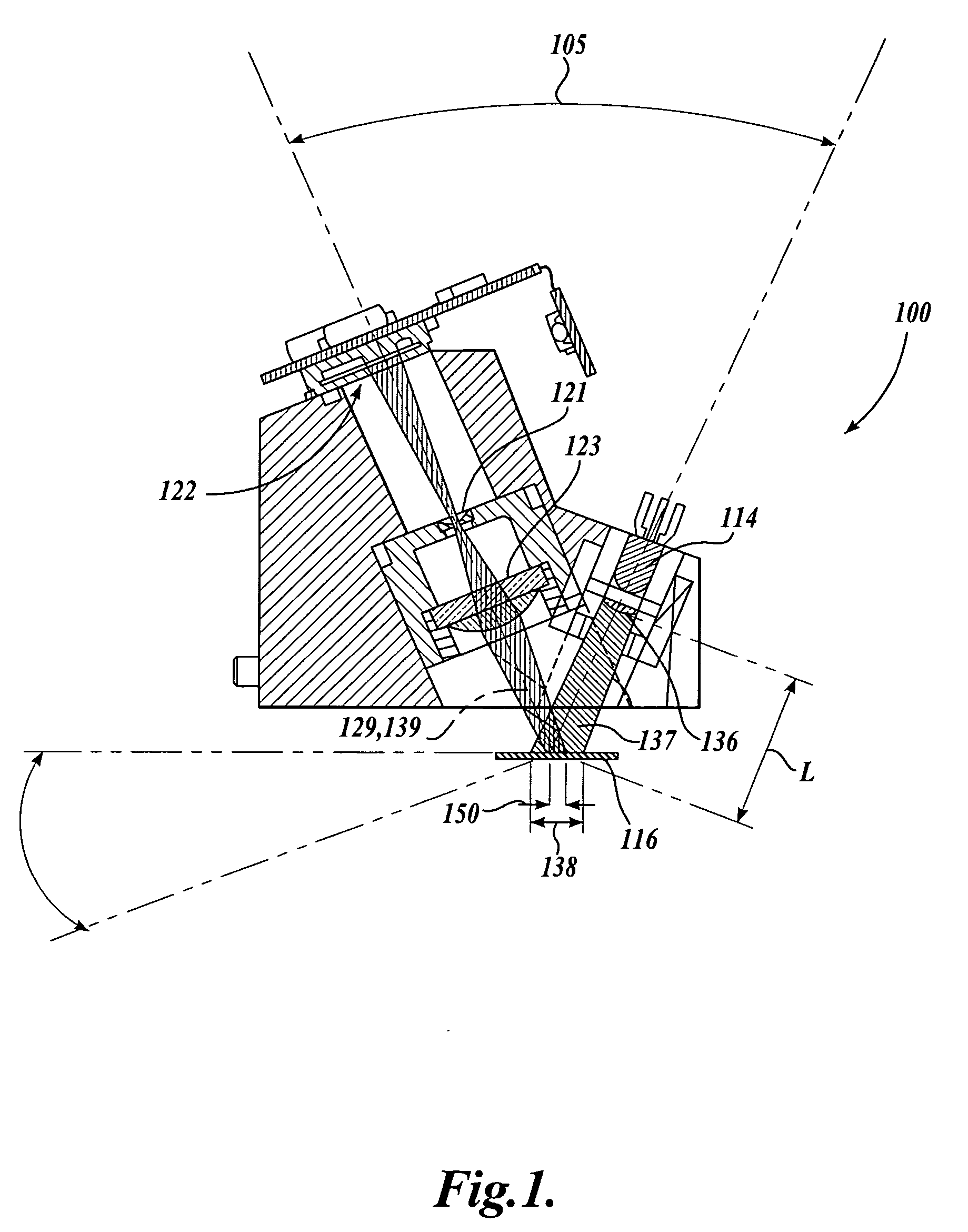

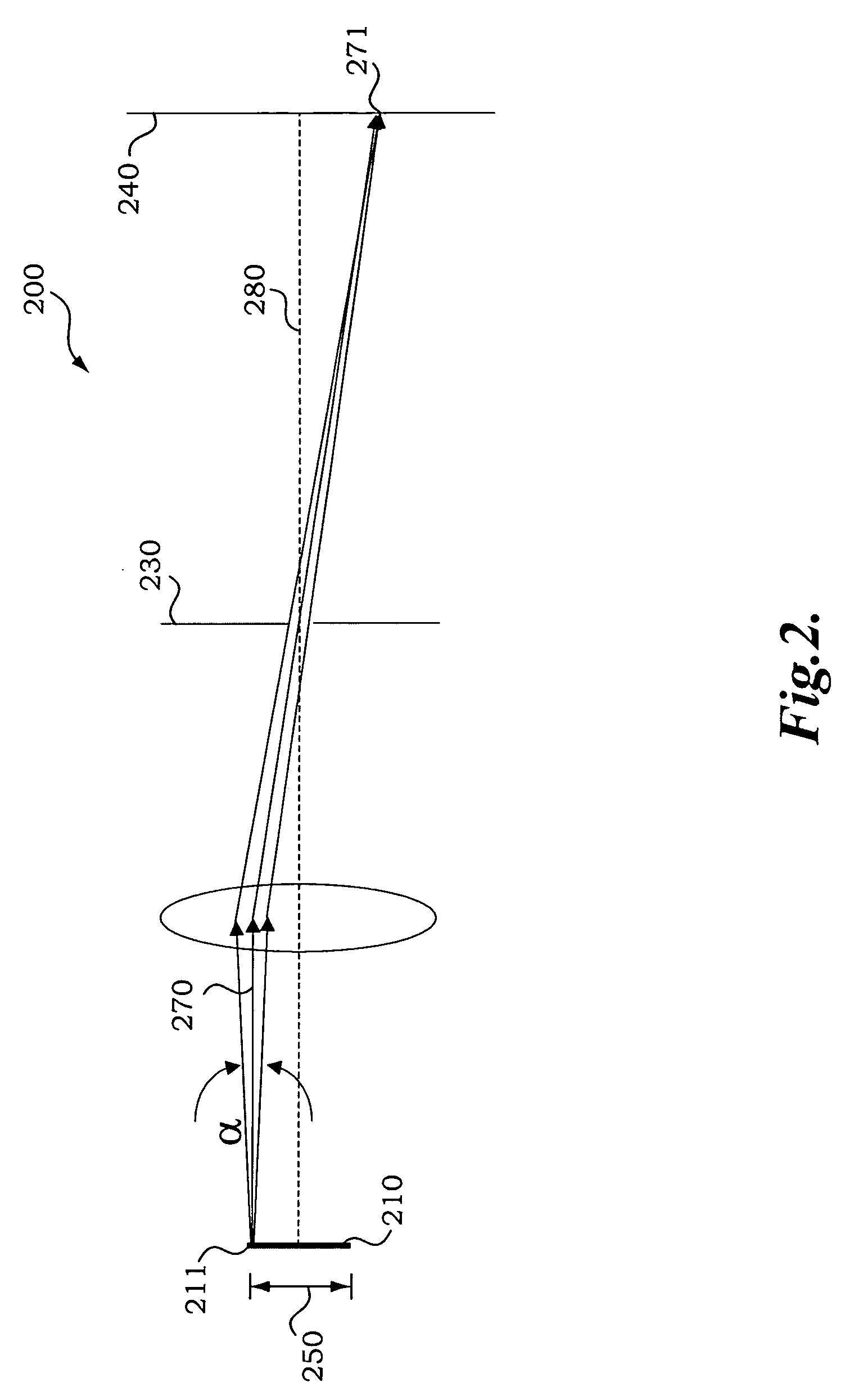

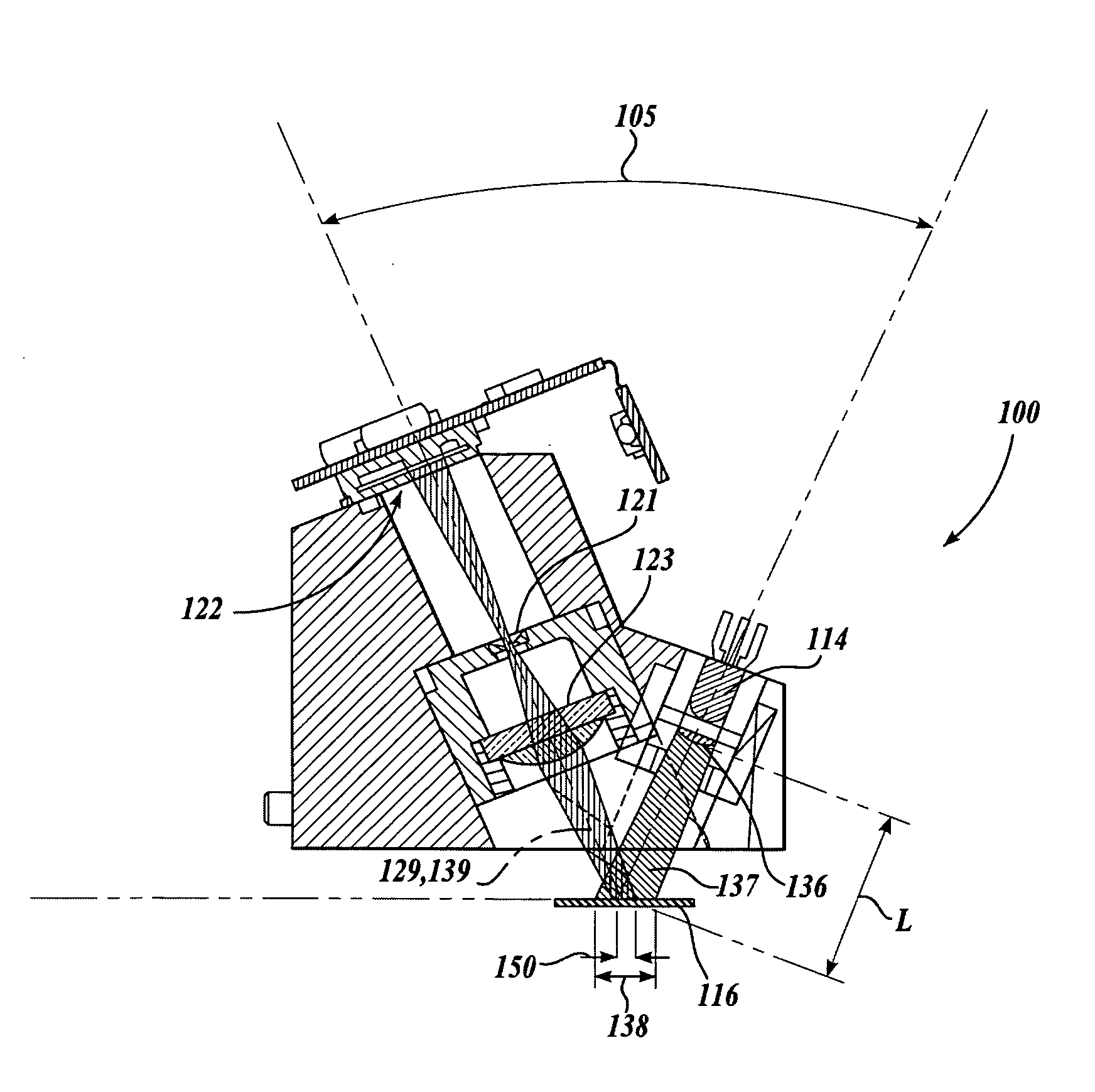

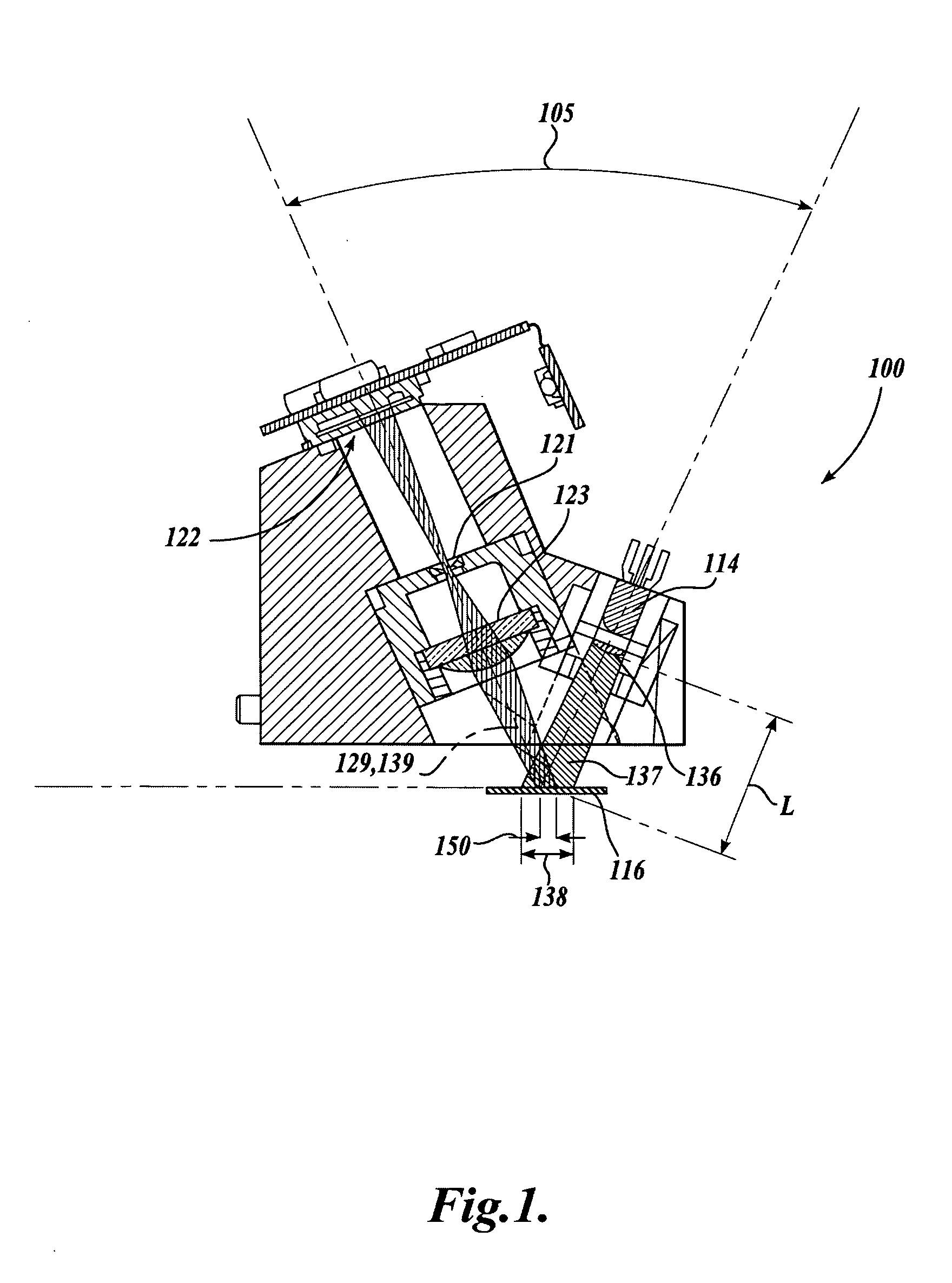

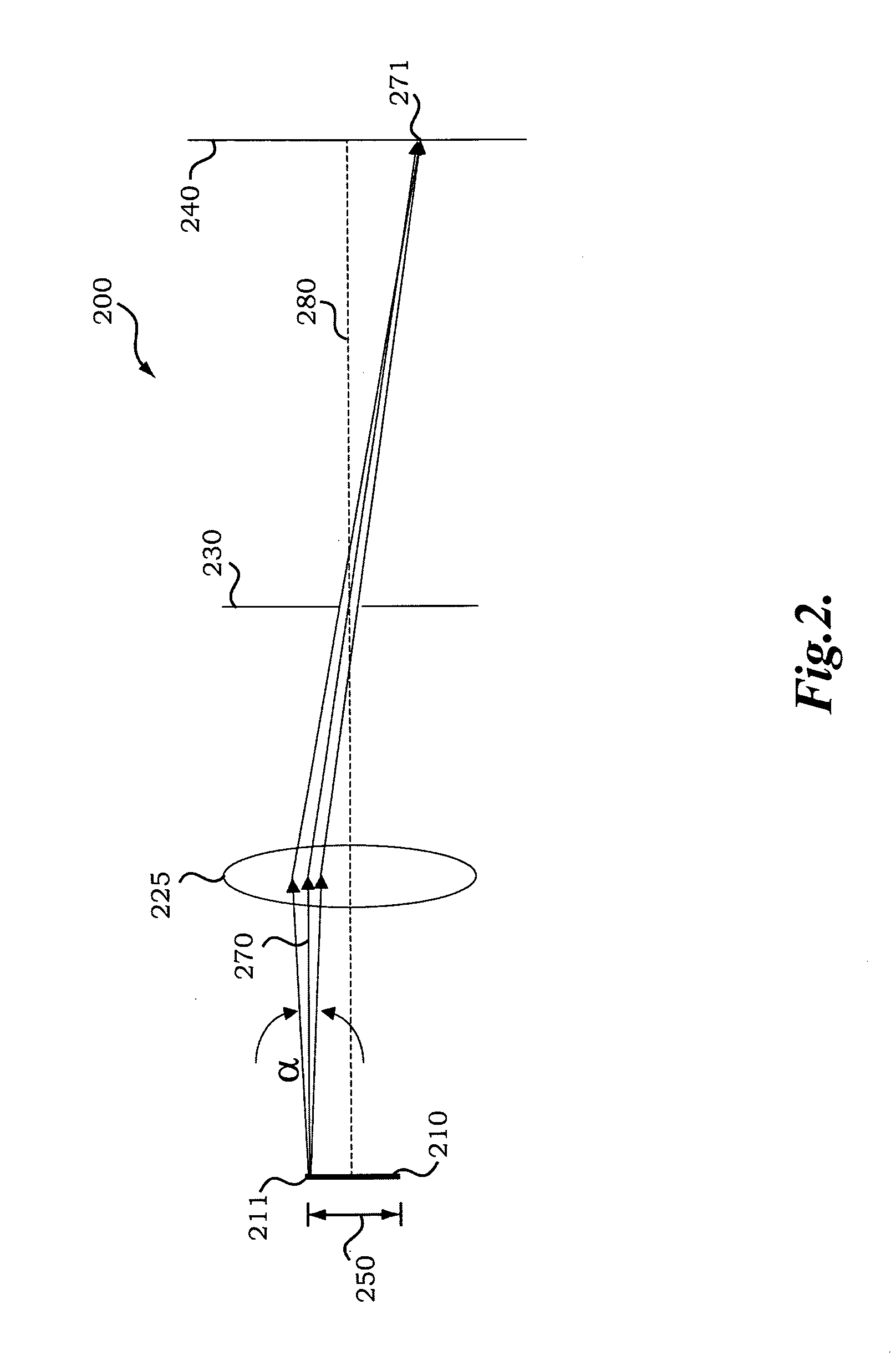

Illumination configuration for imaging-type optical encoders

ActiveUS20060284062A1Enhance and insure uniformityHigh spreadMaterial analysis by optical meansConverting sensor output opticallyImage typeField of view

An illumination configuration for imaging-type optical encoders is provided. The illumination configuration generates uniform brightness images of scales and two-dimensional structures when utilizing telecentric imaging optics in the encoder readhead. In one embodiment, a desirable uniform irradiance distribution is created across the field of view by illuminating with a collimated or quasi-collimated beam, but insuring that the illumination is sufficiently incoherent that potential self-images arising from periodic structures on the scale are suppressed. In one embodiment, the ratio of an effective emitter size to a focal length of the collimating lens falls within a selected range, so as to assure relatively uniform illumination across the field of view and still provide sufficiently incoherent illumination. In another embodiment, a diffuser is placed over the collimating lens, which assists in producing uniform illumination even when the direction of illumination varies relative to the scale due to misalignment between the readhead and the scale surface.

Owner:MITUTOYO CORP

Illumination configuration for imaging-type optical encoders

ActiveUS7227124B2Improve displacement measurement accuracyImprove accuracyMaterial analysis by optical meansConverting sensor output opticallyImage typeField of view

An illumination configuration for imaging-type optical encoders is provided. The illumination configuration generates uniform brightness images of scales and two-dimensional structures when utilizing telecentric imaging optics in the encoder readhead. In one embodiment, a desirable uniform irradiance distribution is created across the field of view by illuminating with a collimated or quasi-collimated beam, but insuring that the illumination is sufficiently incoherent that potential self-images arising from periodic structures on the scale are suppressed. In one embodiment, the ratio of an effective emitter size to a focal length of the collimating lens falls within a selected range, so as to assure relatively uniform illumination across the field of view and still provide sufficiently incoherent illumination. In another embodiment, a diffuser is placed over the collimating lens, which assists in producing uniform illumination even when the direction of illumination varies relative to the scale due to misalignment between the readhead and the scale surface.

Owner:MITUTOYO CORP

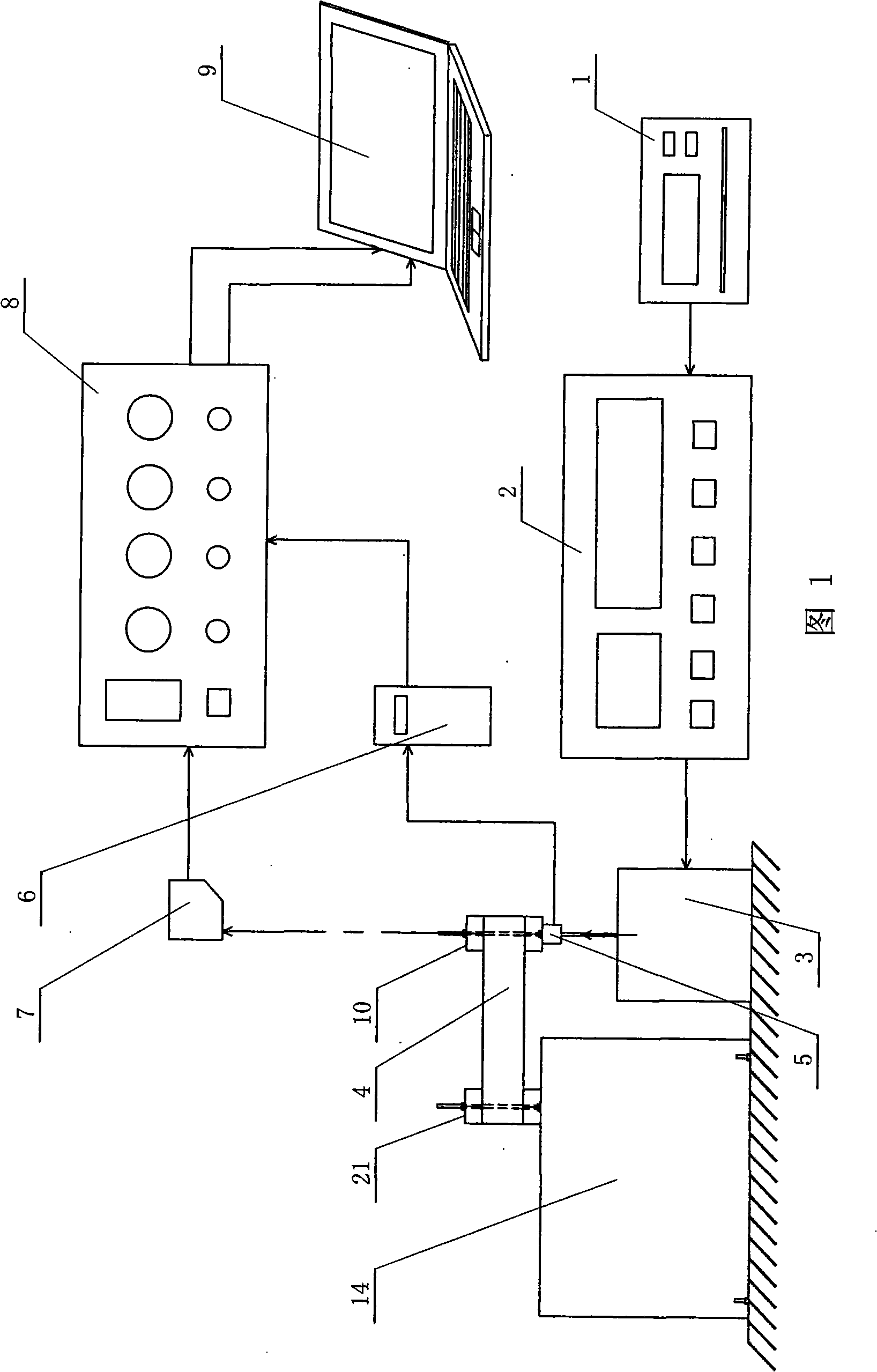

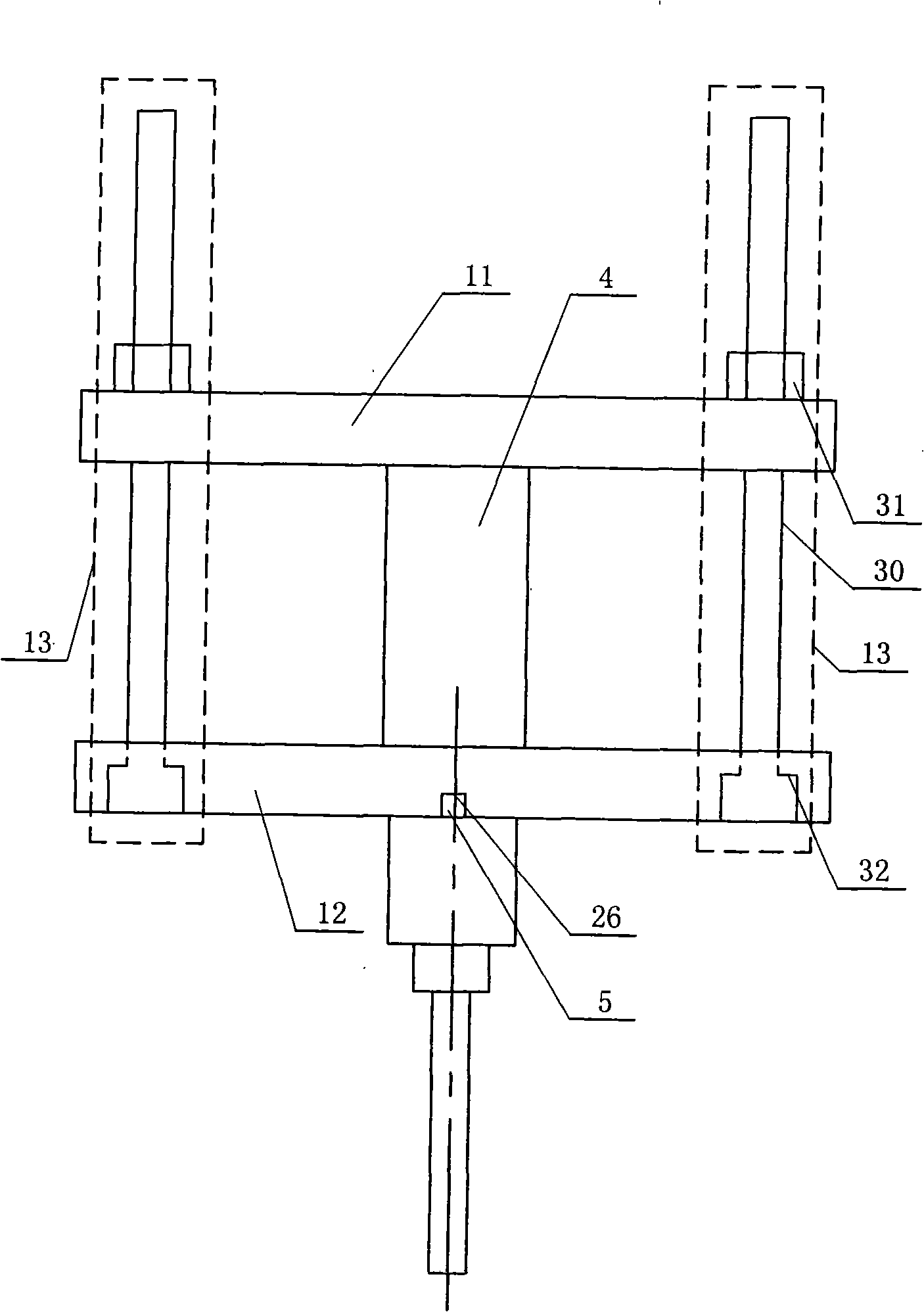

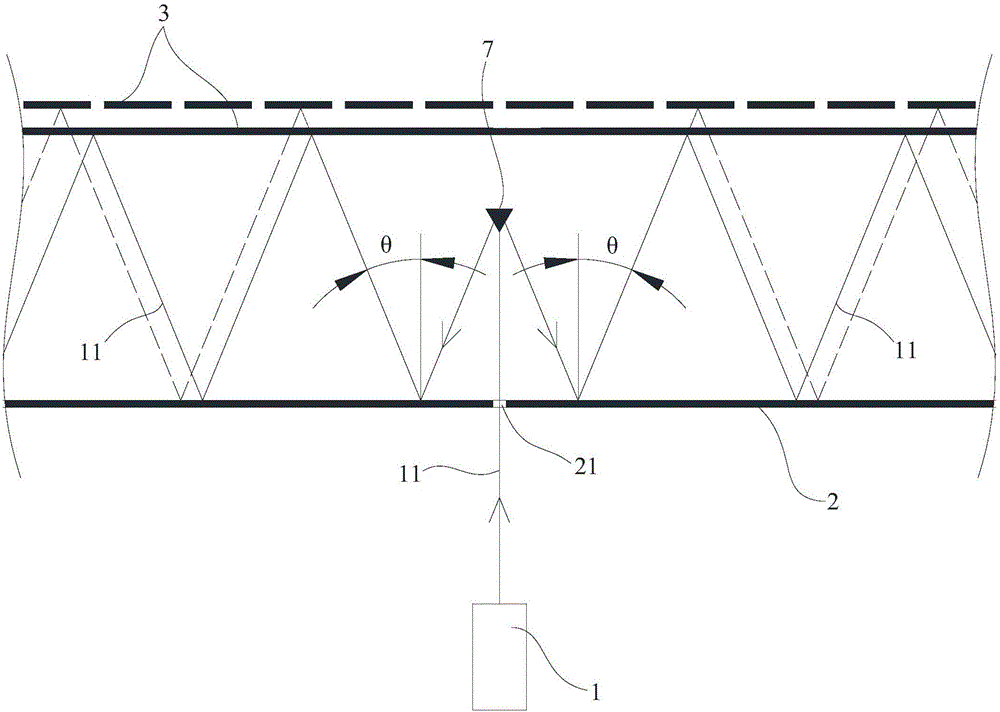

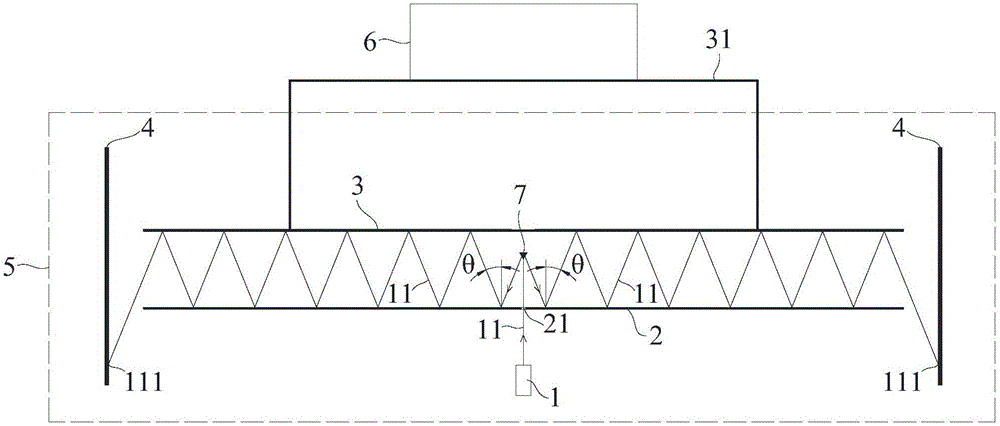

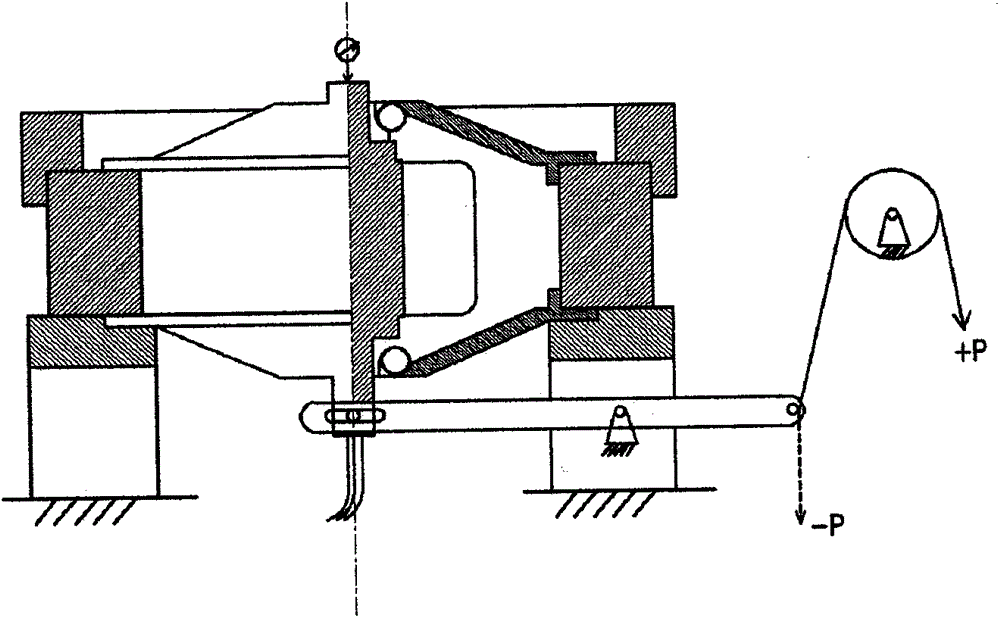

Shearing type large size material damping testing device

InactiveCN101275901AAdjustable sizeSimple structureUsing mechanical meansMaterial testing goodsData acquisitionEngineering

A shearing large-size material damping testing device relates to a device for testing damping property of large-size material used in civil engineering, the invention is aimed to resolve the problem that shear damping characteristic of large-size materials used in the civil engineering can not be tested. The two input ends of a piezoelectric force sensor (5) are connected with the output ends of a load head(10) and a electromagnetic vibration exciter (3).The top of the electromagnetic vibration exciter (3) is provided with a laser displacement sensor (7 ).The output end of the piezoelectric force sensor (5) is connected with the input end of a charge amplifier (6).The two input ends of a voltage amplifier (8) are connected with the output ends of the laser displacement sensor (7)and the charge amplifier (6) .The two output ends of the voltage amplifier (8) are connected with the two input ends of a computer data collector (9) .The input end of the electromagnetic vibration exciter(3) is connected with a signal generator ( 1) through a power amplifier (2) . A base (14) is connected with a fixed external member (21). The present invention can test the damping property and the elastic modulus of large-sized materials under shearing effect.

Owner:刘铁军

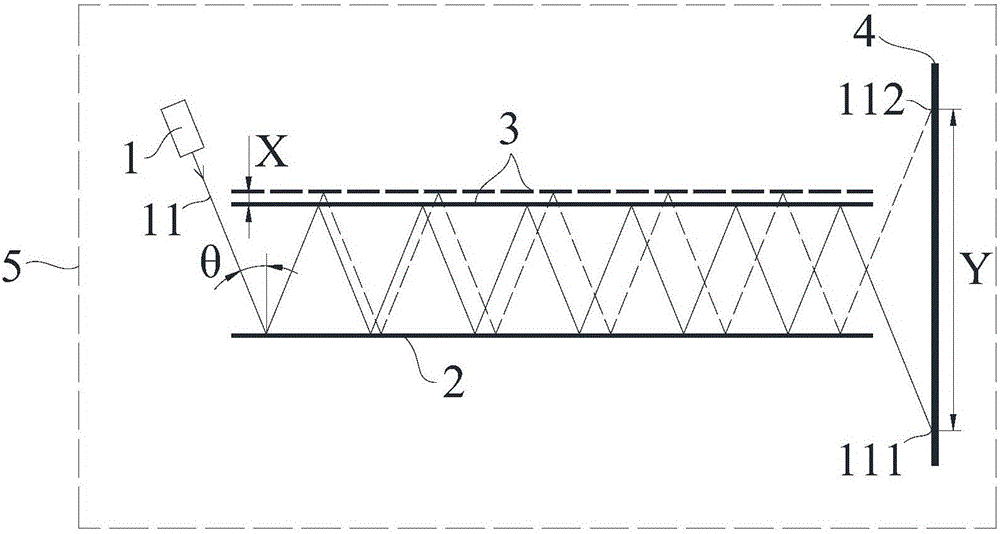

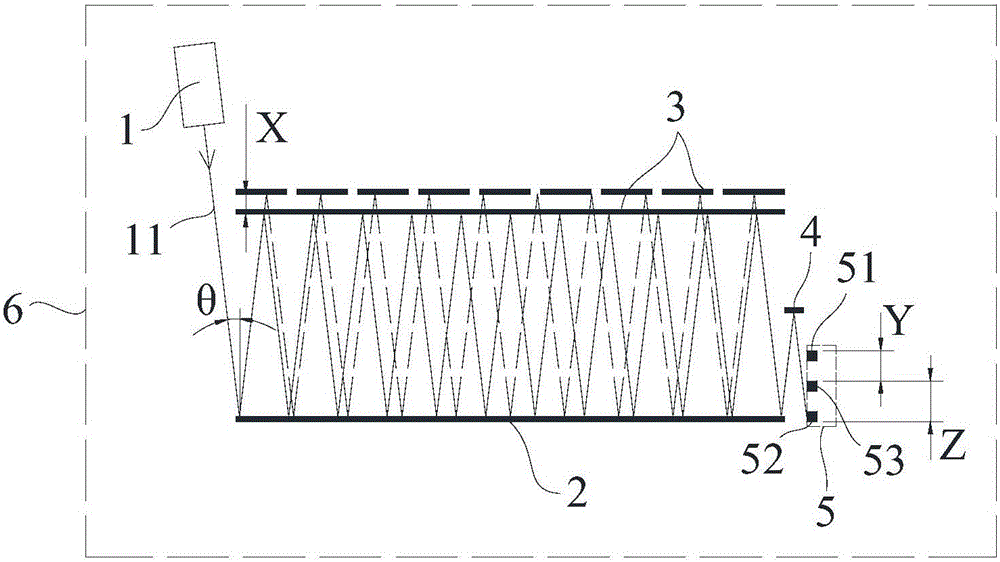

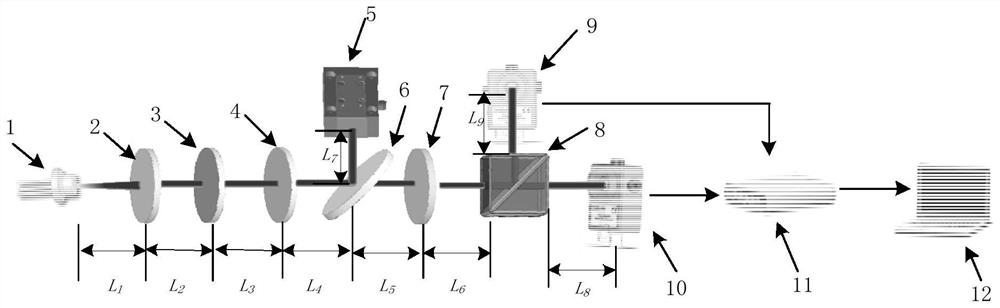

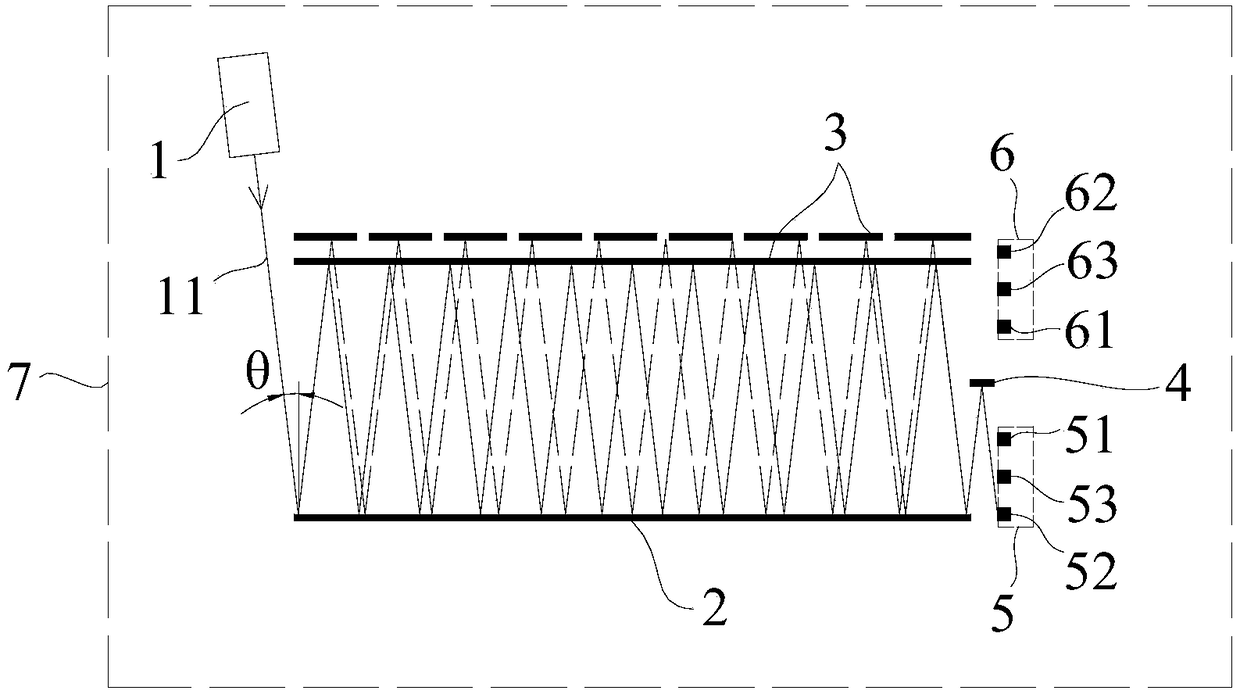

Novel small measuring range ultrahigh precision displacement sensor and measuring method

InactiveCN105783737ASimple structureReliable measurementUsing optical meansPhotovoltaic detectorsLaser beams

The invention discloses a novel small measuring range ultrahigh precision displacement sensor and a measuring method. The sensor comprises a laser beam, two reflectors, a photoelectric detector, and a processing system. According to the sensor, the laser beam is reflected continuously between the two reflectors which are paralleled arranged, and finally the laser beam irradiates at one position of the photoelectric detector; then the space between the two reflectors is changed and therefore the reflecting path of the laser beam is changed so that the laser beam irradiates at another position of the photoelectric detector. The processing system obtains a detection distance value through processing according to the two different positions, wherein the detection distance value is far more than the real change value of the space between the two reflectors; the processing system can calculate the real change value of the space between the two reflectors through the detection distance value. The sensor having a simple structure, reliable measurement and high precision can be applied in measuring continuous displacement change of objects and is easy for batch manufacture.

Owner:BEIFANG UNIV OF NATITIES

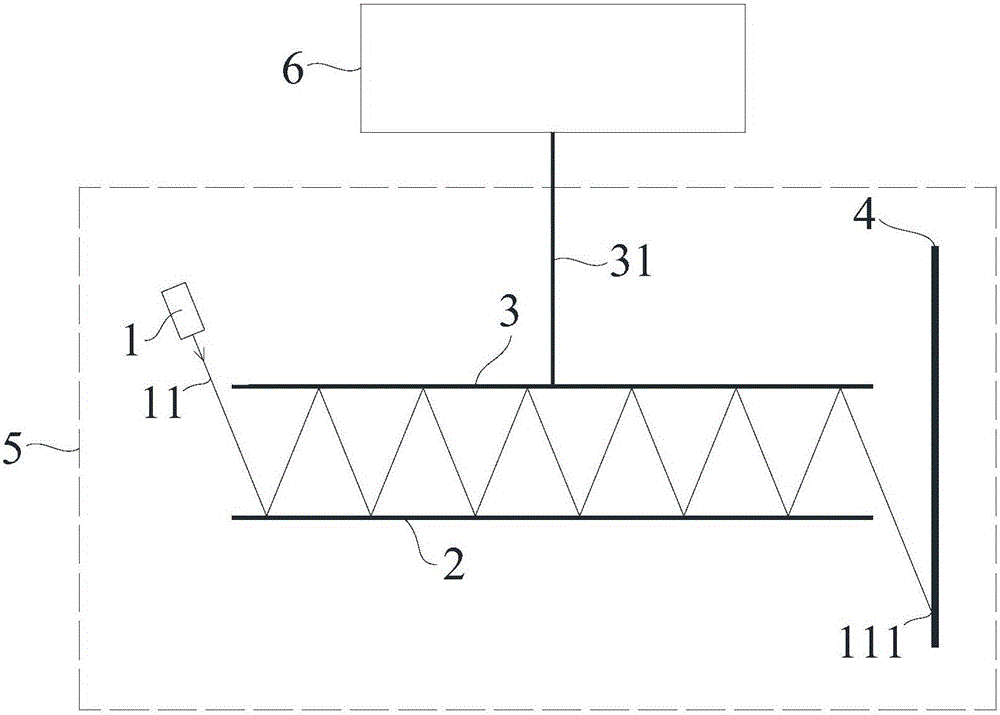

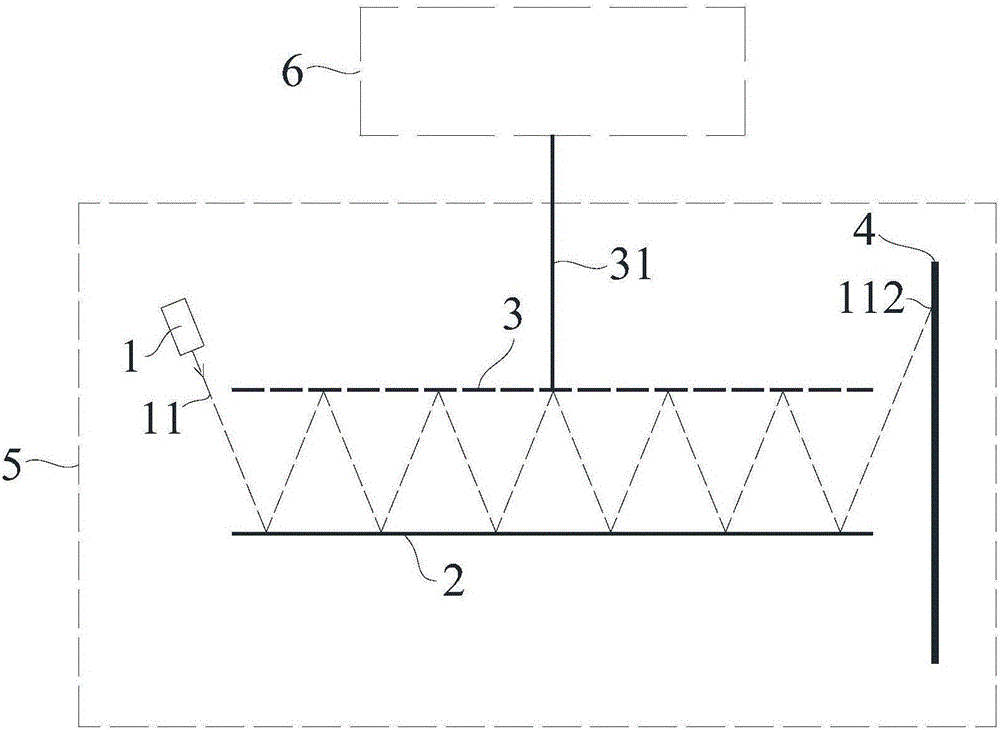

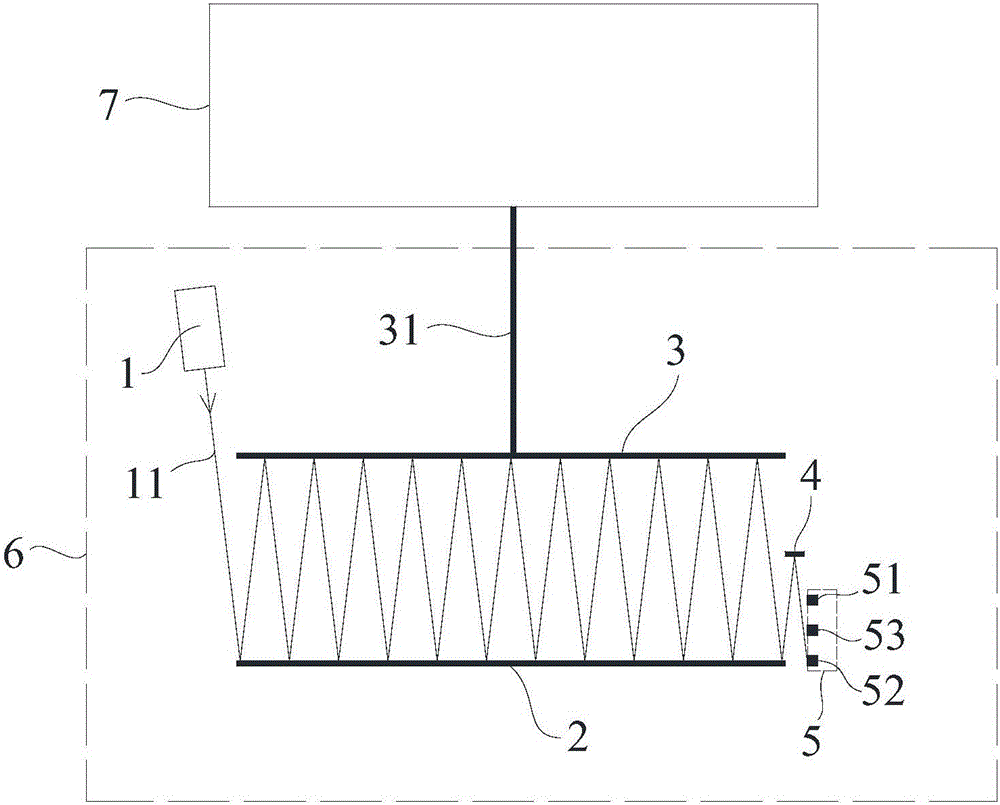

Incremental type small-measurement-range displacement sensor and measurement method

ActiveCN105783738ASimple structureReliable measurementUsing optical meansPhotovoltaic detectorsCapacitive displacement sensor

The invention discloses an incremental type small-measurement-range displacement sensor and a measurement method. The sensor comprises a laser beam, two reflection mirrors, a distributed type photoelectric detector and a processing system. With the adoption of the sensor, the laser beam is reflected continuously between one group of the two reflection mirrors which are arranged in parallel, and is finally illuminated to the distributed type photoelectric detector, so that the distance between the two reflection mirrors is changed, and a reflection path of the laser beam can be changed; a detection part I, a detection part II and a detection part III on the distributed type photoelectric detector are used for inducing the laser beam for three times, and the processing system is used for processing according to the number of times of receiving the laser beam by detection parts and the distance between the detection parts to obtain a detection value; the detection value is larger than a real change value of the distance between the two reflection mirrors; and the processing system can be used for calculating the real change value of the distance between the two reflection mirrors through the detection value. The sensor is simple in structure and is applicable to measurement of displacement changes of an object to be detected; and the sensor can be used for reliably measuring and has relatively high precision, and can be easily manufactured in a large batch.

Owner:泰安泰山科技有限公司

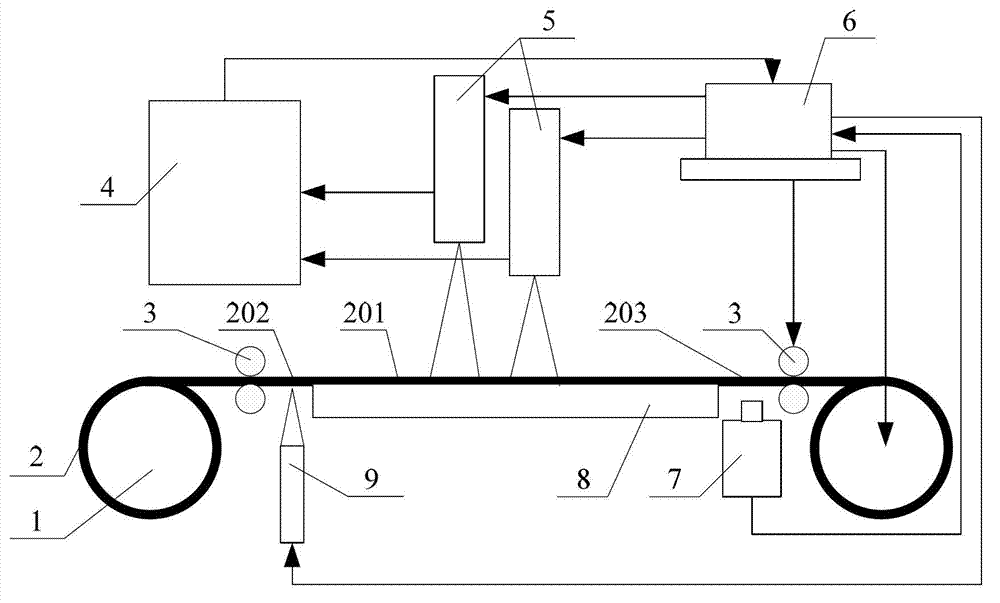

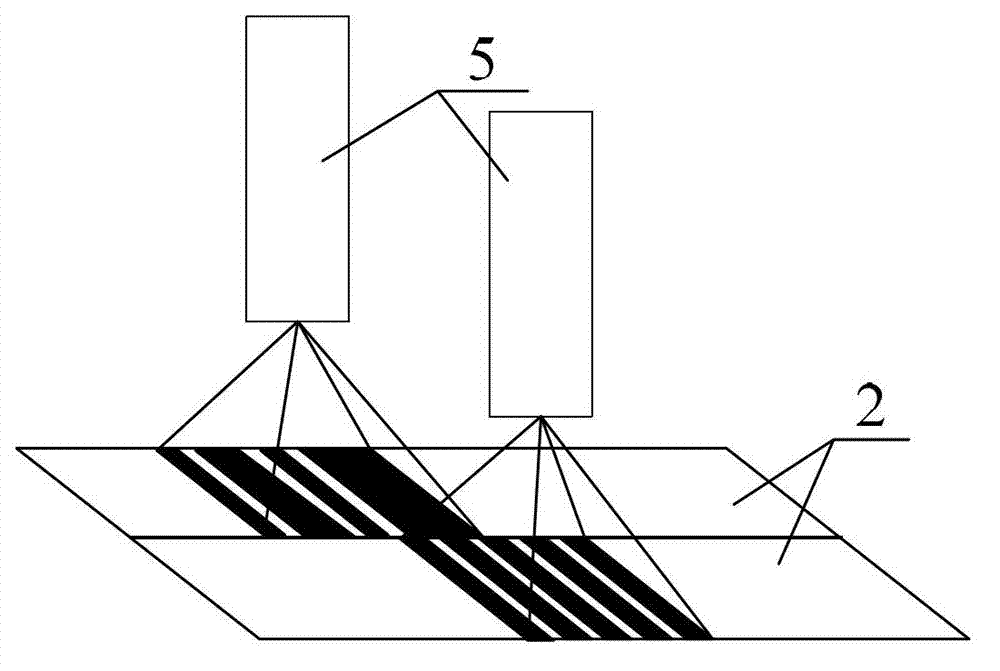

Machining device for manufacturing absolute type steel belt grating ruler

The invention discloses a machining device for manufacturing an absolute type steel belt grating ruler, and belongs to the field of industry machining. The shortcoming that a traditional exposure device cannot manufacture the absolute type steel belt grating ruler with double code channels with a cycle and without a cycle is overcome. Displacement measurement accuracy is improved. Manufacturing of an overlength measuring steel belt ruler is achieved. The machining device comprises projection exposure heads, a charge coupled device (CCD) detector and a laser marking device. The two projection exposure heads respectively expose half of the width of a steel belt. The laser marking device is placed below a starting end of an exposure region of the steel belt. The CCD detector is placed below a finishing end of the exposure region of the steel belt. Control output ends of the CCD detector and the laser marking device are connected with a computer. The two projection exposure heads are used for respectively generating strip patterns of the code channels with the cycle and without the cycle, which is needed by the absolute type grating ruler, manufacturing of the absolute type grating ruler with code channels is achieved, and a laser interferometer is used for controlling micro displacement change and improving accuracy.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

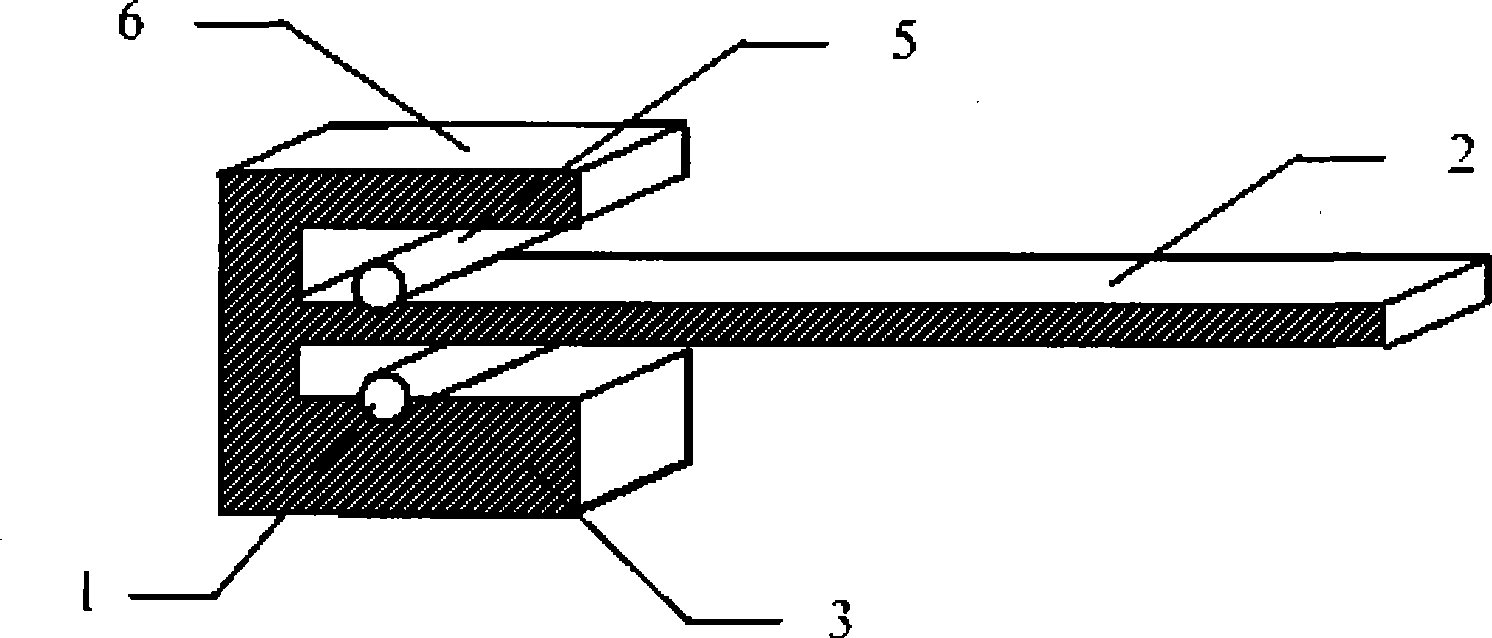

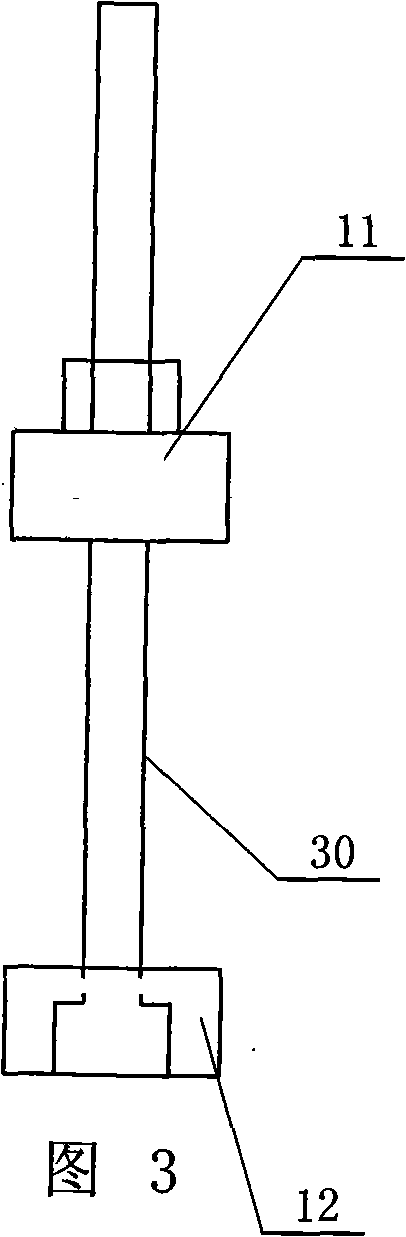

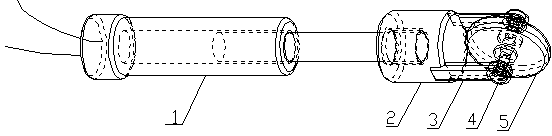

Horizontal direction displacement measuring device of missile vertical launch initial segment

ActiveCN104061892AFix damageReduce the cost of horizontal displacement measurementMeasurement devicesClassical mechanicsHorizontal orientation

The present invention discloses a horizontal direction displacement measuring device of a missile vertical launch initial segment. The horizontal direction displacement measuring device of the missile vertical launch initial segment comprises a displacement sensor (1), a supporting base (2), a supporting rod (3), a shaft (4) and a metal roller (5). A measuring rod of the displacement sensor (1) is in screw joint with the supporting base (2), the supporting base (2) is fixedly connected with the supporting rod (3), the supporting rod (3) is fixedly connected with the shaft (4), and the metal roller (5) and the supporting rod (3) are connected via the shaft (4). The device of the present invention solves the problem that when the horizontal direction displacement of the missile vertical launch initial segment is measured, a frictional force displacement sensor deviates from a horizontal direction, so that the displacement measurement precision is reduced, even the displacement sensor is damaged, and enables the horizontal direction displacement measurement cost of the missile vertical launch initial segment to be reduced and the displacement measurement precision to be improved.

Owner:BEIJING MECHANICAL EQUIP INST

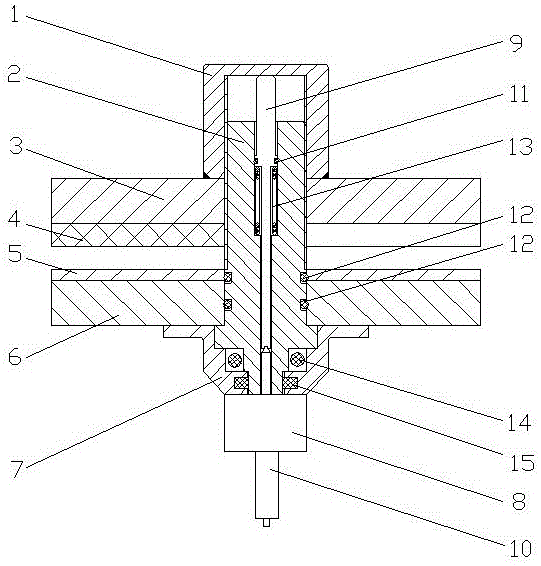

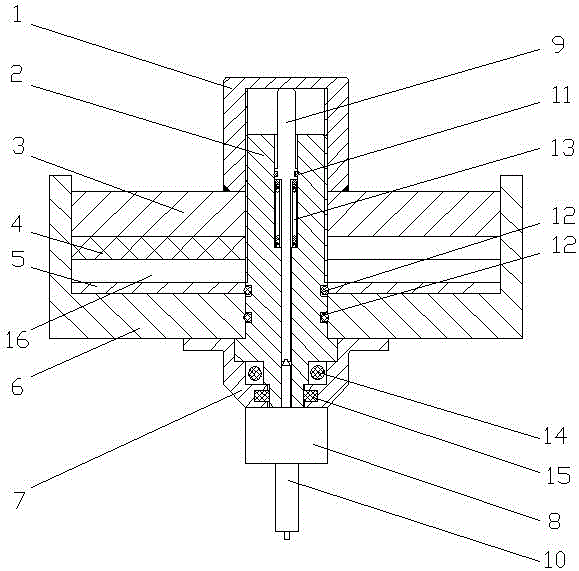

Fracture simulation adjusting mechanism of grouting expansion testing device

ActiveCN105842125ASpeed up the flowReal-time reflection of crack width changesDiffusion analysisInternal pressureSlurry

The invention discloses a fracture simulation adjusting mechanism of a grouting expansion testing device, and belongs to the technical field of grouting expansion testing equipment. The fracture simulation adjusting mechanism comprises adjusting parts and measuring parts, wherein the adjusting parts comprise a fastening screw nut, an adjusting bolt, an upper pressing plate, a visible plate, a lower pressing plate, a bottom plate, a gland and a servo motor; the fastening screw nut is fixed on the upper pressing plate; one end of the adjusting bolt is connected with the fastening screw nut; the other end of the adjusting bolt is connected with the servo motor; the gland is fixedly connected with the bottom plate; the measuring components comprise a displacement measuring rod and a displacement sensor; the displacement measuring rod is arranged inside the adjusting bolt; a first sealing ring is arranged on the displacement measuring rod; a second sealing ring is arranged on the adjusting bolt; a spring is mounted on the displacement measuring rod; the displacement sensor is connected with the servo motor. By adoption of the fracture simulation adjusting mechanism, multiple functions of balancing inner pressure, adjusting fracture width and measuring width are achieved, accurate basis can be provided for grouting construction and establishment of slurry expansion models, and the grouting effect can be ensured.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

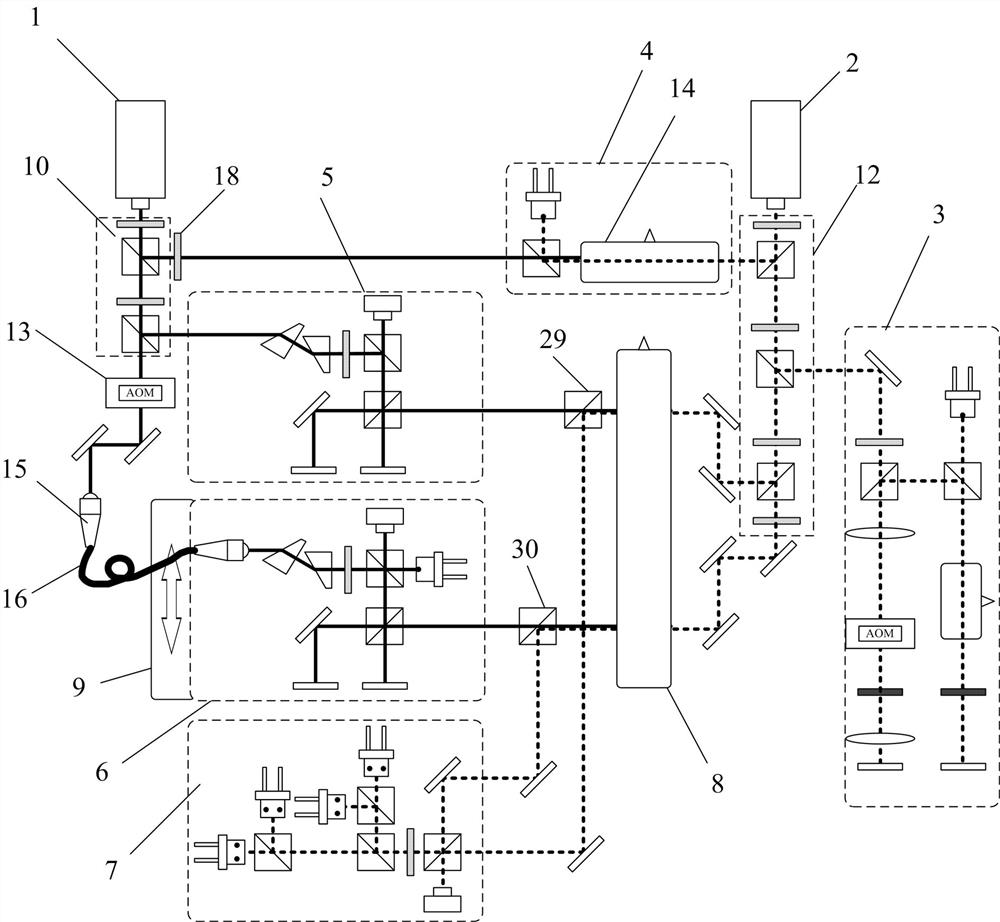

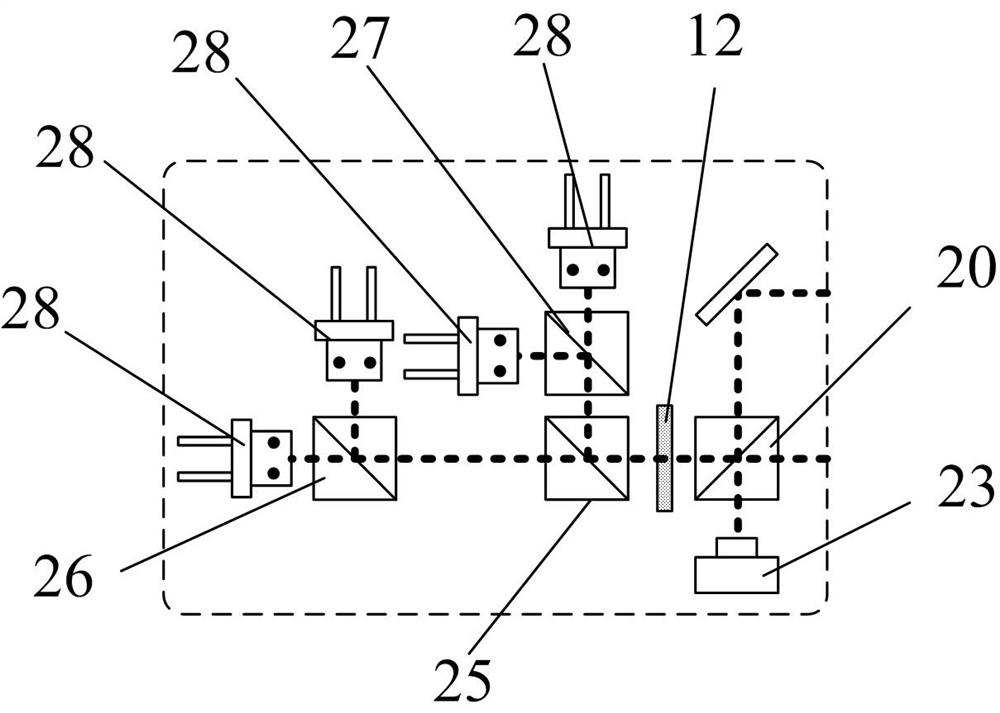

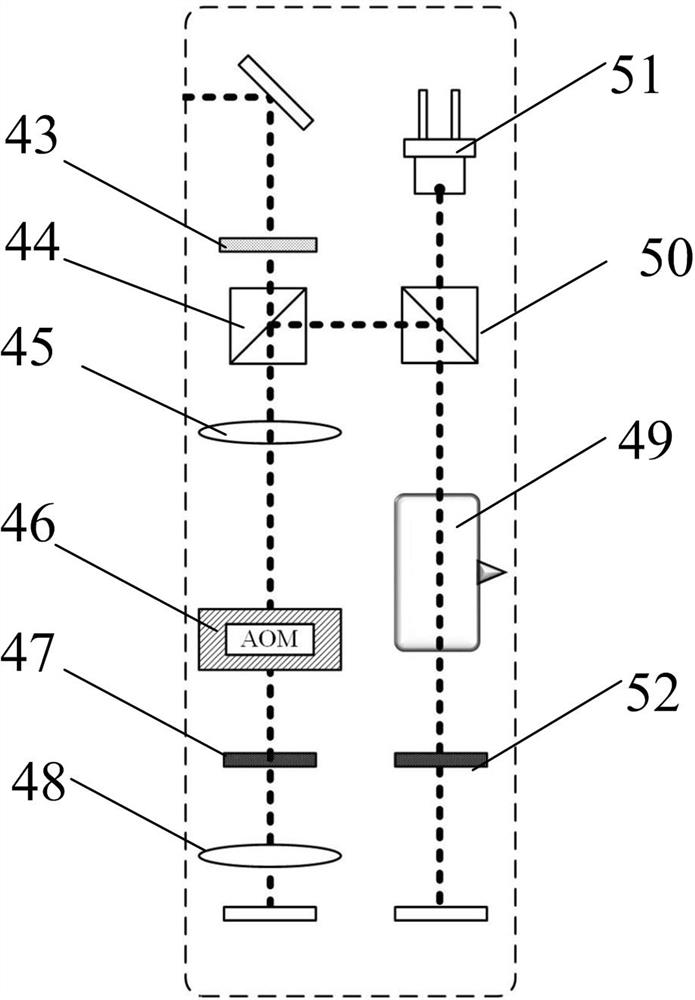

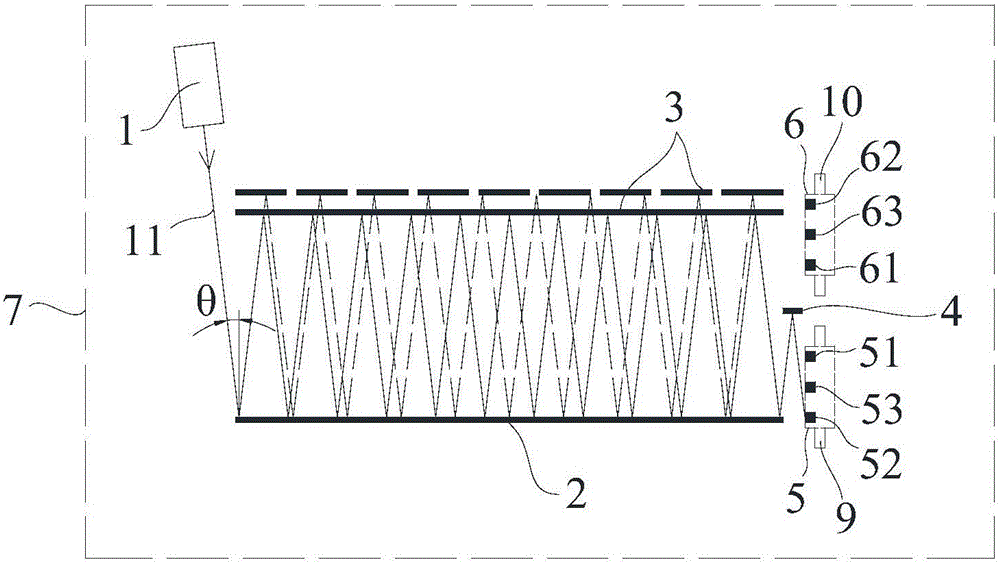

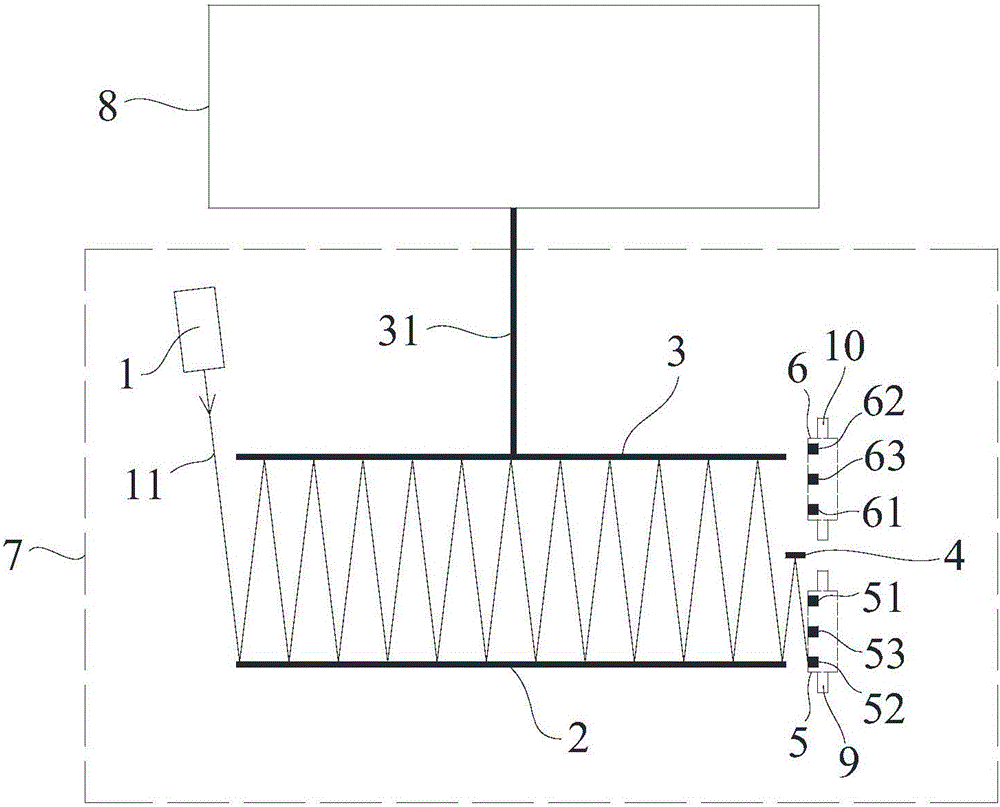

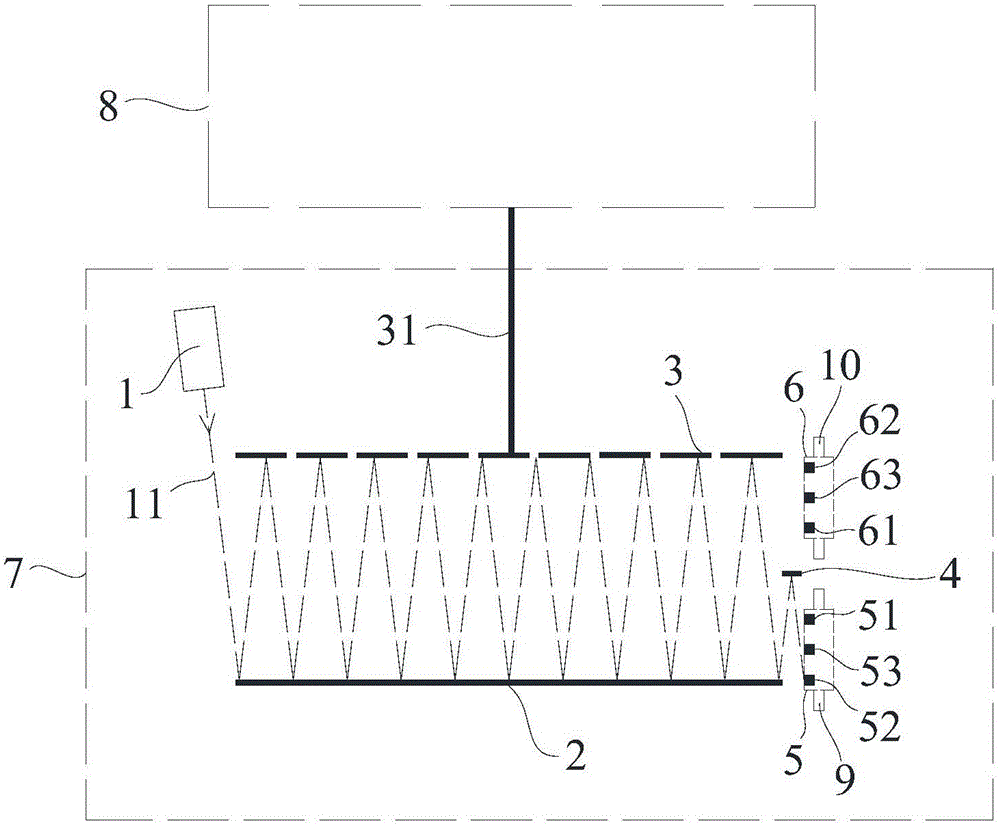

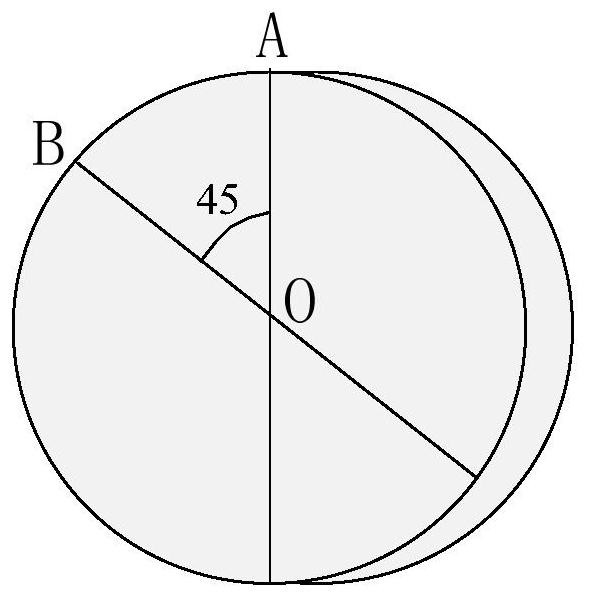

Displacement measuring device and method based on electromagnetic induction transparent atomic grating

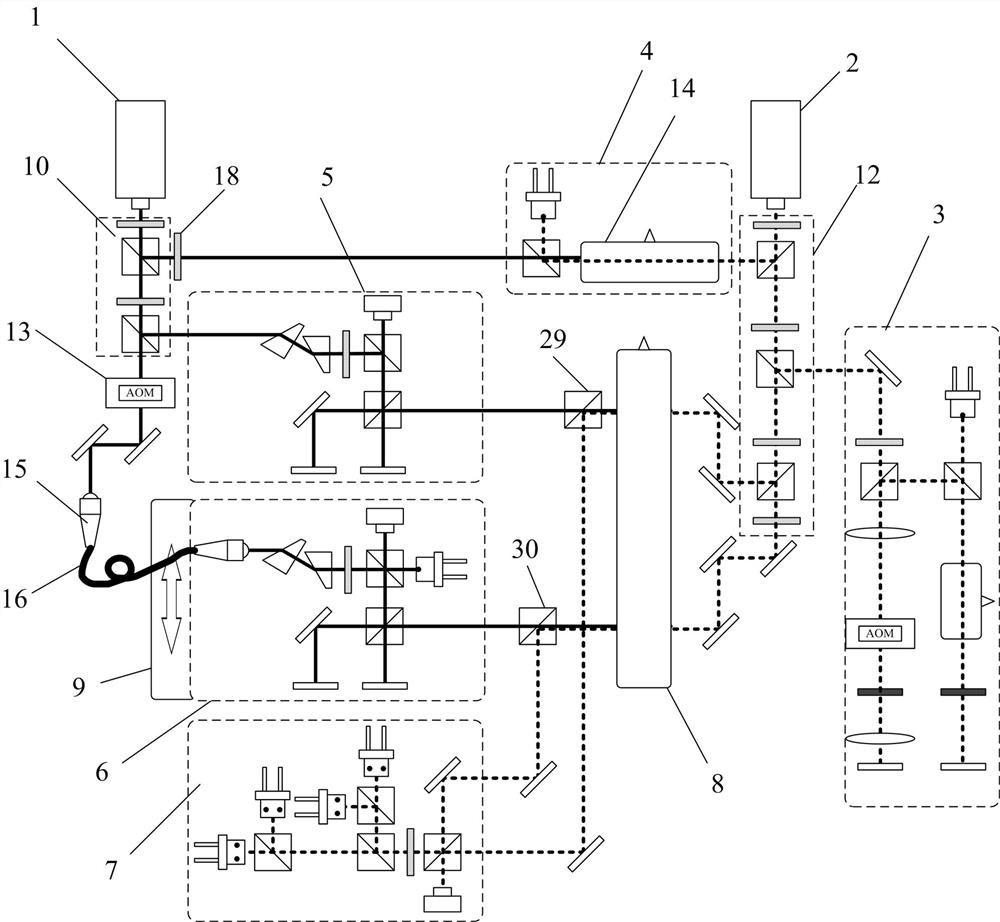

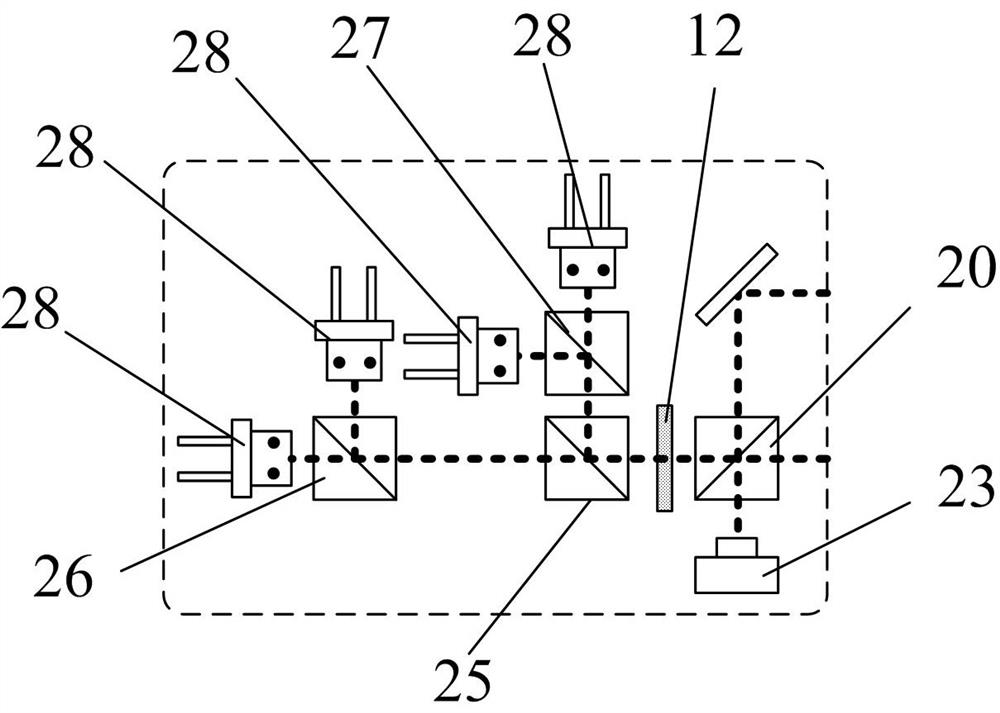

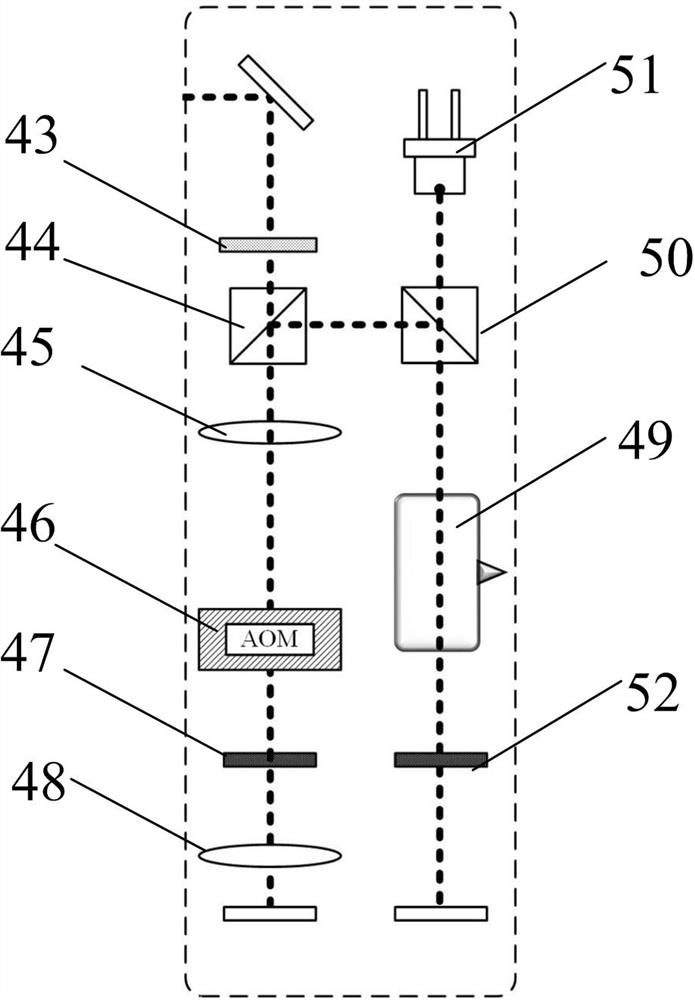

ActiveCN111912338AAvoid errorsImprove displacement measurement accuracyUsing optical meansPhotovoltaic detectorsGrating

The invention belongs to the technical field of precision displacement measurement, and provides a displacement measurement system based on an electromagnetic induction transparent atomic grating, which comprises a coupling laser source, a detection laser source, an offset frequency locking optical path, an electromagnetic induction frequency locking optical path, a reference interference opticalpath, a measurement interference optical path and a photoelectric detection optical path, a corresponding standing wave field structure is built through an interference light path, the refractive index in an atomic medium is periodically modified under an electromagnetic induction transparent mechanism, the atomic grating with the adjustable grating distance is built, detection is carried out through four double-channel photoelectric detectors, displacement measurement is carried out through the atomic grating, and the measurement precision is improved. Moreover, the limitation that the grating distance of the solid grating cannot be adjusted is broken through, the grating distance can be reasonably set according to different displacement degrees of the to-be-measured object, and the grating displacement measurement system with the adjustable minimum displacement resolution is achieved, so that the grating displacement measurement system meets the displacement measurement requirementsin various environments.

Owner:SHANXI UNIV

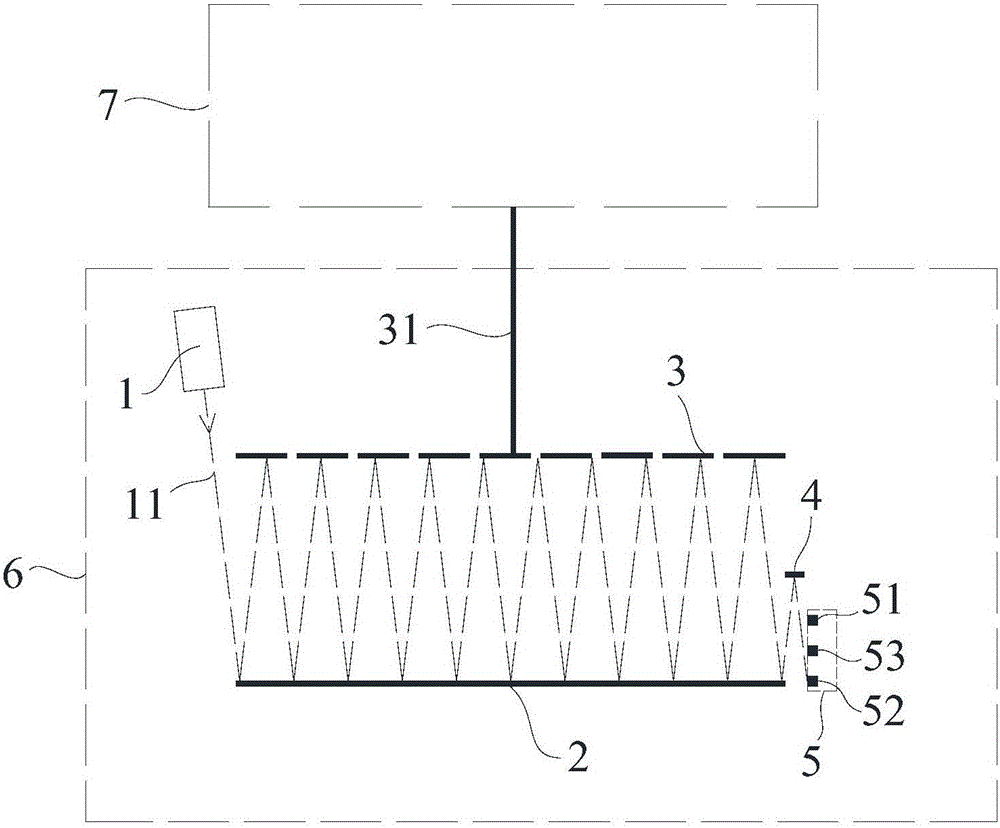

Alternative increment type micro-displacement measurement sensor and measurement method

ActiveCN105783740ASimple structureReliable measurementUsing optical meansLight sensingPhotovoltaic detectors

The invention discloses an alternative increment type micro-displacement measurement sensor. The alternative increment type micro-displacement measurement sensor comprises a laser beam, two reflection mirrors, a photodetector I, a photodetector II, a guide rail I, a guide rail II and a control processing system. With the adoption of the sensor, the laser beam is continuously reflected between one group of two reflection mirrors which are arranged in parallel, and is finally illuminated on the two groups of photodetectors; the distance between the two reflection mirrors is changed so that a reflection path of the laser beam is changed; each group of photodetector moves on the guide rails and the photodetector senses the laser beam; and the control processing system is used for processing according to light sensing mileages and light sensing directions of the photodetectors to obtain a detection displacement value; and the control processing system can also be used for adding or subtracting a movement distance value on the rails of the photodetectors into or by the detection displacement value, and calculating to obtain a real change value between the two reflection mirrors. The sensor disclosed by the invention is simple in structure, reliable in measurement, relatively high in precision and easy to manufacture in a large batch.

Owner:泰安泰山科技有限公司

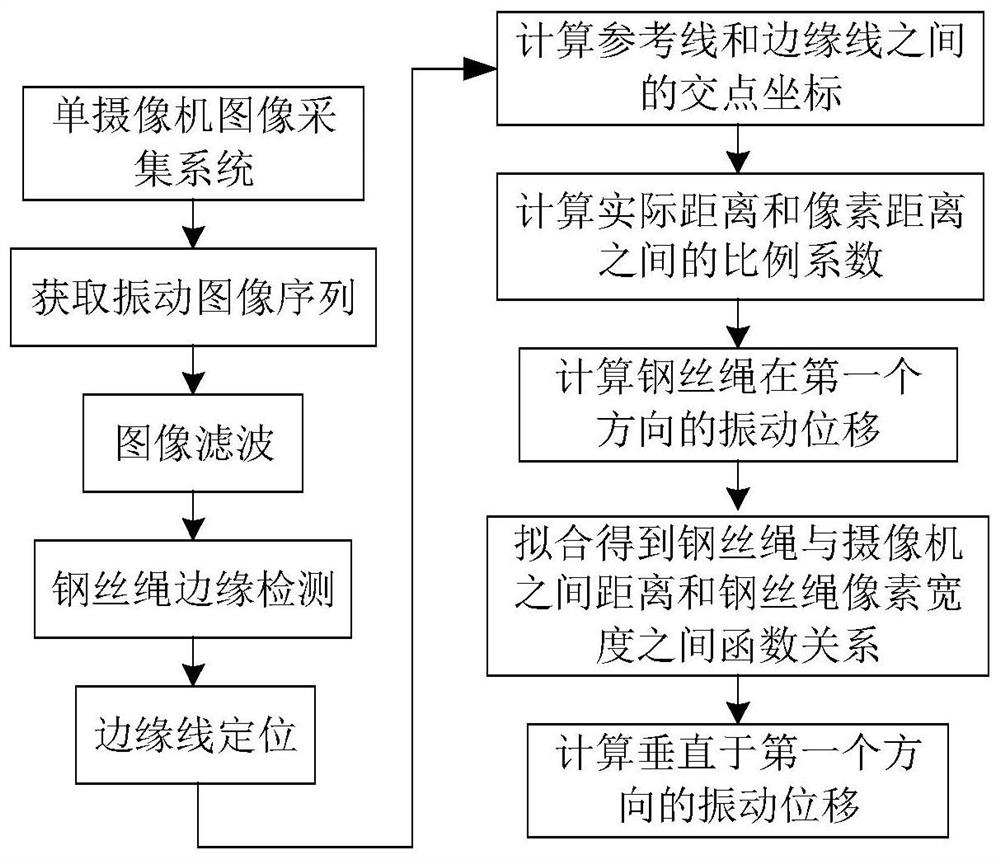

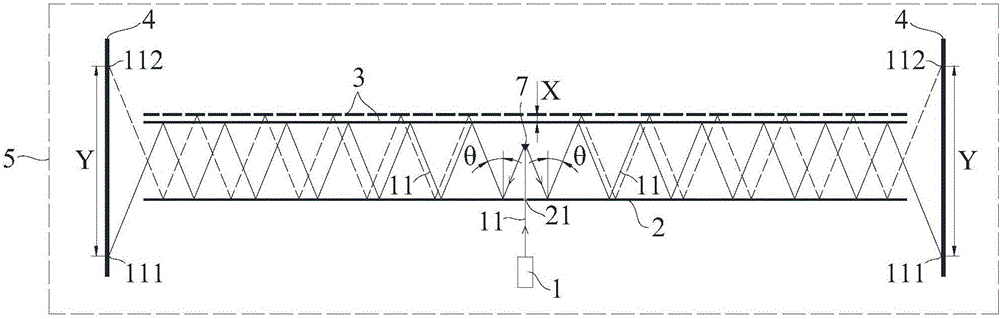

Monocular vision-based hoisting steel wire rope spatial vibration measurement method

PendingCN112085787AImprove displacement measurement accuracyAvoid sureImage enhancementImage analysisVibration measurementNoise reduction

The invention discloses a monocular vision-based hoisting steel wire rope spatial vibration measurement method, which mainly comprises the following steps: respectively installing a camera and a background screen in front of and behind a vertical steel wire rope to acquire a steel wire rope vibration image sequence; performing noise reduction processing on the acquired image; determining the positions of two edge lines of the steel wire rope in each frame of image by utilizing an edge detection and positioning algorithm; adding a virtual reference line perpendicular to the steel wire rope at the measuring point; calculating coordinates of an intersection point between the reference line and the two edge lines, then calculating a proportionality coefficient between the actual width and thepixel width of the steel wire rope, and then calculating the vibration displacement of the steel wire rope in the first direction; determining a function relationship between the vertical distance between the camera and the steel wire rope and the pixel width of the steel wire rope by utilizing a fitting method, and further calculating to obtain the vibration displacement of the steel wire rope inthe direction vertical to the first direction. According to the invention, the monocular vision device is used for measuring the vibration displacement of the steel wire rope in two directions, so that the measurement cost is reduced.

Owner:CHINA UNIV OF MINING & TECH

Novel symmetric small measurement range displacement sensor and measuring method

The invention discloses a novel symmetric small measurement range displacement sensor and a measuring method. The sensor comprises a laser beam, a fixed reflecting mirror, a movable reflecting mirror, a double mirror, a photoelectric detector and a processing system. By applying the sensor, the laser beam is divided into two beams which are respectively reflected to one position on the photoelectric detector at a corresponding side, the space between the fixed reflecting mirror and the movable reflecting mirror is changed, then a reflection path of the laser beam can be changed, the laser beam is finally irradiated to another position of the corresponding photoelectric detector, the processing system calculates according to the two groups of two different positions and obtains two detection distance values which are much larger than real change value of the space between the fixed reflecting mirror and the movable reflecting mirror, and the processing system can calculate the real change value of the space between the fixed reflecting mirror and the movable reflecting mirror according to the average value of the two detection distance values. The sensor disclosed by the invention is simple in structure, applicable to measurement when displacement of an object is continuously changed, reliable in measurement and relatively high in accuracy, and batch manufacturing can be easily realized.

Owner:JIANGSU QIHAO PRECISION MACHINERY

Displacement measurement method based on piezoelectric ceramic open-loop modulation

InactiveCN102506685BImprove hysteresisAdd nonlinearityUsing electrical meansUsing optical meansHysteresisElectricity

Owner:TSINGHUA UNIV

Real-time displacement reconstruction method and device

ActiveCN112747680ALow costImprove real-time performanceUsing optical meansVibration measurementBeam splitter

The invention discloses a real-time displacement reconstruction method and device. The main objective of the invention is to solve a problem that real-time displacement reconstruction cannot be performed on two paths of phase-orthogonal self-mixing signals obtained based on Hilbert transform in an existing self-mixing interference vibration measurement method. The method is characterized by comprising the following steps: generating a self-mixing interference signal based on a first optical signal emitted by a laser and a second optical signal returned by a first object; acquiring two paths of orthogonal self-mixing signals through an attenuation sheet, a polaroid, a spectroscope, a wave plate and a polarization spectroscope; carrying out filtering normalization processing on the two paths of orthogonal self-mixing signals; and dividing the two paths of normalized orthogonal self-mixing signals, carrying out arc tangent transformation, carrying out unwrapping processing, and carrying out displacement reconstruction in real time. The method is high in measurement precision, and meanwhile, real-time displacement reconstruction can be realized after programmed processing is carried out on data by combining a computer.

Owner:NORTHEAST GASOLINEEUM UNIV

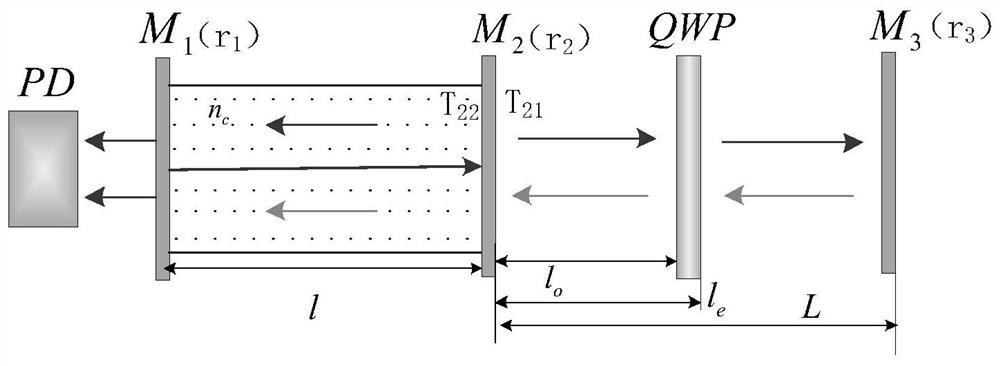

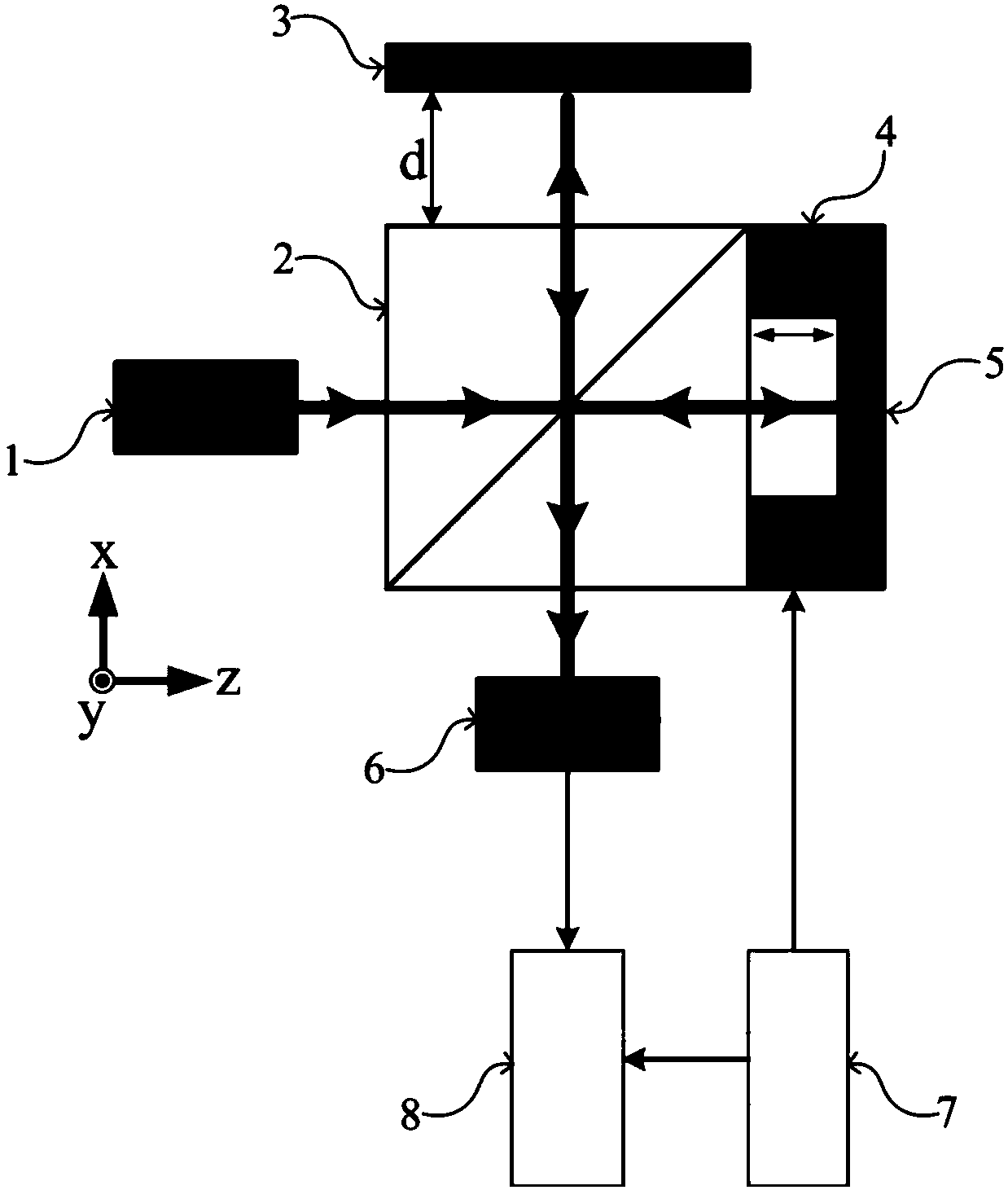

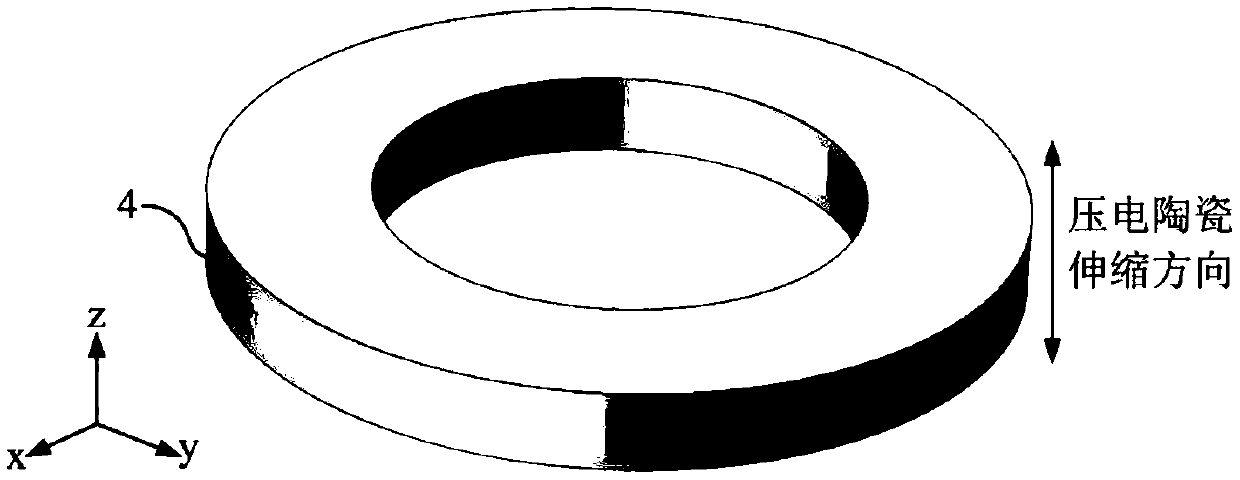

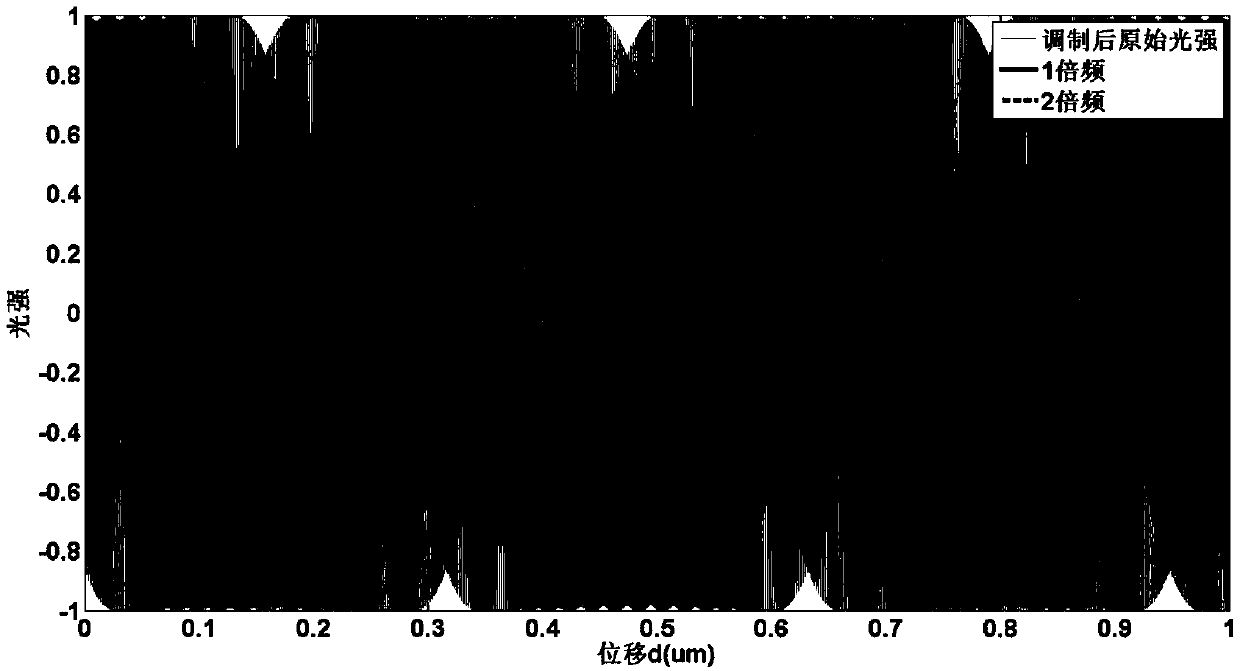

High precision prism displacement measuring device and method based on digital phase lock

InactiveCN108680107AEliminate low sensitivity issuesEliminate measurement effectsUsing optical meansPrismLaser light

The invention relates to the high precision displacement measurement technical field, and more specifically relates to a high precision prism displacement measuring method based on a digital phase lock; the device does not need a wave-plate; a piezoelectric ceramics driver is added on a reference reflector so as to carry out sine modulation; the phase lock can amplify one time frequency and two time frequency signals, thus realizing high precision and high sensitivity measurement of displacement, and eliminating influences on measurements by background noises and laser intensity fluctuations;the method does not need to know a zero light path difference point and interpolation, only gathers PEM modulation interference signals for a time length (see description), and has nothing to do witha sampling start point and a finish point; the method uses the phase lock amplification technology to improve the displacement precision, can phase lock one time frequency signal and two time frequency signal amplitudes, and divides to eliminate the displacement measuring precision reduction problems caused by laser light intensity fluctuations; the displacement form is arc tangent, thus ensuringthe same linear sensitivity, and eliminating the low sensitivity problem of certain positions of a conventional sine and cosine.

Owner:ZHONGBEI UNIV

A Measuring Method for Alternate Incremental Measuring Micro Displacement Sensor

ActiveCN105783739BSimple structureReliable measurementUsing optical meansPhotovoltaic detectorsHandling system

The invention discloses a novel alternative incremental sensor for measuring the micrometric displacement. The novel alternative incremental sensor comprises a laser beam, a fixed reflecting mirror, a movable reflecting mirror, a detection reflecting mirror, a photoelectric detector I, a photoelectric detector II and a processing system. In operation of the sensor, the laser beam is continuously reflected to the reflecting mirrors in the fixed reflecting mirror and the movable reflecting mirror which are parallel, and finally irradiates onto the two groups of photoelectric detectors, and the reflecting path of the laser beam can be changed when the distance between the fixed reflecting mirror and the movable reflecting mirror is changed; the laser beam is induced for multiple times by three detection parts on each group of photoelectric detector, the processing system obtains a detection distance value according to the laser-beam induction times and the laser induction sequence of each group of detection parts and the distance processing among the detection parts, and then can calculate out a real change value of the distance between the fixed reflecting mirror and the mobile reflecting mirror by the detection distance value; the novel alternative incremental sensor is simple in structure, reliable in measurement, higher in accuracy and easy in implementation of batch manufacture.

Owner:苏州致将智能光电有限公司

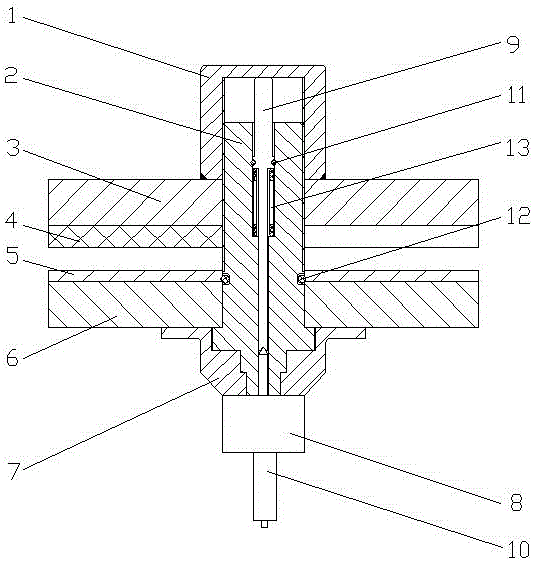

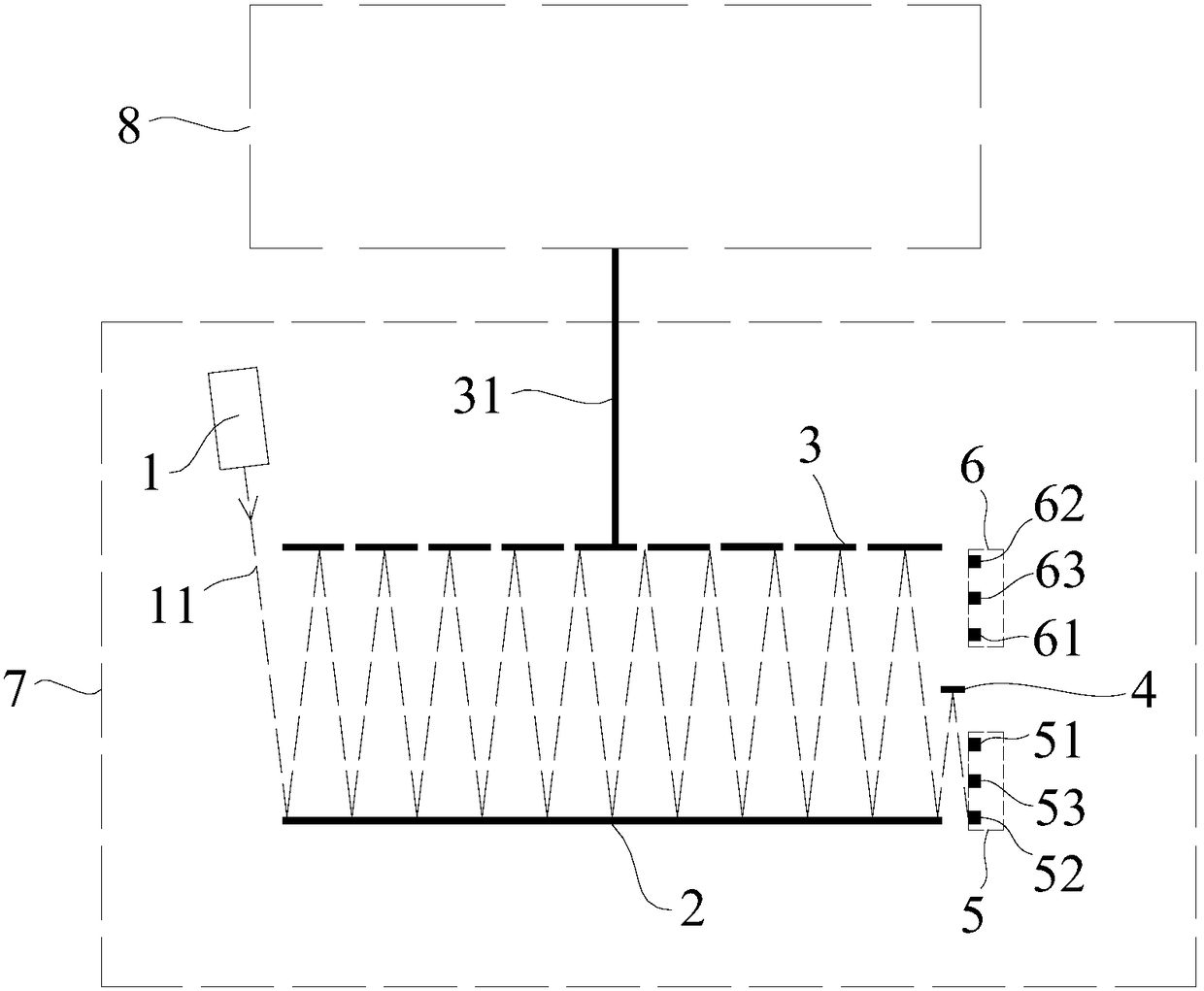

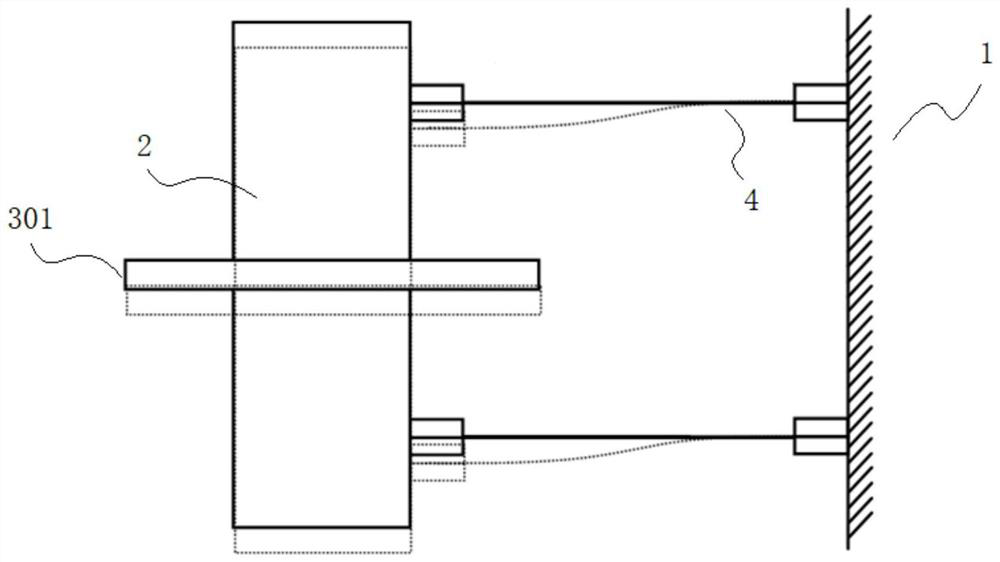

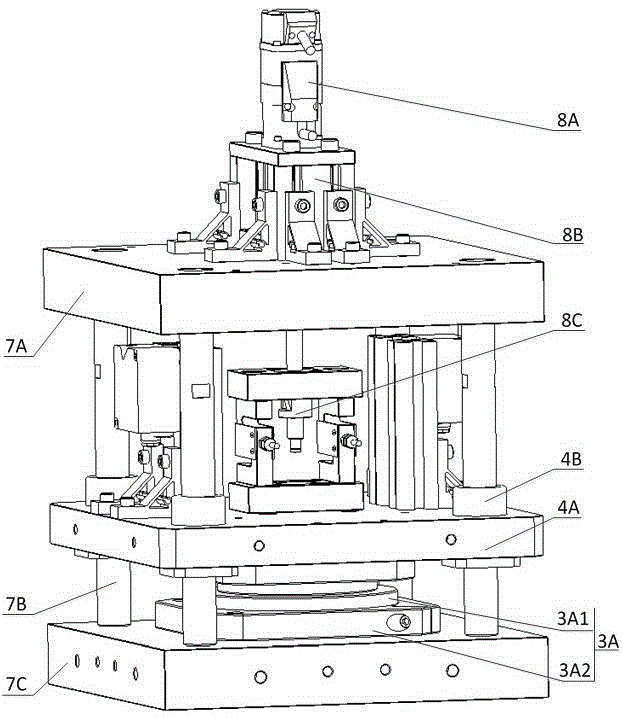

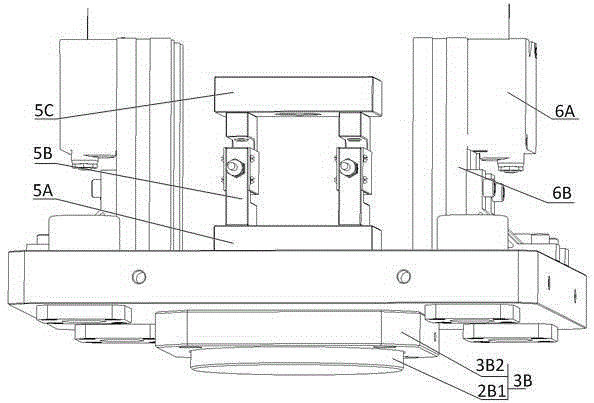

A high-precision gyro motor bearing loading method

ActiveCN103148818BImprove displacement measurement accuracyHigh loading accuracyMeasurement devicesAir bearingDifferential measurement

The invention relates to a high precision gyro motor bearing loading method. The loading can be achieved by using of a gyro motor loading device, and the gyro motor loading device consists of a machine frame, a platform surface, a horizontal guide rail system, a lifting guide rail system, two displacement sensors, an air bearing support, weights, an air shaft, a bearing centering sleeve and a bearing centering base. The centring can be achieved through a shaft at one end of the gyro motor, and the positioning can be achieved on an outer ring of a bearing, weights are placed in a weight plate, and required loads (namely, preloads) are added on an outer ring of a bearing at the other end through the air bearing. Then the size between two sets of bearing outer ring shaft shoulders is measured with a method of differential measurement through a displacement sensor 1 and a displacement sensor 2 which are calibrated. The height size of an outer rotor of the gyro motor is matched according to the measured size, and the post-installed preload of the gyro motor is guaranteed. The loading precision is greatly improved, errors caused by that the loading force does not pass through the center line of the motor bearing are eliminated, and the displacement measurement accuracy is improved.

Owner:BEIJING INST OF CONTROL ENG

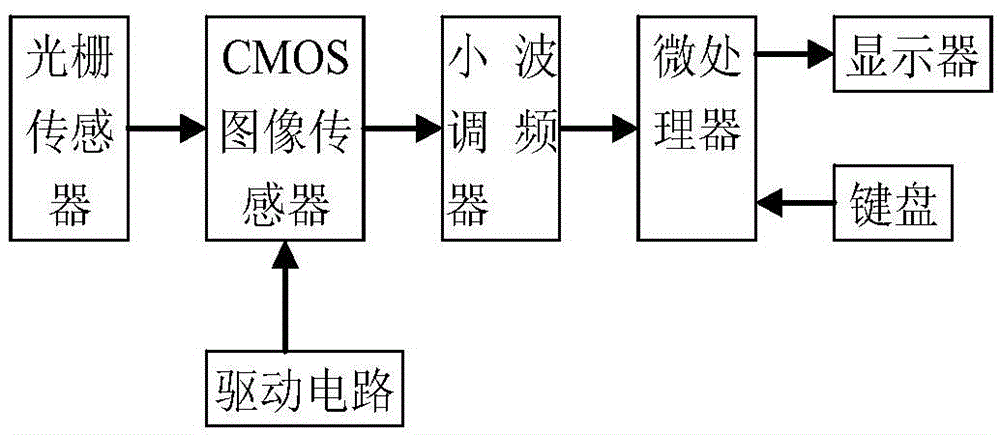

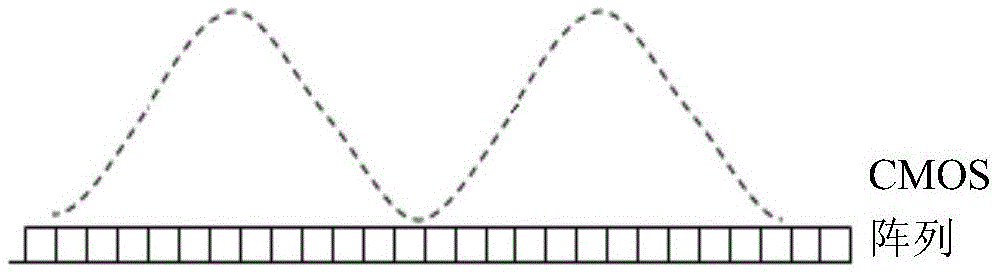

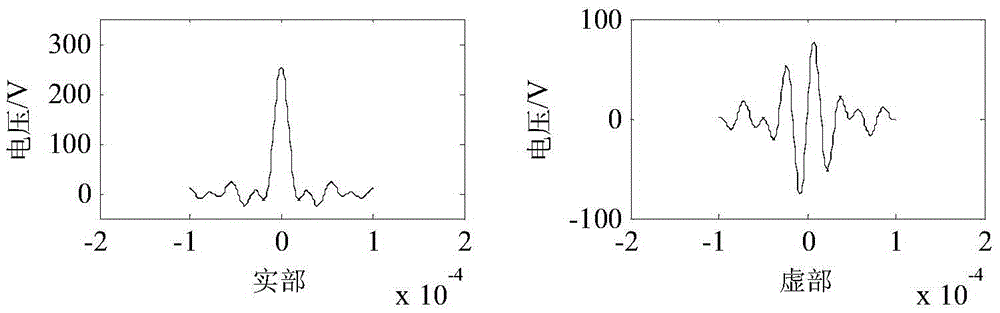

Grating speed measurement method and device

InactiveCN103592454BHigh pixel resolutionUniform pixelUsing optical meansDevices using optical meansGratingEngineering

In the position control system, multiple feedbacks such as displacement and speed are used to improve control accuracy. The grating has the advantages of precision, large range, and low cost as displacement feedback. This paper proposes the use of wavelet transform to realize the dual-parameter simultaneous extraction of the displacement and velocity of grating Moiré fringes. The scale factor corresponds to the velocity, the translation factor corresponds to the displacement, and the modulation changes The traditional grating Moiré fringe only measures single parameter of displacement and multi-parameter sensor realizes multi-parameter feedback, which is of great significance for improving positioning accuracy and simplifying the structure of the positioning system.

Owner:SHENYANG POLYTECHNIC UNIV

Translational gravity/acceleration measuring sensitive structure

PendingCN113687435AIncrease the capacitive displacement sensing areaImprove displacement measurement accuracyAcceleration measurementGravitational wave measurementPhysicsEngineering

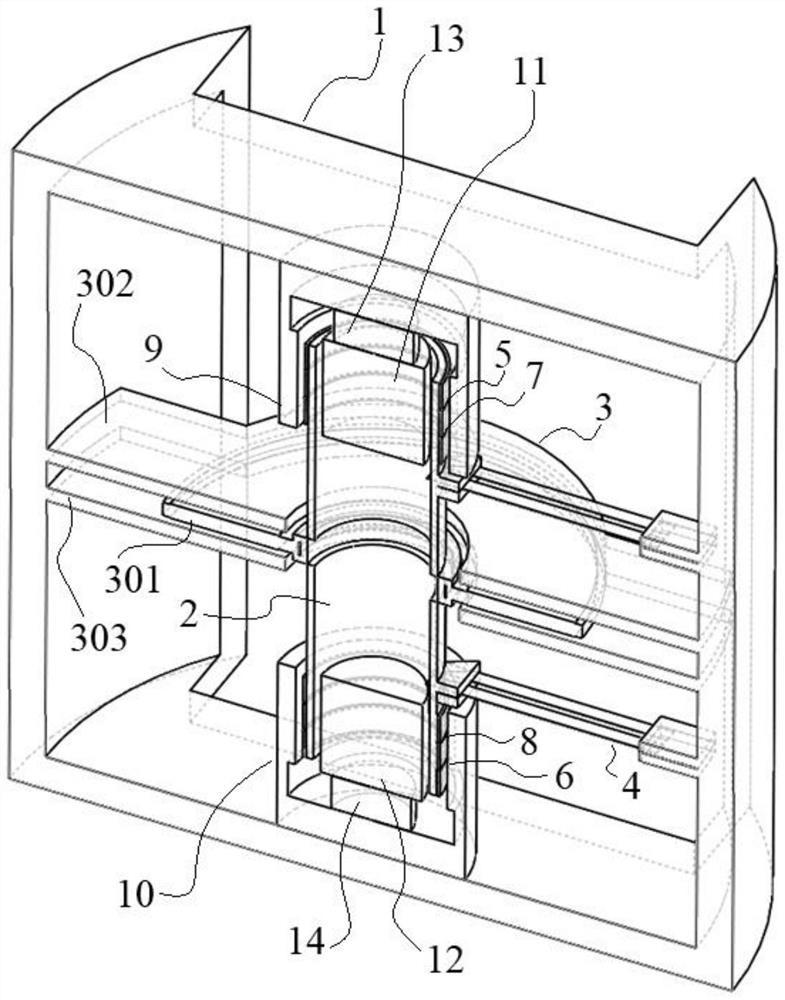

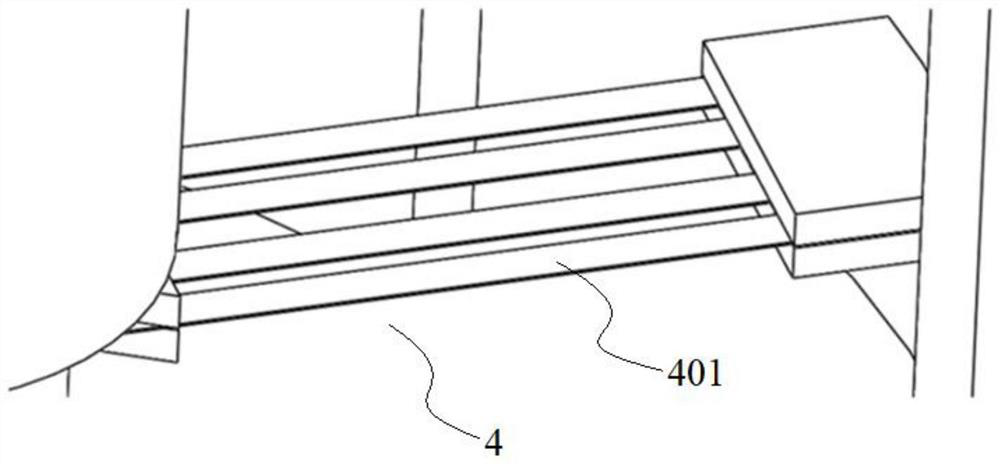

The invention discloses a translational gravity / acceleration measuring sensitive structure, which comprises a frame, a sampling mass cylinder, a variable-spacing capacitive displacement sensor and a reed group, and is characterized in that the sampling mass cylinder is connected with the variable-spacing capacitive displacement sensor; and one end of each reed group is in insulated connection with the side wall of the sampling mass cylinder, and the other end is in insulated connection with the inner wall of the frame. An upper acceleration compensation coil and a lower acceleration compensation coil which are connected in series, and an upper acceleration measuring coil and a lower acceleration measuring coil which are connected in series are respectively arranged outside the upper end and the lower end of the sampling mass cylinder. According to the invention, the deflection motion mode of the sampling mass cylinder is eliminated in principle, and the translational motion of the sampling mass cylinder in the measuring process is realized; the displacement measuring precision is improved; and the heat dissipation area of the coil is increased, assembling is easy, and the size is obviously reduced.

Owner:INNOVATION ACAD FOR PRECISION MEASUREMENT SCI & TECH CAS

An Observation Device for Liquid Bridge Separation Between Parallel Plates

ActiveCN103940703BEasy to separateGuaranteed verticalitySurface/boundary effectParallel plateEngineering

The present invention discloses an precise observation apparatus for rapid liquid bridge separation between parallel plates, wherein an upper base plate and a lower base plate are connected through a guide shaft, the lower base plate is fixedly arranged on an observation frame, a movement plate sleeves on the guide shaft to move up and down, the top surface of the lower base plate and the bottom surface of the movement plate are respectively provided with an upper plane flat crystal assembly and a lower plane flat crystal assembly, parallel and coaxial upper plane flat crystal and lower plane flat crystal are fixed on the upper base plate and the lower base plate, a liquid bridge is formed between the upper plane flat crystal and the lower plane flat crystal, a drive assembly is positioned on the top surface of the upper base plate, a tensile force measurement assembly is arranged between the drive assembly and a movement plate assembly, a displacement measurement assembly is arranged on the movement plate, and the side surface and the bottom of the observation frame are provided with high speed cameras. According to the invention, the process of precise observation on rapid liquid bridge separation between parallel plates is achieved, advantages of high parallel plate parallel degree, high separation speed verticality, high measurement precision and the like are provided, and precise observation on contour evolution and capillary force of the liquid bridge between the parallel plates under different separation speed conditions can be achieved, wherein the initial distance between the parallel plates is 100 mum.

Owner:ZHEJIANG CHEER TECH CO LTD

Displacement or acceleration sensor

InactiveCN101464138BHigh sensitivityHigh precisionAcceleration measurement using interia forcesUsing optical means

The invention discloses a displacement sensor or an acceleration sensor, belongs to the technical field of fiber sensors, and is characterized in that the displacement sensor or the acceleration sensor comprises a first fiber laser, a cantilever beam and a first platform, wherein, the first fiber laser is clamped between the surfaces of the cantilever beam and the first platform; the first fiber laser and the first platform are arranged below or above the cantilever beam; and the deformation generated by the cantilever beam generates acting force to the first fiber laser. The invention has the effects and benefits that the sensor overcomes the defect that the conventional electrical sensor is liable to electromagnetic interference; and the invention provides the fiber displacement sensor or the fiber acceleration sensor having the advantages of high sensitivity, large measurement range, simple structure, low demodulation cost and better signal-to-noise ratio.

Owner:DALIAN UNIV OF TECH

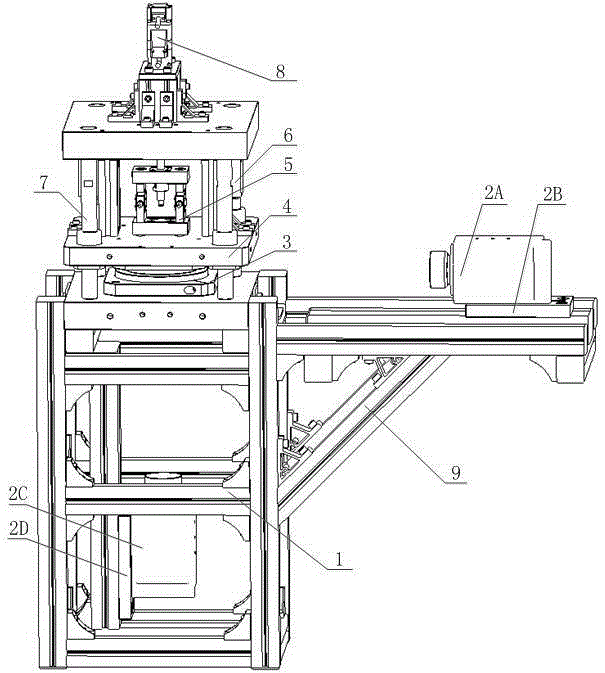

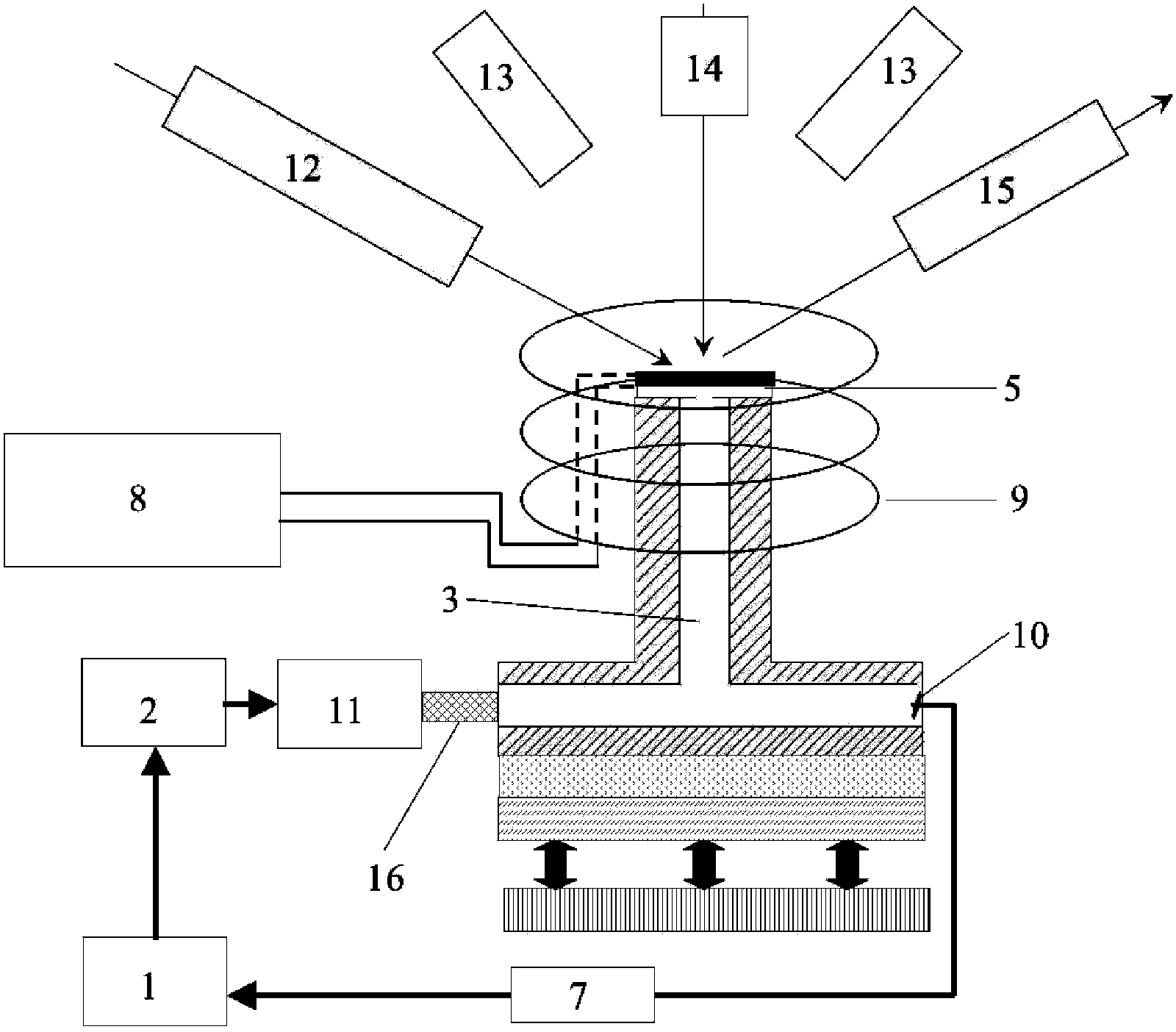

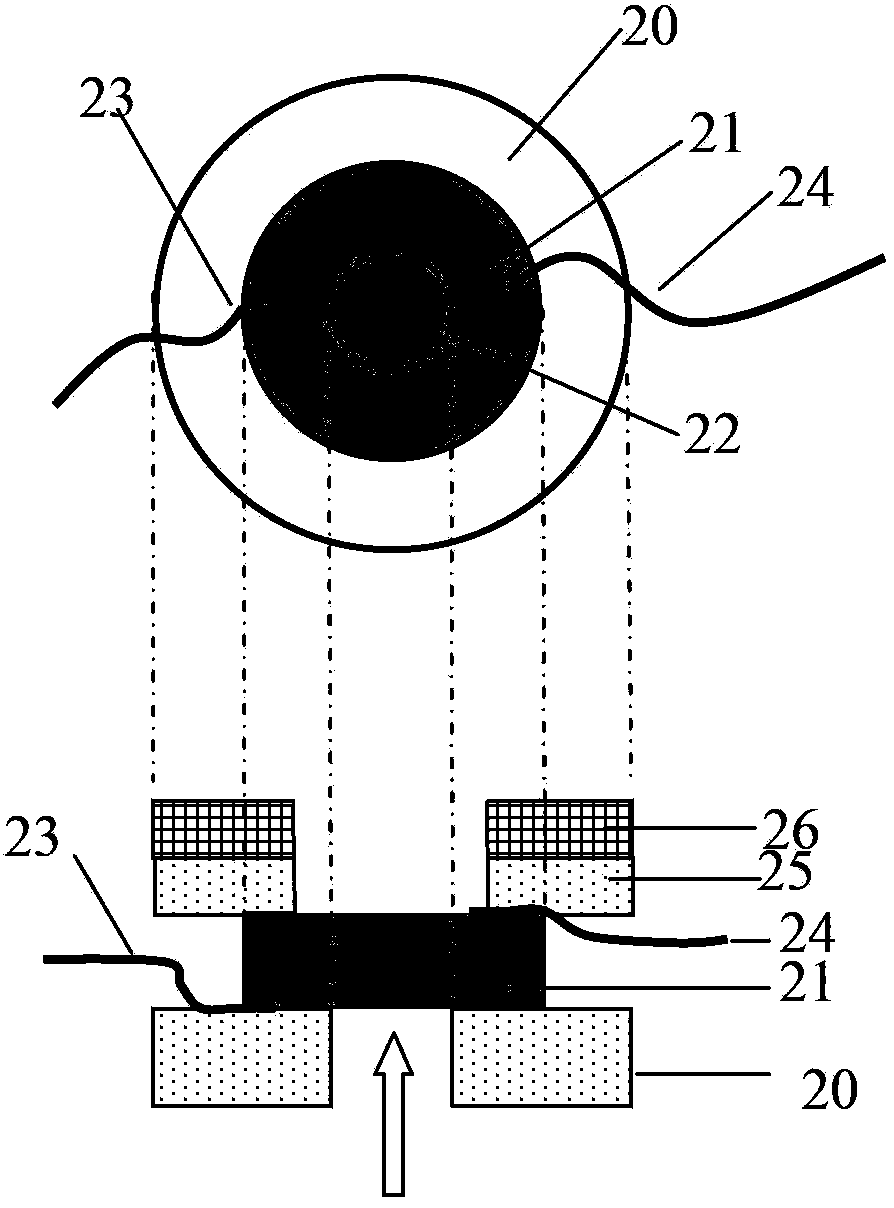

Bubbling experiment device for mechanical-electric-magnetic coupling behavior of electromagnetic intelligent material and test method

InactiveCN102645372BRealize non-contact 3D deformation testingUnderstand clearly and thoroughlyElectrical testingMaterial strength using tensile/compressive forcesClosed loopEngineering

The invention discloses a bubbling experiment device for the mechanical-electric-magnetic coupling behavior of an electromagnetic intelligent material and a test method. In the invention, the tested film material is subjected to elastic deformation, plastic deformation, interface cracking and even self fracture by a bubbling method under the effect of full coupling of the mechanical-electric-magnetic fields, and the device realizes real-time testing on the mechanical, electric and magnetic response of the tested material in the process, thereby being favorable for obtaining the information of the functional film material in multiple aspects and for understanding the internal mechanism more clearly and thoroughly; in the existing oil-pressure bubbling loading device, a closed-loop control mode is adopted to control the oil pressure loading for the first time, and multiple oil pressure loading modes are realized so as to widen the representation functions of the bubbling test device; by adopting the projection speckle and digital image related technology, the non-contact three-dimensional deformation test is realized on the film sample, and the displacement measurement accuracy is improved to 20nm; and the device and method are favorable for researching the mechanical, electric and magnetic comprehensive performance of the novel functional film material.

Owner:PEKING UNIV +1

A Displacement Measuring Device and Method Based on Electromagnetically Induced Transparent Atom Grating

ActiveCN111912338BAvoid errorsImprove displacement measurement accuracyUsing optical meansGratingPhotovoltaic detectors

The invention belongs to the technical field of precision displacement measurement, and provides a displacement measurement system based on an electromagnetically induced transparent atomic grating, including a coupled laser source, a detection laser source, an offset frequency-locked optical path, an electromagnetically induced frequency-locked optical path, a reference interference optical path, and a measuring Interference optical path and photoelectric detection optical path; the present invention builds the corresponding standing wave field structure through the interference optical path, periodically modifies the refractive index in the atomic medium under the mechanism of electromagnetic induction transparency, and constructs an atomic grating with adjustable grating pitch. The channel photodetector is used for detection, and the displacement measurement through the atomic grating is realized, which improves the measurement accuracy. Moreover, the present invention breaks through the limitation that the pitch of the grating cannot be adjusted, and can reasonably set the pitch according to the different displacement degrees of the object to be measured, so as to realize a grating displacement measurement system with adjustable minimum displacement resolution, thereby adapting to various environments. Displacement measurement needs.

Owner:SHANXI UNIV

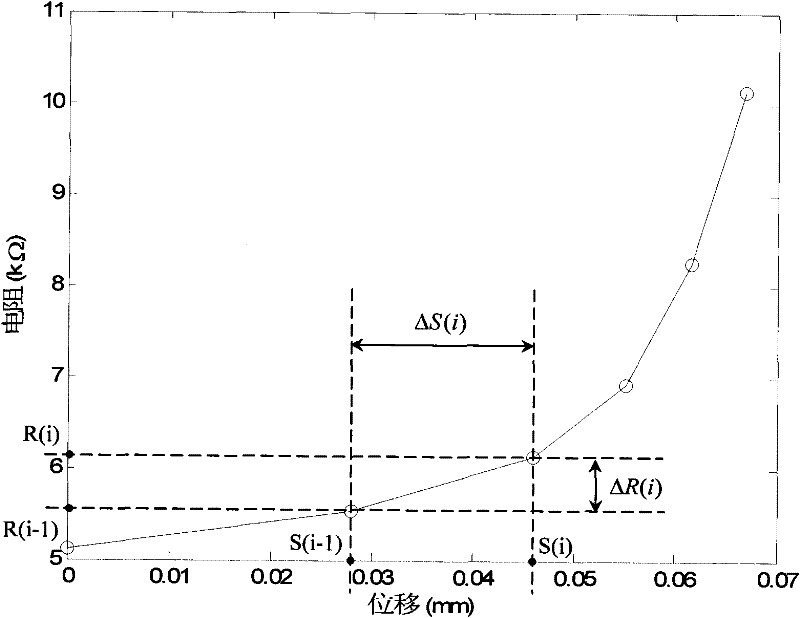

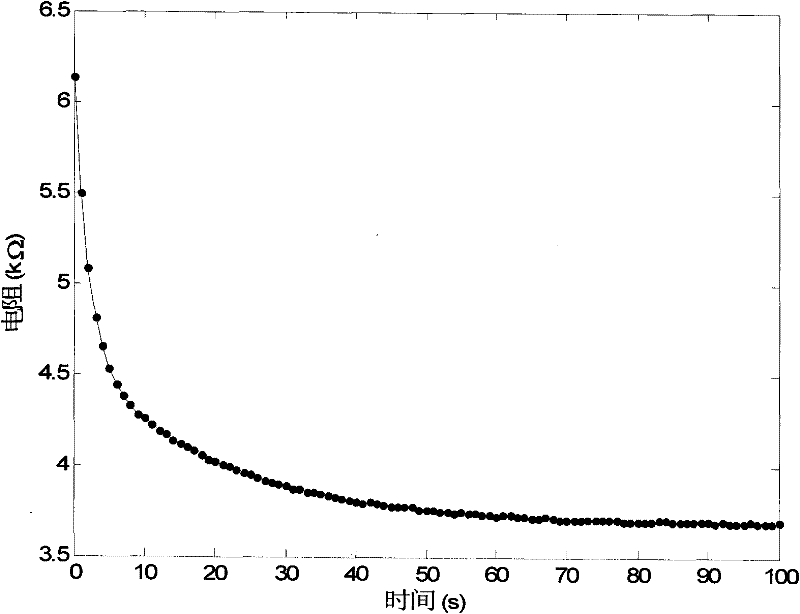

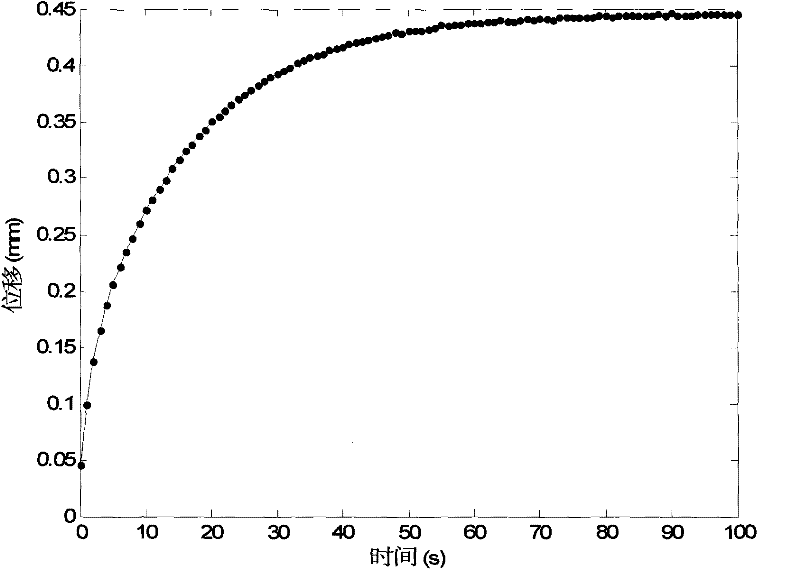

Displacement measurement method based on resistance creep of composite conductive polymer pressure sensitive material

InactiveCN101975544BCreep uninhibitedPrevent creepUsing electrical meansElectrical resistance and conductanceConductive polymer

The invention relates to a displacement measurement method based on resistance creep of a composite conductive polymer pressure sensitive material, belonging to the technical field of measurement. The method uses resistance creep to reflect displacement variation in real time instead of inhabiting resistance creep. In calibration, resistance-strain properties at the moment of finishing loading application and during creep stage are respectively obtained, and corresponding algorithms are respectively compiled; and in monitoring, at first, the stress phase of the pressure sensitive material is judged through the variation of resistance, and then a corresponding algorithm is used to obtain the real-time displacement value. According to different stress states, the measurement method of the invention uses different calibration methods and algorithms and considers time factors, thus further eliminating the adverse effects of resistance creep of the pressure sensitive material on displacement measurement. As the traditional method of adding nano powder to the substrate to reduce resistance creep is not used, the flexibility of the pressure sensitive material is ensured.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com