Novel small measuring range ultrahigh precision displacement sensor and measuring method

A technology of a displacement sensor and a measurement method, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problems of unsatisfactory measurement accuracy and difficulty in improving the measurement accuracy, and achieve reliable measurement, simple structure, and easy mass production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

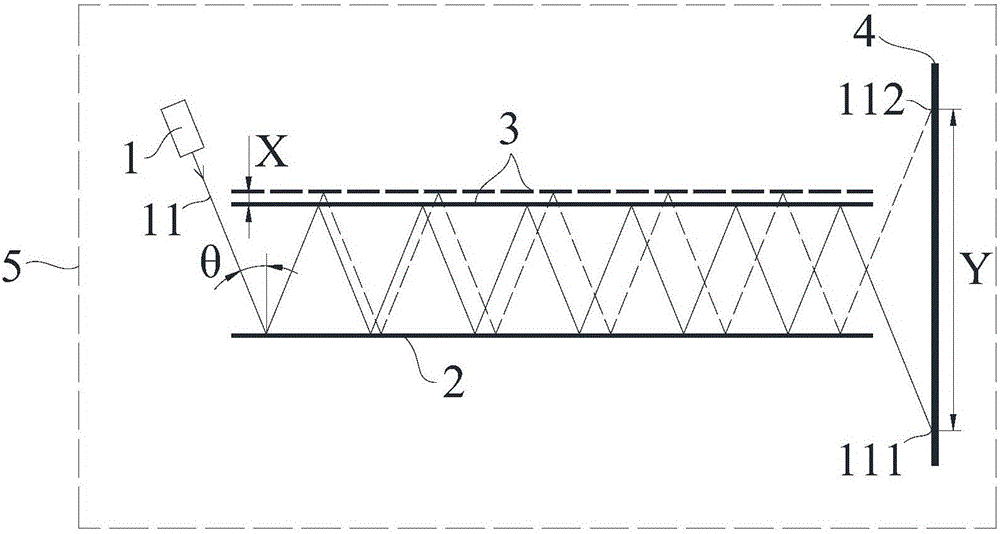

[0043] Such as Figure 1-4 As shown, a novel small-range ultra-high-precision displacement sensor described in the present invention includes a laser beam 11, two mirrors, a photodetector 4 and a processing system.

[0044] The two reflecting mirrors are arranged in parallel and can move relative to each other. The laser beam 11 is arranged at both ends of the two reflecting mirrors opposite to the photodetector 4, and the laser beam 11 is incident on one of the reflecting mirrors. After being alternately reflected by the two reflectors, it is emitted onto the photodetector 4 and sensed, and the processing system is used to process the position where the photodetector 4 receives the laser beam 11 .

[0045] Using a new type of small-scale ultra-high-precision displacement sensor described in the present invention, the laser beam 11 is continuously reflected in a set of two mirrors arranged in parallel, and finally irradiates a position on the photodetector 4 , changing the di...

Embodiment 2

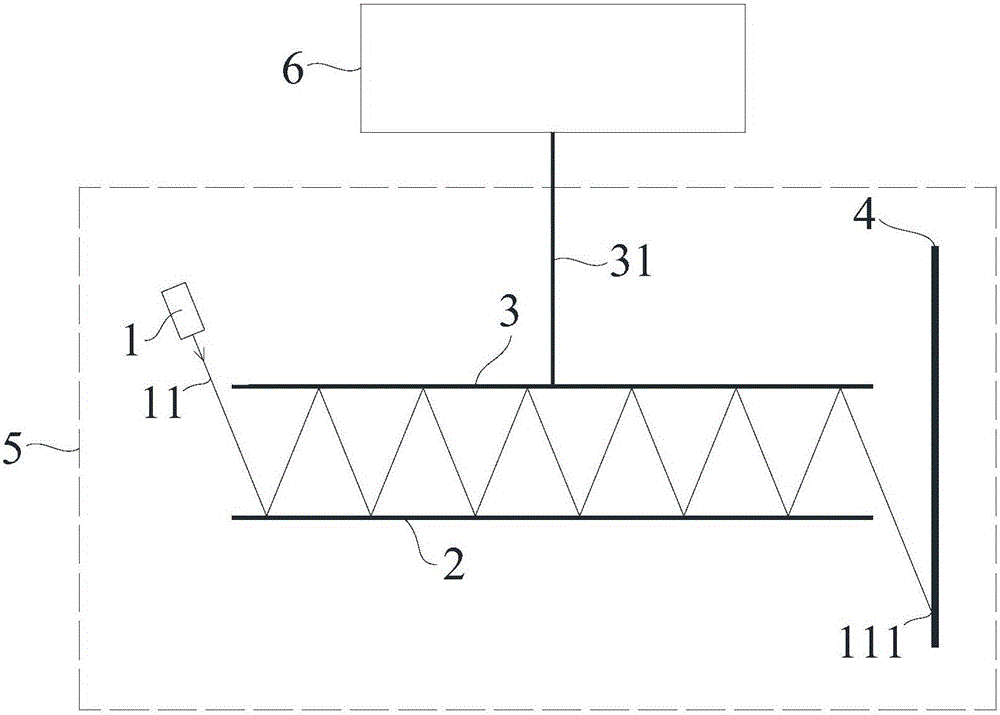

[0047] Such as Figure 1-4 As shown, a new type of small-scale ultra-high-precision displacement sensor and the measured object 6 described in the present invention, the sensor includes a laser beam 11, a fixed mirror 2, a moving mirror 3, a photodetector 4 and a processing system.

[0048] The measured object 6 is connected to the moving mirror 3 through a rigid member, the fixed mirror 2 is arranged in parallel with the moving mirror 3, and the moving mirror 3 can move relative to the fixed mirror 2, so The laser beam 11 and the photodetector 4 are arranged at both ends of the fixed reflector 2 and the movable reflector 3, the laser beam 11 is incident on the fixed reflector 2 or the movable reflector 3, and passes through the moving reflector 2 and the movable reflector 3. After the reflector 3 and the fixed reflector 2 are alternately reflected, the output is sensed on the photodetector 4, and the processing system is used to process the position where the photodetector 4 ...

Embodiment 3

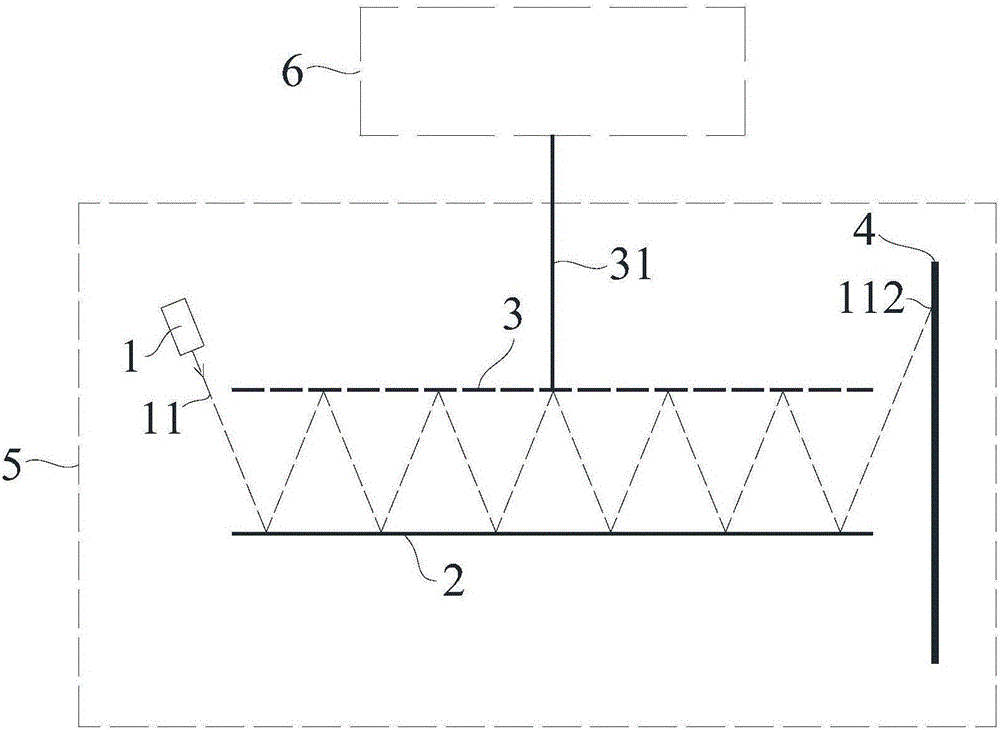

[0052] Such as Figure 1-4 As shown, a novel small-range ultra-high-precision displacement sensor and a measured object 6 according to the present invention, the sensor includes a laser source 1, a laser beam 11, a fixed mirror 2, a moving mirror 3, and a photodetector 4 and processing system, also including housing.

[0053] The laser beam 11 is emitted by the laser source 1, and the laser source 1, the fixed mirror 2, the movable mirror 3 and the photodetector 4 are all located in the housing to form a reading head 5, and the reading head 5 is set There are installation holes or stickers, the measured object 6 is connected to the moving mirror 3 in the reading head 5 through a rigid piece, the fixed mirror 2 is arranged in parallel with the moving mirror 3, and the moving reflector The mirror 3 can move relative to the fixed reflector 2, and the laser beam 11 is arranged at both ends of the fixed reflector 2 and the movable reflector 3 opposite to the photodetector 4, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com