Novel symmetric small measurement range displacement sensor and measuring method

A technology of a displacement sensor and a measurement method, which is applied in the direction of measuring devices, instruments, and optical devices, and can solve the problems of unsatisfactory measurement accuracy and difficult improvement of measurement accuracy, and achieve reliable measurement, simple structure, and high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

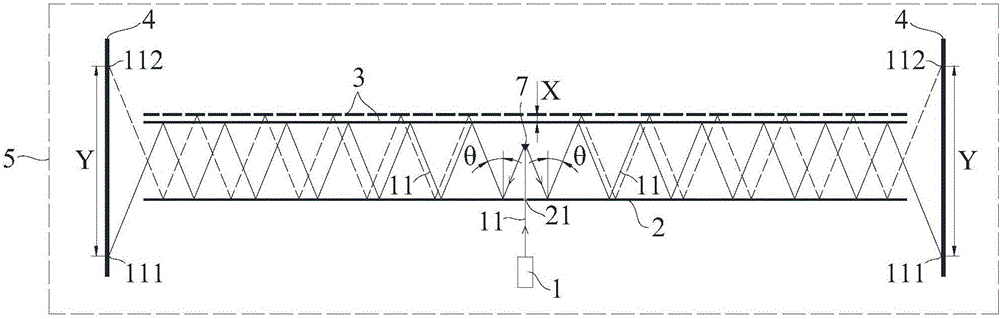

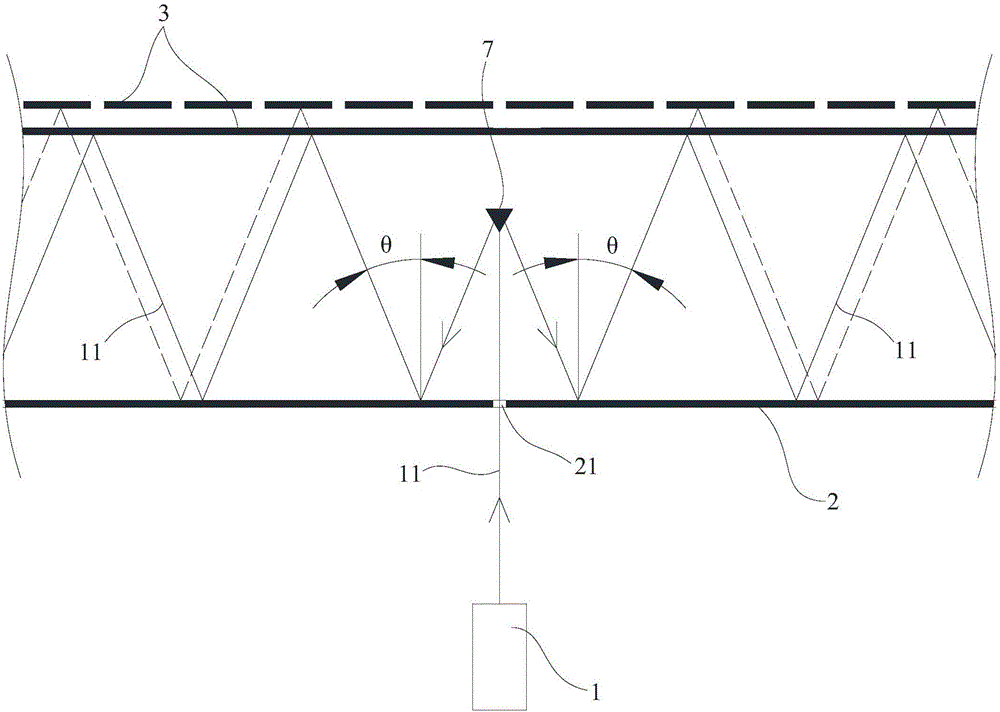

[0042] Such as Figure 1-5 As shown, a new symmetrical small-range displacement sensor described in the present invention includes fixed reflectors 2 and movable reflectors 3 arranged in parallel with adjustable spacing and a processing system.

[0043] Two photodetectors 4 are symmetrically arranged at both ends of the fixed reflector 2 and the movable reflector 3, and a double reflector 7 is arranged between the fixed reflector 2 and the movable reflector 3, and a double reflector 7 is arranged on the fixed reflector 2. There is a through hole 21, a laser beam 11 passing through the through hole 21 is incident on the double reflector 7, and is separated into two laser beams 11 after being reflected by the double reflector 7. The laser beam 11 is incident on the fixed reflector 2, after being alternately reflected by the fixed reflector 2 and the movable reflector 3, it is respectively emitted to the photodetector 4 on the corresponding side to be sensed, and the processing s...

Embodiment 2

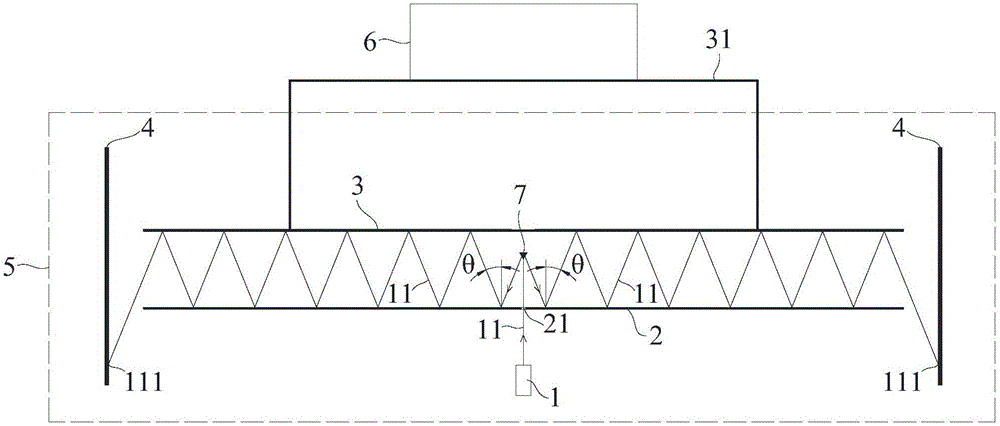

[0047] Such as Figure 1-5 As shown, a new type of symmetrical small-range displacement sensor and a measured object 6 according to the present invention, the sensor includes a fixed reflector 2 and a movable reflector 3 arranged in parallel with an adjustable distance, a processing system and a housing.

[0048] The displacement sensor described in this embodiment also includes a laser source 1 for emitting the laser beam 11, two photodetectors 4 are arranged symmetrically at both ends of the fixed reflector 2 and the movable reflector 3, and the fixed reflector 2 A double reflector 7 is arranged between the movable reflector 3, the laser source 1 is located on one side of the fixed reflector 2, and the fixed reflector 2 is provided with a through hole 21, and the laser light source 1 passing through the through hole 21 A laser beam 11 is incident on the double reflector 7, and the double reflector 7 adopts an existing structure, that is, two reflectors (primary mirror and se...

Embodiment 3

[0052] Such as Figure 1-5 As shown, a new symmetrical small-range displacement sensor described in the present invention includes fixed reflectors 2 and movable reflectors 3 arranged in parallel with adjustable spacing and a processing system.

[0053] The difference from Embodiment 1 is that a through hole 21 is provided at the center of the fixed reflector 2, namely:

[0054] Two photodetectors 4 are symmetrically arranged at both ends of the fixed reflector 2 and the movable reflector 3, and a double reflector 7 is arranged between the fixed reflector 2 and the movable reflector 3, and the fixed reflector 2 and the movable reflector 3 Reflector 3 is parallel and symmetrically designed, and the central position of the fixed reflector 2 is provided with a through hole 21. A laser beam 11 passing through the through hole 21 is incident on the double reflector 7, and is reflected by the double reflector. The mirror 7 is separated into two beams of laser beams 11 after being r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com