Machining device for manufacturing absolute type steel belt grating ruler

A technology of processing devices and grating rulers, which is applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of inability to manufacture absolute grating rulers, and achieve the effect of improving the accuracy of displacement measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

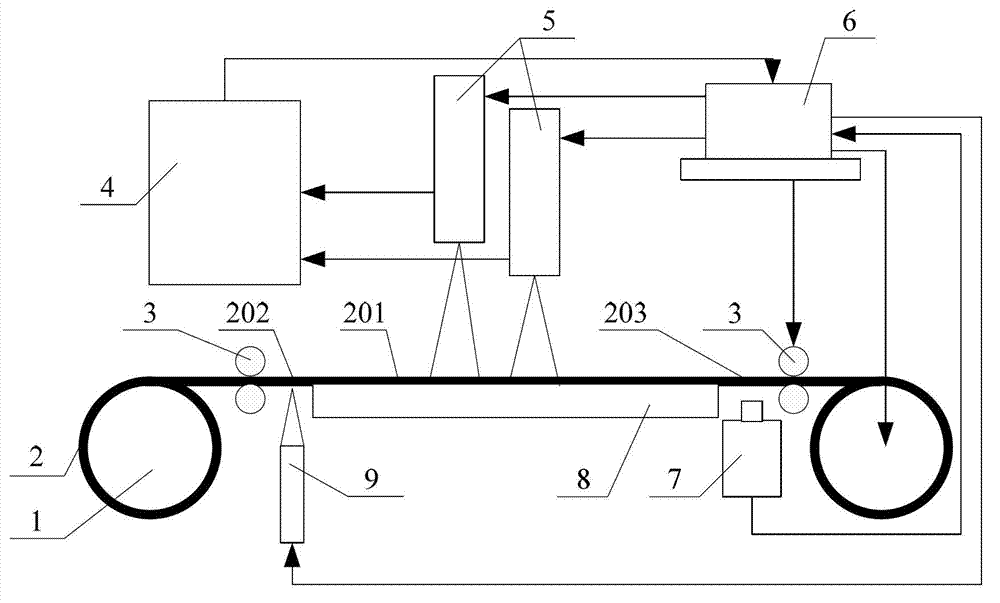

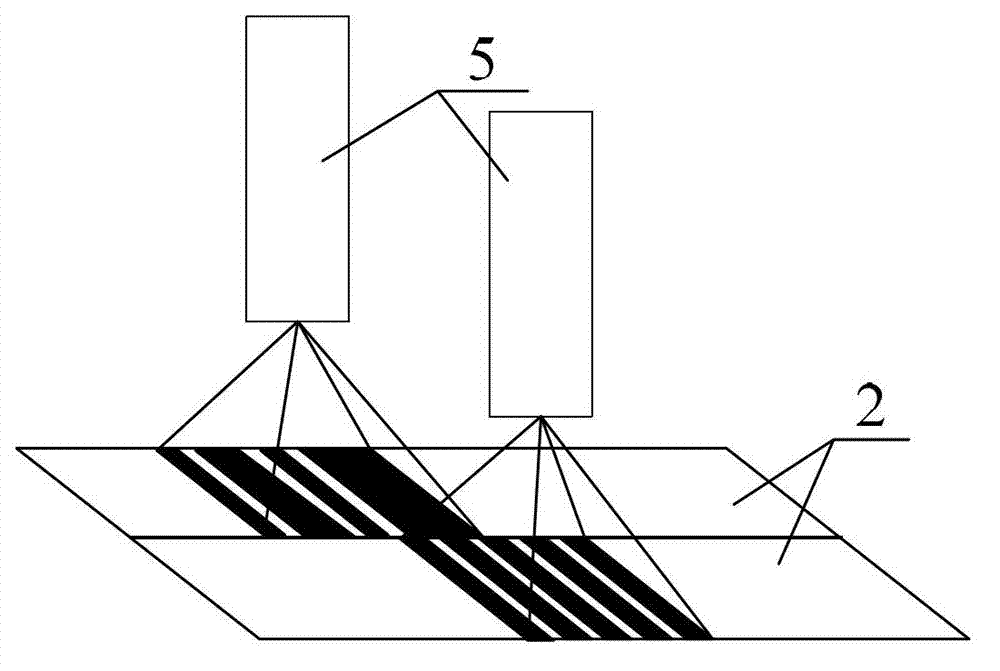

[0021] See attached figure 1 , attached figure 2 And attached image 3 As shown, a processing device for manufacturing an absolute steel tape scale of the present invention includes a drive wheel 1, a belt tensioner 3, a laser interferometer 4, a projection exposure head 5, a computer 6, an ultra-smooth shockproof platform 8, and a CCD Detector 7 and laser marking device 9; the steel belt 2 is conveyed between the two transmission wheels 1, and a group of belt tensioners 3 are respectively placed at both ends of the exposure zone 201 of the steel belt 2, and the The two projection exposure heads 5 move above the exposure area 201 of the steel strip 2 to expose the entire exposure area 201, and measure their tiny displacements through the laser interferometer 4, and the laser interferometer 4 feeds back the information to the computer 6. The upper surface of the ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com