Swinging type self-centering steel frame and concrete shear wall anti-seismic system

A technology of concrete shear wall and concrete wall, applied in the direction of wall, shockproof, building components, etc., to achieve the effect of less damage, quality assurance, and accelerated construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

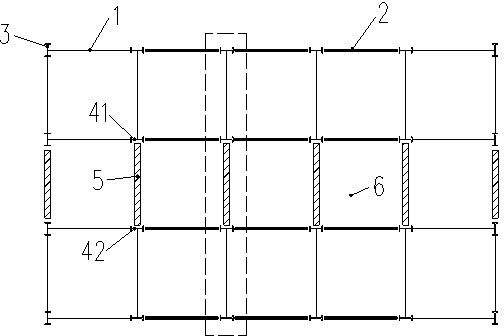

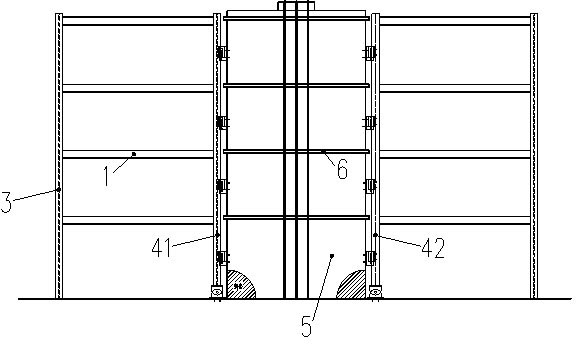

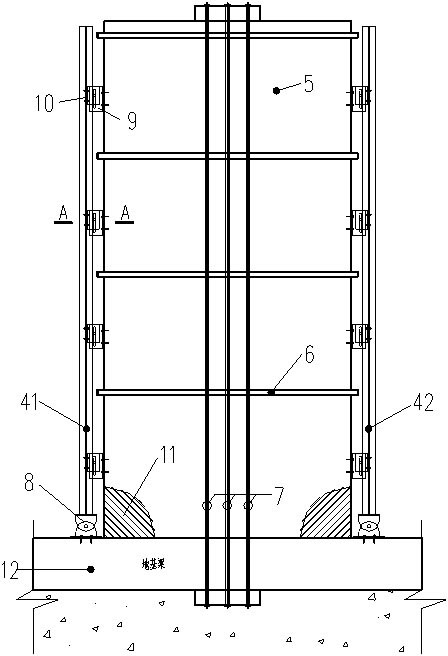

[0034] The present invention will be described below with reference to the accompanying drawings.

[0035] The present invention provides a frame that arranges one span or several spans in a steel frame in a swinging geometrically variable form (the following discussion is all about this span frame)——the steel column foot of this span is connected to the Base hinge. A concrete wall is used to provide lateral rigidity for the span frame, and the concrete wall and the steel column are connected by a friction member. The joint of the friction member has the ability to displace the steel column and the concrete wall in the same horizontal direction and move relative to each other in the vertical direction. properties, and energy can be dissipated due to friction when a vertical relative displacement occurs. The bottom of the concrete wall here is separated from the foundation, and is tied to the foundation through several bundles of vertical prestressed tendons passing through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com