Vibration monitoring and failure diagnosis system of gas turbine

A fault diagnosis system and vibration monitoring technology, applied in vibration testing, testing of machine/structural components, measuring devices, etc., can solve the problems of not drawing the rotor axis, not introducing time-frequency analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

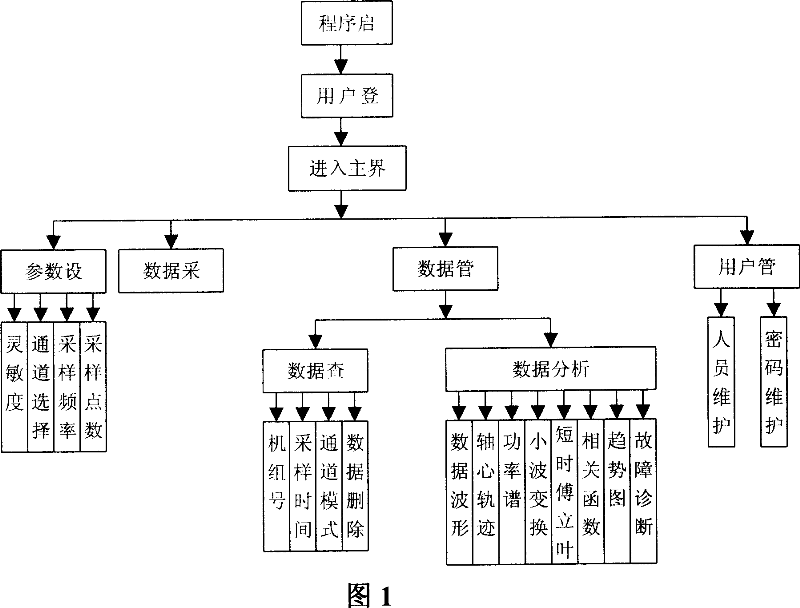

[0025] As shown in Figure 1, the description of each step in the program flow is as follows:

[0026] 1. Program start: A program start interface pops up here.

[0027] 2. User login: Here the user is prompted to enter the user name and password, and the main interface can only be entered after the program confirms.

[0028] 3. Enter the main interface: here the user can select the corresponding menu to operate according to the needs.

[0029] 4. Parameter settings: respectively described as follows,

[0030] 4.1 Sensitivity: The user enters the sensitivity of the sampled data and its unit here.

[0031] 4.2 Channel selection: The user enters the required number of data acquisition channels here.

[0032] 4.3 Sampling frequency: The user enters the frequency of collecting data here.

[0033] 4.4 Number of sampling points: The user enters the number of sampling points of sampling data here.

[0034] 5. Data collection: The program collects data according to the sampling pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com