Railway vehicle bogie static load comprehensive detection system

A comprehensive detection and rail vehicle technology, applied in the field of rail vehicle manufacturing safety, can solve problems such as the inability to apply subway bogies, the inability to calibrate multiple performances of bogies, and the inability to realize real-time data display and data monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

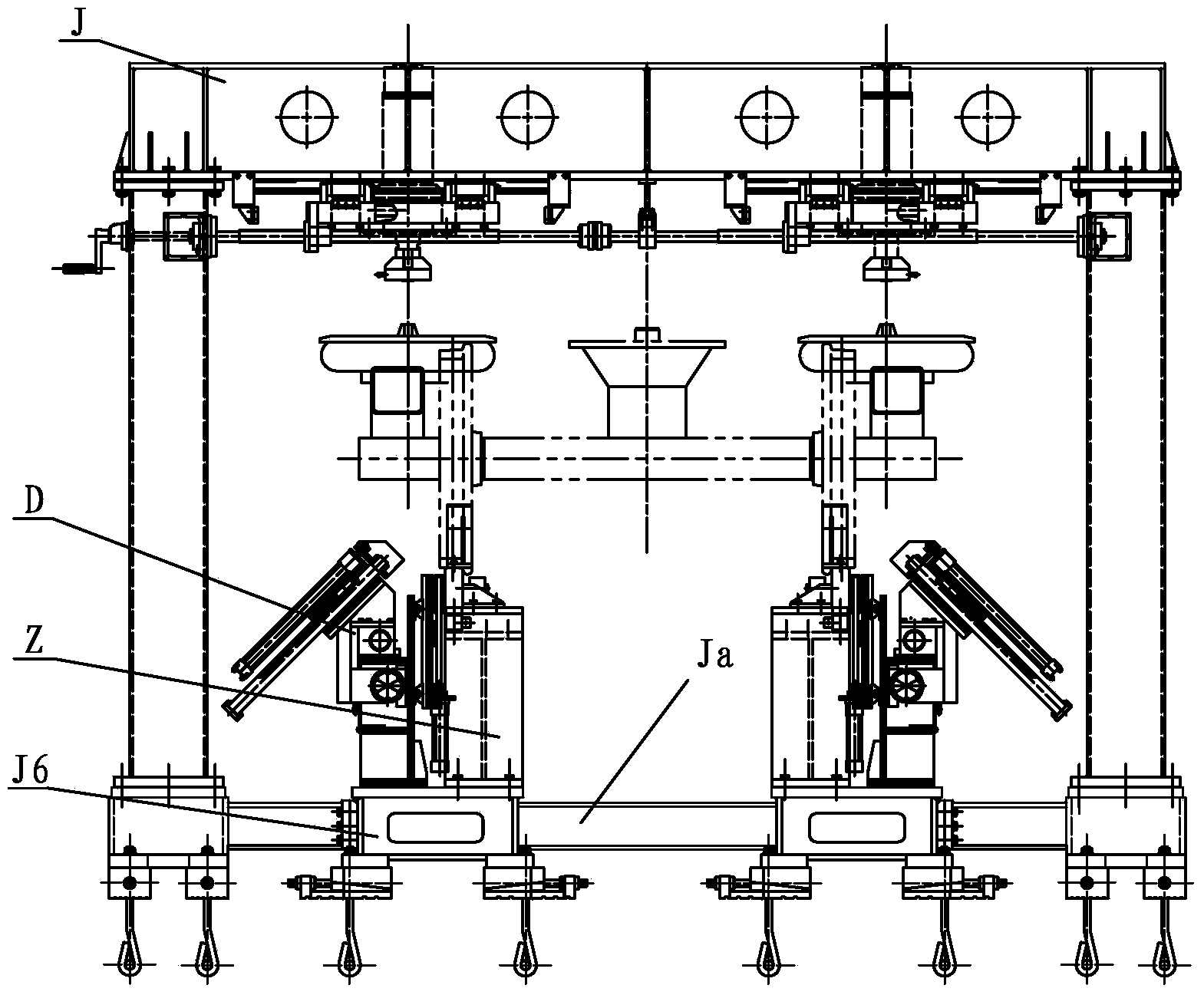

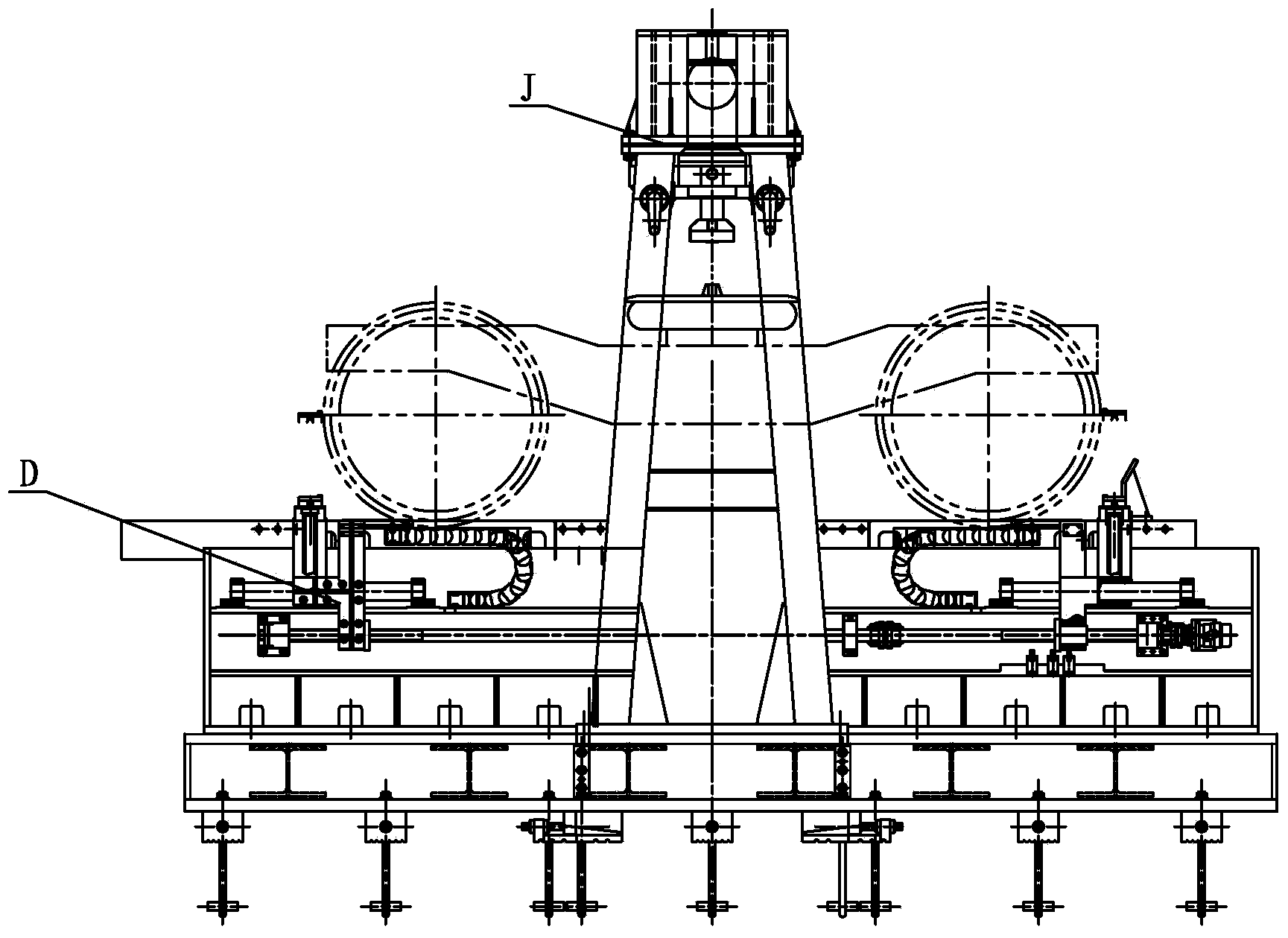

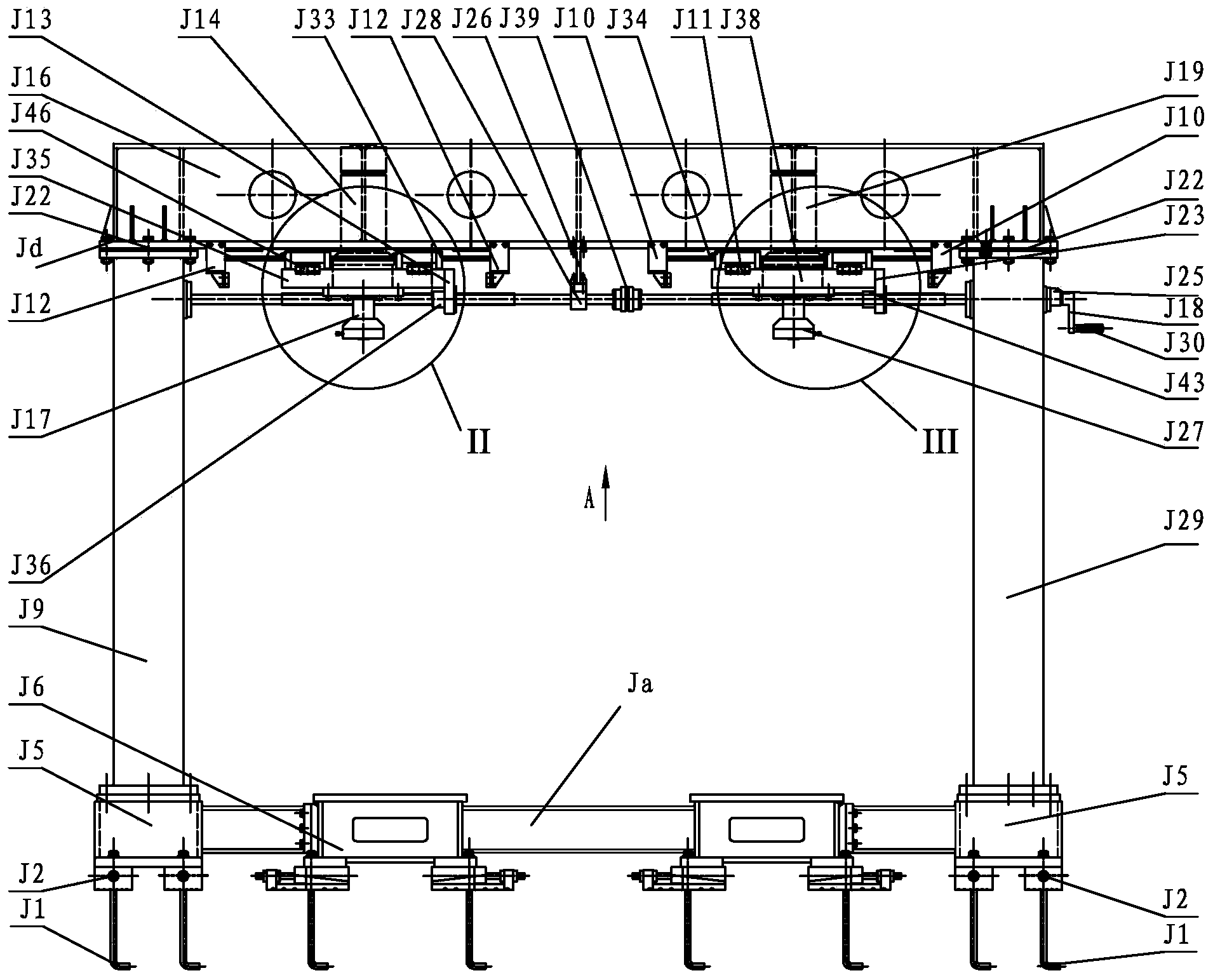

[0091] Specific implementation mode one: see Figure 1 to Figure 24 , the rail vehicle bogie static load comprehensive detection system includes a loading device J, a weighing device Z and a centering device D, and the weighing device Z and the centering device D are installed on the main bed J6 of the basic platform Ja of the loading device , the weighing device Z is placed inside the centering device D;

[0092] The loading device includes a basic platform Ja, a left transmission mechanism Jb, a right transmission mechanism Jc, and a gantry Jd; the basic platform Ja includes a main bed J6 and two auxiliary bed J5, and the main bed J6 is connected by anchor bolts J1 Fixed on the foundation, the two auxiliary beds J5 are symmetrically connected to the left and right sides of the main bed J6; the gantry Jd includes a left column J9, a right column J29 and a beam J16, and the left column J9 and the right column J29 is arranged side by side on the left and right sides, and the l...

specific Embodiment approach 2

[0126] Specific implementation mode two: see Figure 25 to Figure 26 , the rail vehicle bogie static load comprehensive detection system also includes a hydraulic system, and the hydraulic system includes a pumping station Y1, two loading system hydraulic controllers Y2, a lifting system hydraulic controller Y3, a tilting system hydraulic controller Y4 and The hydraulic controller Y5 of the centering system and the pumping station Y1 provide power sources for the two hydraulic controllers Y2 of the loading system, Y3 of the lifting system, Y4 of the inclined system and Y5 of the centering system. The system hydraulic controller Y2 is used to control the left hydraulic cylinder J14 and right hydraulic cylinder J19 of the loading device J, the lifting system hydraulic controller Y3 is used to control the lifting cylinder D22 of the wheelbase measuring component of the centering device, and the hydraulic controller of the tilting system Y4 is used to control the tilt-out cylinder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com