Floating centring-type installation device for shaft parts

A technology for installing devices and shaft parts, which is applied in the field of installation of shaft parts in machinery manufacturing and assembly, can solve problems such as limited centering and guiding effects, aggravated press wear, and press-fit impact force, etc., to extend the service life of equipment , Avoid impact and wear, and smooth stuck effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

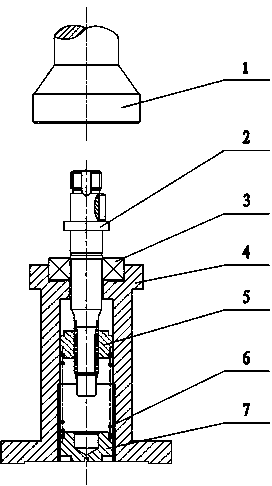

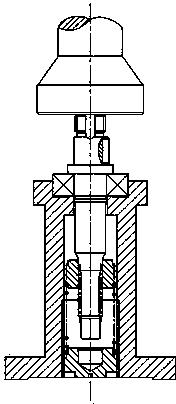

[0010] The structure of the floating centering installation device for shaft parts of the present invention is as follows: figure 1 and figure 2 As shown, the adjusting screw plug 7 is installed on the lower part of the positioning seat 4, the spring 6 is installed on the upper part of the adjusting screw plug 7 inside the positioning seat 4, the floating sliding sleeve 5 is installed on the upper part of the spring 6, and the outer circle of the floating guide sleeve 5 is centered with the inner cavity of the positioning seat 4 Sliding fit installation, the bearing 3 is coaxially installed in the upper positioning hole of the positioning seat 4, the shaft 2 is installed in the inner hole of the bearing 3, the spline part of the lower part of the shaft 2 coincides with the inner hole of the floating guide sleeve 5, and the shaft 2 and the positioning seat 4 coaxial.

[0011] When in use, first put the floating guide sleeve 5 into the positioning seat 4 and then put it into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com