Robotic tyre changing apparatus and associated hardware and methods

a technology of robots and tyres, applied in the field of robot tyre changing apparatuses, can solve the problems of exposing workers to crushing or explosion risk, tyres falling or exploding, and posing a substantial risk of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

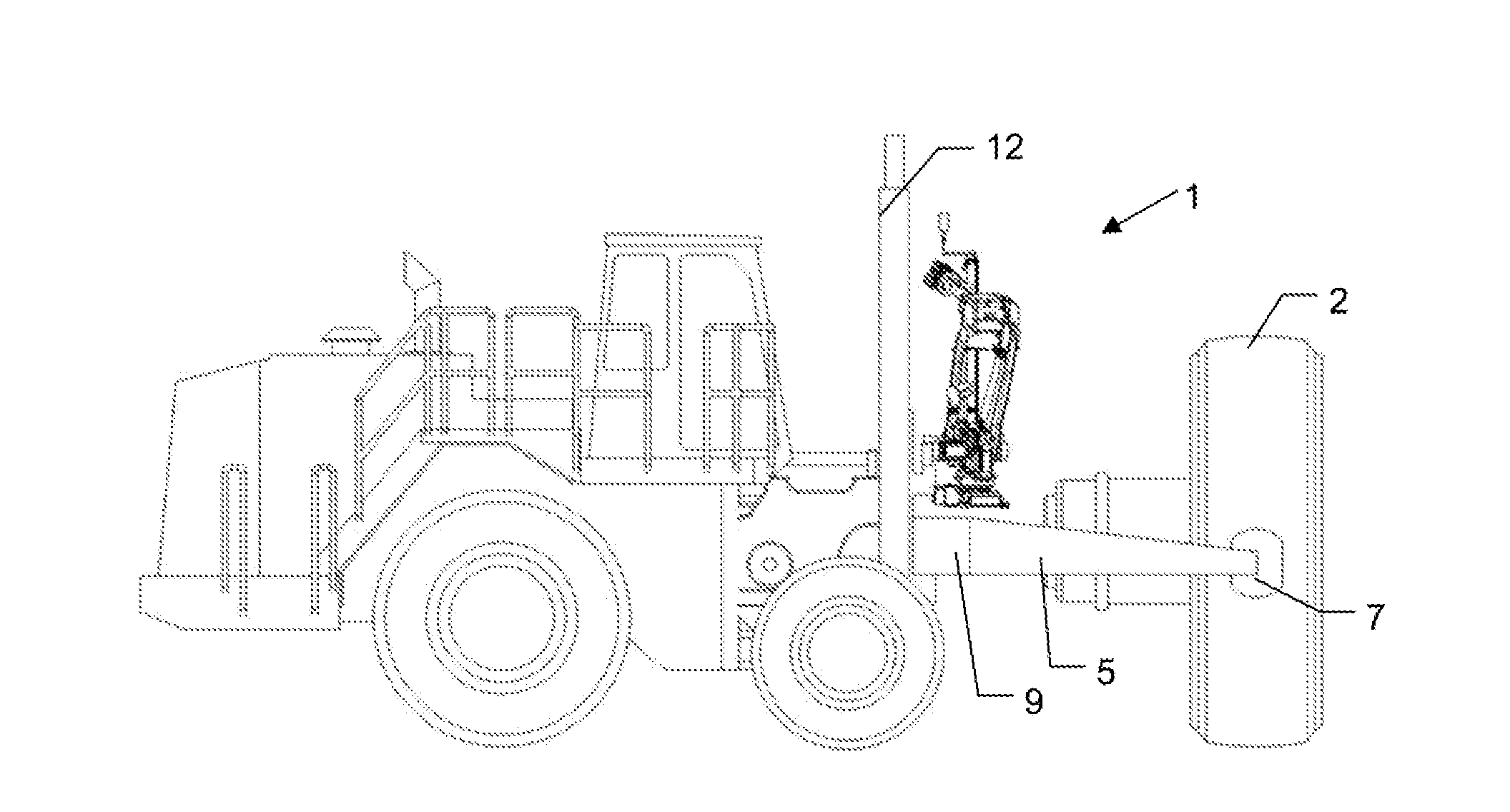

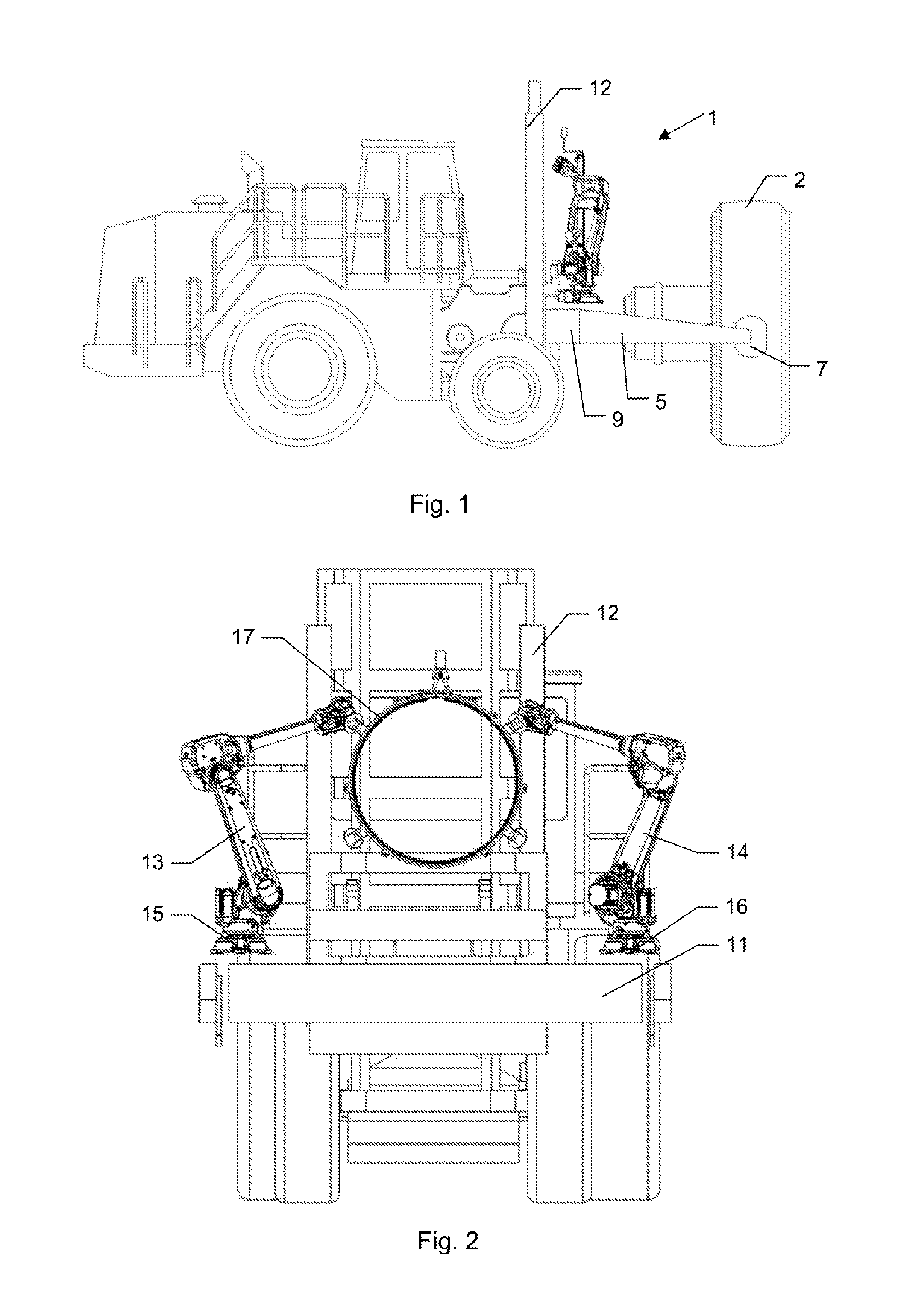

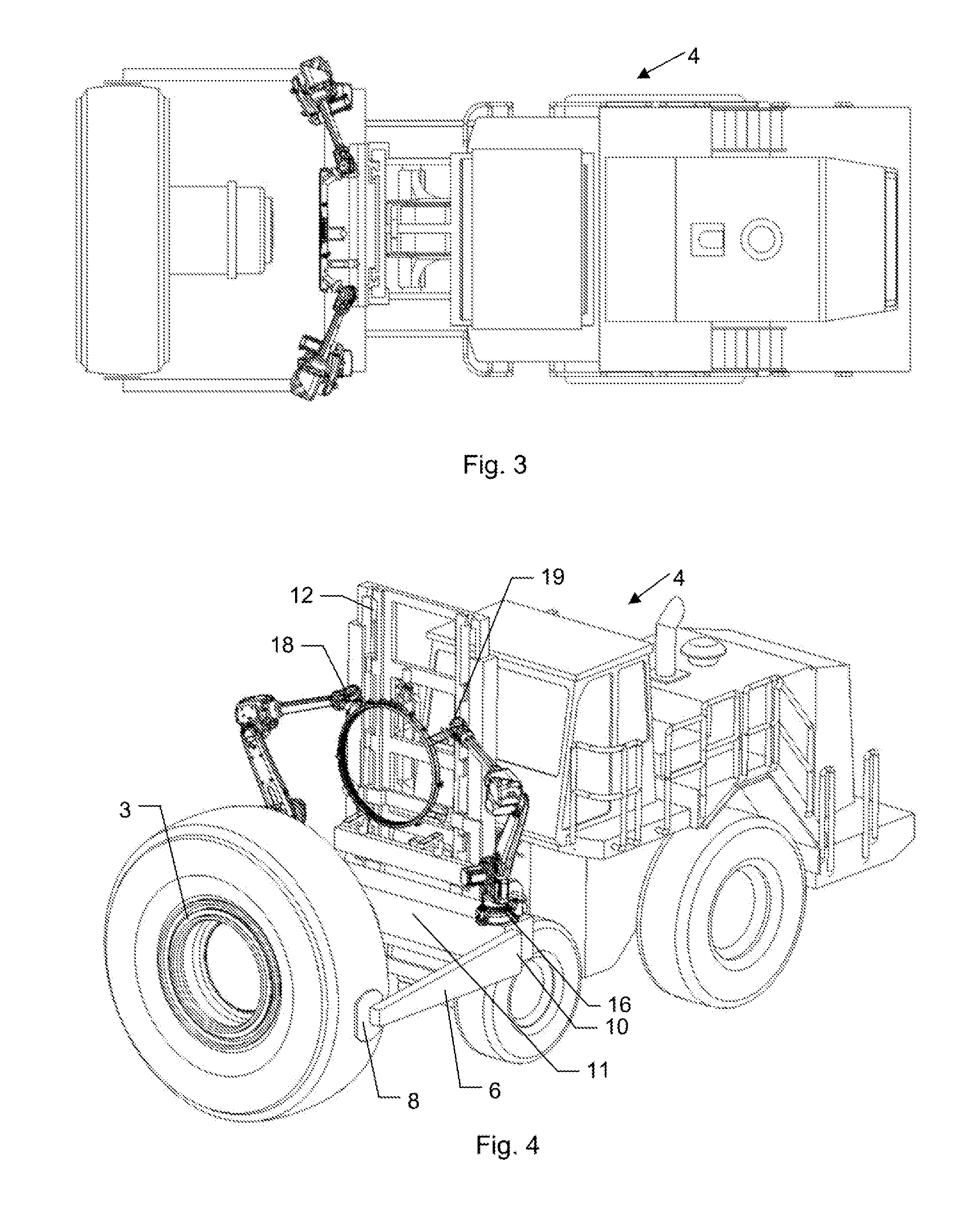

[0057]The embodiment of the tyre changing apparatus 1 as depicted for example in FIGS. 1 to 4 is for use with a tyre 2 disposed on a wheel 3 of the type commonly used for large haul trucks and in particular those typically employed in mining operations. The apparatus 1 includes a tyre handler 4, which may be any one of the various commercially available tyre handlers on the market, such as those marketed for example by: Iowa Mold Tooling Co. Inc, which is based in Garner, Iowa, USA; or Austin Engineering Ltd, which is based in Brisbane, Queensland, Australia; or Cascade Europe, which is based in El Amere, Netherlands. Such tyre handlers 4 are typically fork lift-type trucks that support two outwardly extending generally parallel arms 5 and 6, which respectively define distal ends 7 and 8. The operator of the tyre handler can manipulate the controls to cause the distal ends 7 and 8 of the arms 5 and 6 to clamp onto the tyre 2, which allows for manipulation of the large and heavy tyre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com