Method for spraying upper surface and outer side face of workpiece

A technology for the outer side and the workpiece, applied in the direction of the spray device, etc., can solve the problems of poor spraying effect, etc., to achieve the effect of uniform and consistent paint surface cloth, improve the spraying efficiency, and keep the coating amount consistent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

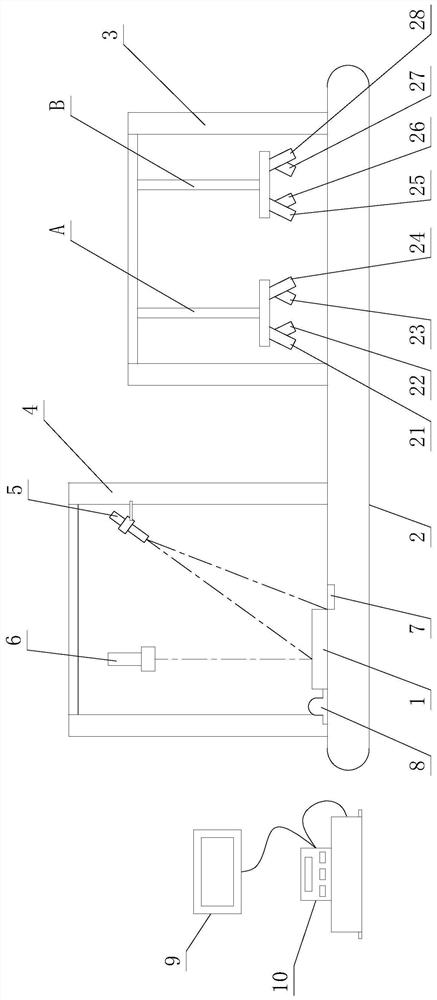

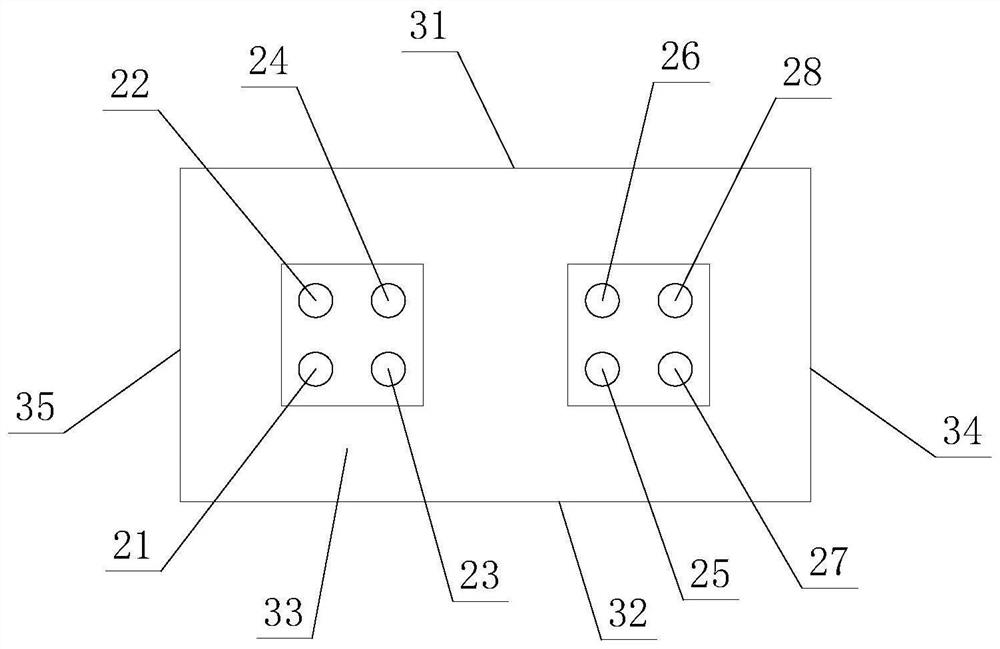

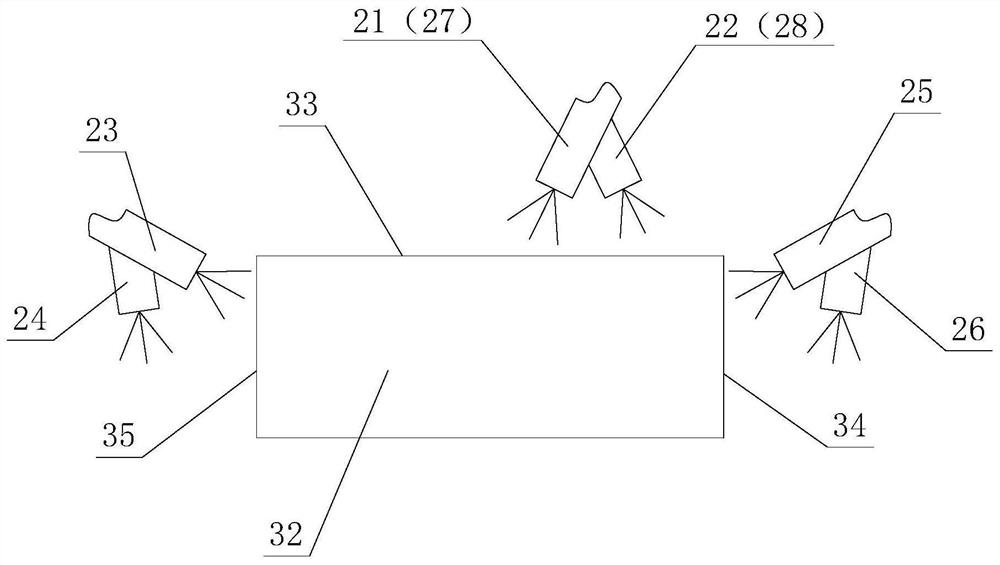

[0049] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0050] see Figure 1-Figure 4 , the method for spraying the upper surface and the outer side of the workpiece, comprising a workpiece 1, a conveying line 2 for conveying the workpiece 1, and a three-dimensional scanning system for scanning the length, width and height of the workpiece 1 during conveyance, and for all A control system for processing the scanning information of the above-mentioned three-dimensional scanning system, and a first spraying support A and a second spraying support B for planning a spraying path through the control system.

[0051] The first spraying support A and the second spraying support B are respectively controlled by the control system to slide laterally and move up and down along the conveying direction of the workpiece 1 .

[0052] The first spraying bracket A and the second spraying bracket B are respectively provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com