Spraying system and plant protection unmanned aerial vehicle

A plant protection drone and spraying system technology, which is applied to aircraft parts, transportation and packaging, devices for catching or killing insects, etc., can solve problems such as the inability to guarantee the amount of spraying, calibration, and adverse effects of operations, and achieve accurate The effects of spraying operations, increasing spraying flow, improving spraying accuracy and spraying uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

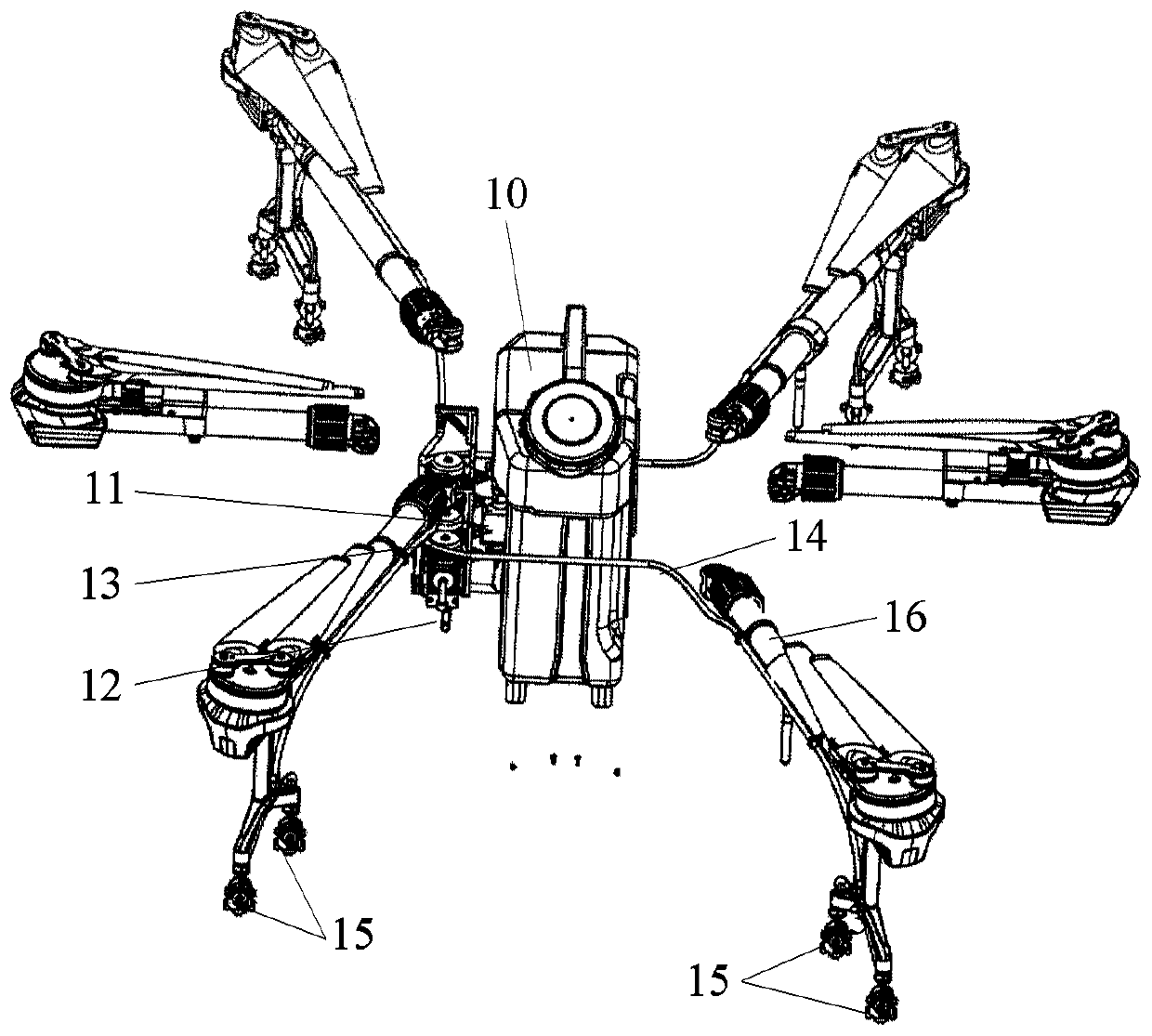

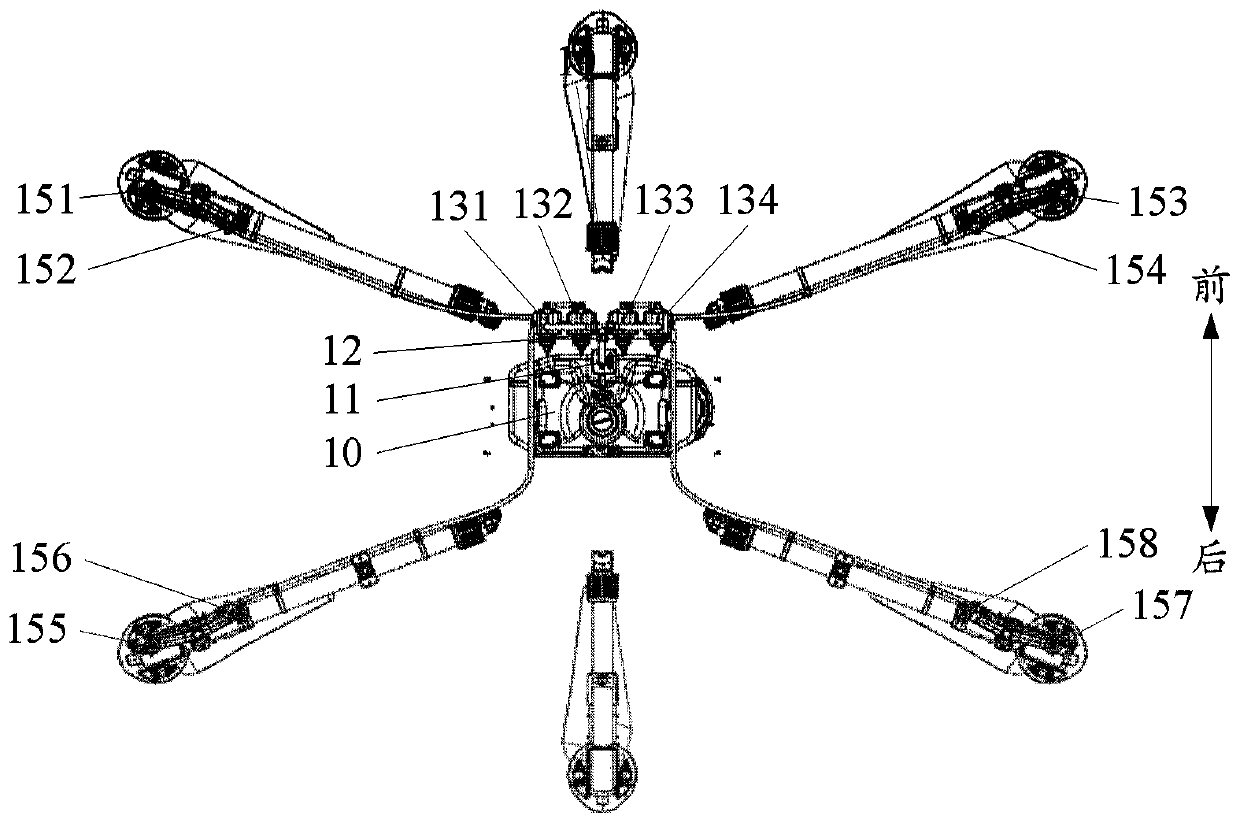

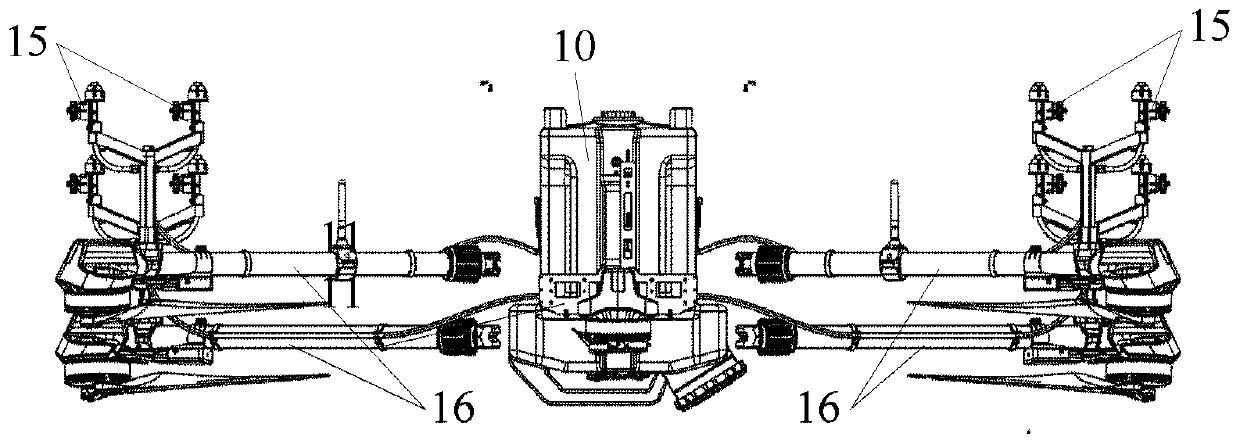

[0026] Such as Figure 1 to Figure 4 As shown, a flow meter 11 is provided between the liquid outlet of the liquid storage tank 10 and the water separator 12. The flow meter 11 detects the actual flow rate of the water pump 13 when the single water pump 13 is turned on, so that the flow rate and The actual flow is compared to calibrate the output flow of the water pump 13 .

[0027] Specifically, before the plant protection UAV performs the spraying operation, the flow meter 11 is used to calibrate the output flow of each water pump 13 of the spraying system, so as to ensure that the spraying flows of the nozzles on both sides of the spraying system are consistent. During the specific calibration operation, One of the water pumps 13 can be turned on separately first, and the actual flow through the water pump 13 is detected by the flow meter 11, and then the reference flow input by the user is compared with the actual flow actually detected by the flow meter 11, if the differe...

Embodiment 2

[0034] The water inlet pipe, water inlet, water outlet or water outlet pipe of each water pump 13 is provided with a flow meter 11, and the flow meter 11 detects the actual flow of the water pump 13 flowing through the corresponding water pump 13 when the water pump 13 is turned on. The output flow of the water pump 13 is calibrated by comparing the flow with the actual flow.

[0035]Specifically, before the plant protection drone performs the spraying operation, the flow meter 11 is used to calibrate the output flow of each water pump 13 of the spraying system to ensure that the spraying flow of the nozzles on both sides is consistent during the spraying operation. During the specific calibration operation, The flow meter 11 can be used to detect the actual flow of the corresponding water pump 13, and then compare the reference flow input by the user with the actual flow detected by the flow meter 11. If the difference between the two is within the preset range, then Indicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com