A synchronous control system and method for automatic coal feeding and emission reduction equipment in a coal-fired barn

A technology of synchronous control and control system, applied in the fields of tobacco preparation, application, tobacco, etc., can solve the problems of environmental hazards, large heat consumption, etc., and achieve the effects of saving electric energy, saving costs, and reducing contact efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

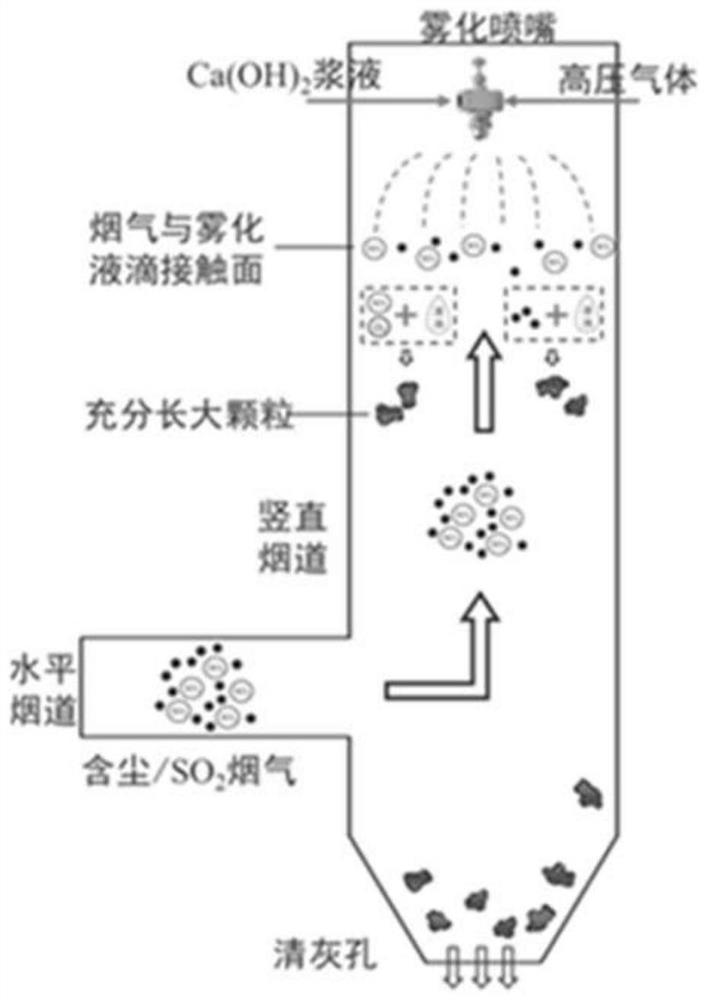

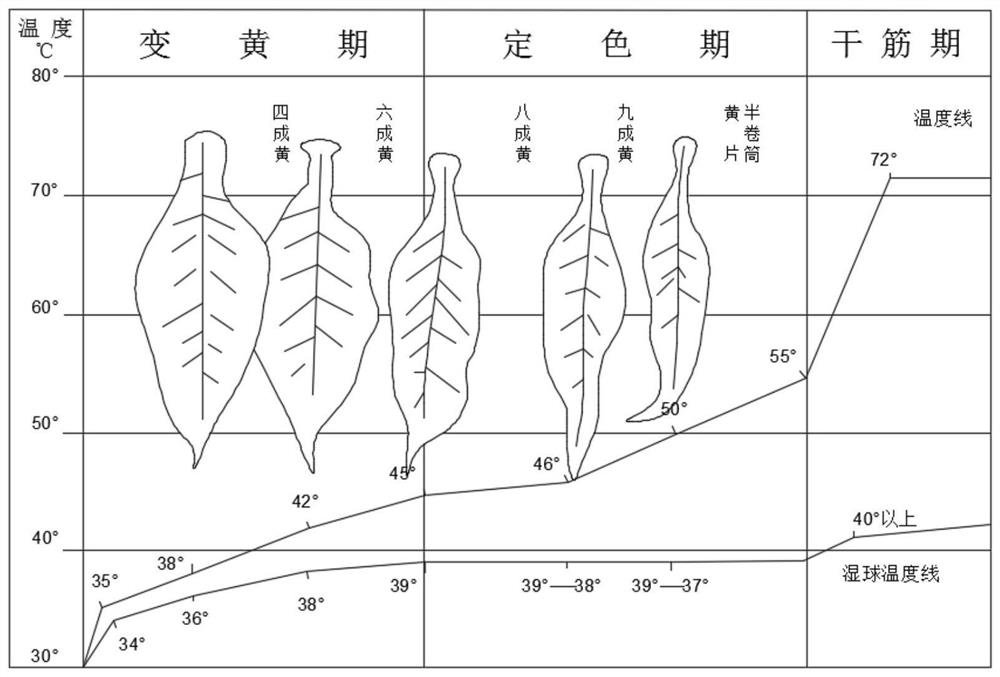

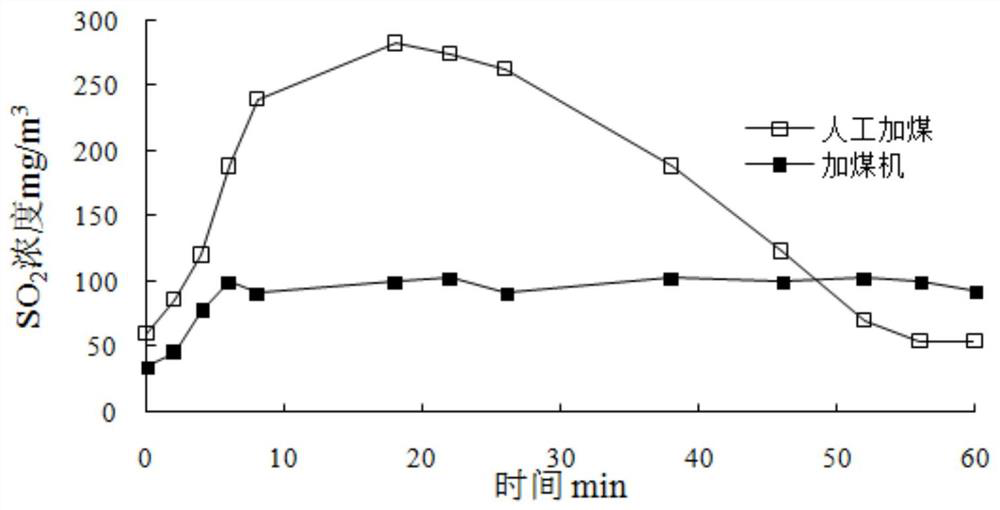

[0072] like Figure 1 to Figure 7 As shown, based on the existing baking process of a coal-fired barn, the present invention proposes a synchronous control system and method for automatic coal feeding and emission reduction equipment in a coal-fired barn, including an emission reduction control system, and the emission reduction control system includes The main controller, the desulfurization and dust removal equipment connected with the flue of the coal-fired barn, the automatic coal feeding device connected with the furnace of the coal-fired barn, and the combustion-supporting fan connected with the furnace; the desulfurization and dust removal equipment includes a device The atomizing nozzle with the nozzle facing down inside the flue, and the jetting device and the liquid supplying device respectively connected with the atomizing nozzle through pipes, the pipes between the jetting device and the atomizing nozzle are connected with a Gas valve, the pipeline between the liqu...

Embodiment 2

[0092] Based on the operation control method of the emission reduction control system in Embodiment 1, this embodiment proposes an adjustment control method of the emission reduction control system, including the following steps:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com