System and method for comprehensively controlling spraying industrial robot based on virtual reality technology

A virtual reality technology, industrial robot technology, applied in instruments, injection devices, special data processing applications, etc., can solve the problems of monotonous color reflective characteristics, single system interaction mode, high computer performance requirements, shorten the development cycle, and achieve economic benefits. High, improve the effect of spraying accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

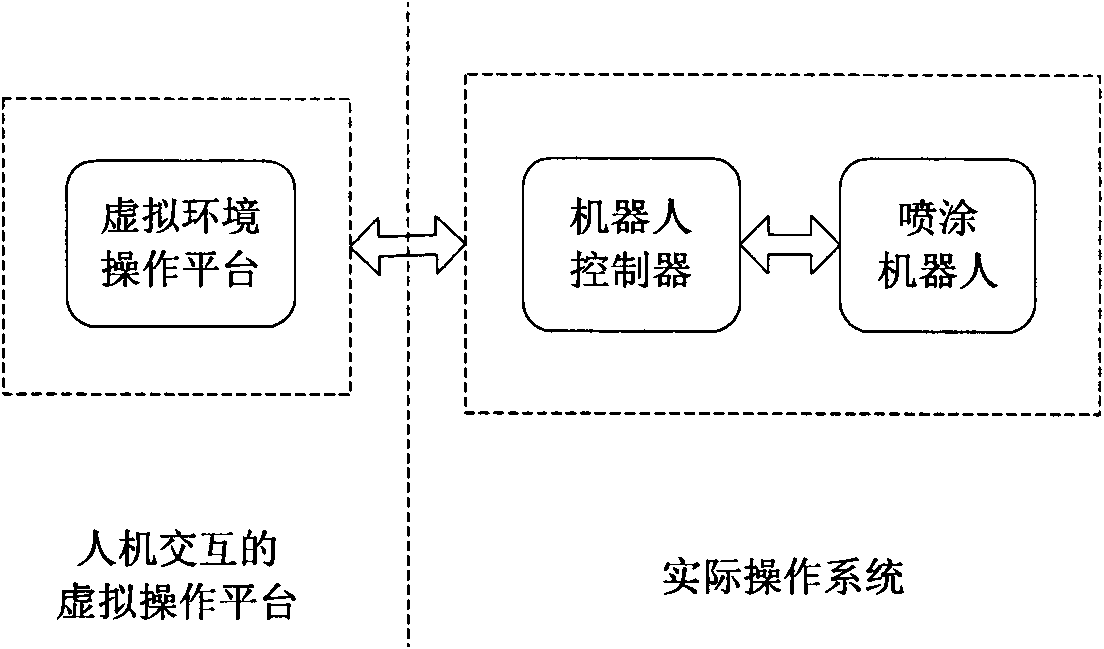

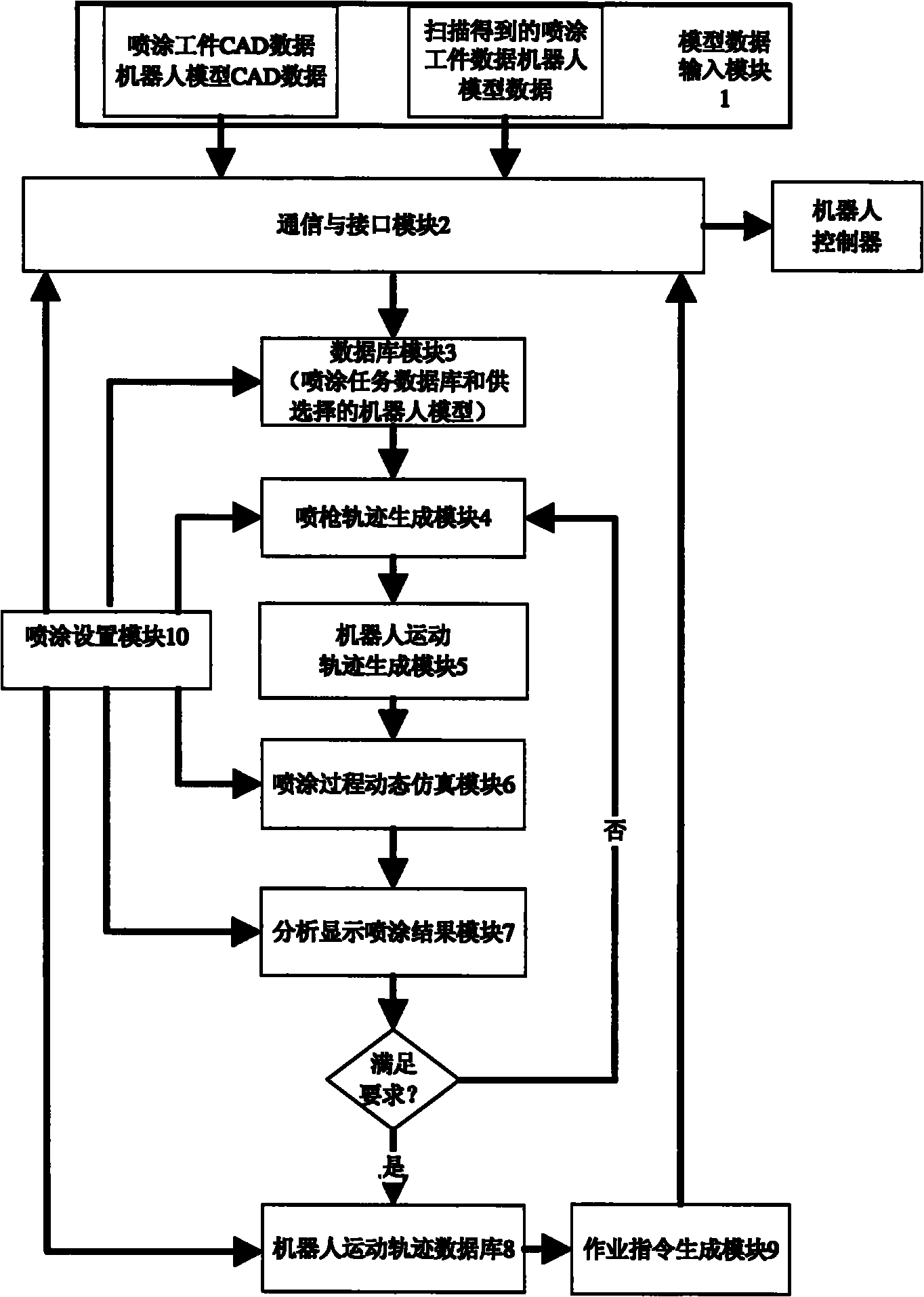

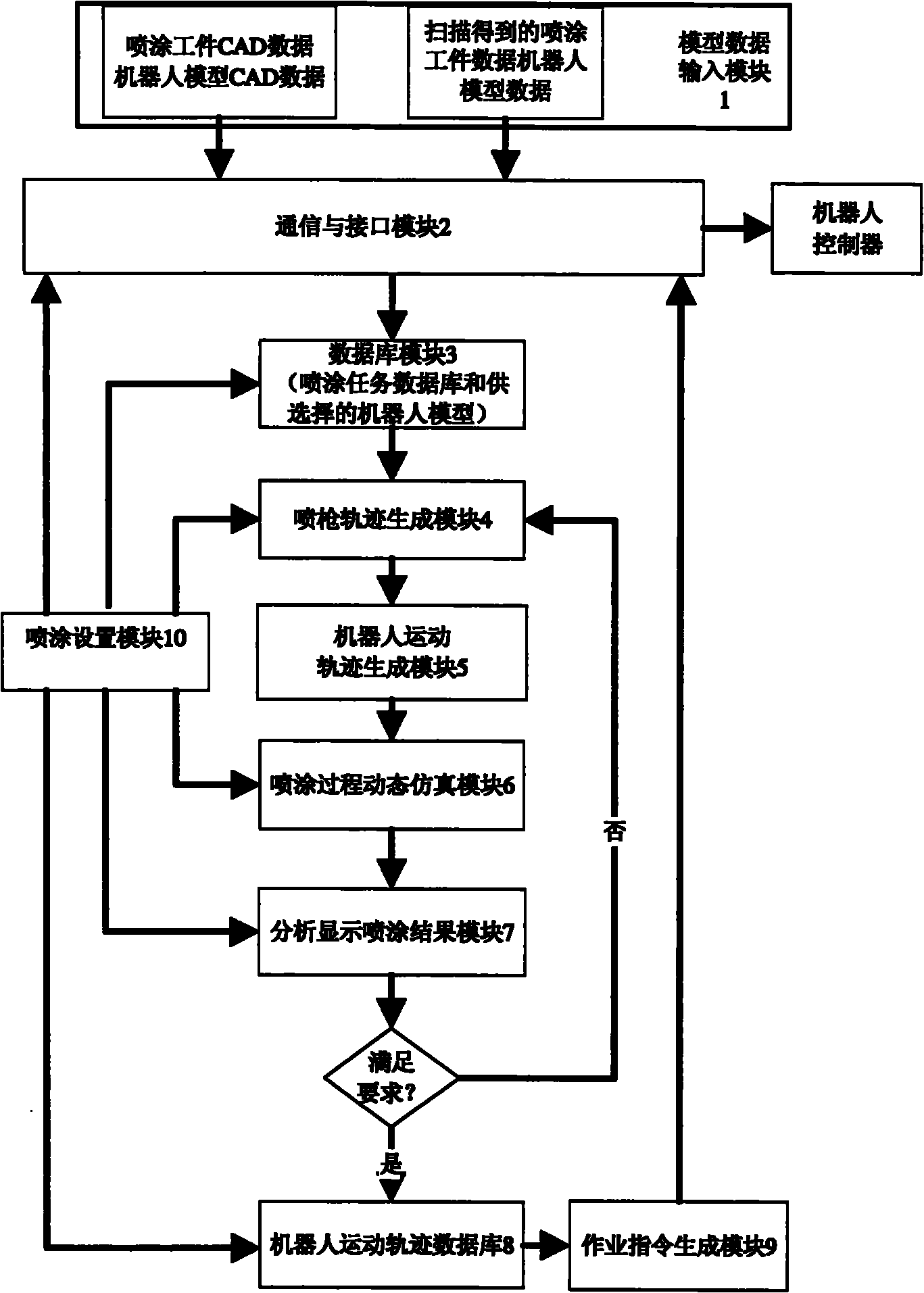

[0027] Such as figure 1 , figure 2 The present invention shown is an integrated control system for spraying industrial robots based on virtual reality technology, which is characterized in that it includes: a virtual environment operating platform, a robot controller and a spraying robot; the robot controller is connected with the spraying robot; the virtual environment The controller is connected with the robot controller;

[0028] Before giving a spraying task command, the user first sends this command to the virtual simulation system. Through the virtual simulation, the preview of the spraying process is completed. During the simulation process, the user can observe the spraying results of the virtual simulation system. If the spraying robot is running Stable and the spraying effect meets the requirements, the robot motion track data that meets this requirement will be stored and the corresponding robot file will be transmitted to the spraying robot controller of the actu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com