Automatic bundle splitting and lay-feeding device and control method thereof

A beam splitting and spreading technology, which is applied in mechanical equipment, sugarcane machining, etc., can solve the problems of not being able to adapt to the mechanization requirements of straw weaving and affecting the treatment and reuse of rice straw

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

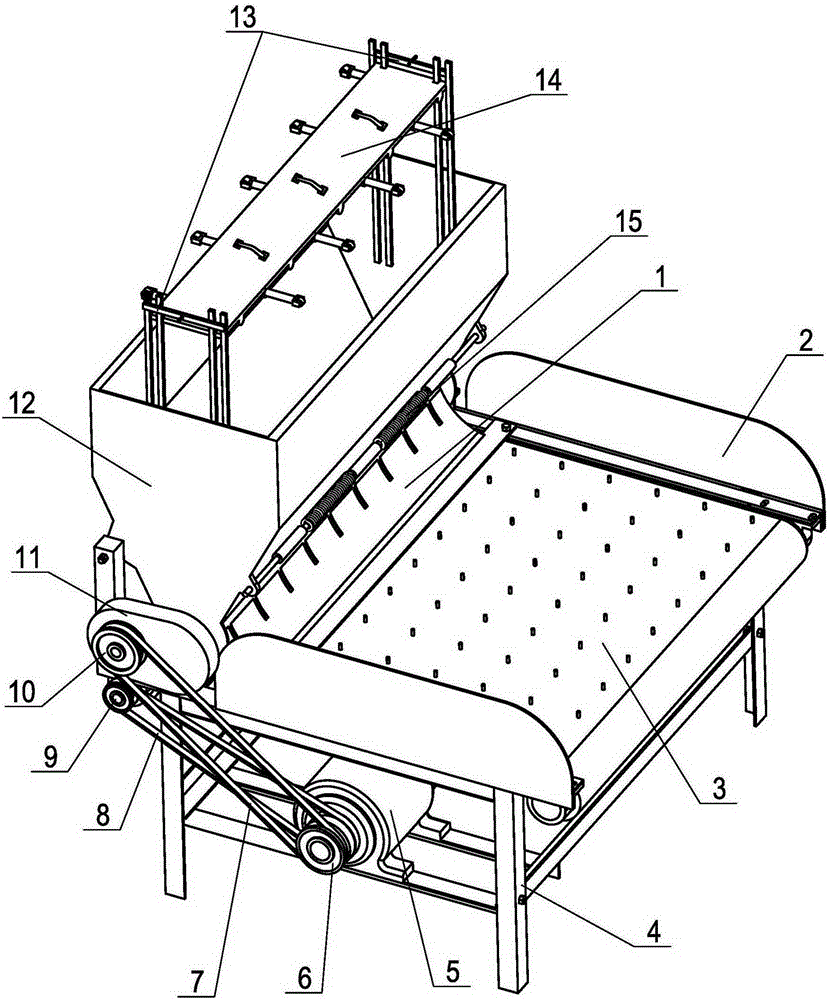

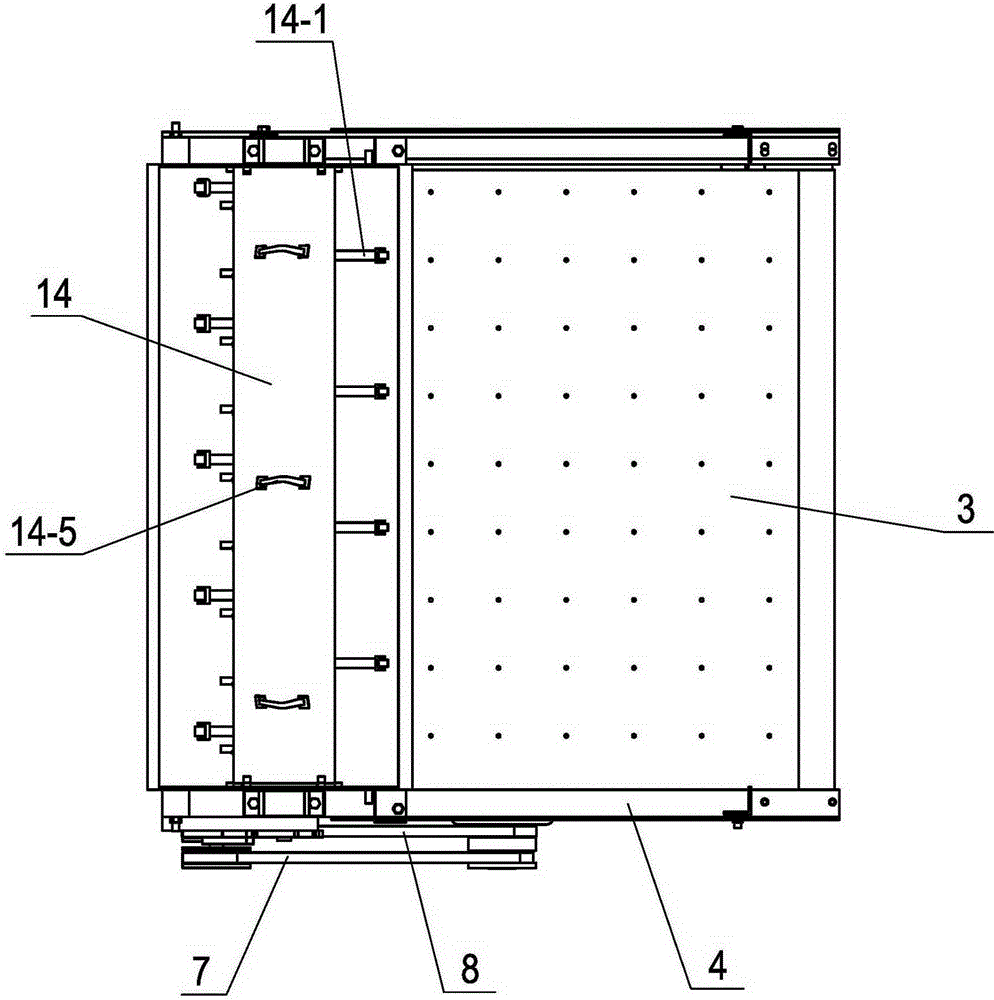

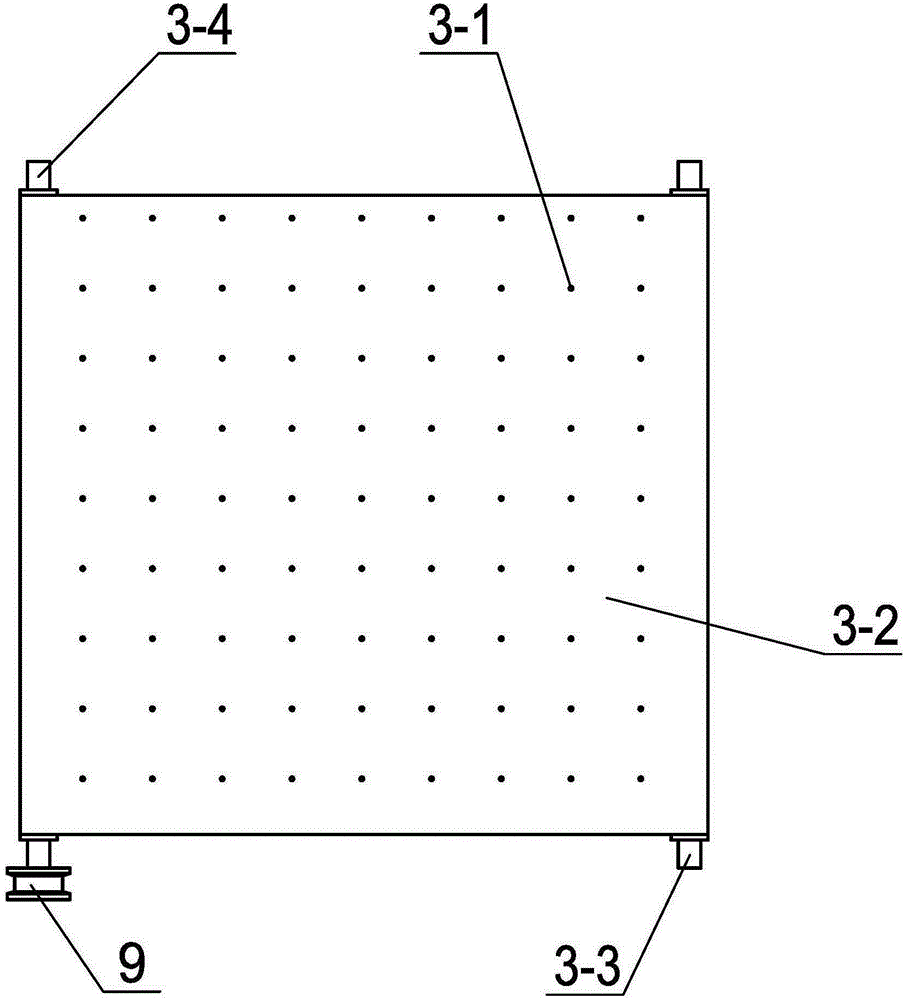

[0047] see Figure 1~Figure 16 An automatic beam splitting and paving device, including a lower fixed scraper 1, an arc-shaped scraper 1-1, a shifting tooth groove 1-2, a scraper mounting plate 1-3, a side baffle 2, a conveying part 3, a conveying Nail teeth 3-1, conveyor belt 3-2, conveyor driven shaft 3-3, conveyor drive shaft 3-4, frame 4, motor 5, motor pulley 6, feed drive belt 7, conveyor drive belt 8, conveyor Pulley 9, feed pulley 10, feed transmission mechanism 11, feed dial part 11-1, first dial block outer arc 11-1-1, first dial rocking arm 11-1-2, the first dial One rocking arm is with dial pin 11-1-3, the first dial block inner arc 11-1-4, the second dial block outer arc 11-1-5, dial block 11-1-6, the second dial block Inner circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com