Control apparatus for internal combustion engine

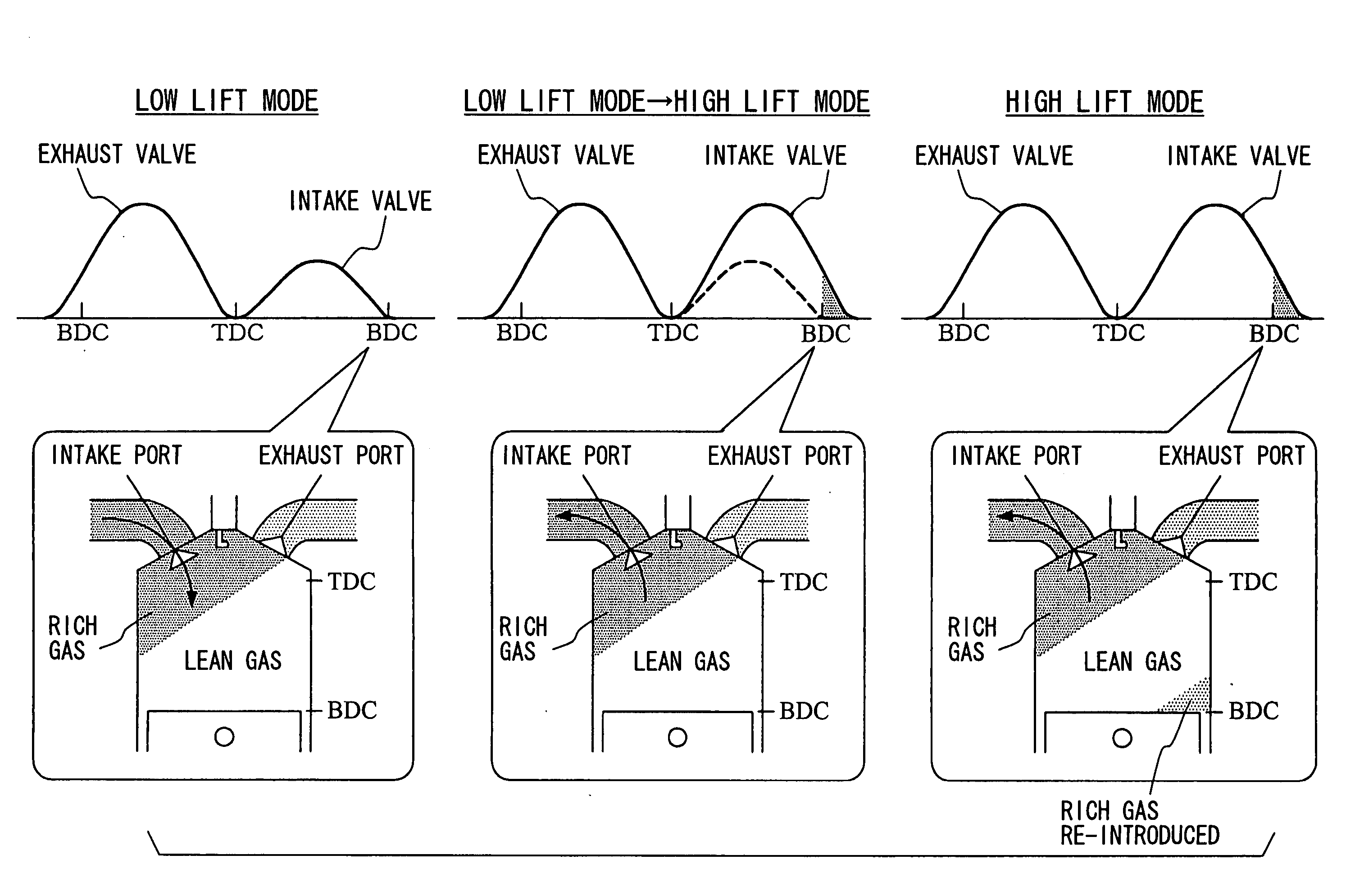

a control apparatus and internal combustion engine technology, applied in electrical control, machines/engines, non-mechanical valves, etc., can solve the problems of deterioration of exhaust emission, degrading drivability or deteriorating exhaust emission, and affecting the operation of the control apparatus, so as to increase the lift of the intake valve 29 and increase the amount of fuel sucked into the cylinder. , the effect of increasing the amount of fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

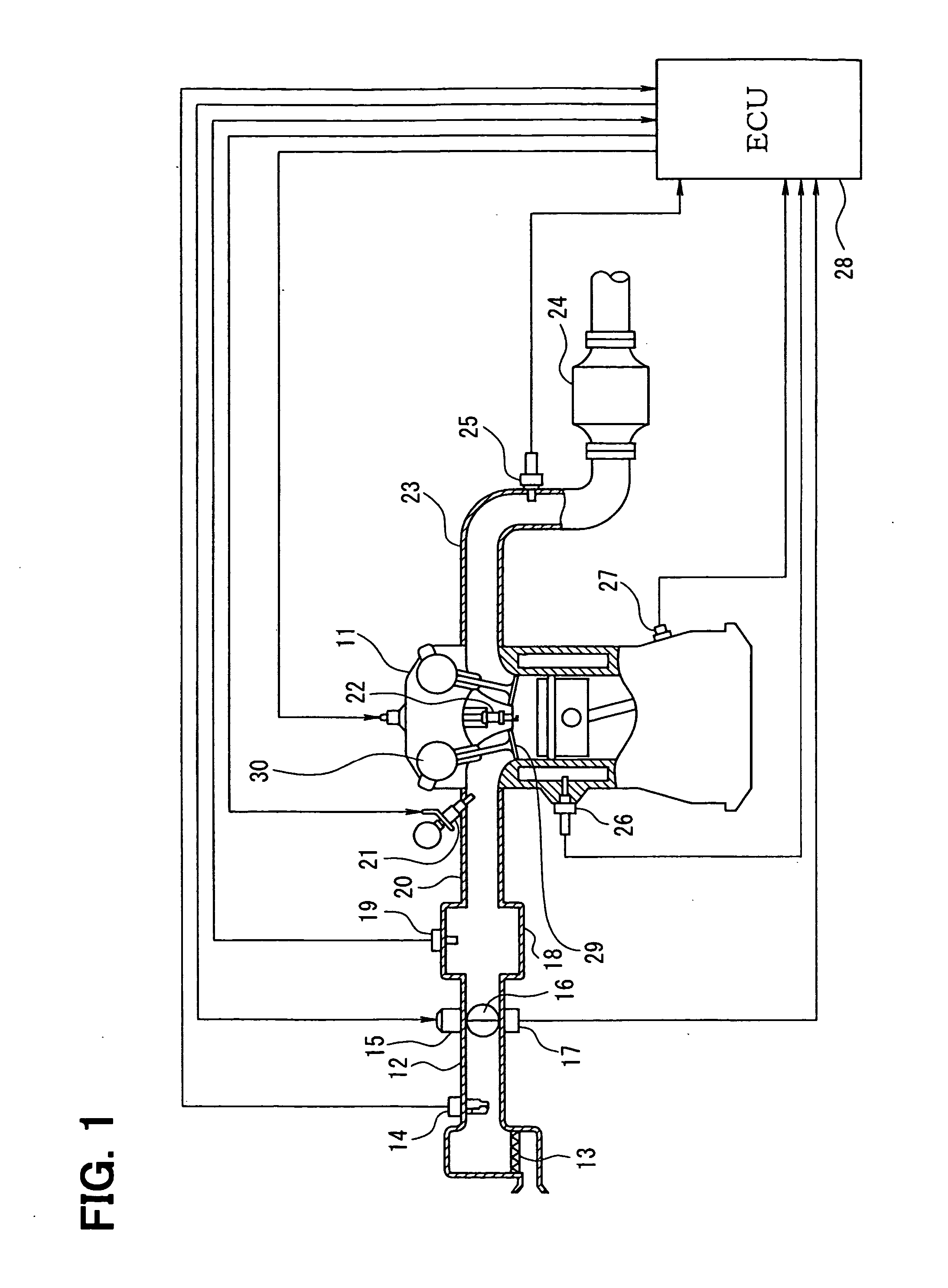

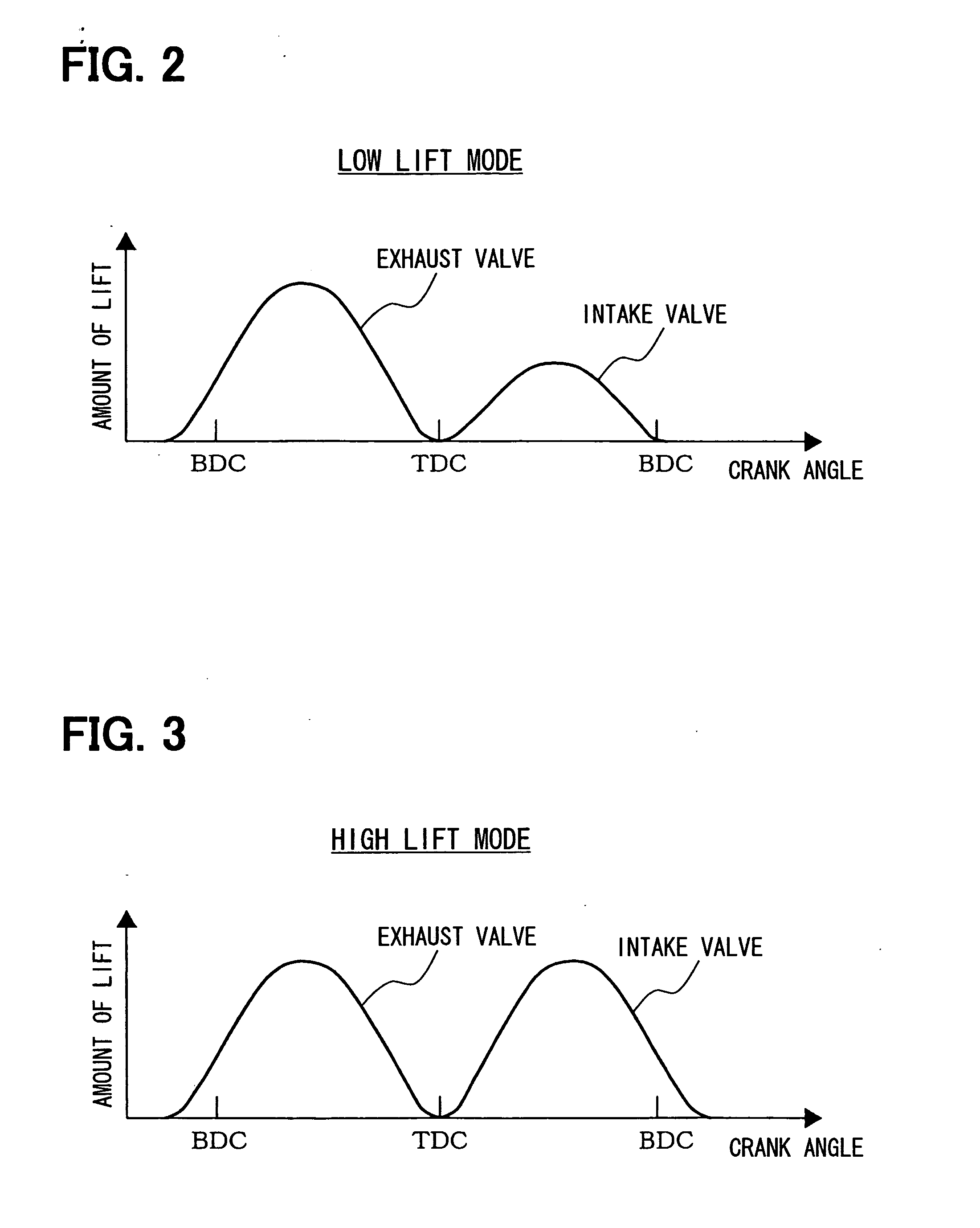

[0029] Description will be given to the first embodiment of the invention with reference to FIG. 1 to FIG. 4.

[0030] First, description will be given to the general configuration of an engine control system with reference to FIG. 1. An air cleaner 13 is provided at the most upstream portion of the intake pipe 12 of an internal combustion engine 11. An air flow meter 14 that detects the quantity of intake air is provided downstream of this air cleaner 13. Downstream of this air flow meter 14, there are provided a throttle valve 16 and a throttle angle sensor 17. The angle of the throttle valve 16 is adjusted by a motor 15 (e.g., a DC motor), and the throttle angle sensor 17 detects the angle of the throttle valve 16.

[0031] A surge tank 18 is provided downstream of the throttle valve 16, and this surge tank 18 is provided with an intake manifold pressure sensor 19 that detects intake manifold pressure. The surge tank 18 is provided with an intake manifold 20 that guides air into each...

second embodiment

[0050] Next, description will be given to the second embodiment of the invention with reference to FIG. 5. Generally, when the variable intake valve lifter 30 is switched from low lift mode to high lift mode to increase the amount of lift of the intake valve 29, the injection quantity is corrected and increased to reduce the likelihood of a lean spike. Also, when the variable intake valve lifter 30 is switched from high lift mode to low lift mode to reduce the amount of lift of the intake valve 29, the injection quantity is corrected and reduced to reduce the likelihood of a rich spike.

[0051] The injection quantity computation program illustrated in FIG. 5 is executed at predetermined intervals while the engine is in operation. When the program is started, the current amount of lift of the intake valve is computed in Step S201, and the current valve closing timing of the intake valve is computed in step S202. Then in Step S203, the ECU computes a basic injection quantity based on t...

third embodiment

[0063] Description will be given to the third embodiment of the invention with reference to FIG. 6 and FIG. 7.

[0064] As illustrated in FIG. 6, the engine 11 is a four-valve engine having four valves for each cylinder. Each cylinder is provided with two intake ports 31 and two exhaust ports 32. Each intake port 31 is provided with an intake valve 29, and each exhaust port 32 is provided with an exhaust valve 33.

[0065] A swirl valve 34 (i.e., a swirl flow generating device) is included in either of the two intake ports 31 of the cylinder. The swirl valve 34 generates a swirl flow in the corresponding cylinder. The swirl valve 34 of each cylinder is so constructed that it is driven and opened / closed by a motor or the like (not shown). The ECU 28 executes the swirl valve control program illustrated in FIG. 7. As such, when the engine is in a predetermined operating range (e.g. low-revolution, low-load operating range, etc.), the swirl valve 34 is closed to generate a swirl flow in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com