Patents

Literature

31results about How to "Harsh environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

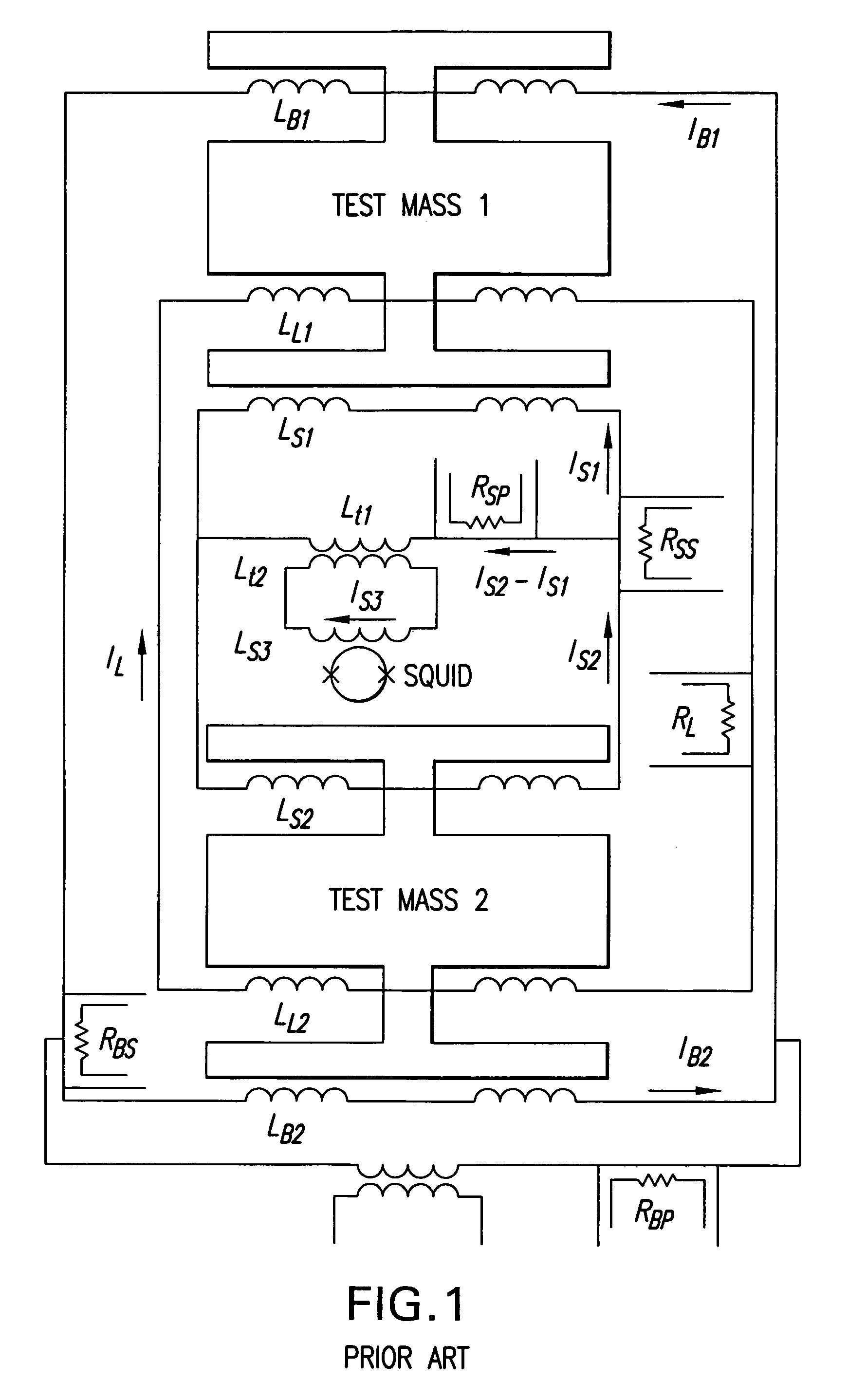

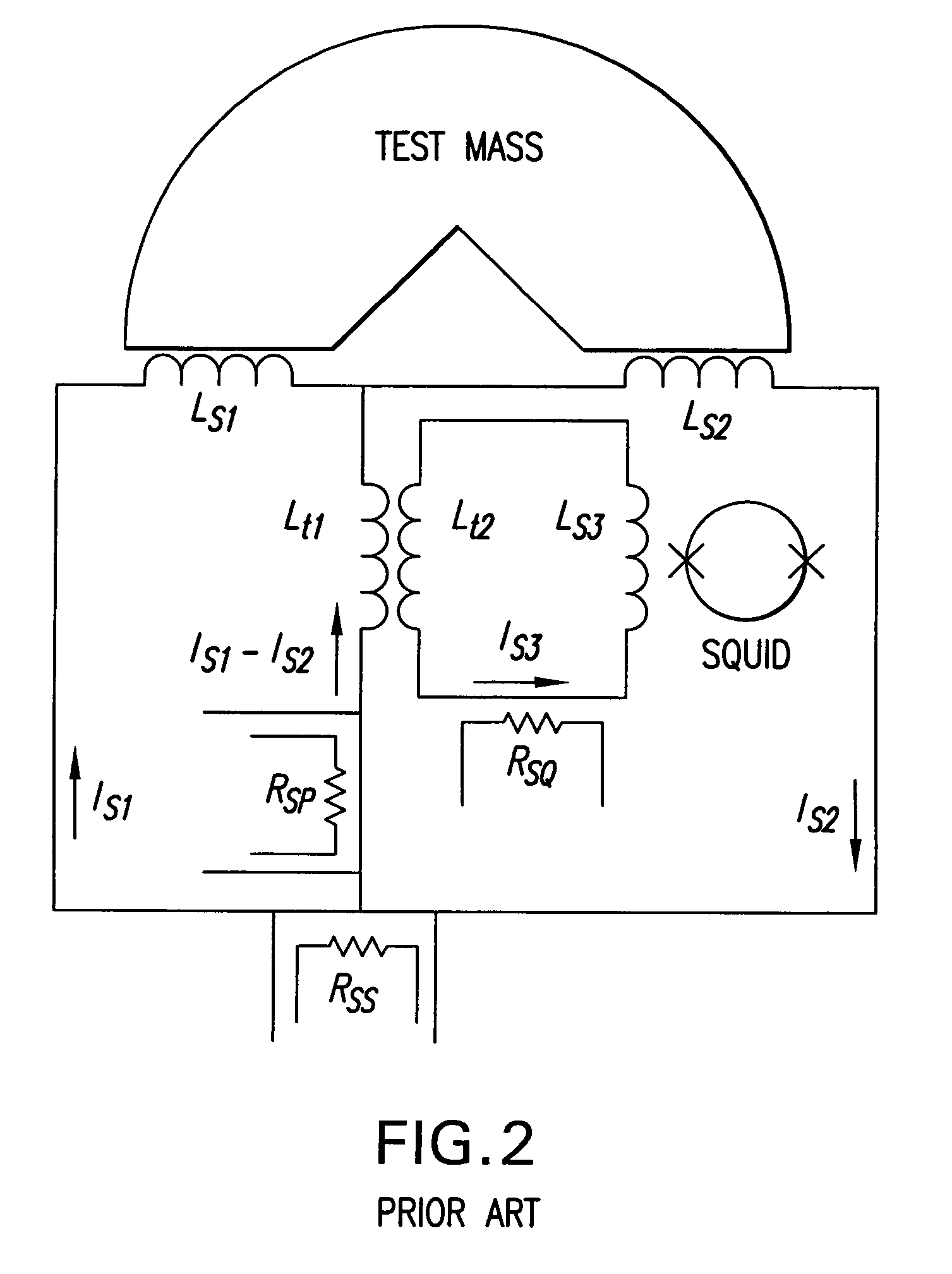

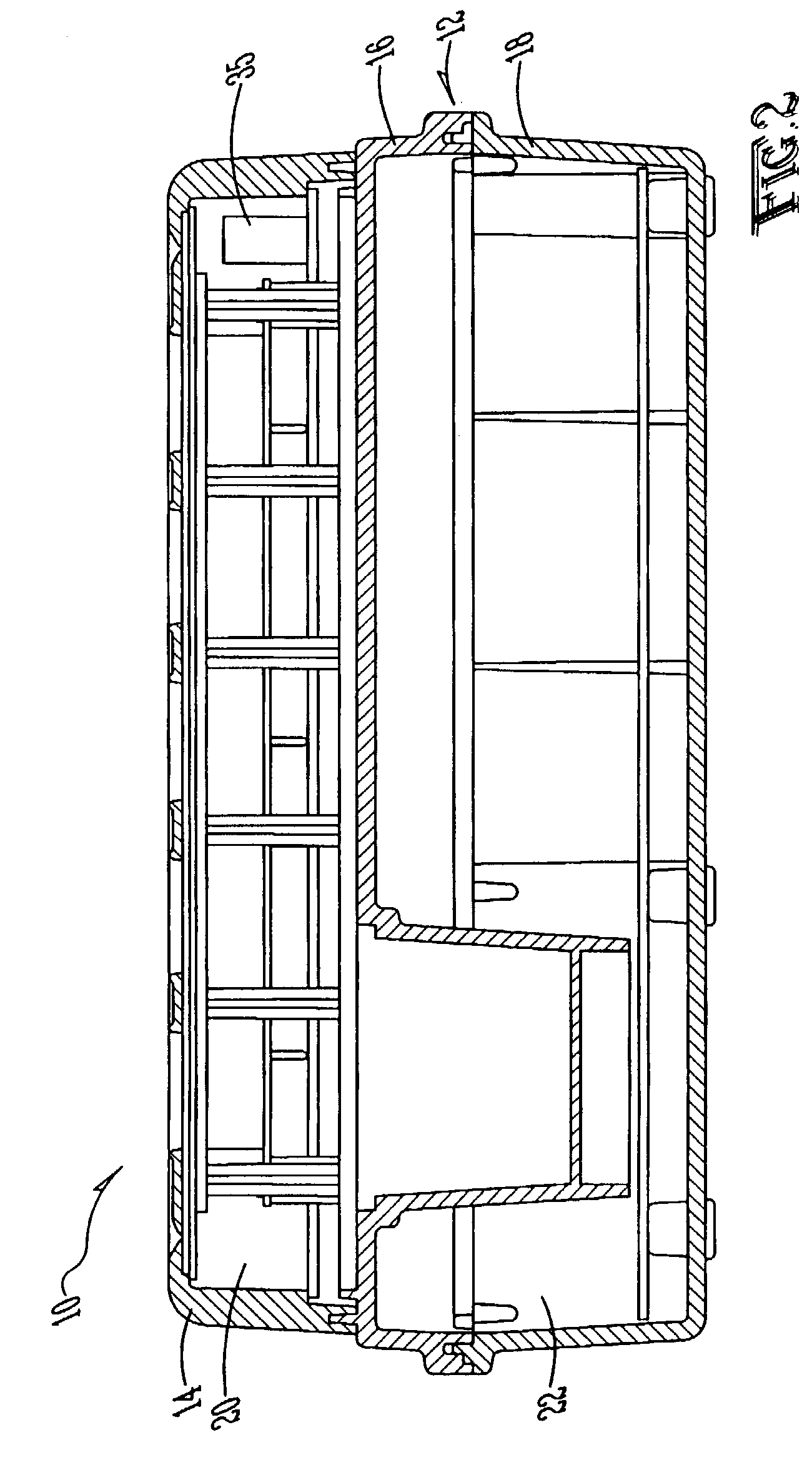

Cross-component superconducting gravity gradiometer with improved linearity and sensitivity and method for gravity gradient sensing

ActiveUS20060207326A1Improve linearityReduce sensitivityAcceleration measurement using interia forcesGravitational wave measurementAccelerometerOperability

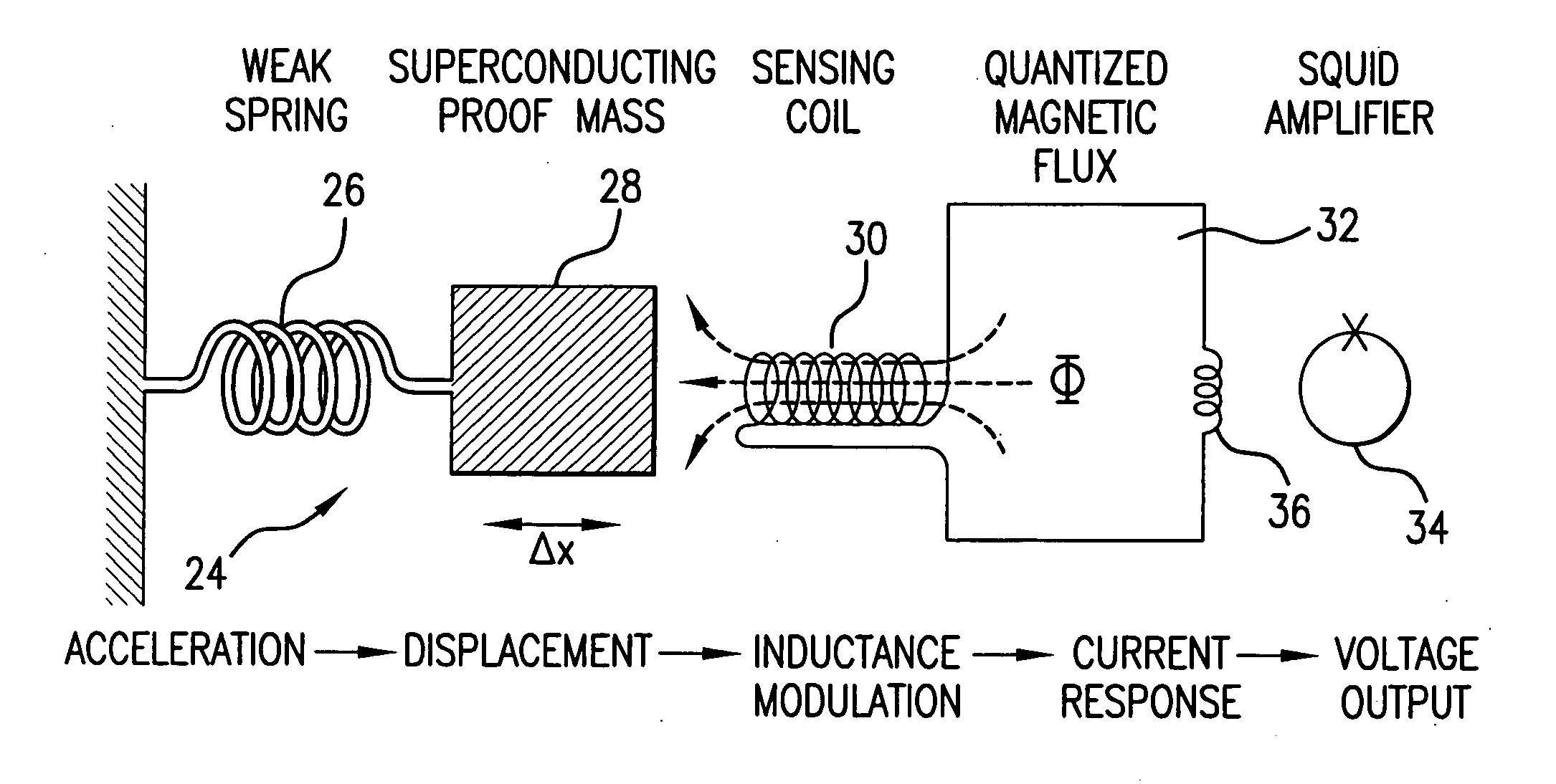

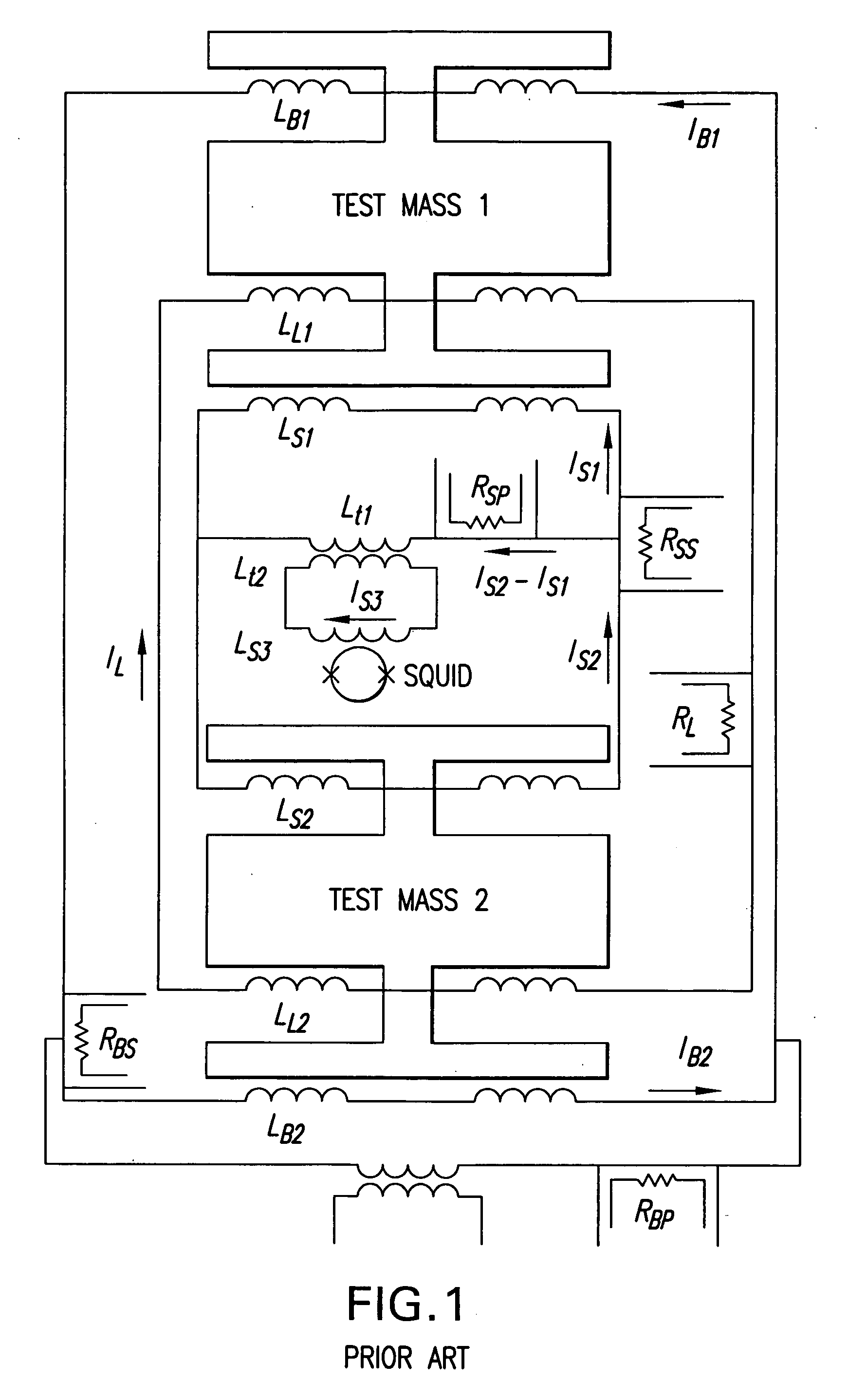

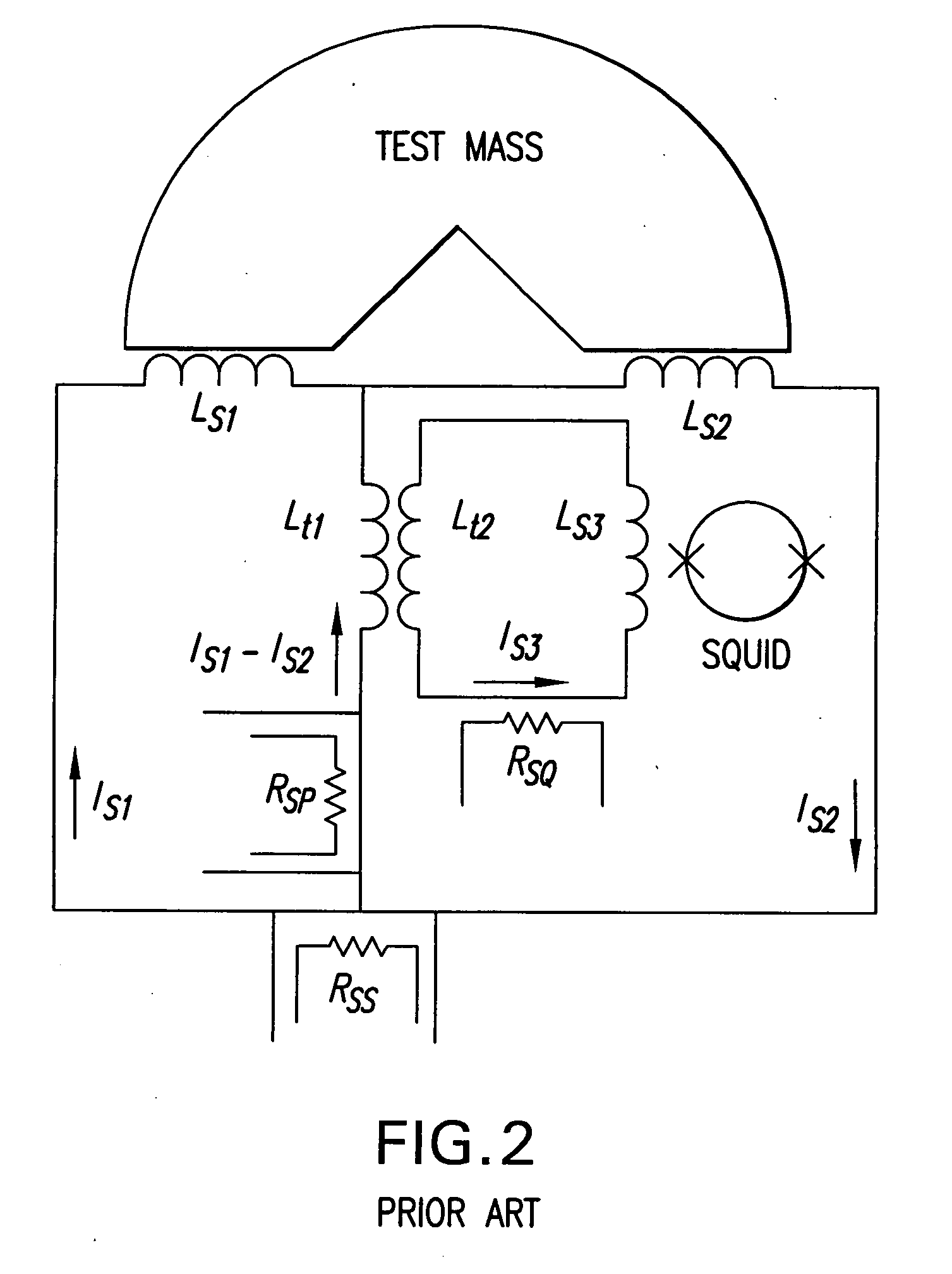

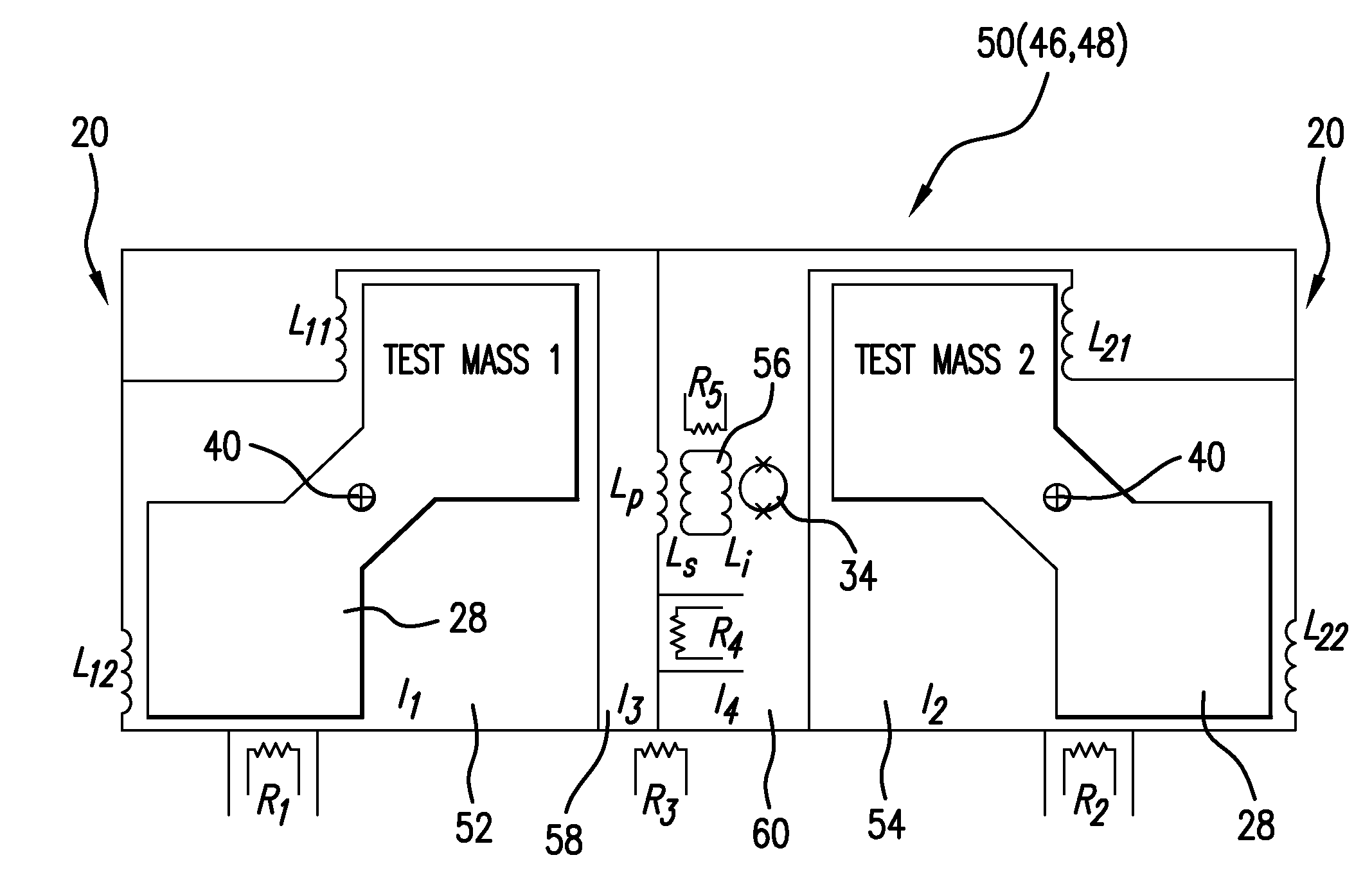

A cross-component superconducting gravity gradiometer sensitive to off-diagonal components of the gradient tensor includes, for each gradient axis, a pair of closely matched angular accelerometers coupled by superconducting circuitry, including sensing circuits designed to minimize the sensitivity of the instrument to angular acceleration of the platform at which the angular accelerometers are mounted; and a mode-splitting circuitry designed to reduce a nonlinear coupling of angular acceleration to the output of the gravity gradiometer and to attain the operability of the instrument in a broader range in the frequency domain.

Owner:MARYLAND UNIV OF

Cross-component superconducting gravity gradiometer with improved linearity and sensitivity and method for gravity gradient sensing

ActiveUS7305879B2Improve linearityReduce sensitivityAcceleration measurement using interia forcesGravitational wave measurementAccelerometerOperability

A cross-component superconducting gravity gradiometer sensitive to off-diagonal components of the gradient tensor includes, for each gradient axis, a pair of closely matched angular accelerometers coupled by superconducting circuitry, including sensing circuits designed to minimize the sensitivity of the instrument to angular acceleration of the platform at which the angular accelerometers are mounted; and a mode-splitting circuitry designed to reduce a nonlinear coupling of angular acceleration to the output of the gravity gradiometer and to attain the operability of the instrument in a broader range in the frequency domain.

Owner:MARYLAND UNIV OF

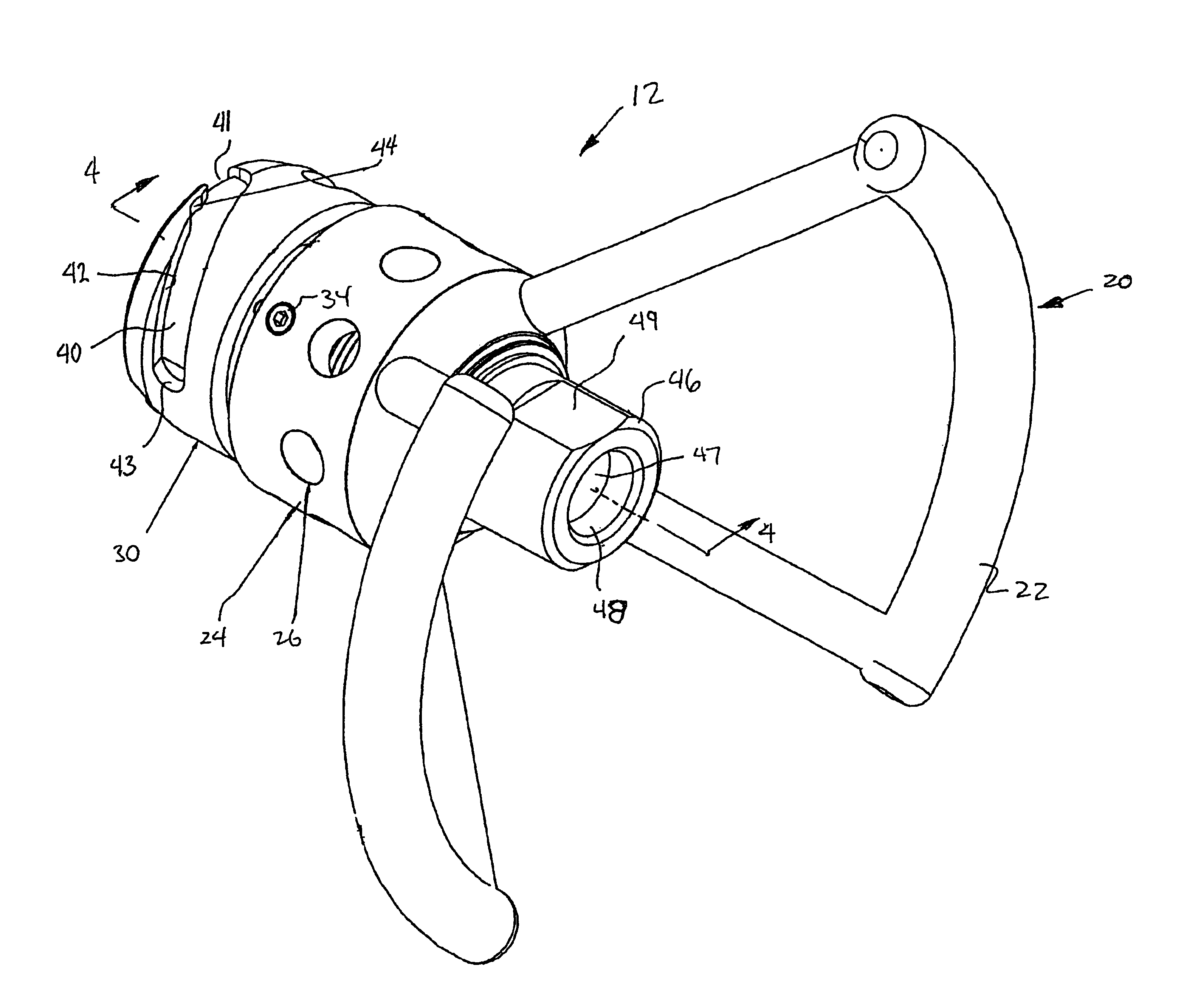

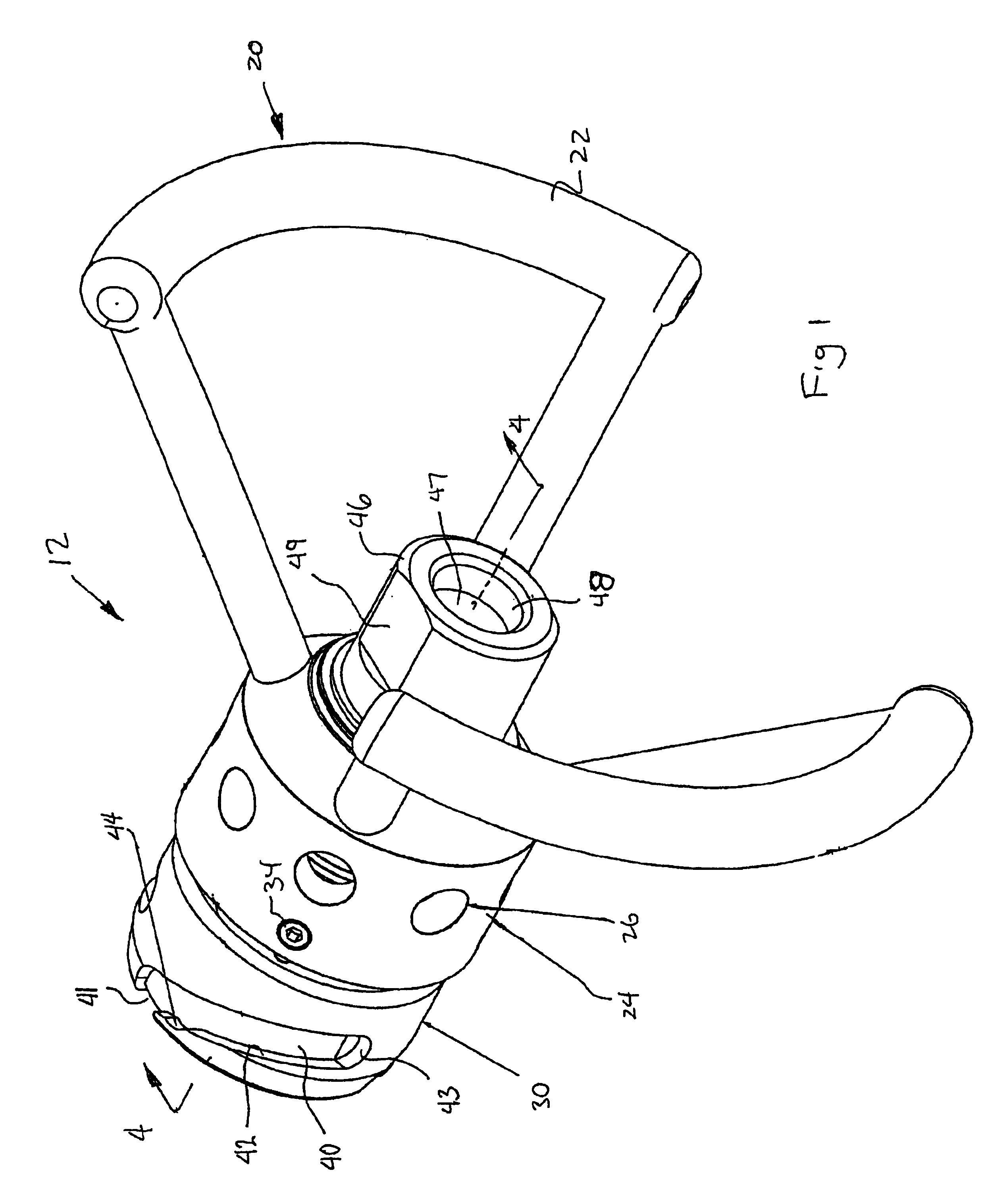

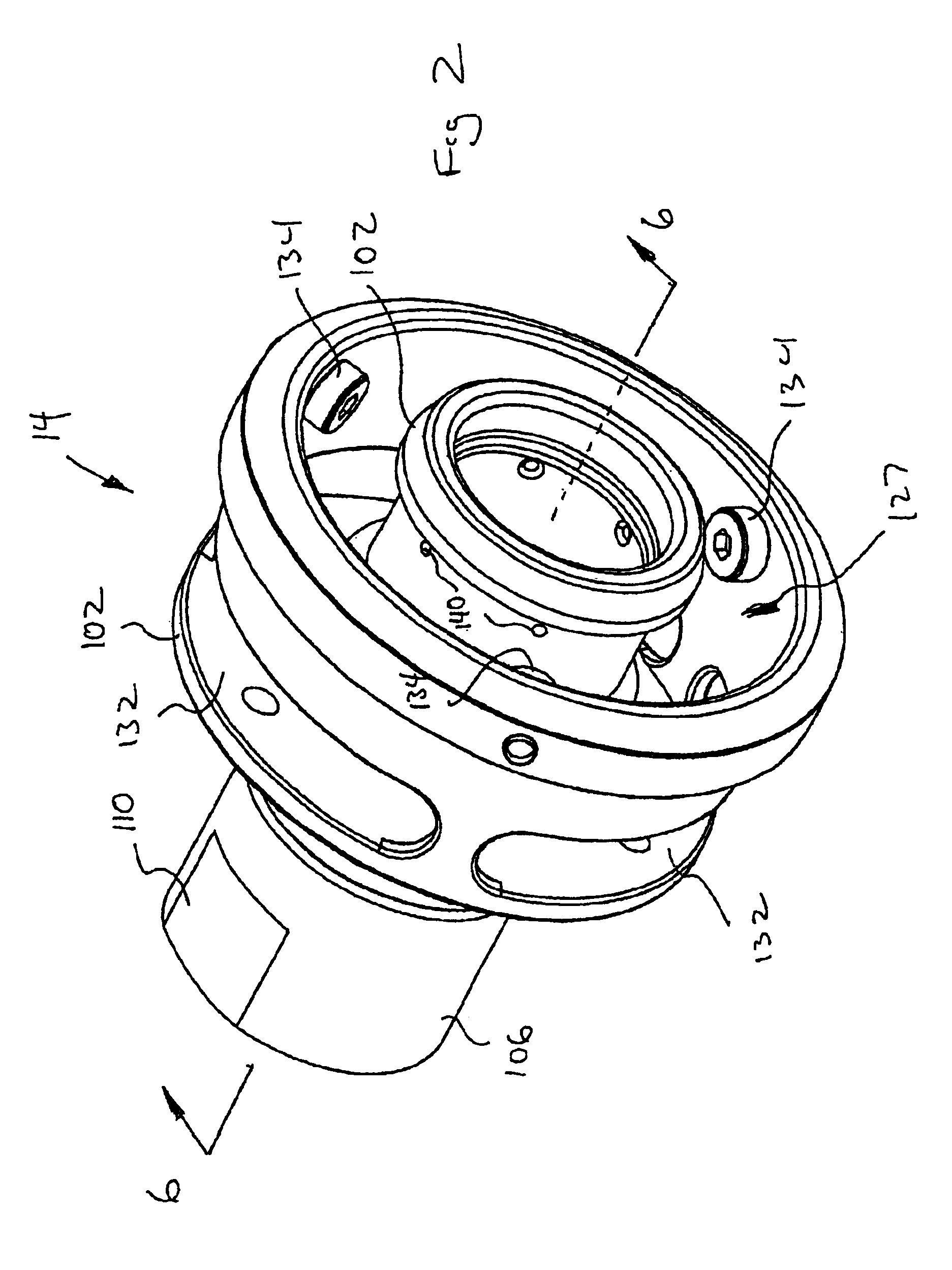

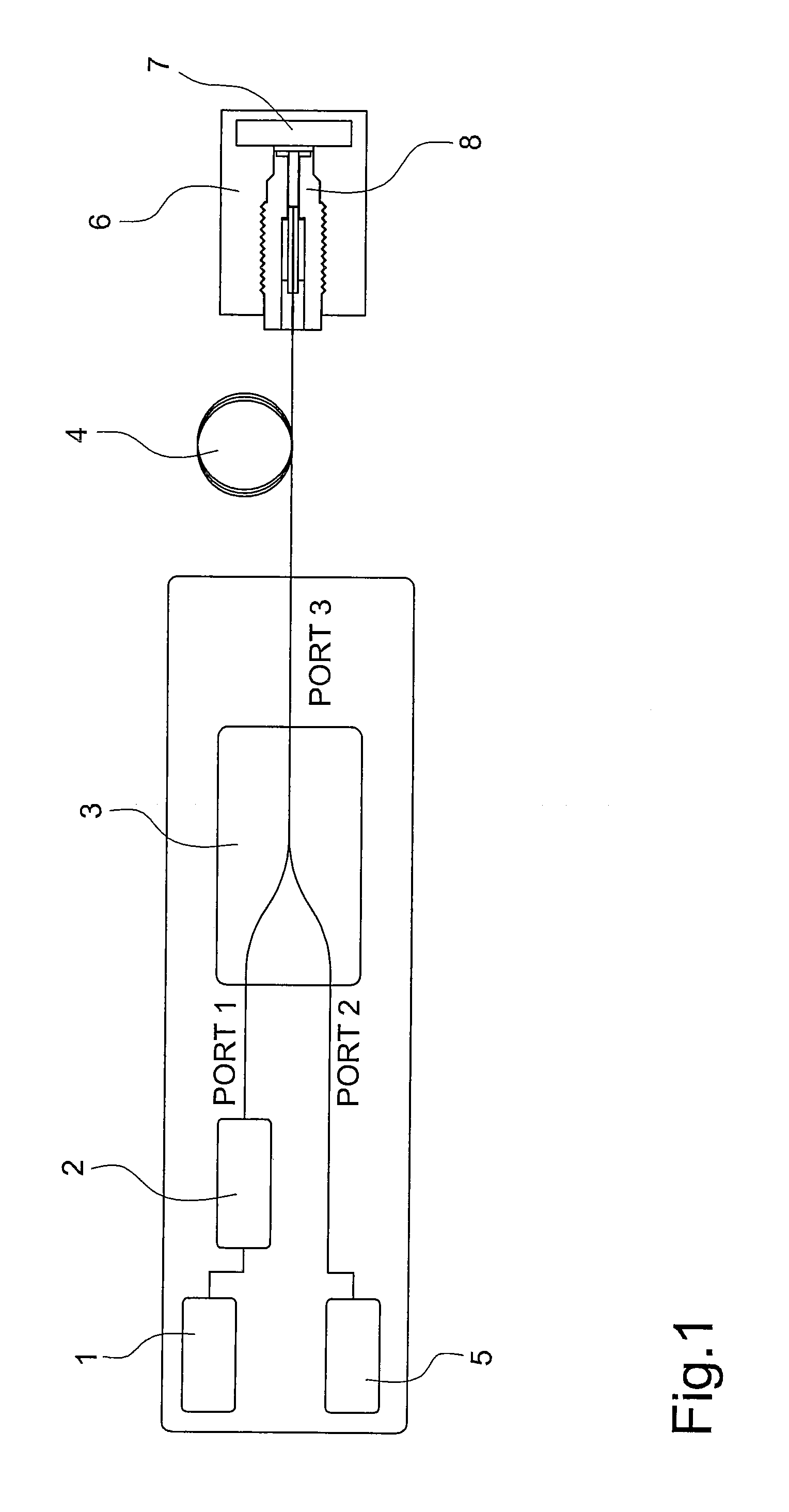

Cryogenic coupling device

ActiveUS6945477B2Prevent overflowSmall sizeVessel mounting detailsSpray nozzlesThermal breakCoupling

A cryogenic coupling device includes a valved receptacle and a valved nozzle. Rollers in an outer collar of the receptacle are received in helical channels along a collar of the nozzle. A notch or detent in each of the channels provides a vent position to vent fluid before the nozzle is fully disconnected from the receptacle. Interface seals on the nozzle include first and second annular seals that function as ice and containment scrapers, as well as fluid seals. The nozzle has a rotatable handle assembly, isolated from the fluid path, which provides easy connect and disconnect of the nozzle from the receptacle. The handle assembly includes a thermal break, and is easily removable from the nozzle, along with other parts of the nozzle and receptacle, for service and maintenance.

Owner:PARKER INTANGIBLES LLC

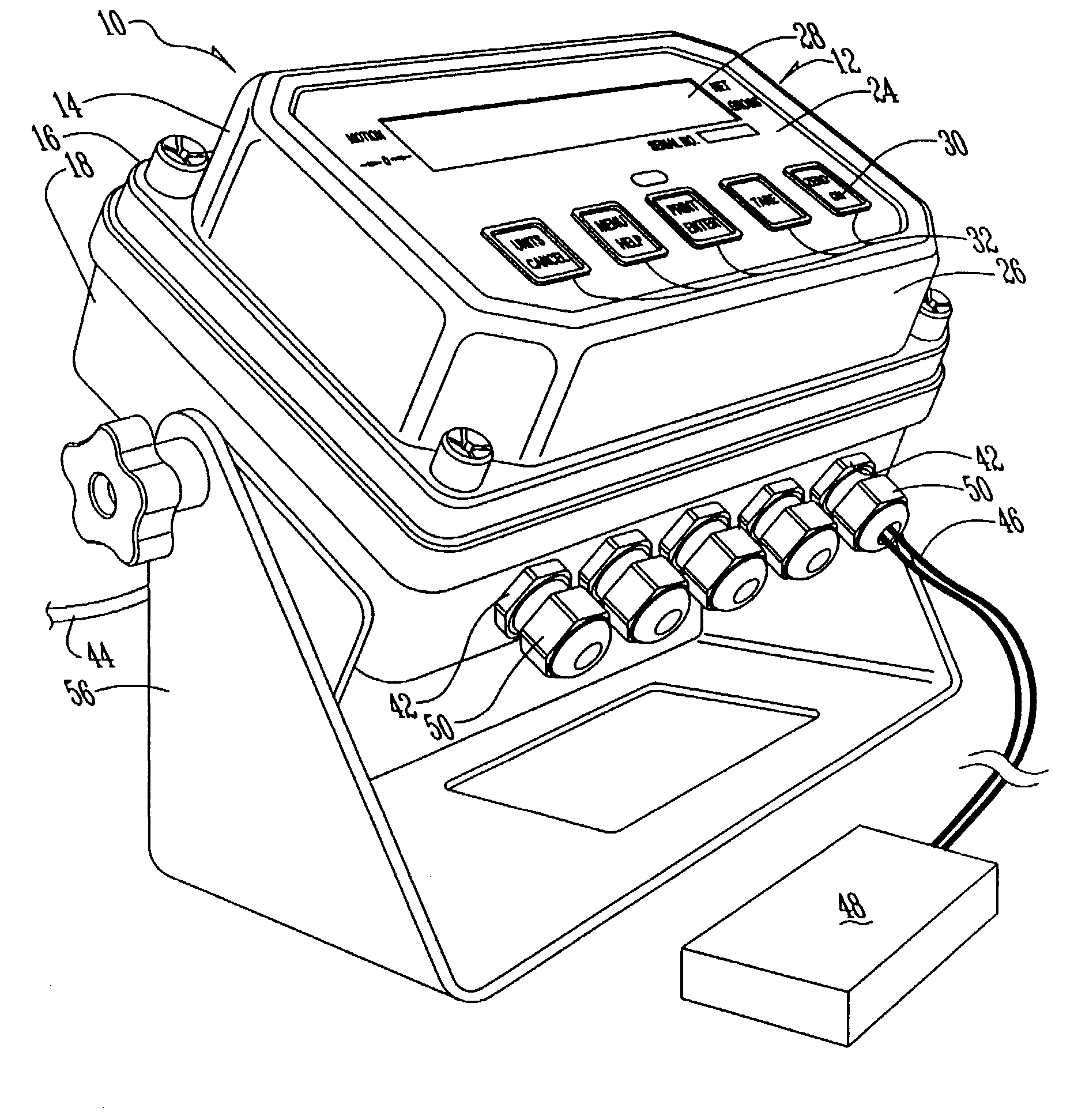

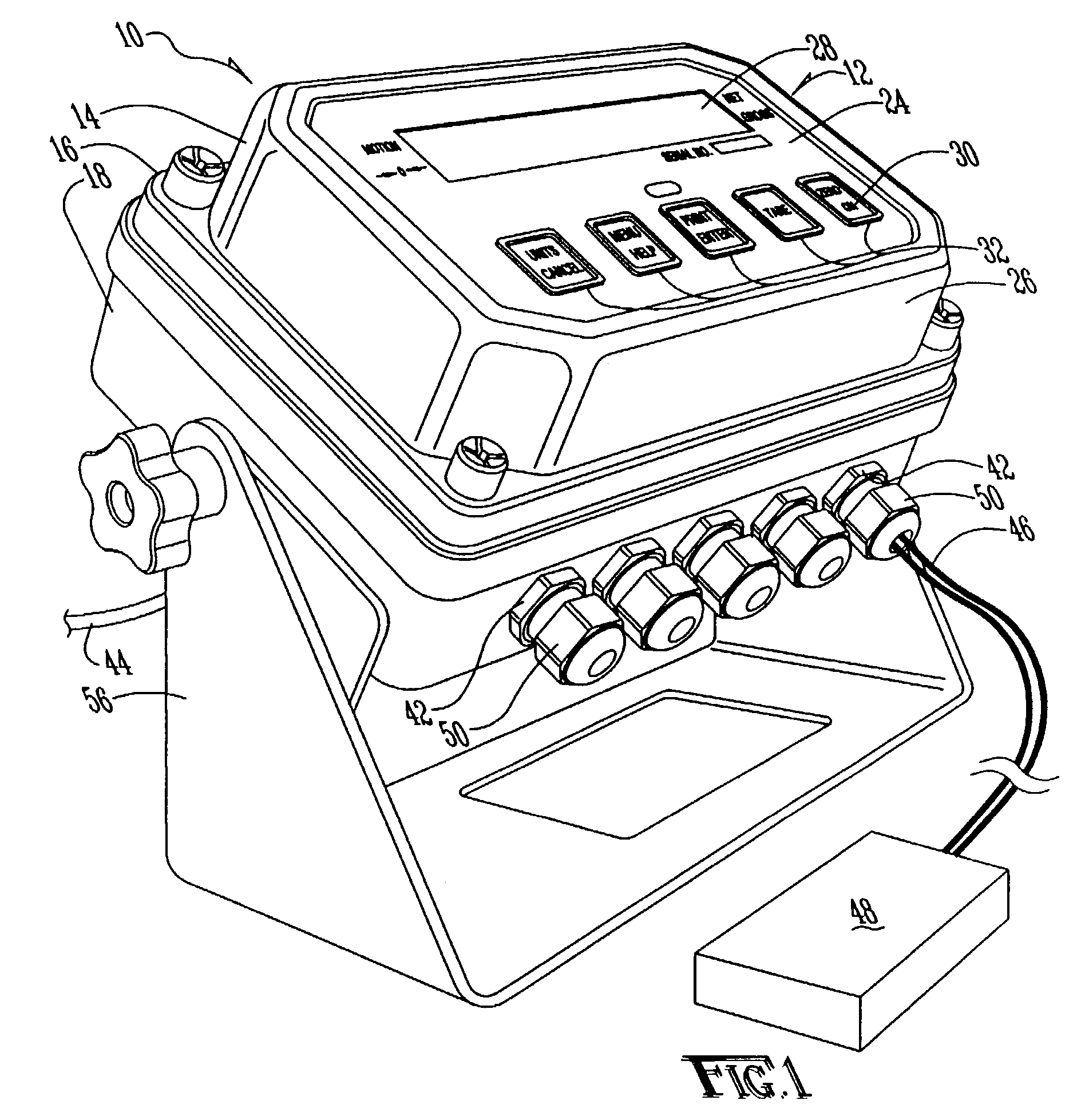

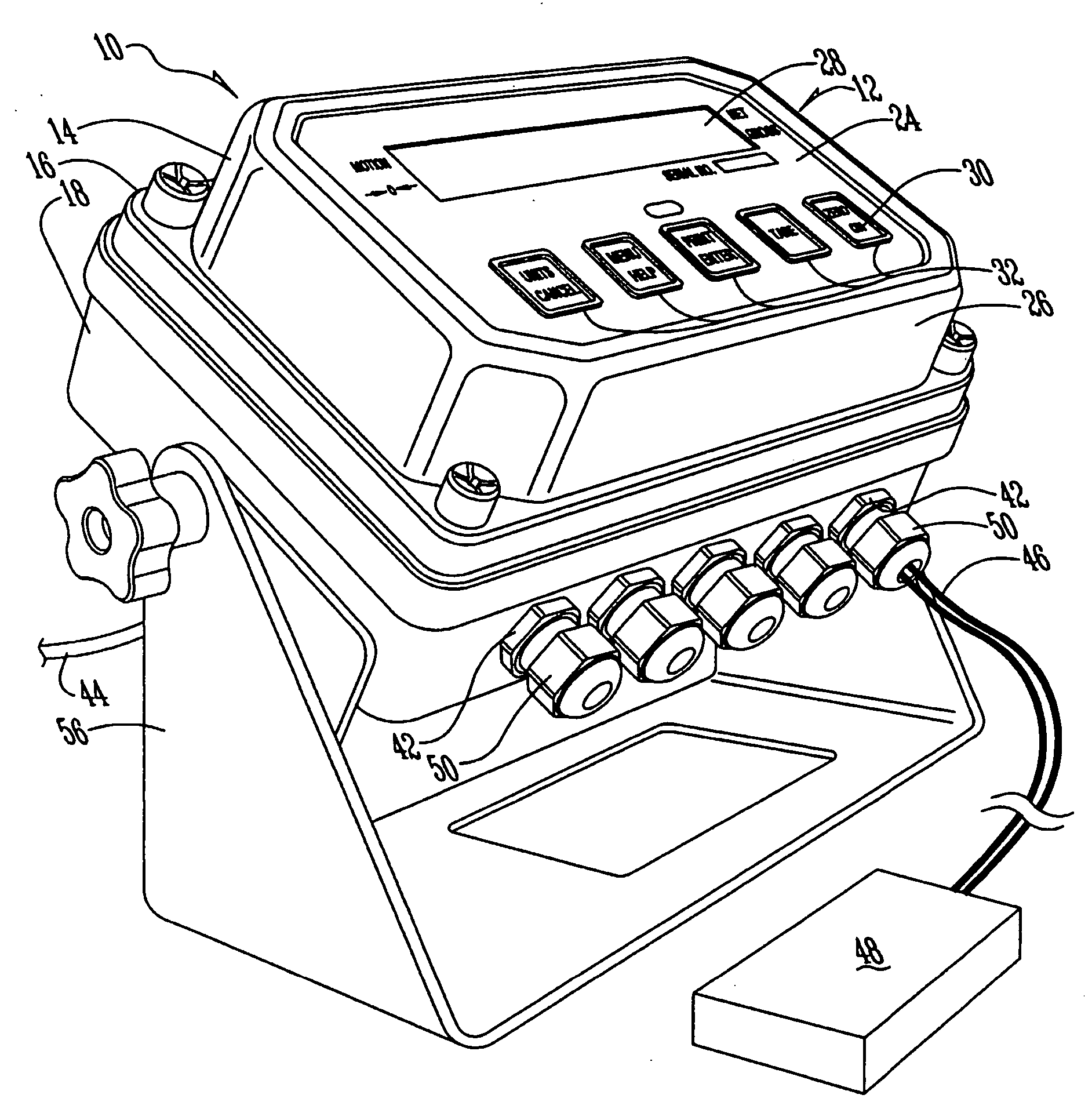

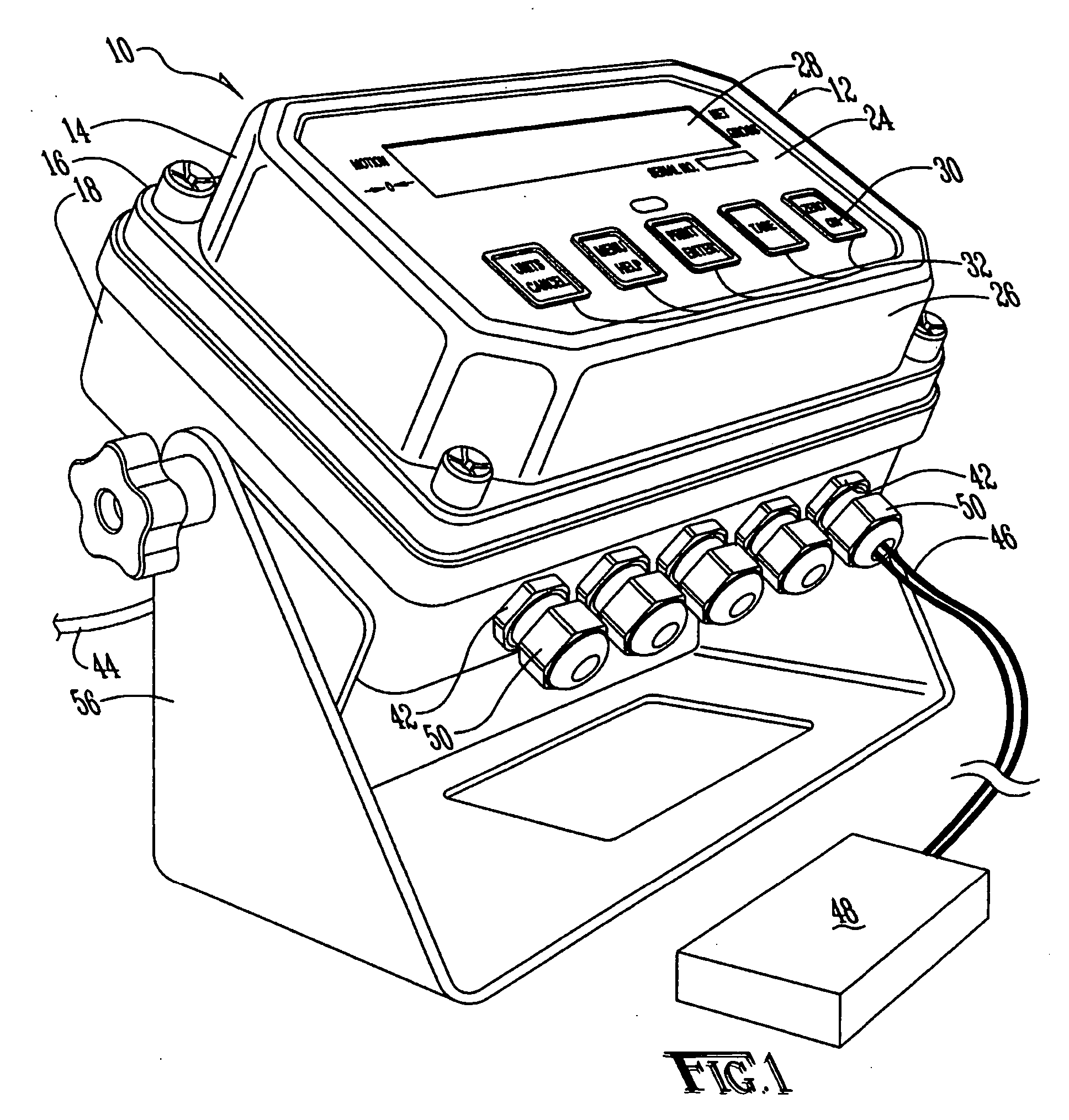

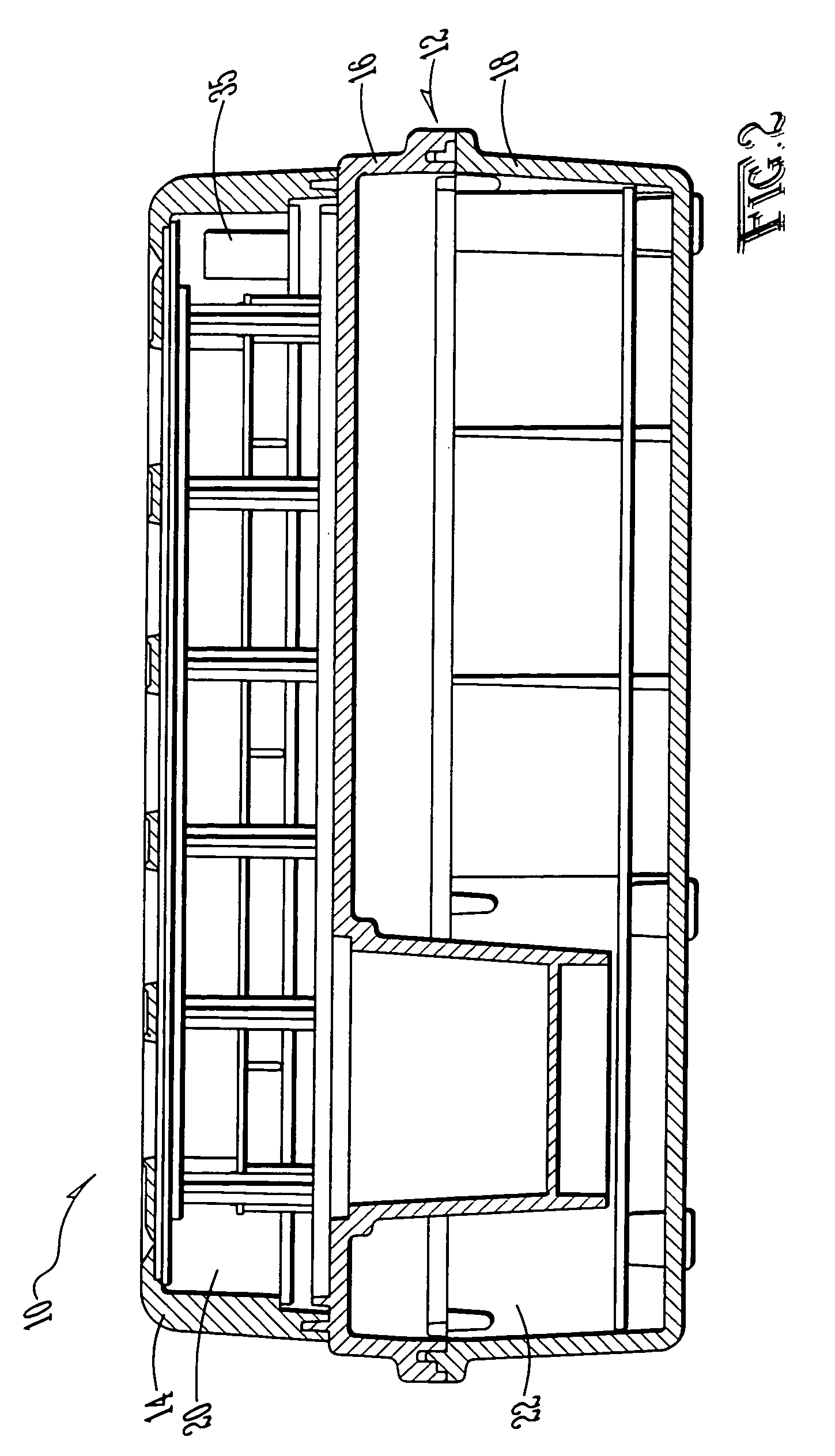

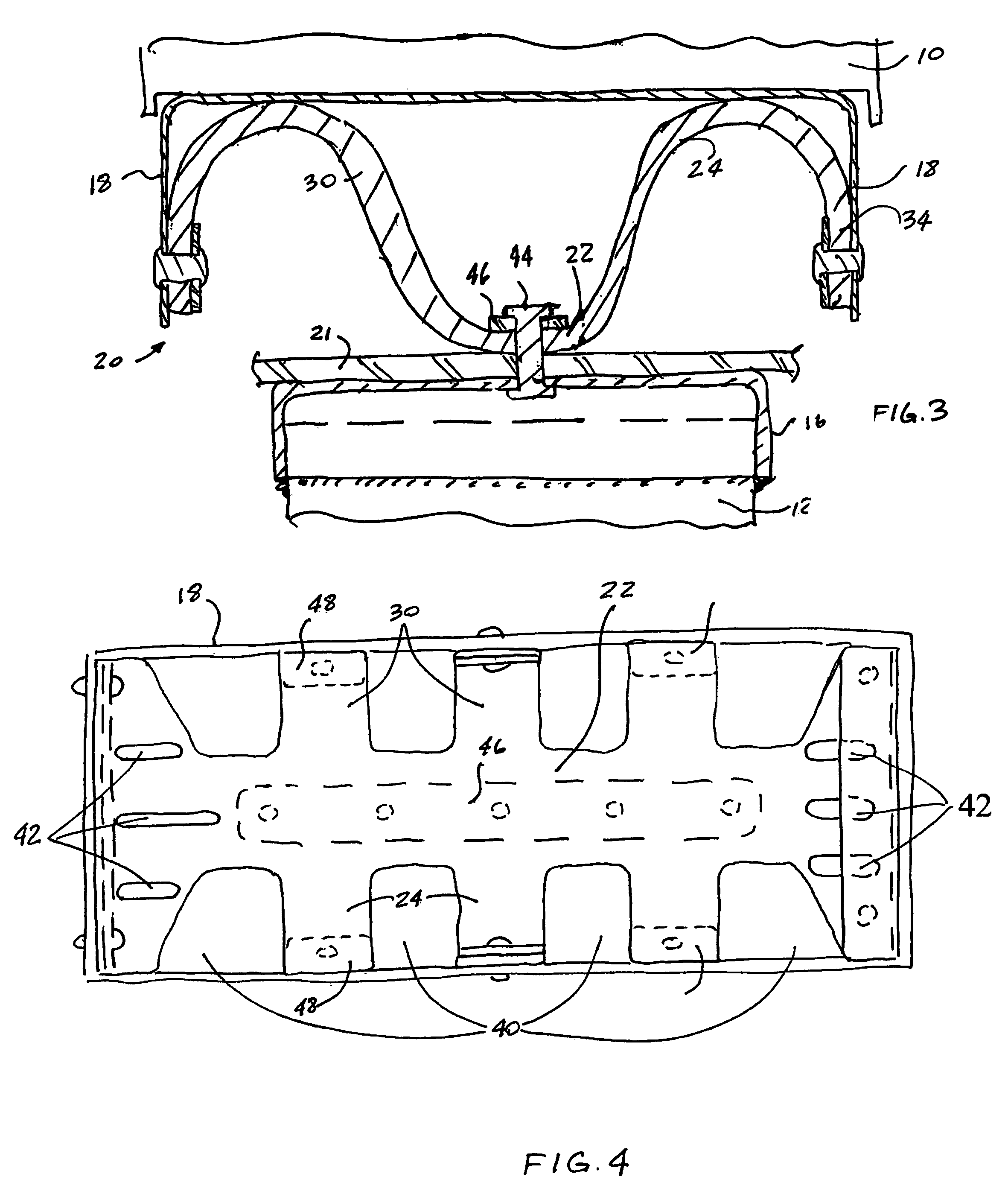

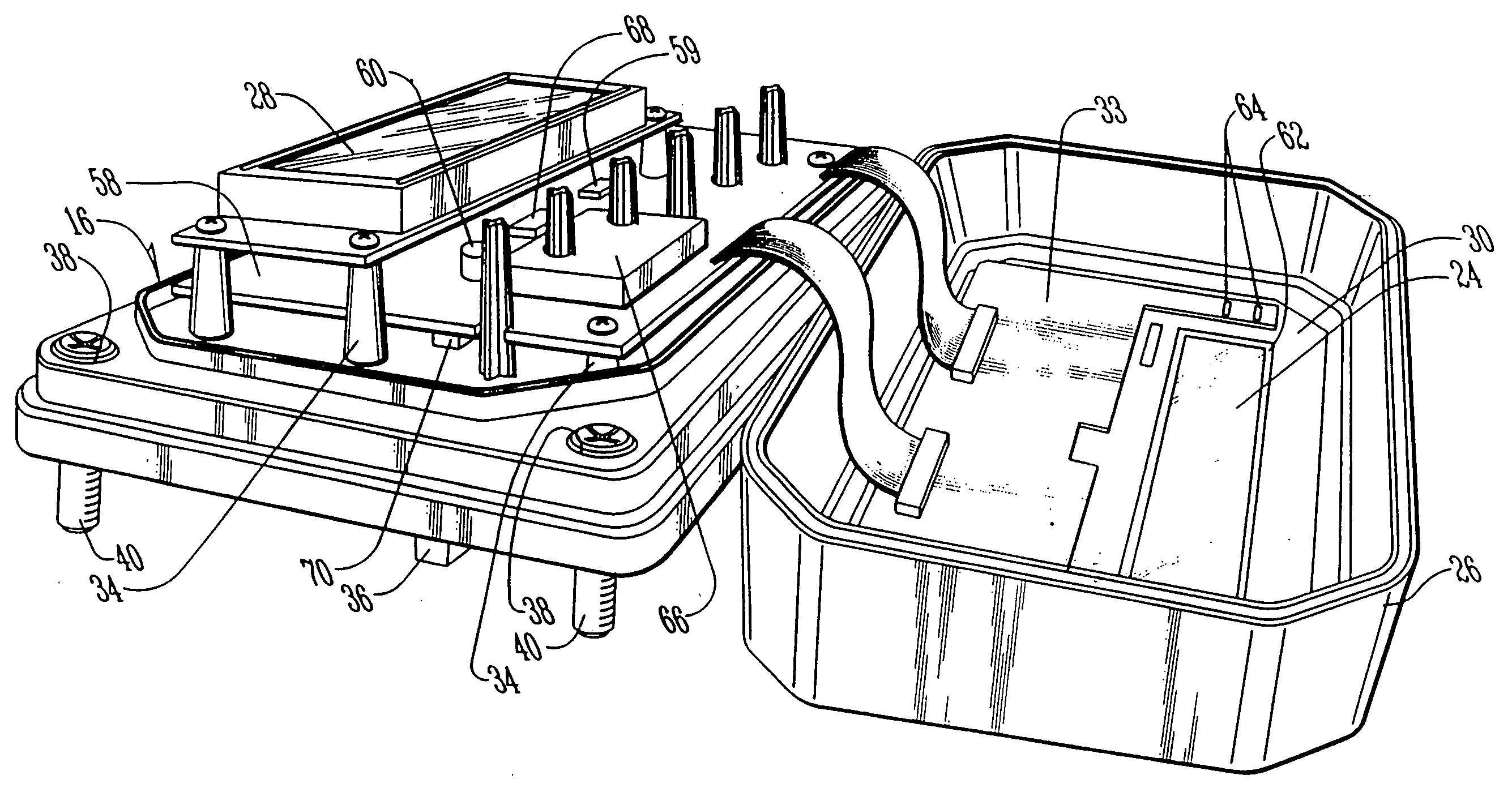

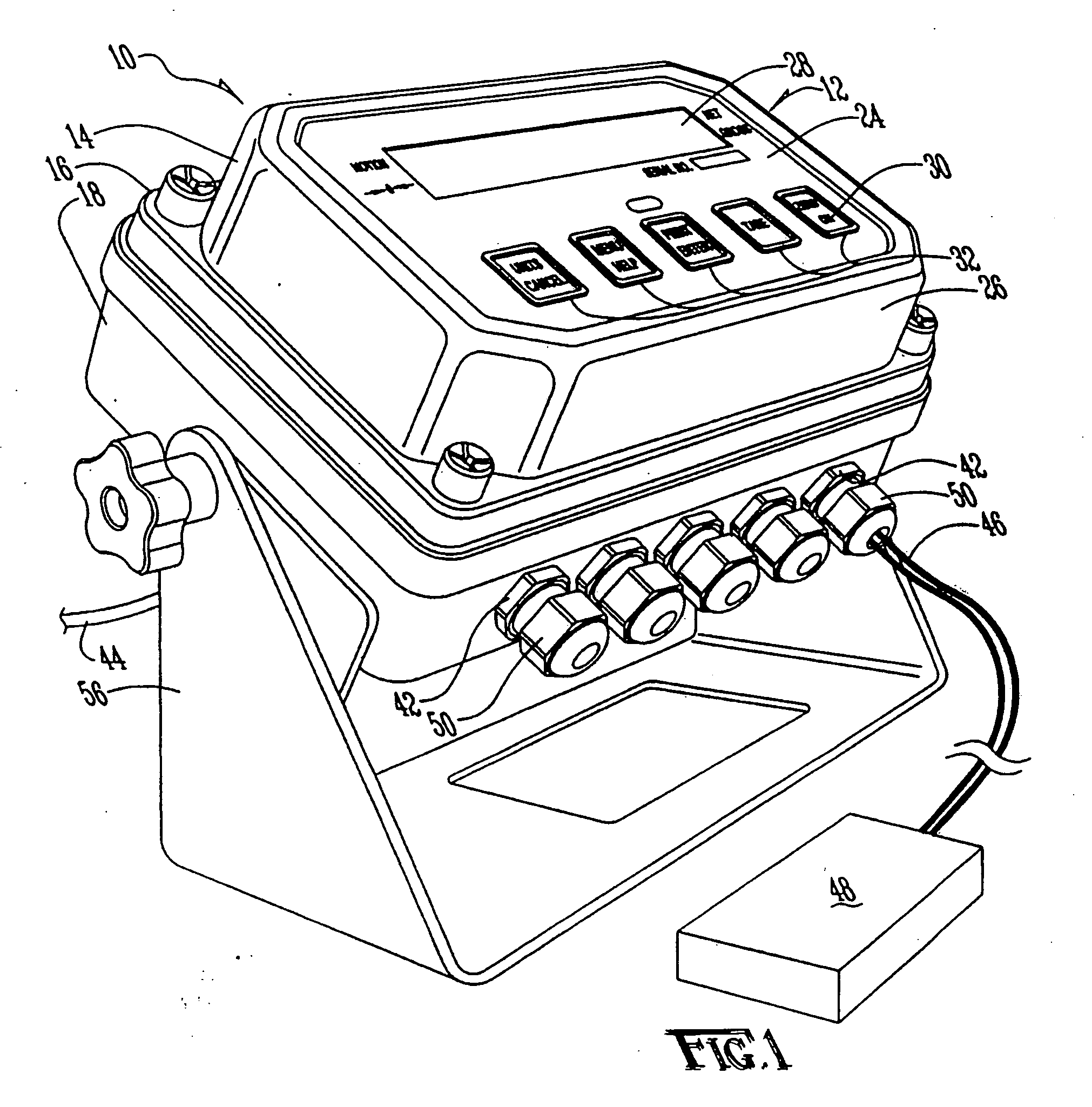

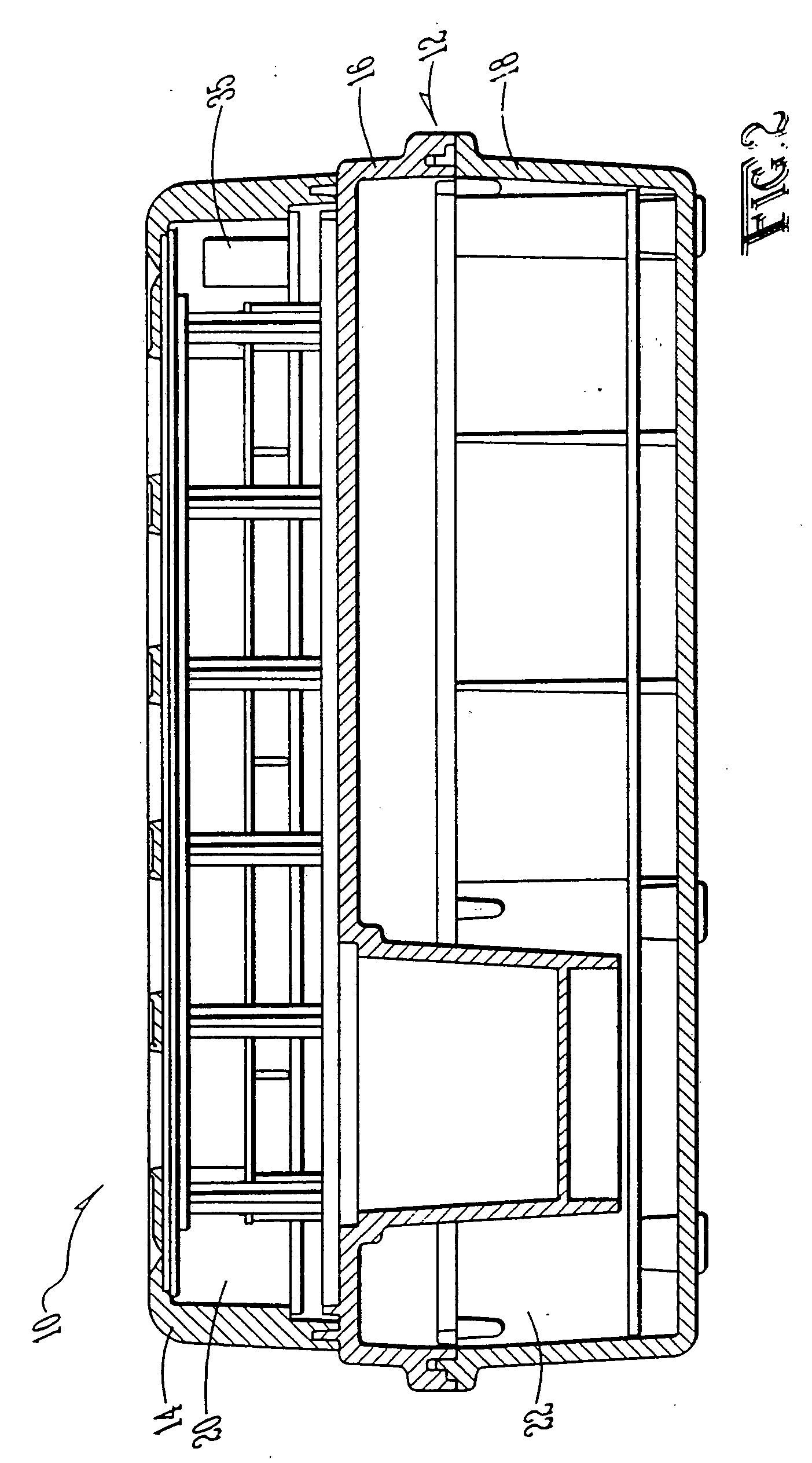

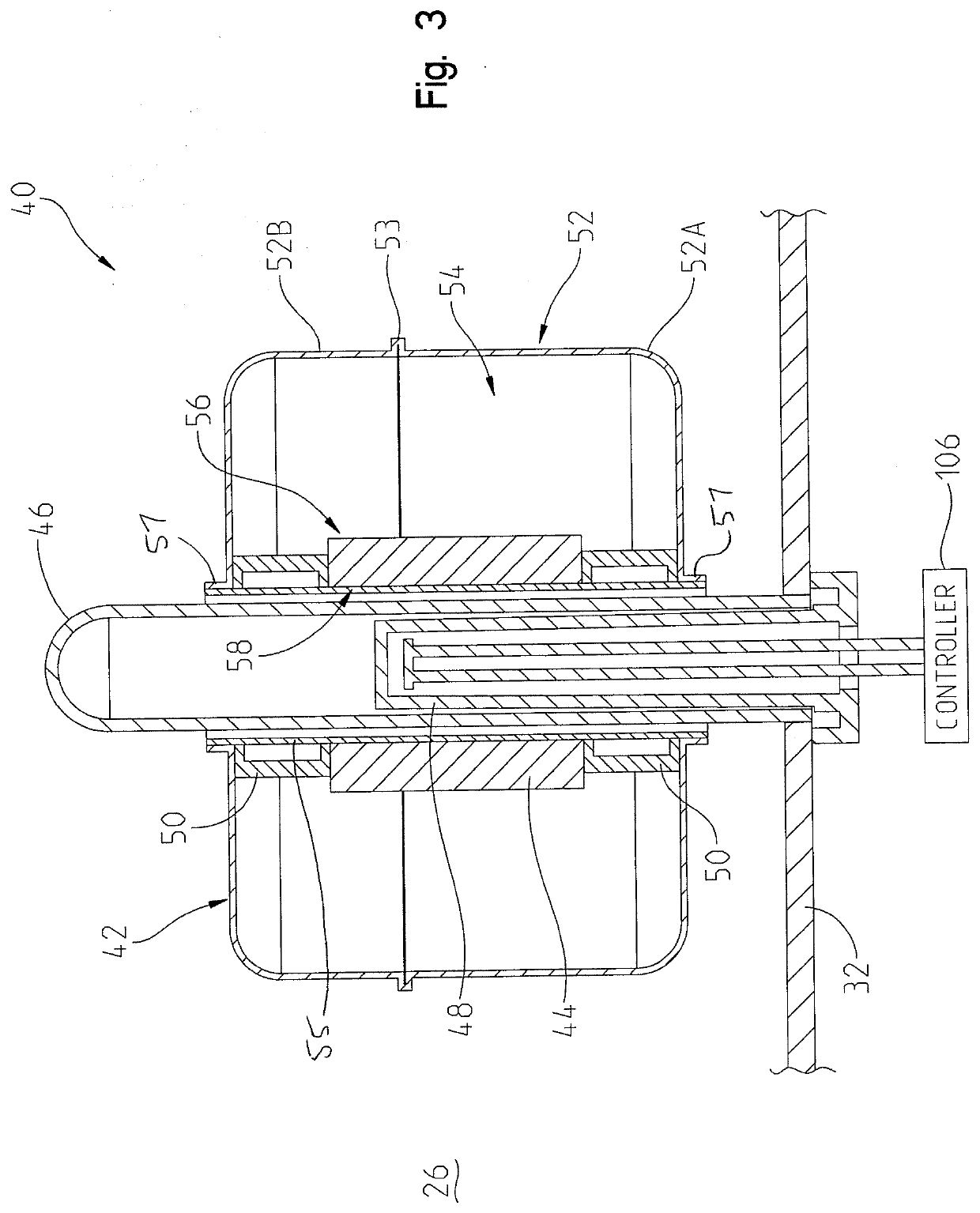

Modular sealed portable digital electronic controller

InactiveUS7002084B2Harsh environmentComponent is quite sensitiveCasings/cabinets/drawers detailsCouplings bases/casesElectricityTransceiver

An electronic digital controller, such as a load cell indicator, is disclosed in which a number of components, such as a circuit board, display, and keypad are placed within an enclosure, and the enclosure is bonded closed, such as using an adhesive, to render the enclosure watertight. The keypad is a touch sensitive, capacitive keypad with no moving parts, and it is housed behind a rigid panel. An optoelectronic transceiver allows for data exchange with an electronic memory device housed in the adhesively sealed enclosure and allows for data exchange and for updating or modification of software code housed therein. Other components, such as another circuit board, a power supply, and block connectors, are placed in an adjacent enclosure, and the circuit boards in the two enclosures are electrically connected. The power supply is preferably a potted AC power supply but may also include a battery.

Owner:WEIGH TECH

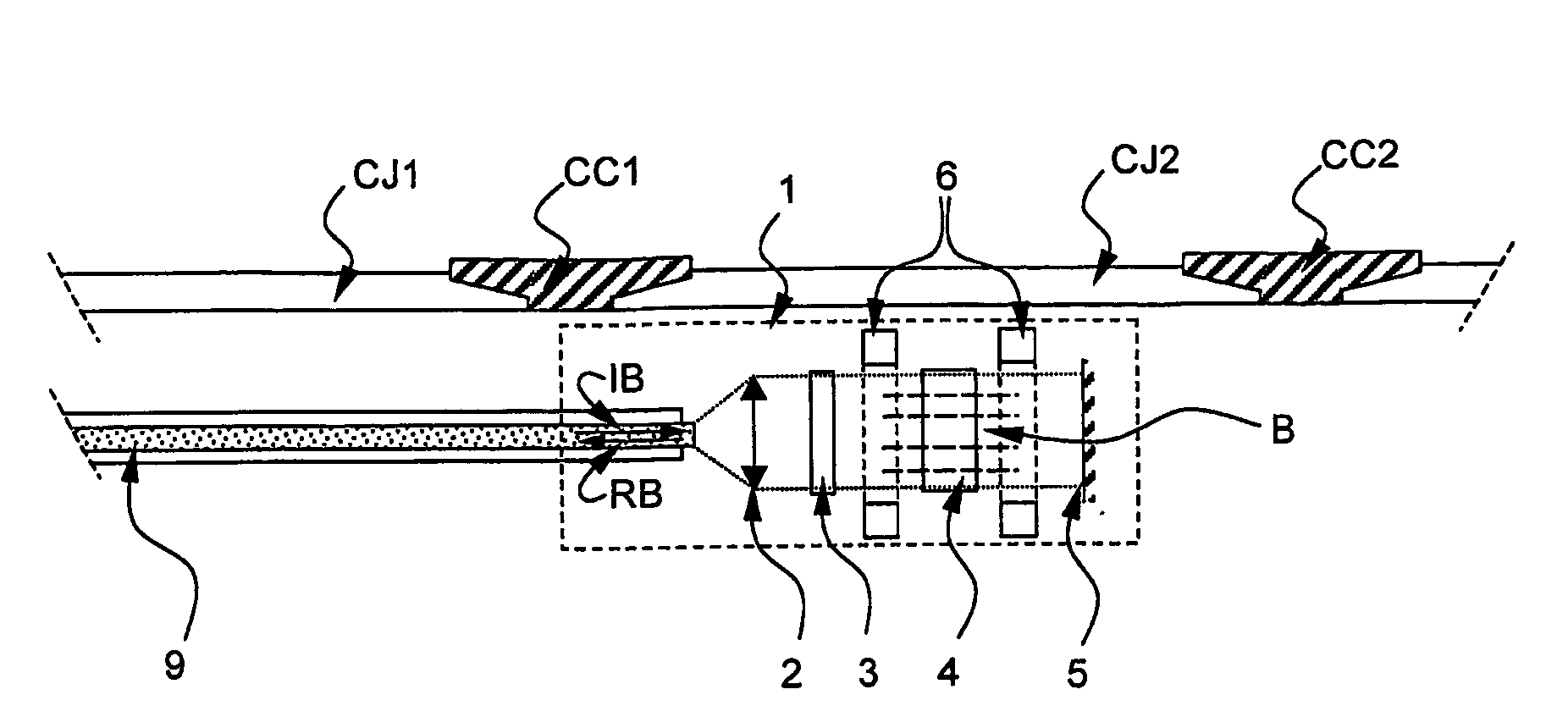

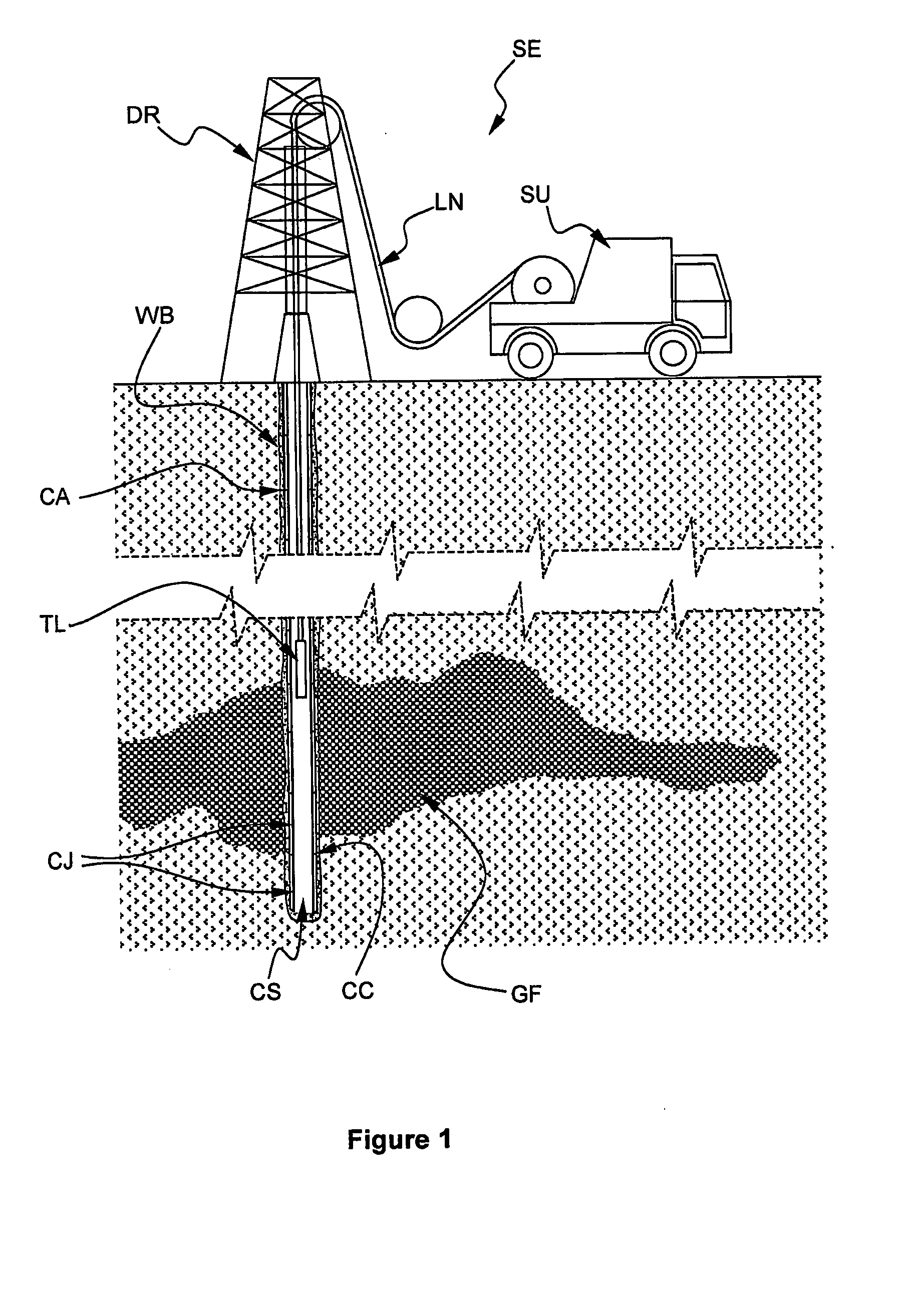

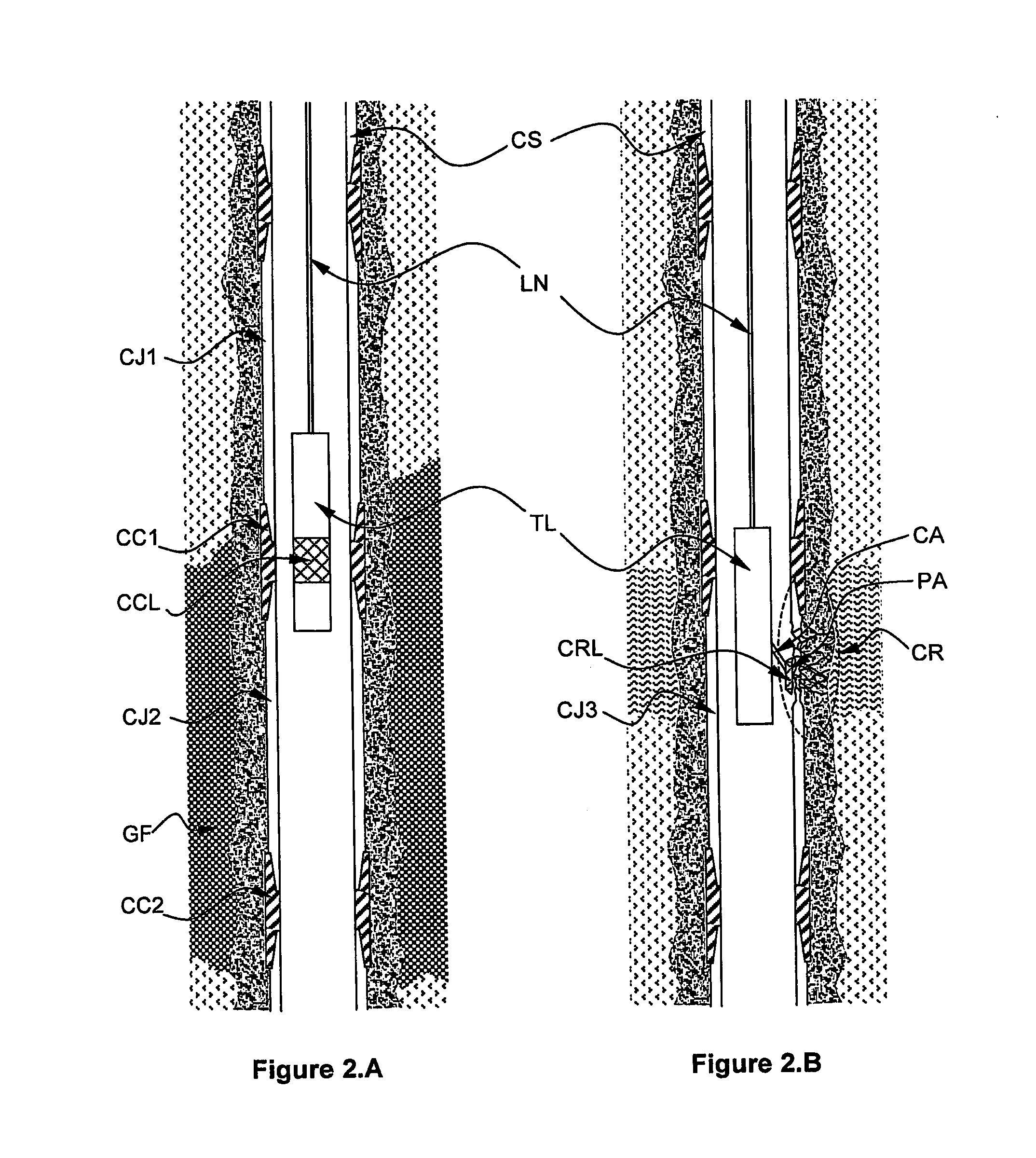

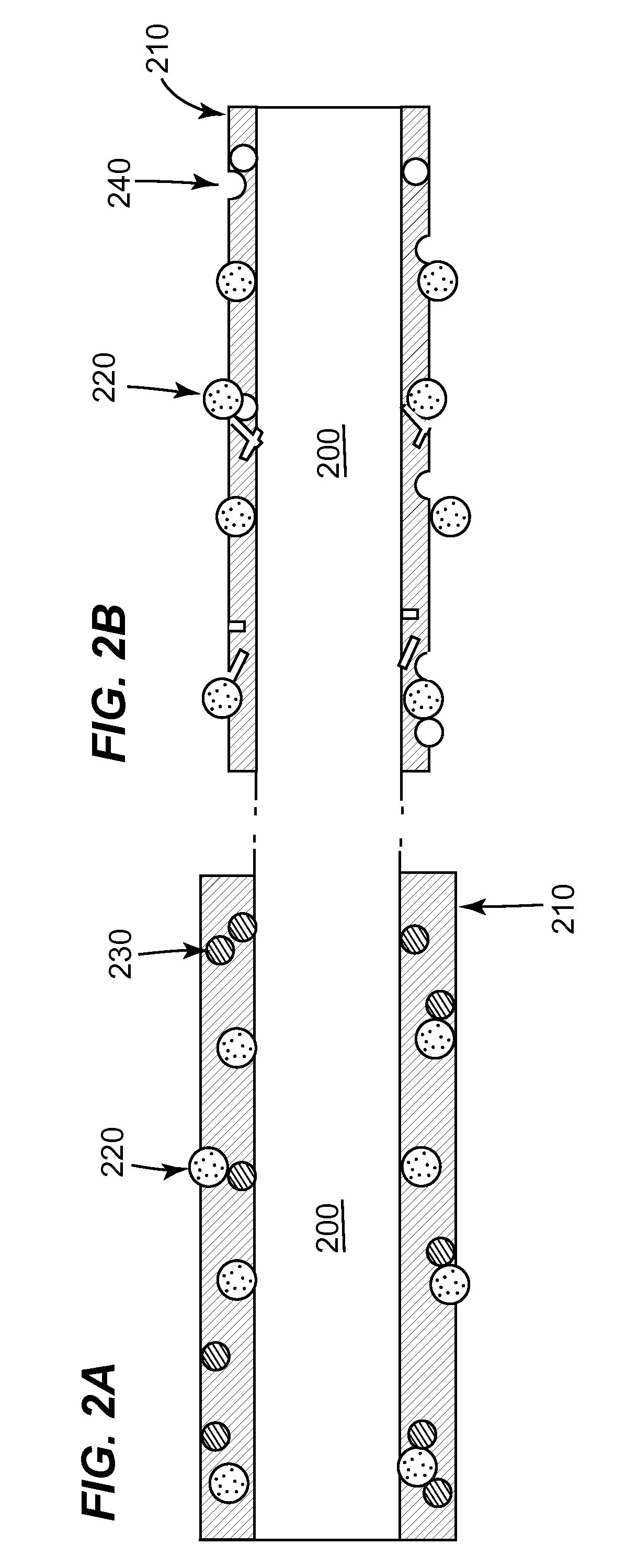

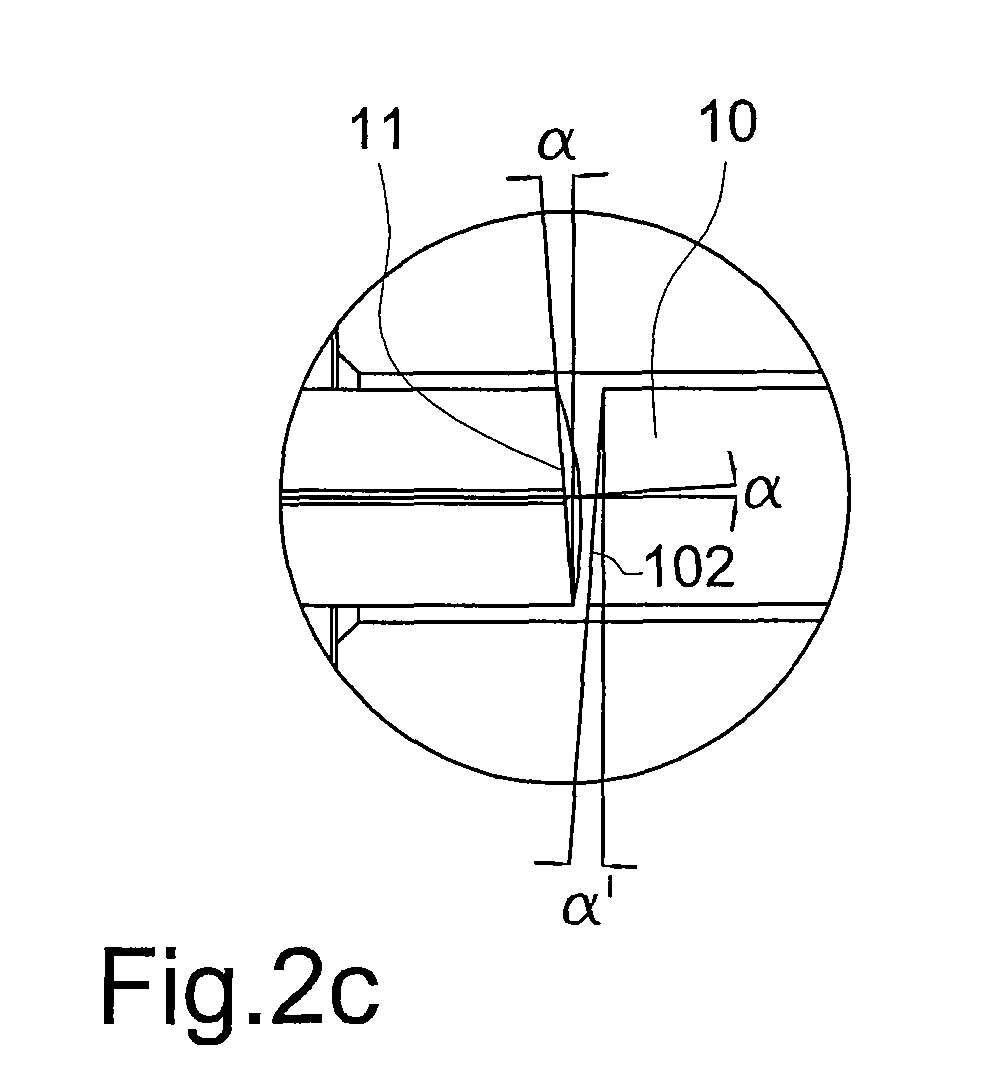

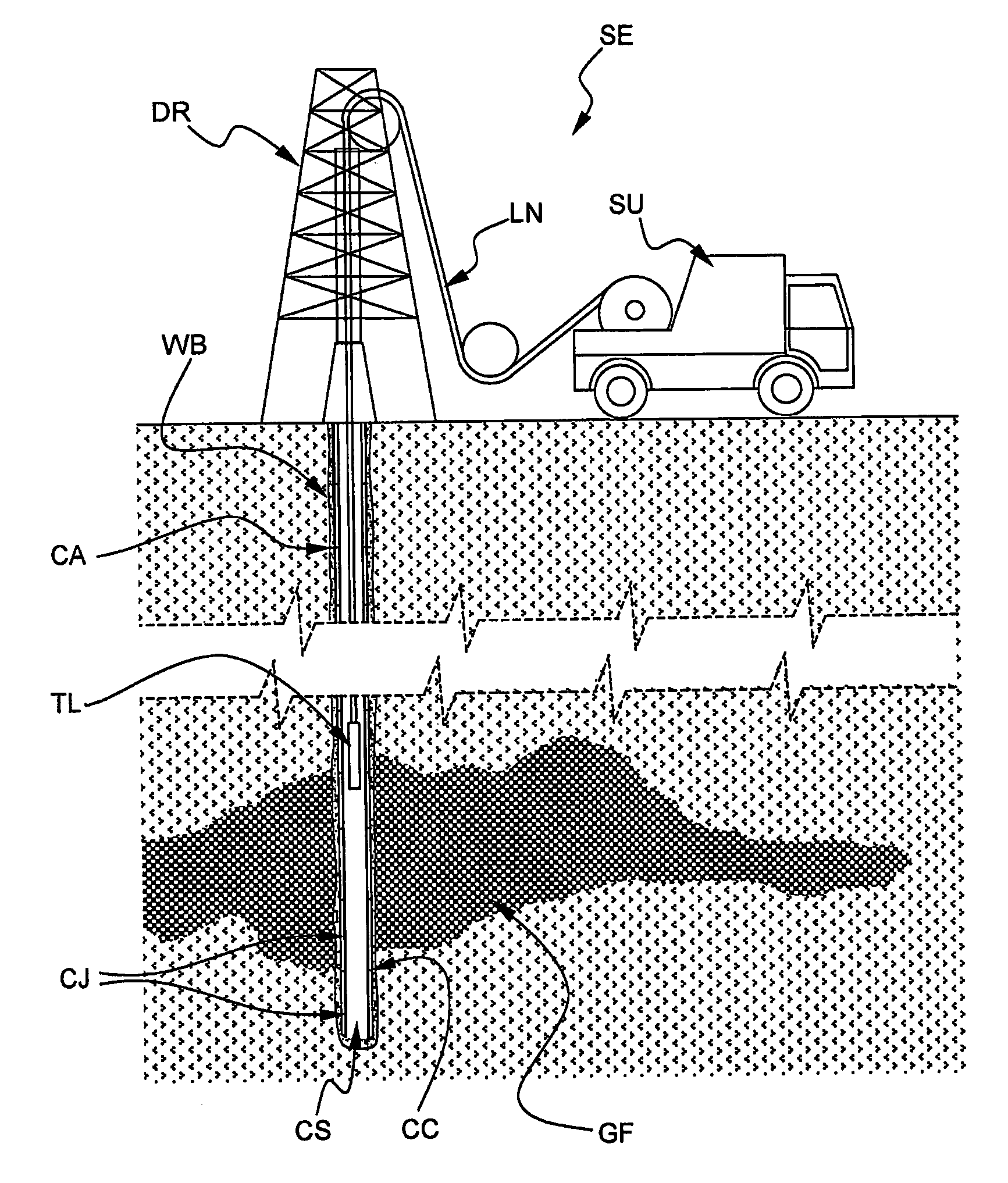

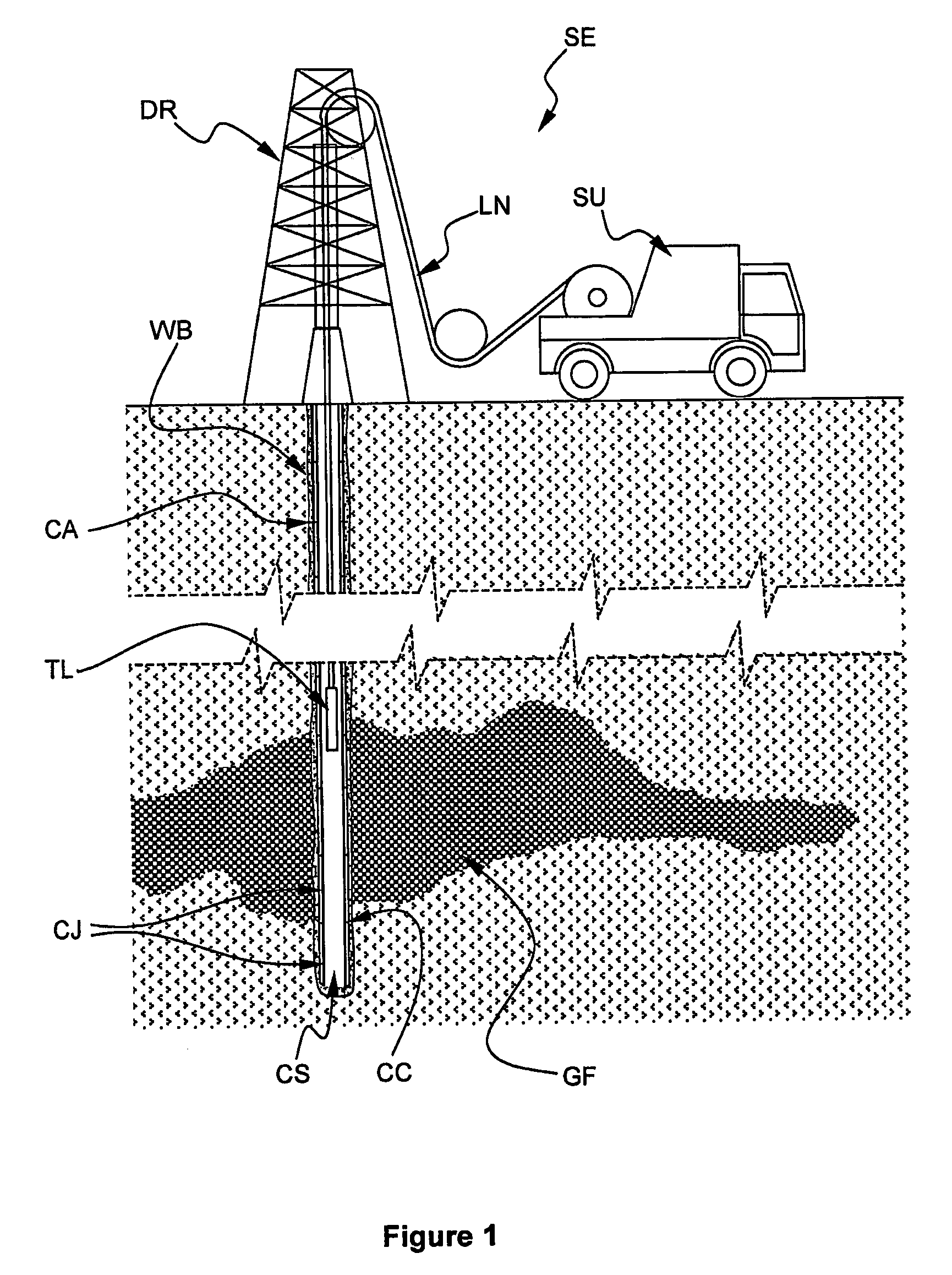

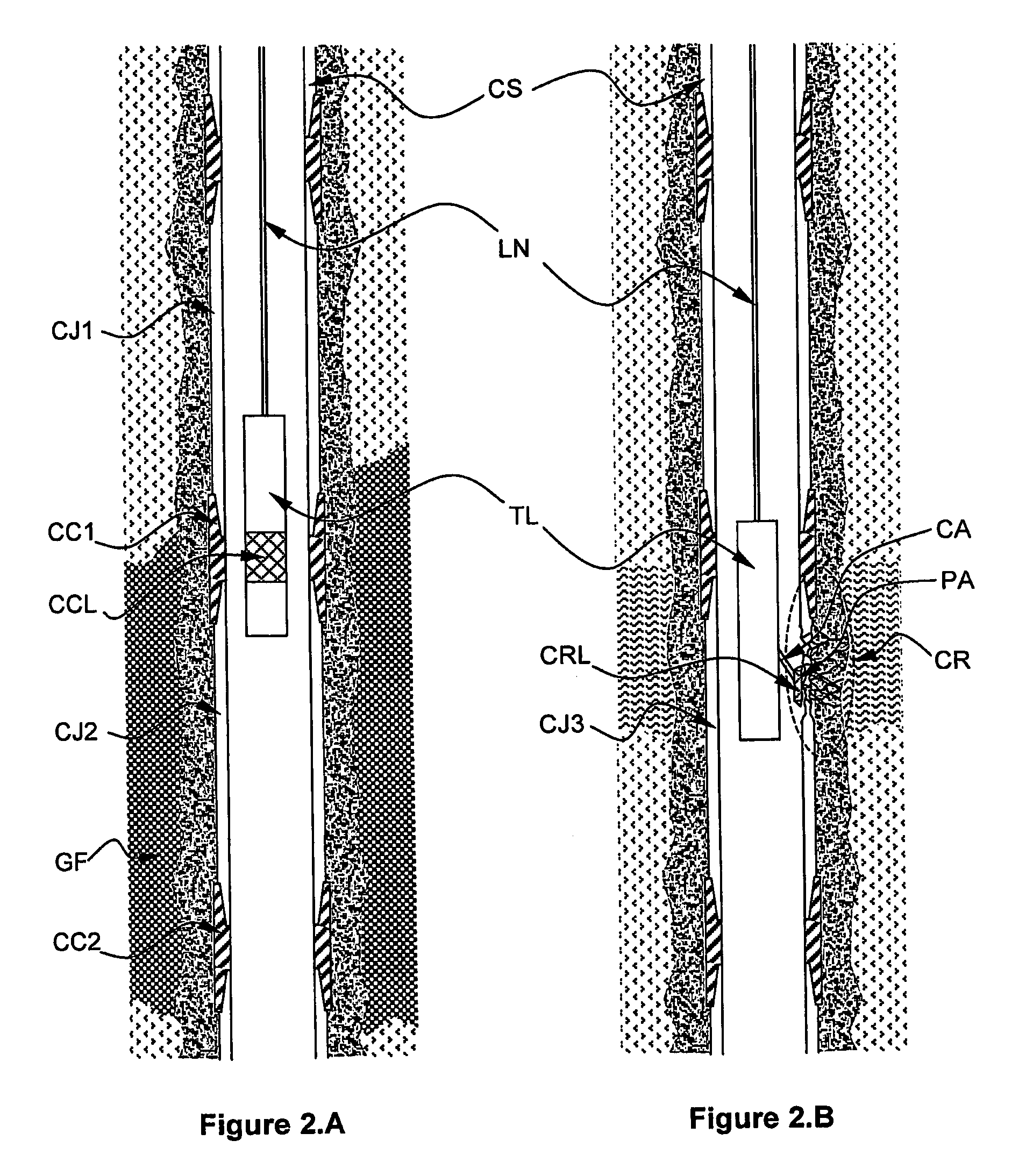

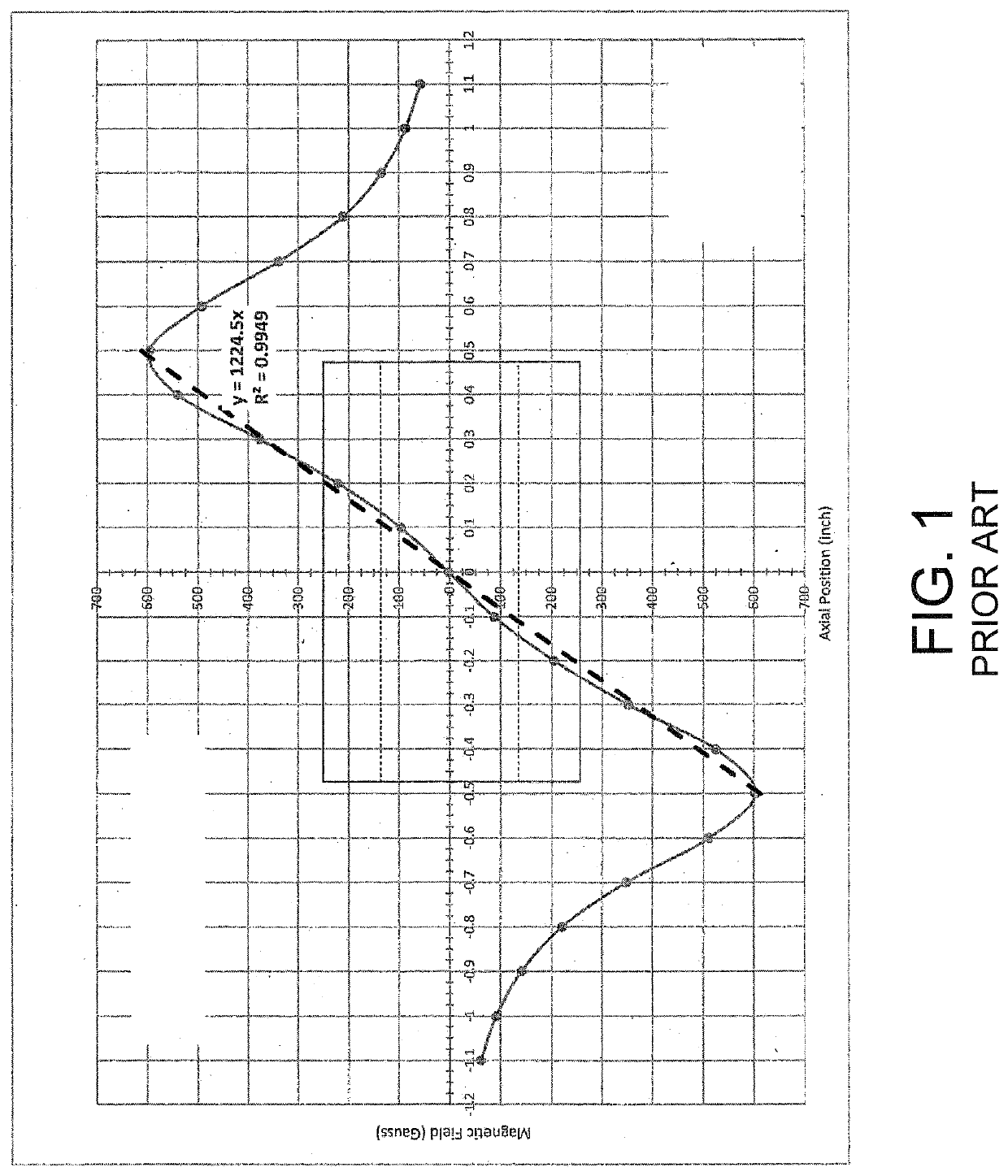

Magneto-Optical Sensor

InactiveUS20090250213A1High spatial resolutionImprove measurement sensitivitySurveyConstructionsMagnetoMagneto optical

A magneto-optic sensor for oilfield application, the sensor (1, 1′, 101, 101′) receives an incident beam IB, IBA, IBB, IBC, IBD and comprises a polarizing element (3, 103) for providing a determined state of polarization beam and a Faraday rotator (4, 104) for providing a response beam having a modified state of polarization. The sensor provides a response beam (RB, RBA, RBB, RBC, RBD having an intensity dependent on an external magnetic field representative of a particular characteristic of a well-bore casing CC, CR applied on the Faraday rotator (4, 104).

Owner:SCHLUMBERGER TECH CORP

Modular sealed portable digital electronic controller

InactiveUS20050269140A1Easy to installEasy maintenanceDigital data processing detailsCircuit arrangements on support structuresCapacitanceElectronic controller

An electronic digital controller, such as a load cell indicator, is disclosed in which a number of components, such as a circuit board, display, and keypad are placed within an enclosure, and the enclosure is bonded closed, such as using an adhesive, to render the enclosure watertight. The keypad is a touch sensitive, capacitive keypad with no moving parts, and it is housed behind a rigid panel. An optoelectronic transceiver allows for data exchange with an electronic memory device housed in the adhesively sealed enclosure and allows for data exchange and for updating or modification of software code housed therein. Other components, such as another circuit board, a power supply, and block connectors, are placed in an adjacent enclosure, and the circuit boards in the two enclosures are electrically connected. The power supply is preferably a potted AC power supply but may also include a battery.

Owner:WEIGH TECH

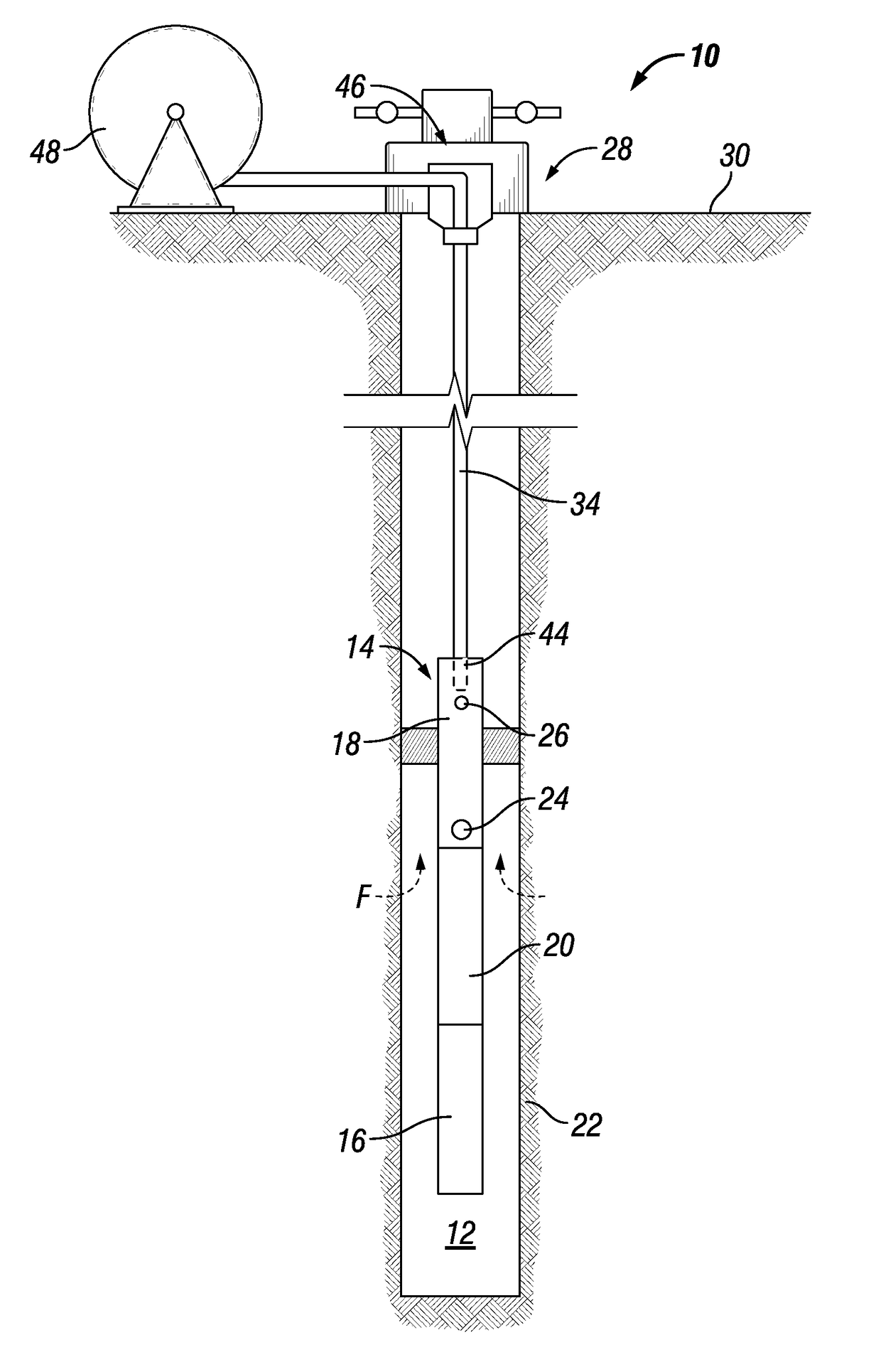

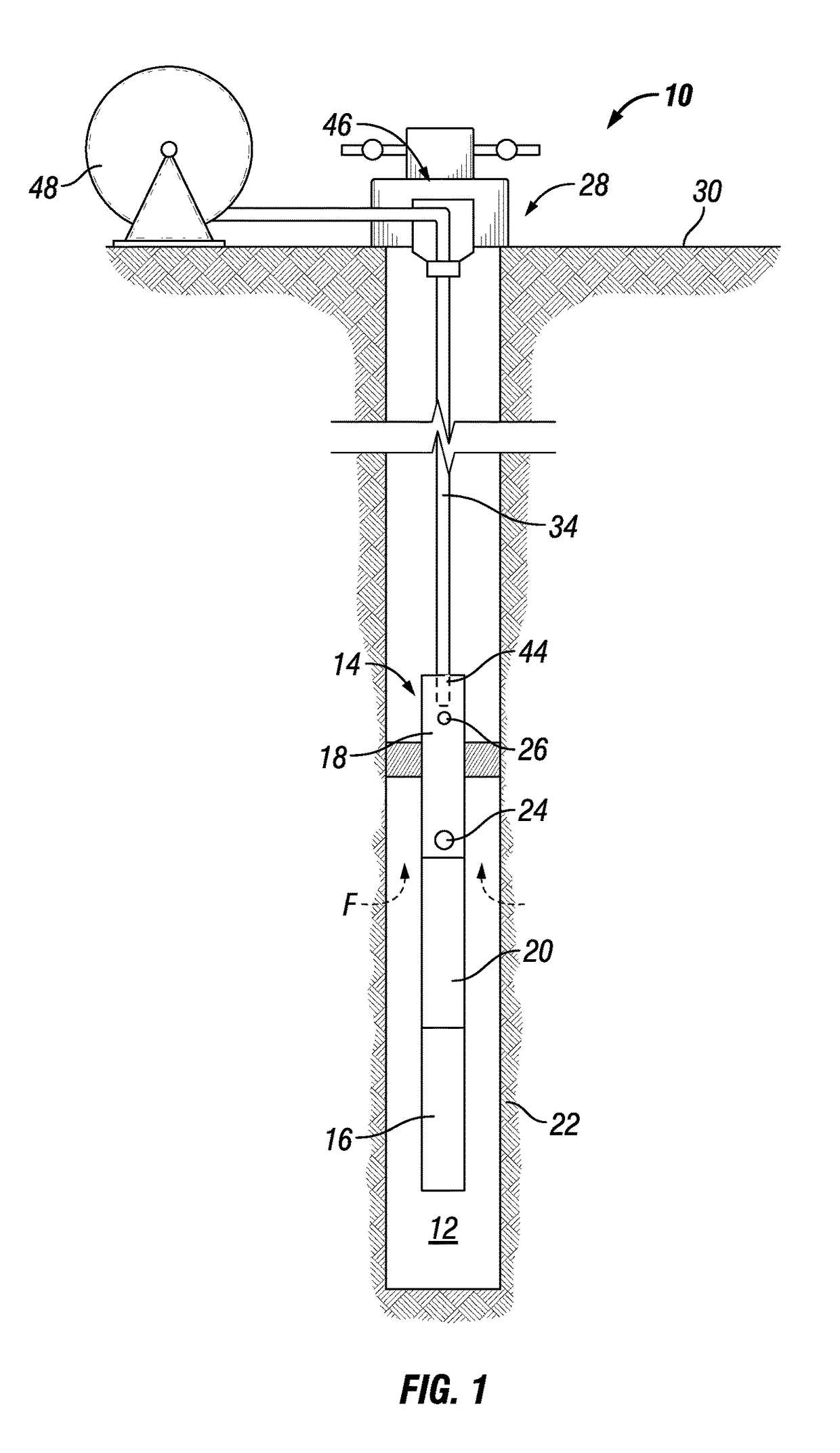

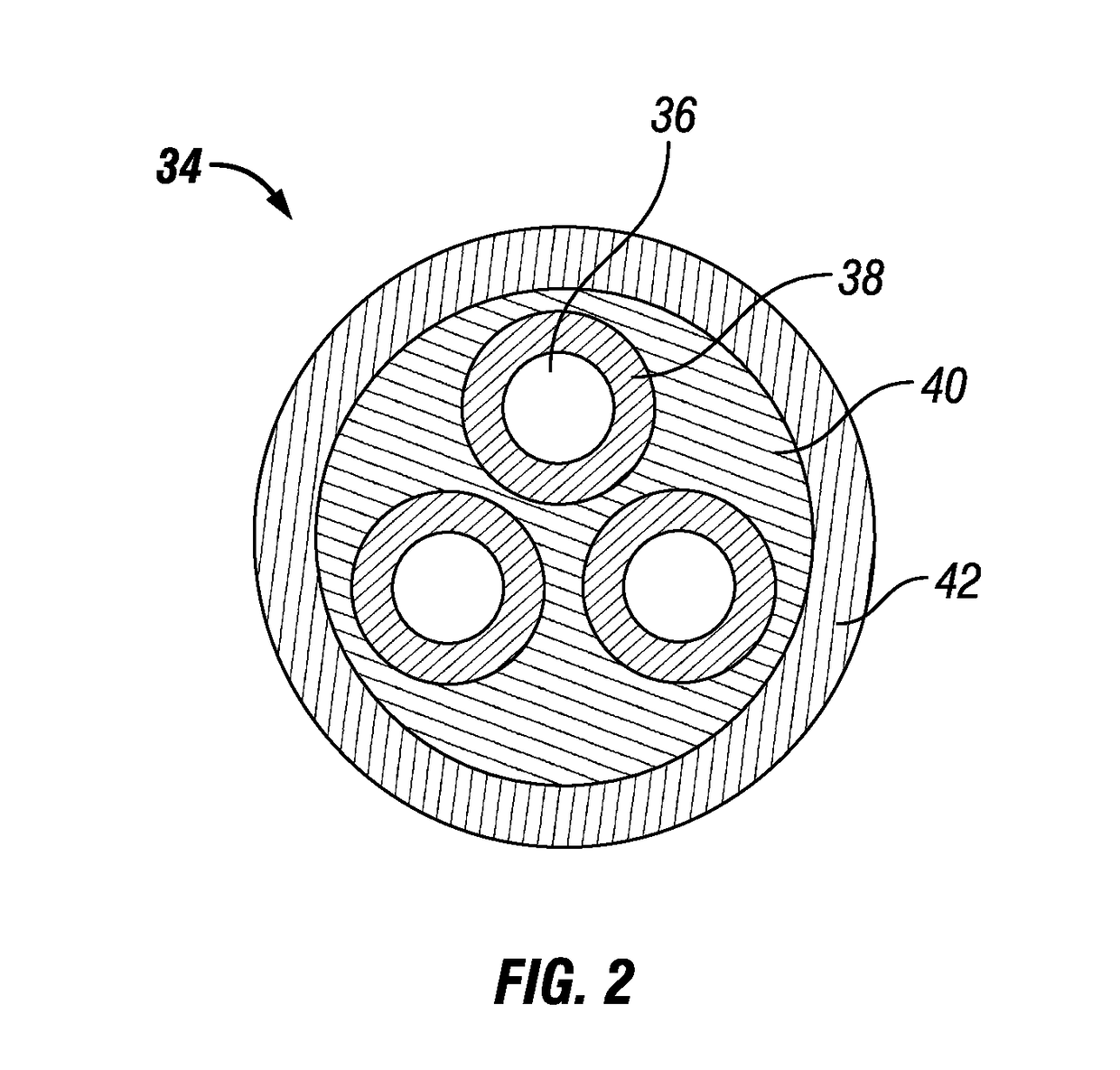

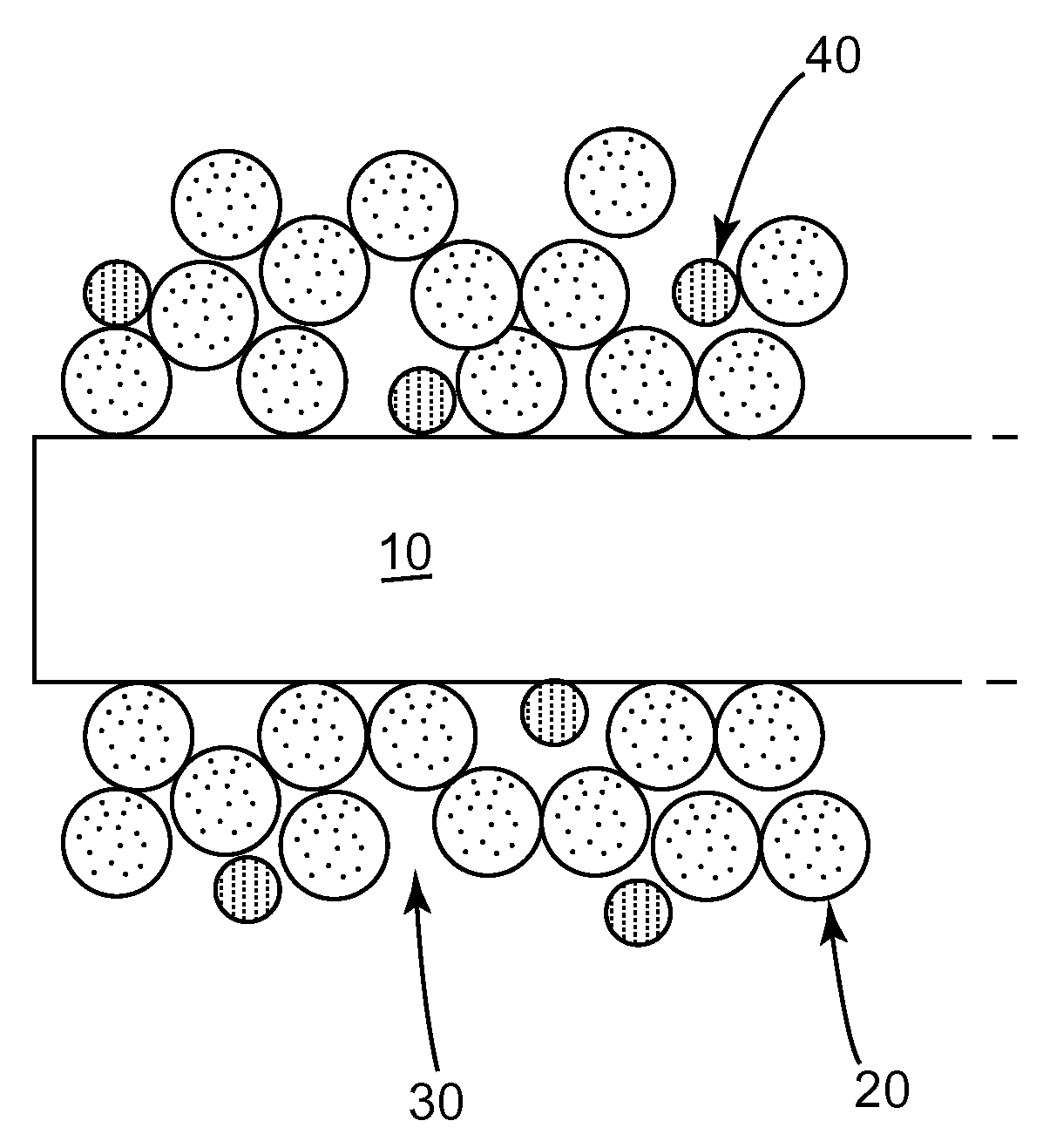

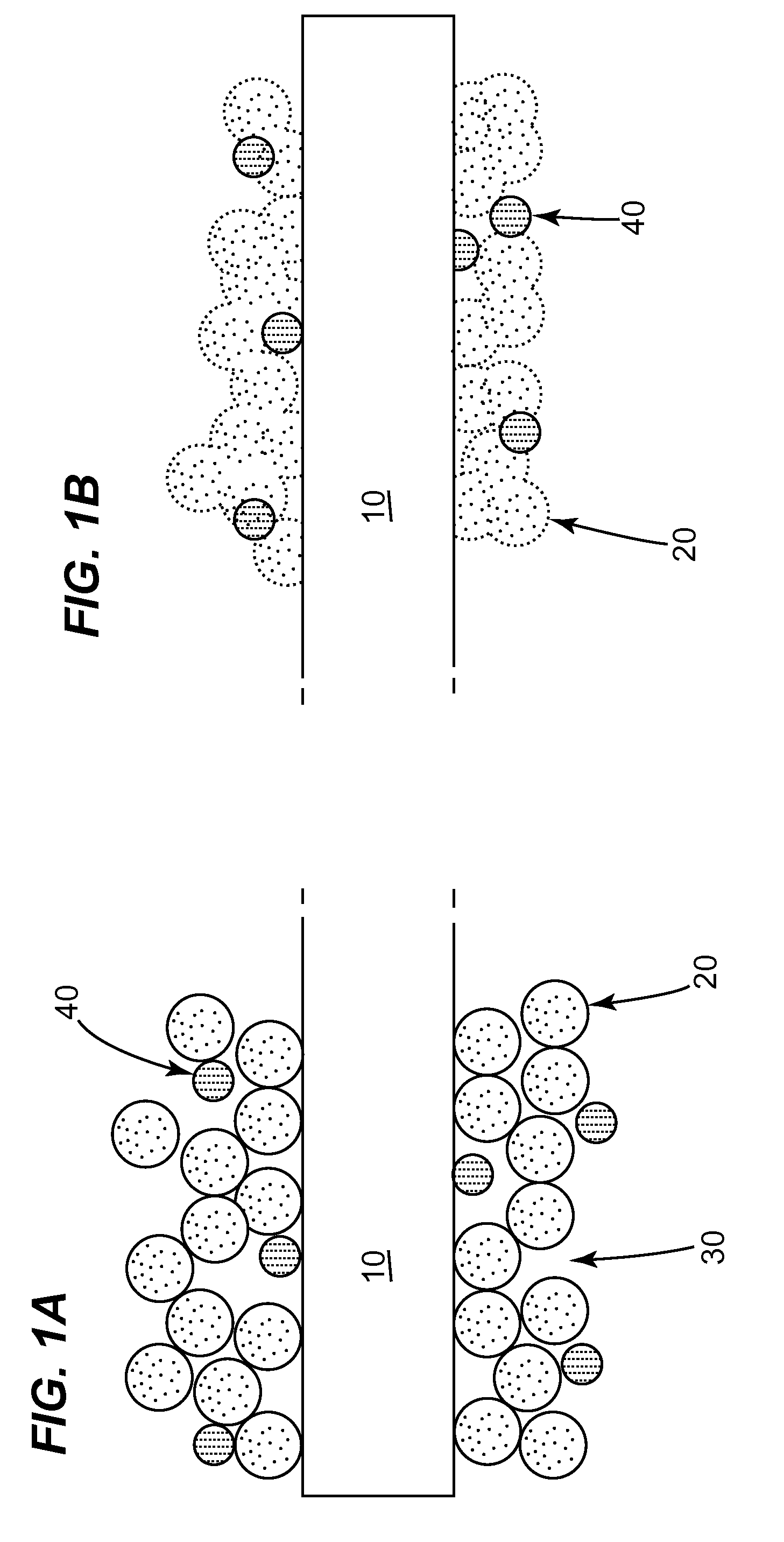

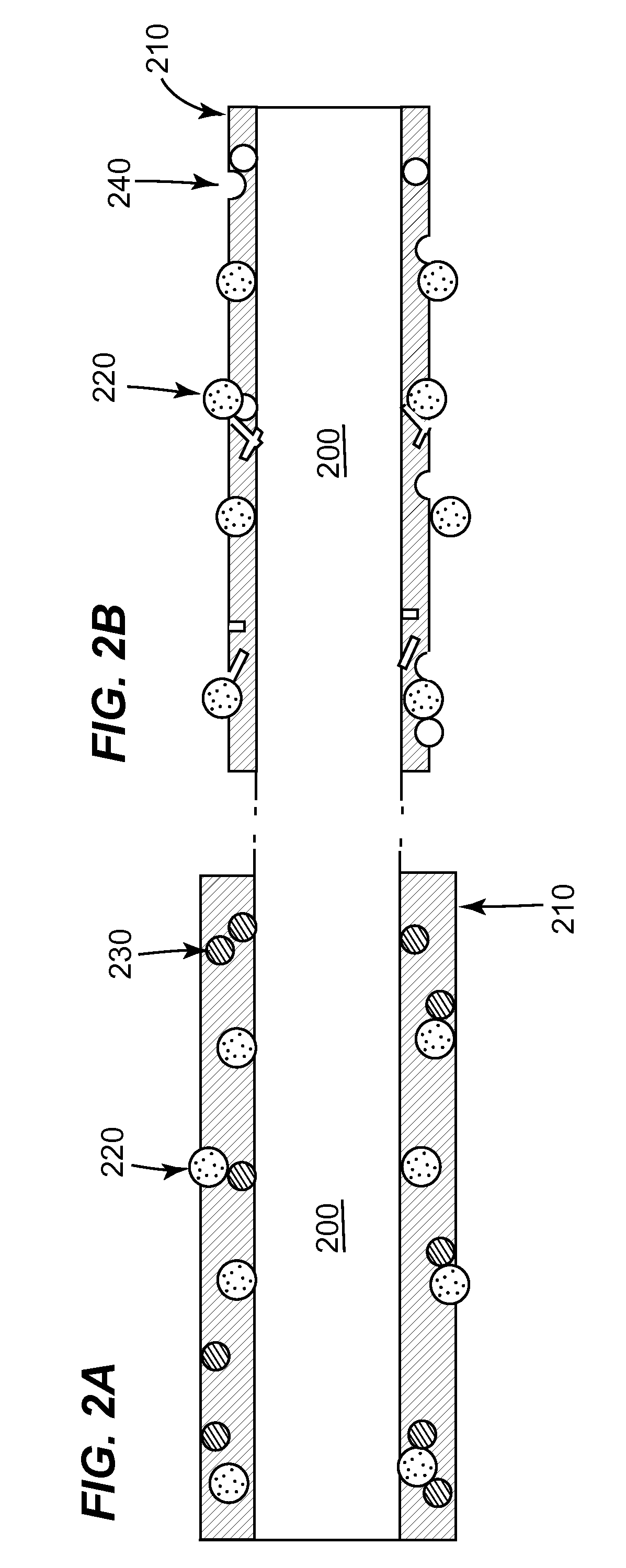

Power Cable for Use with Artificial Lift Systems

InactiveUS20170330647A1High strengthMaintain electrical integrityDrilling rodsFluid removalFiberPower cable

A method for providing power to an artificial lift system includes providing at least two conductors, each conductor being an insulated conductor having insulating material surrounding such conductor. The at least two conductors are surrounded with a composite fiber jacket to form a power cable, the composite fiber jacket being an outermost member of the power cable and having a substantially smooth exterior surface. The power cable is connected to the artificial lift system such that a load of the artificial lift system is transferred to the composite fiber jacket of the power cable.

Owner:SAUDI ARABIAN OIL CO

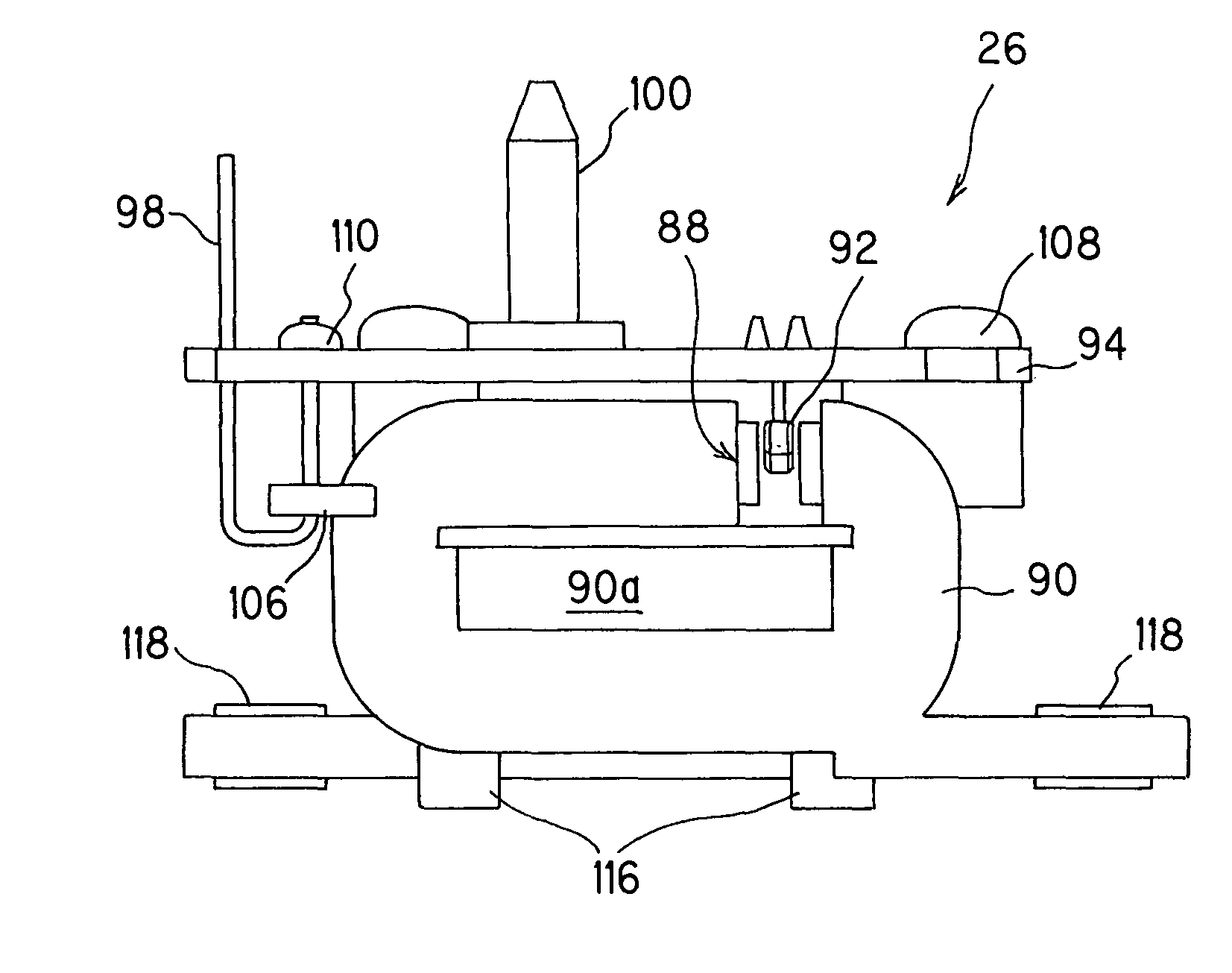

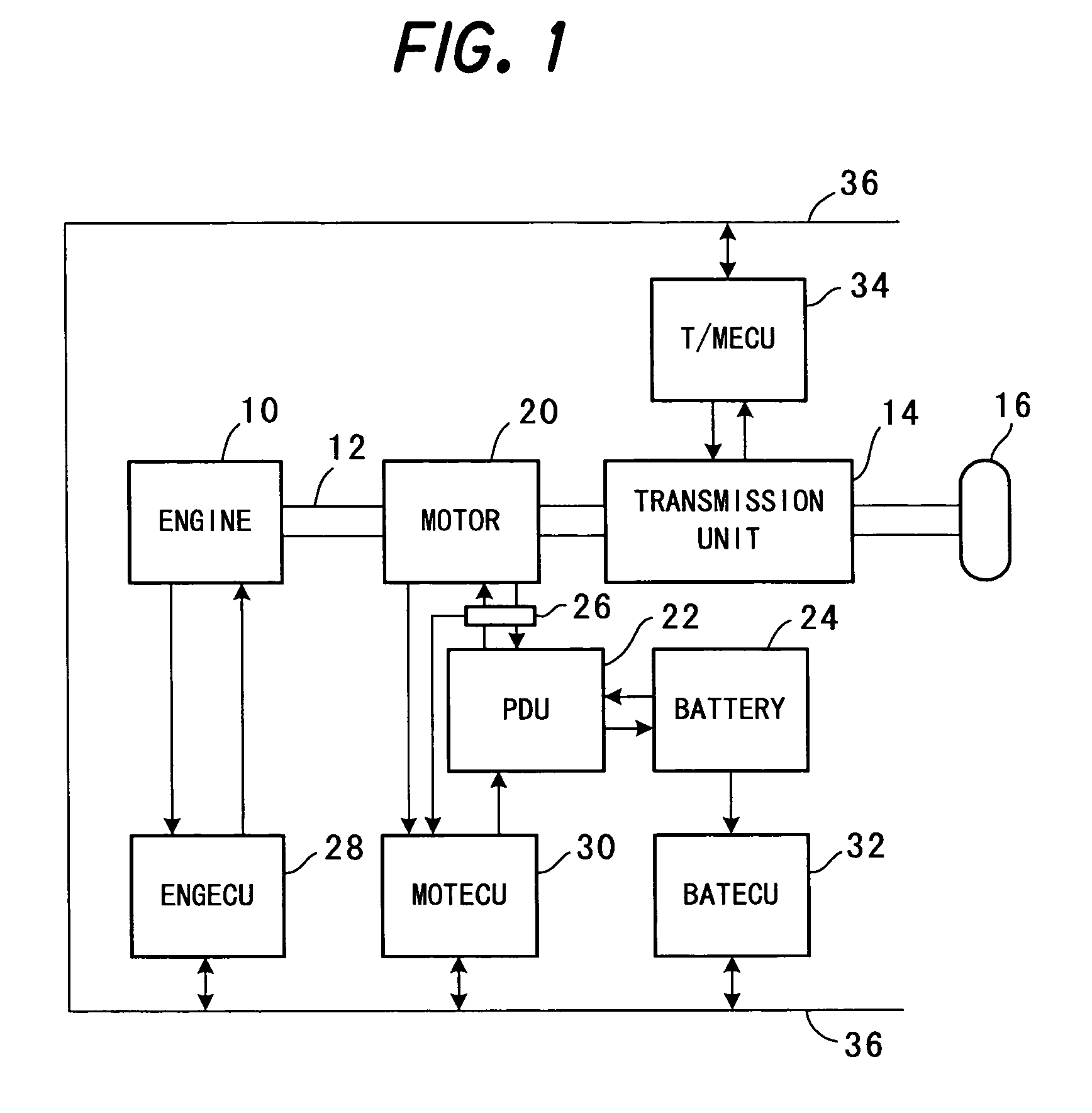

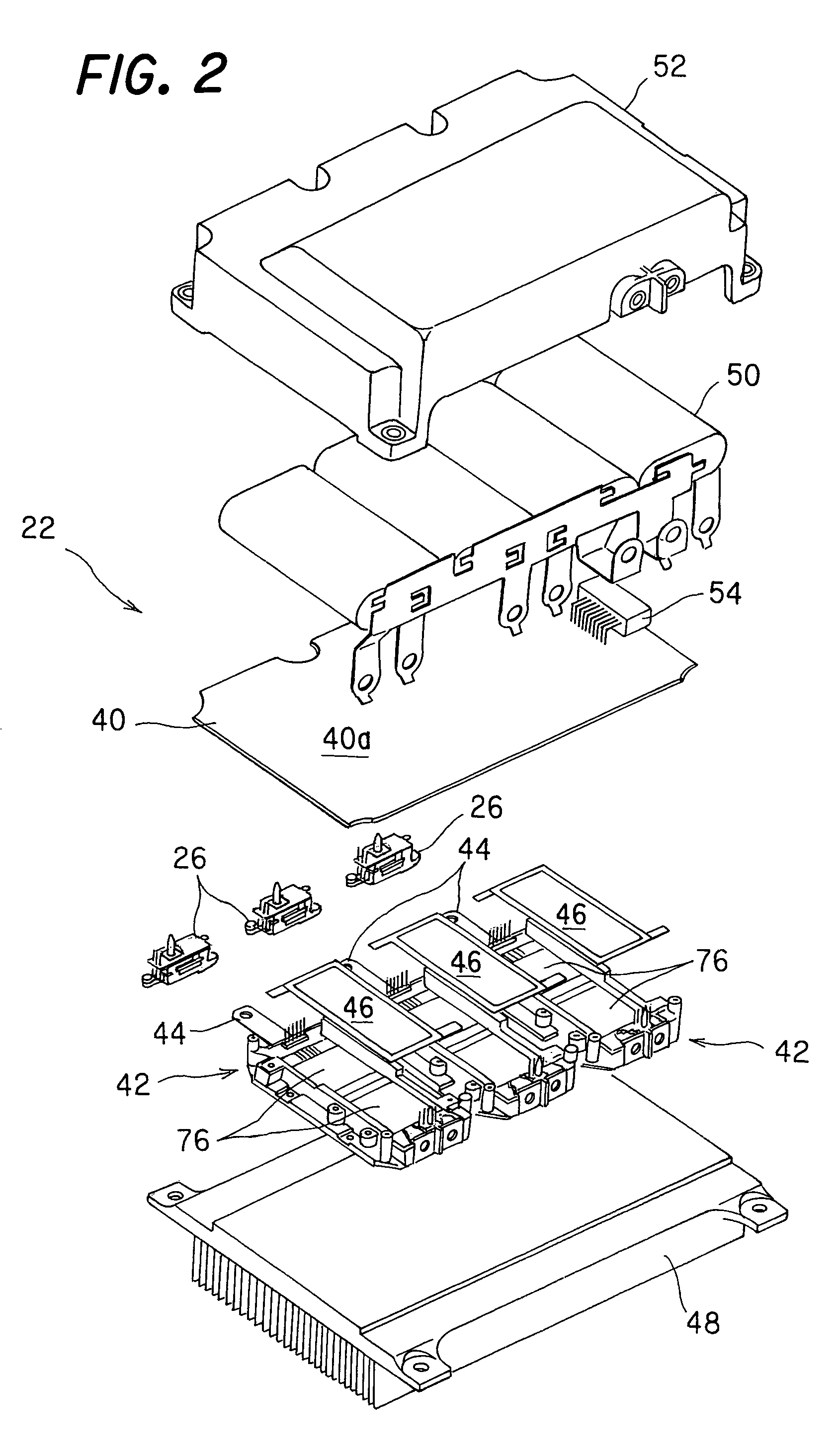

Power drive unit

InactiveUS7835156B2Minimized in sizeRelieve pressureElectrically conductive connectionsPrinted circuit board receptaclesCurrent sensorControl circuit

In a power drive unit having power modules (three-phase inverter circuits) connected to a control circuit board, bus bars extending from the power modules and a current sensor each installed near the bus bars and including a sensing element that detects currents outputted from the bus bars, there are provided a sensor board on which the sensing element is mounted, and lead pins each connecting the sensor board to the control circuit board and having a bowed shape whose one end is connected to the sensor board and other end once extends away from the circuit board and then turns back toward the circuit board. With this, the circuit board and current sensors can be connected through the lead pins without increasing the distance therebetween and stress produced in the lead pins can be alleviated, thereby enabling the unit to be minimized in size and utilized in a harsh service environment.

Owner:KEIHIN CORP +1

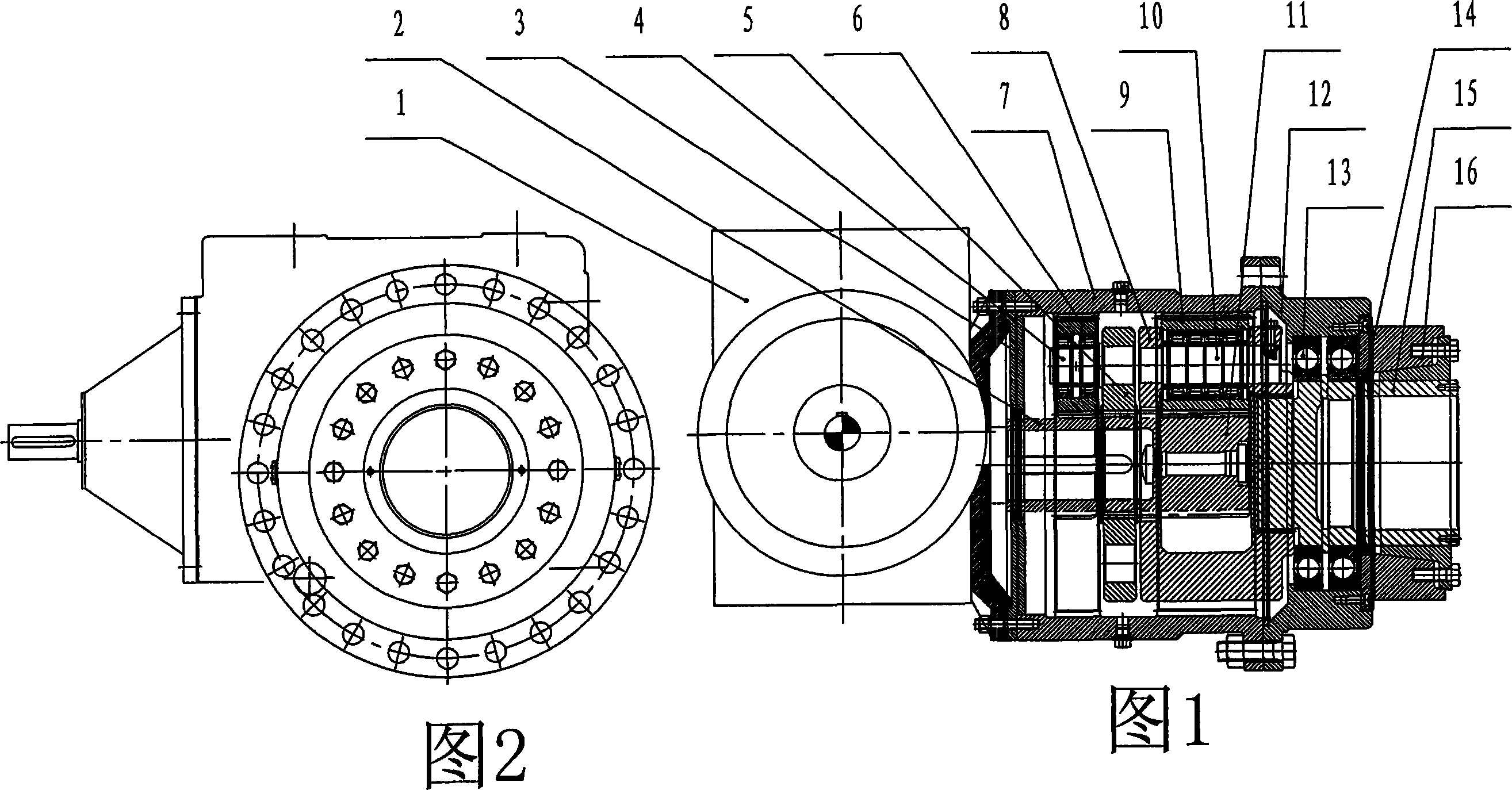

Planetary speed reducer specially for roller way

The planetary speed reducer specially for roller way includes flange, cabinet, the first and the second sun gears, the first and the second planet carriers, planet gears and hollow output shaft. The first and the second sun gears, the planet carrier and the hollow output shaft are coaxial; the first sun gear is connected to the output shaft of the speed reducer; the first planet carrier is connected to the second sun gear, and the second planet carrier is connected to the output shaft of the speed reducer; there are at least two planet gears around each of the first and the second planet carriers; and the first planet gears and the second planet gears are meshed to corresponding ring gear and sun gear.

Owner:NINGBO DONLY CO LTD

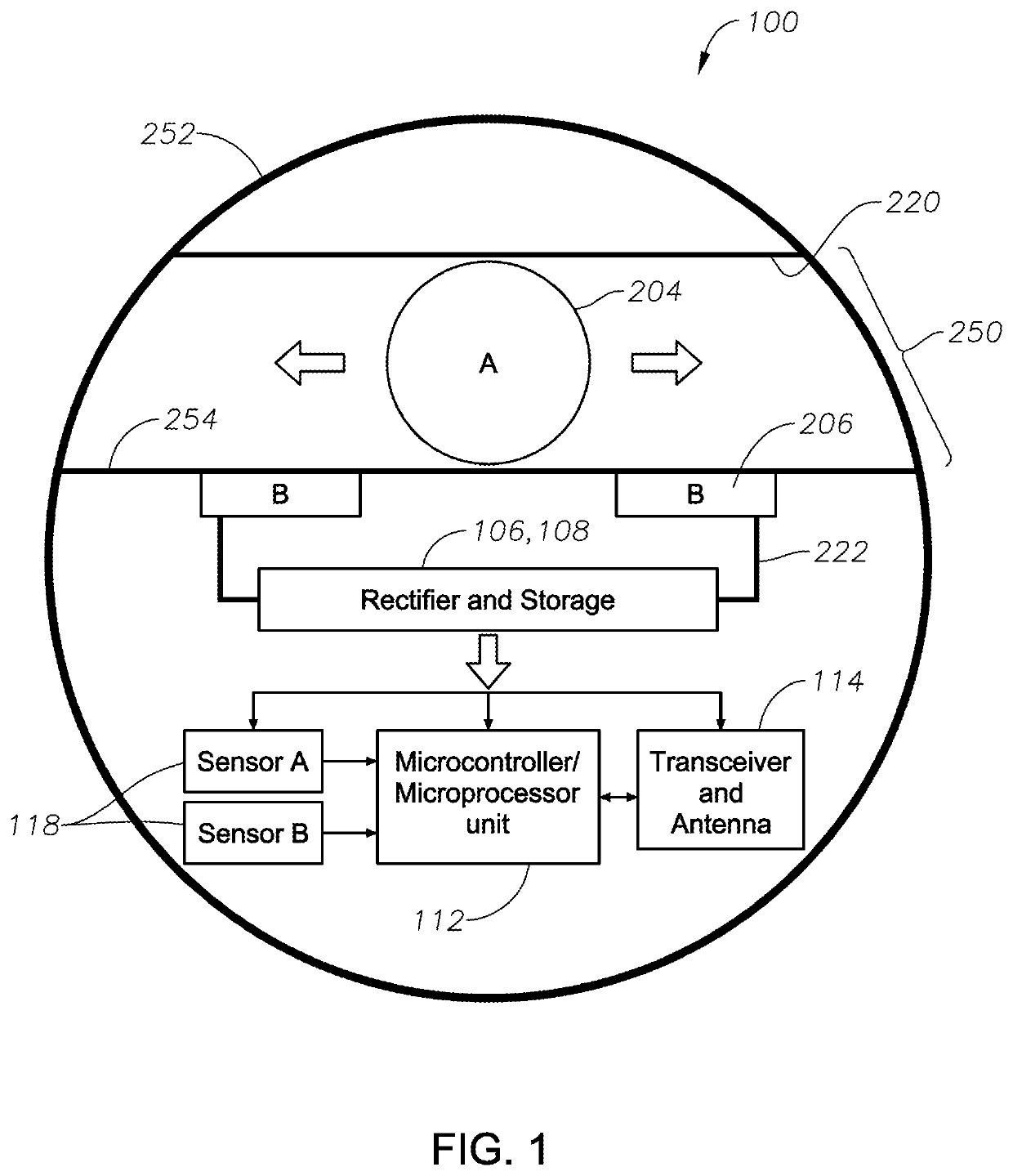

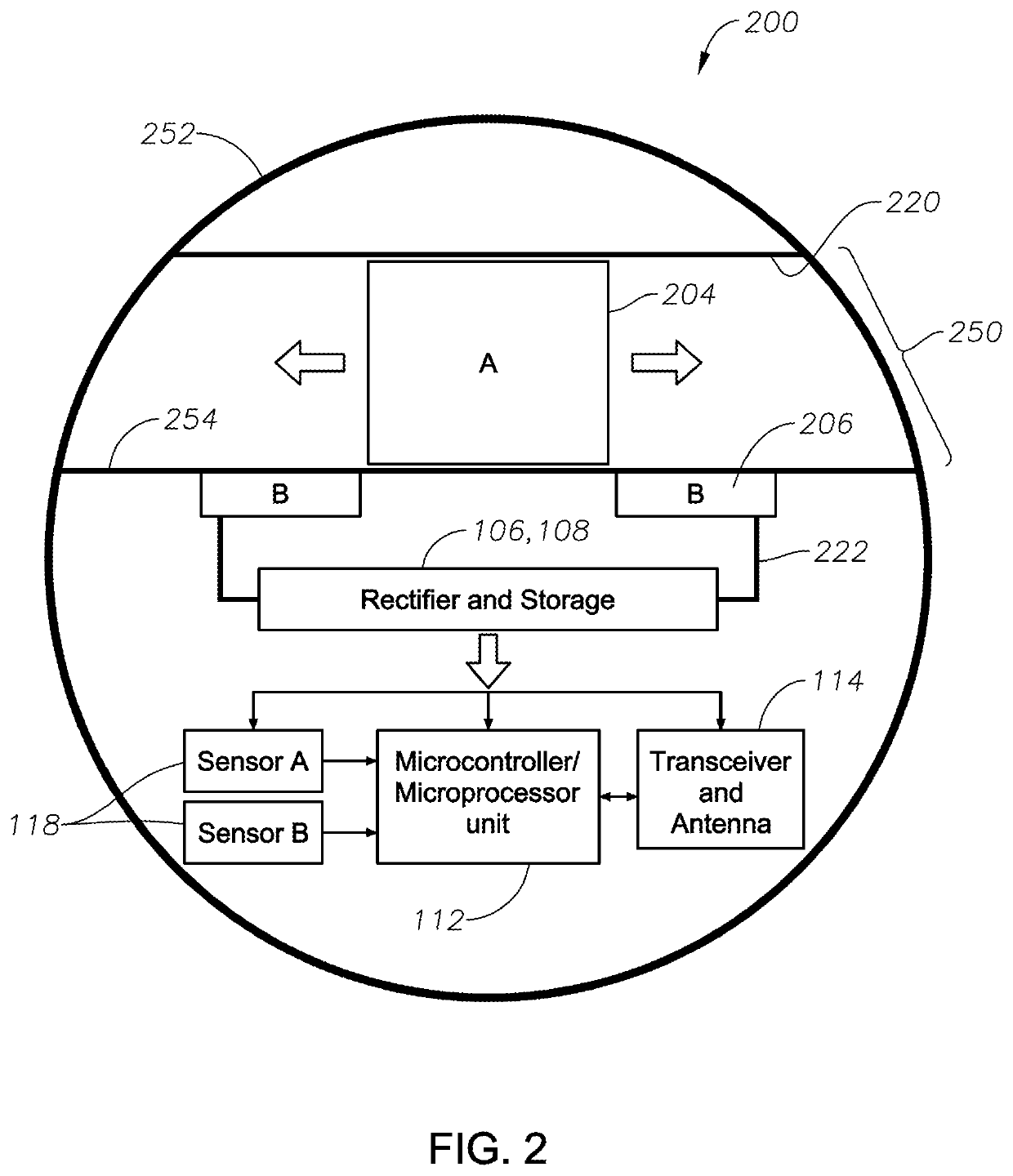

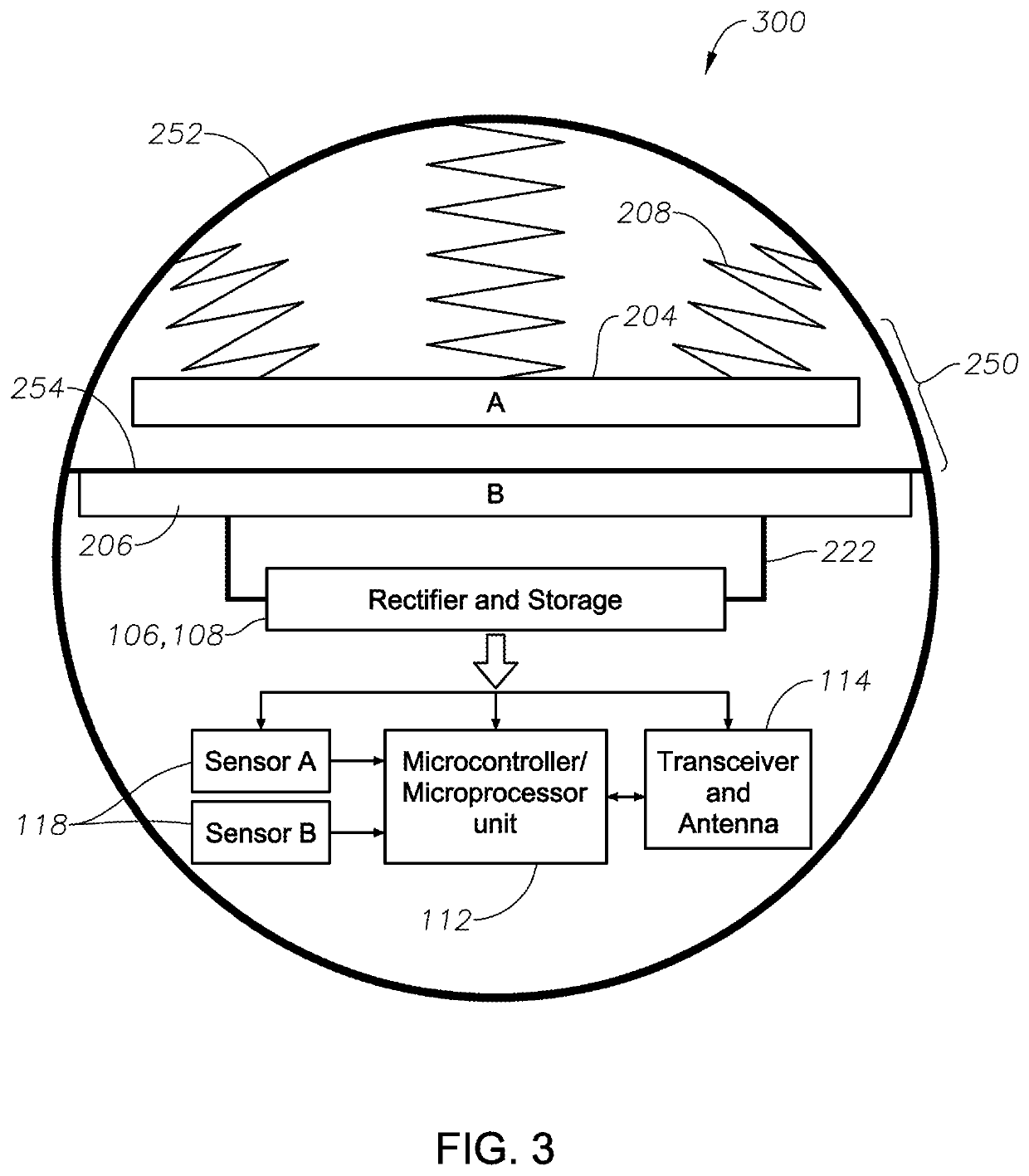

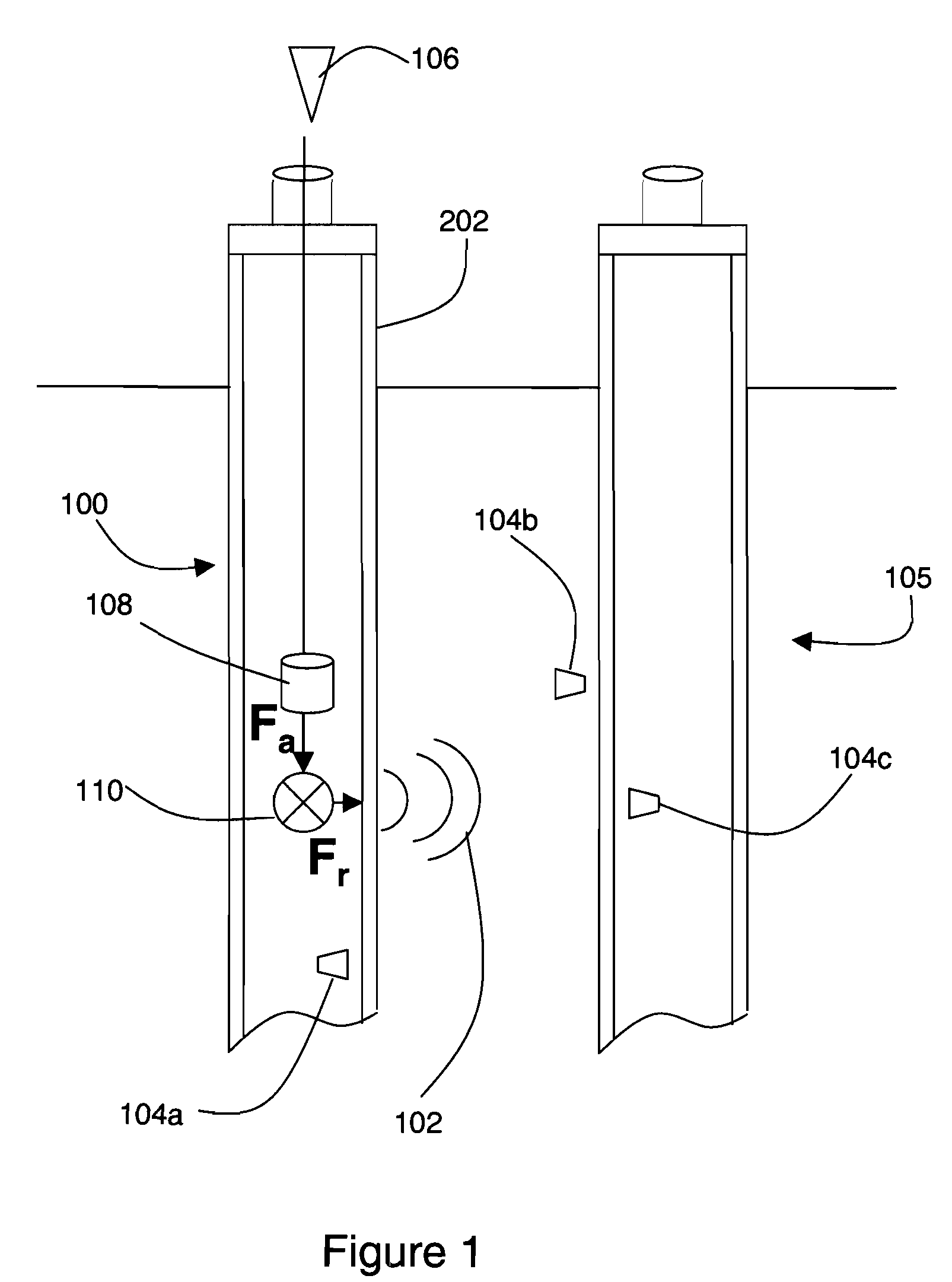

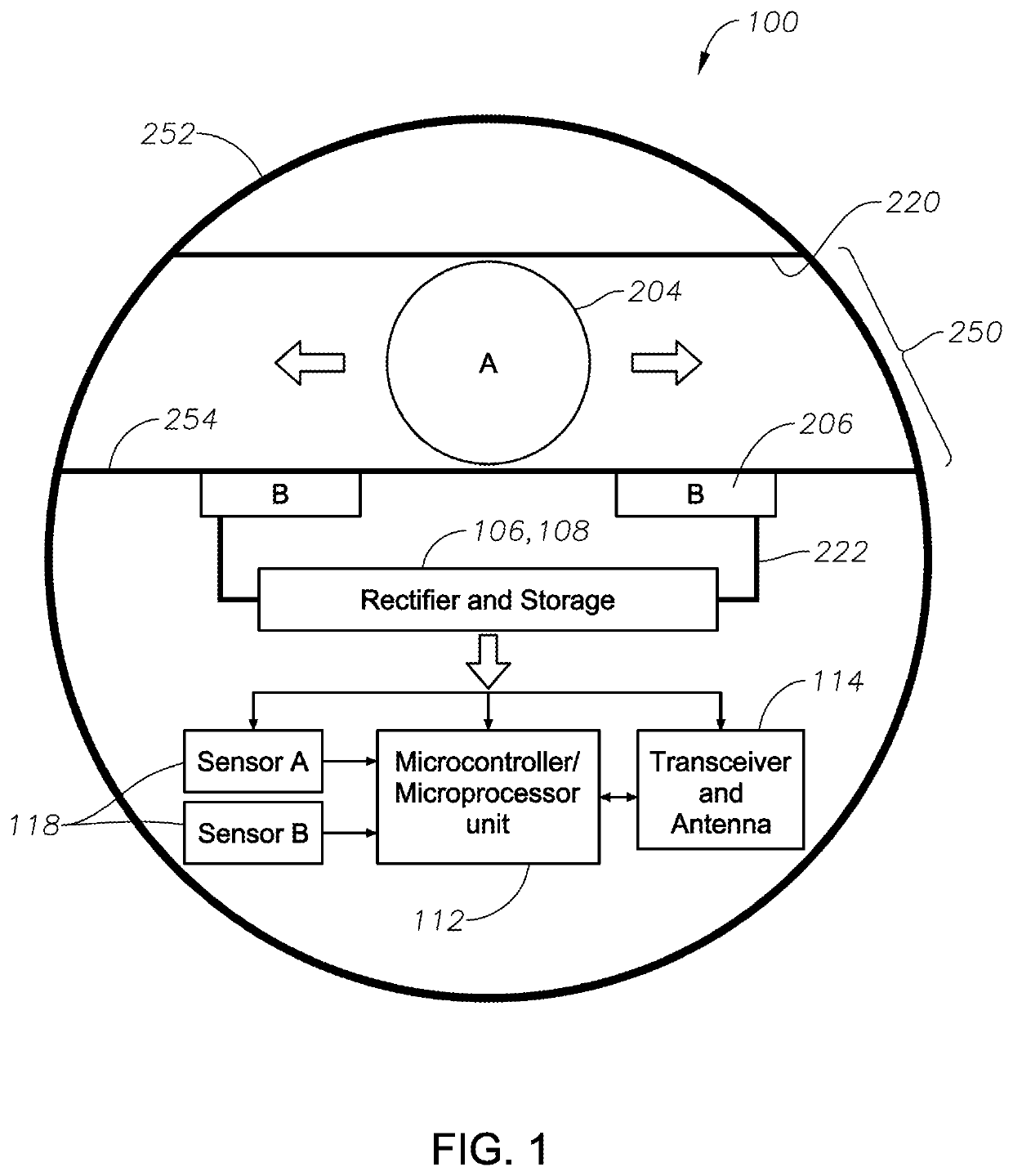

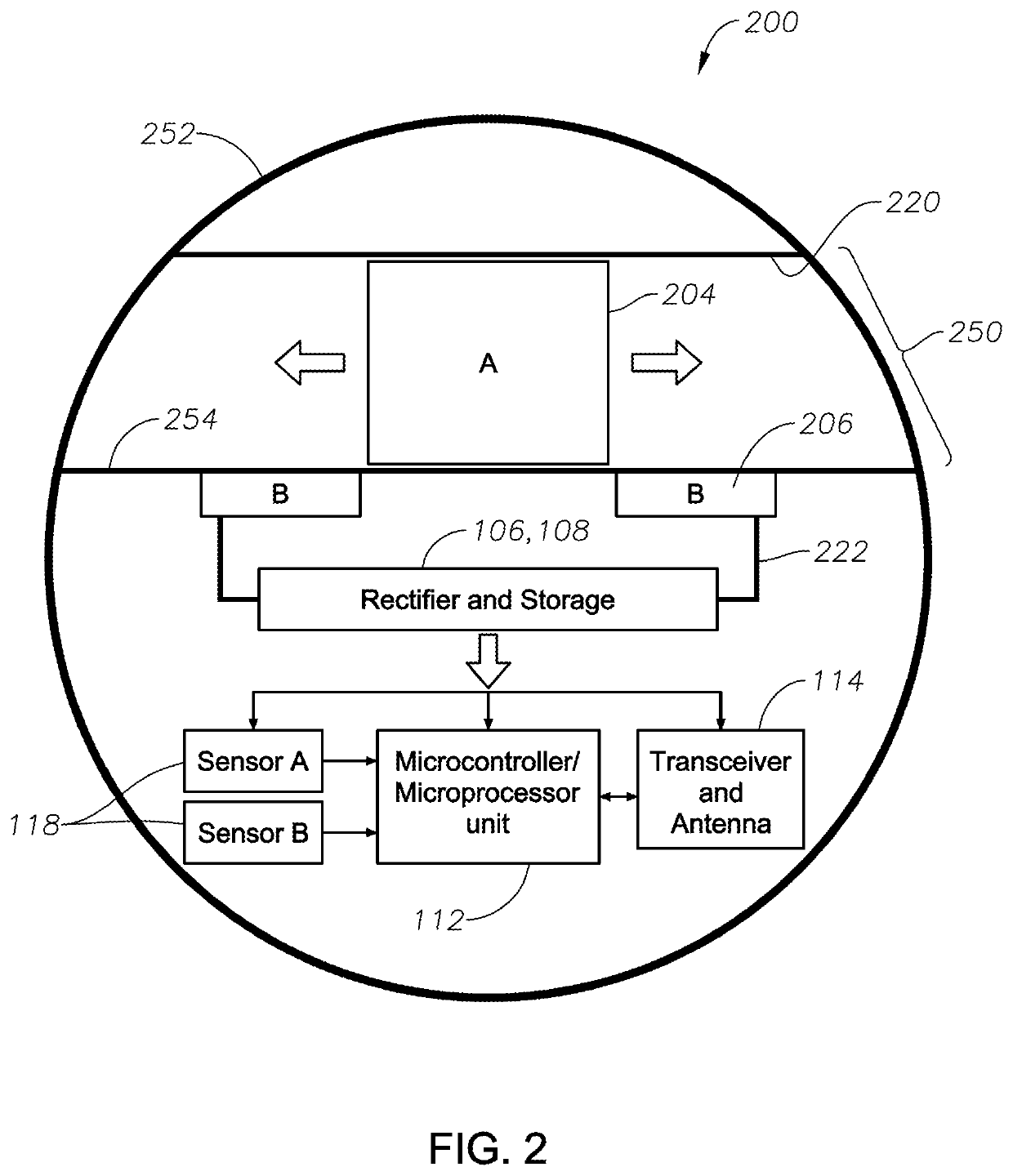

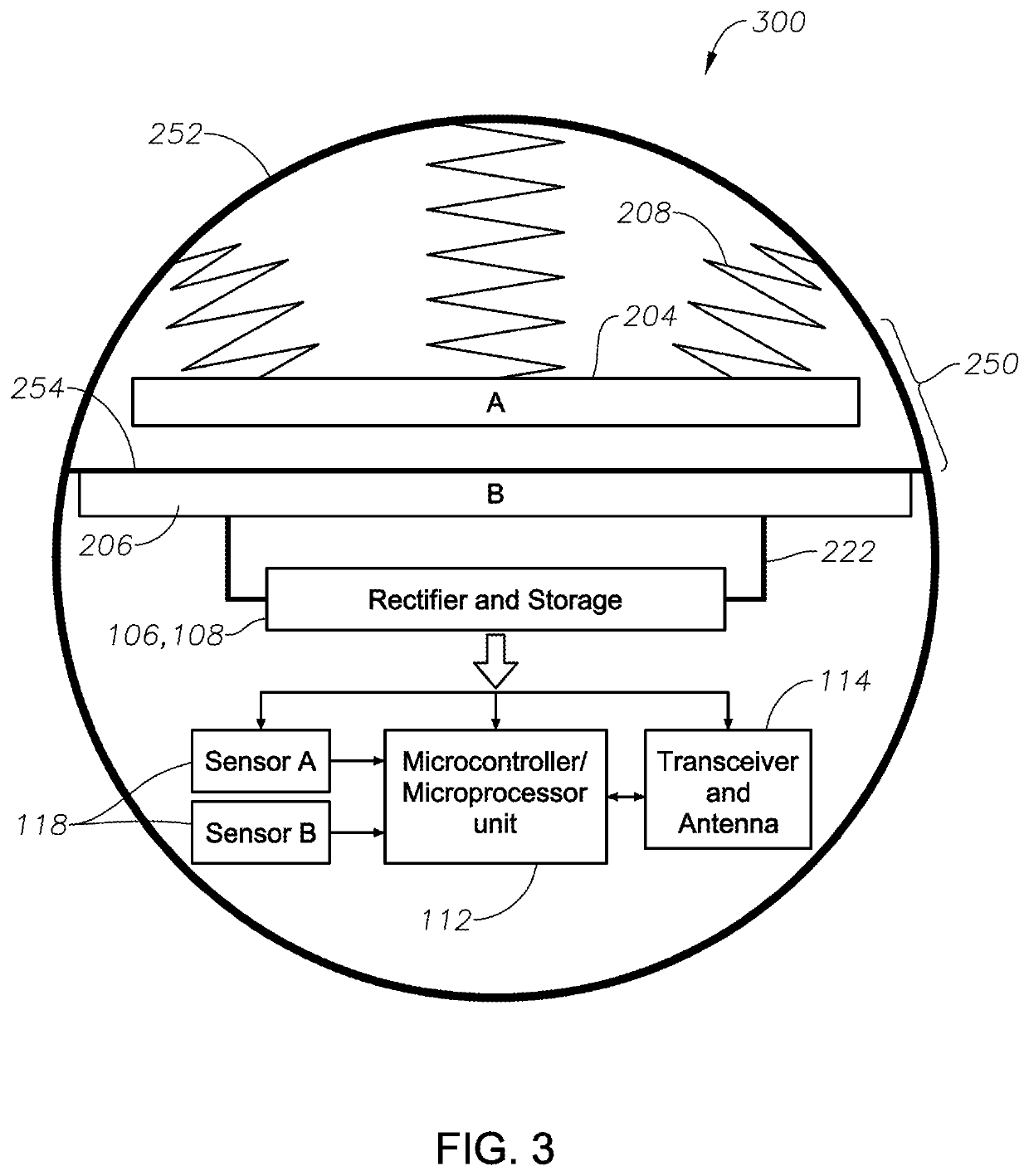

Self-Powered Miniature Mobile Sensing Device

ActiveUS20200165905A1Less power to operateLess powerSurveyConstructionsEngineeringMechanical engineering

Owner:SAUDI ARABIAN OIL CO

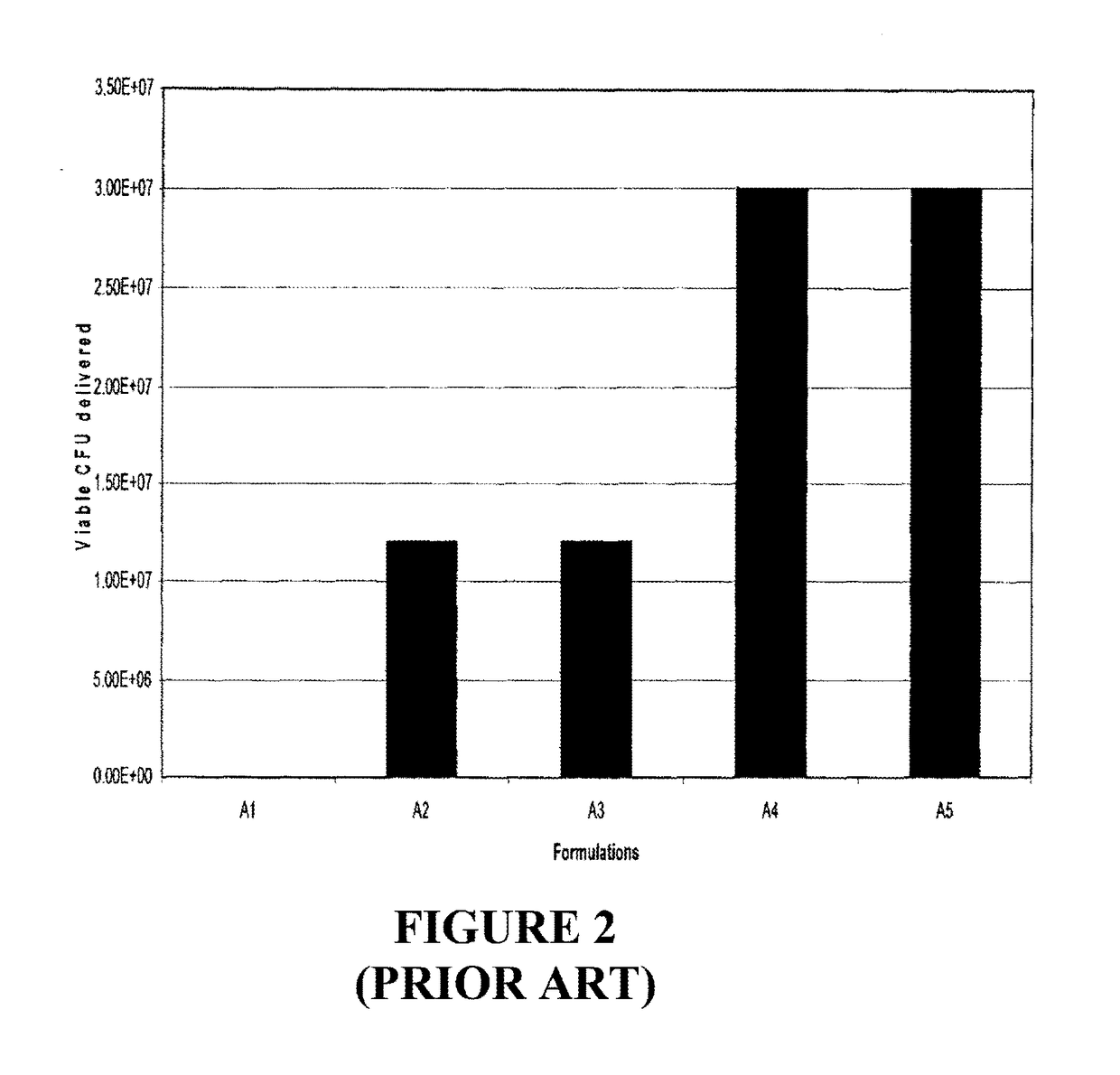

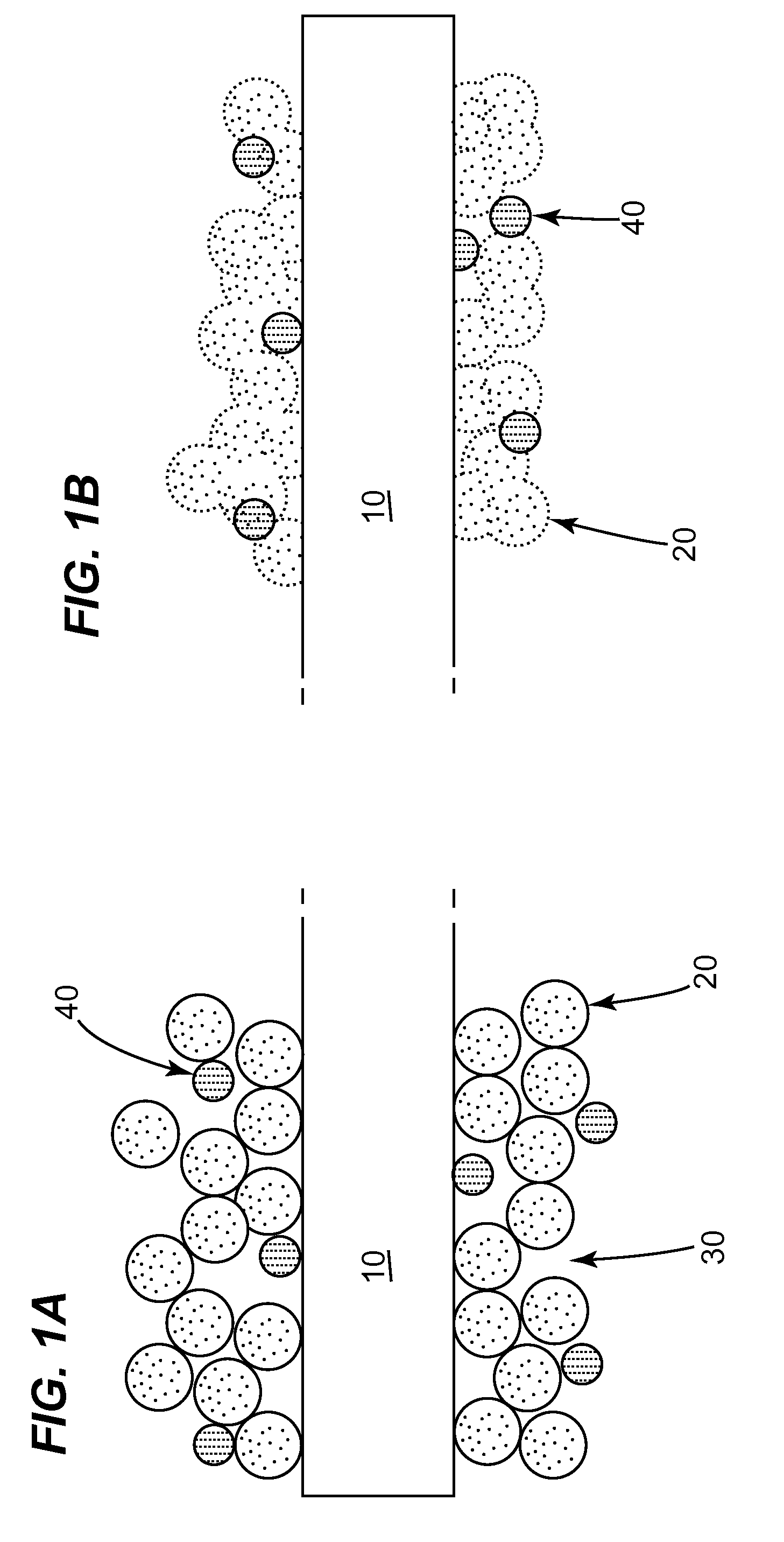

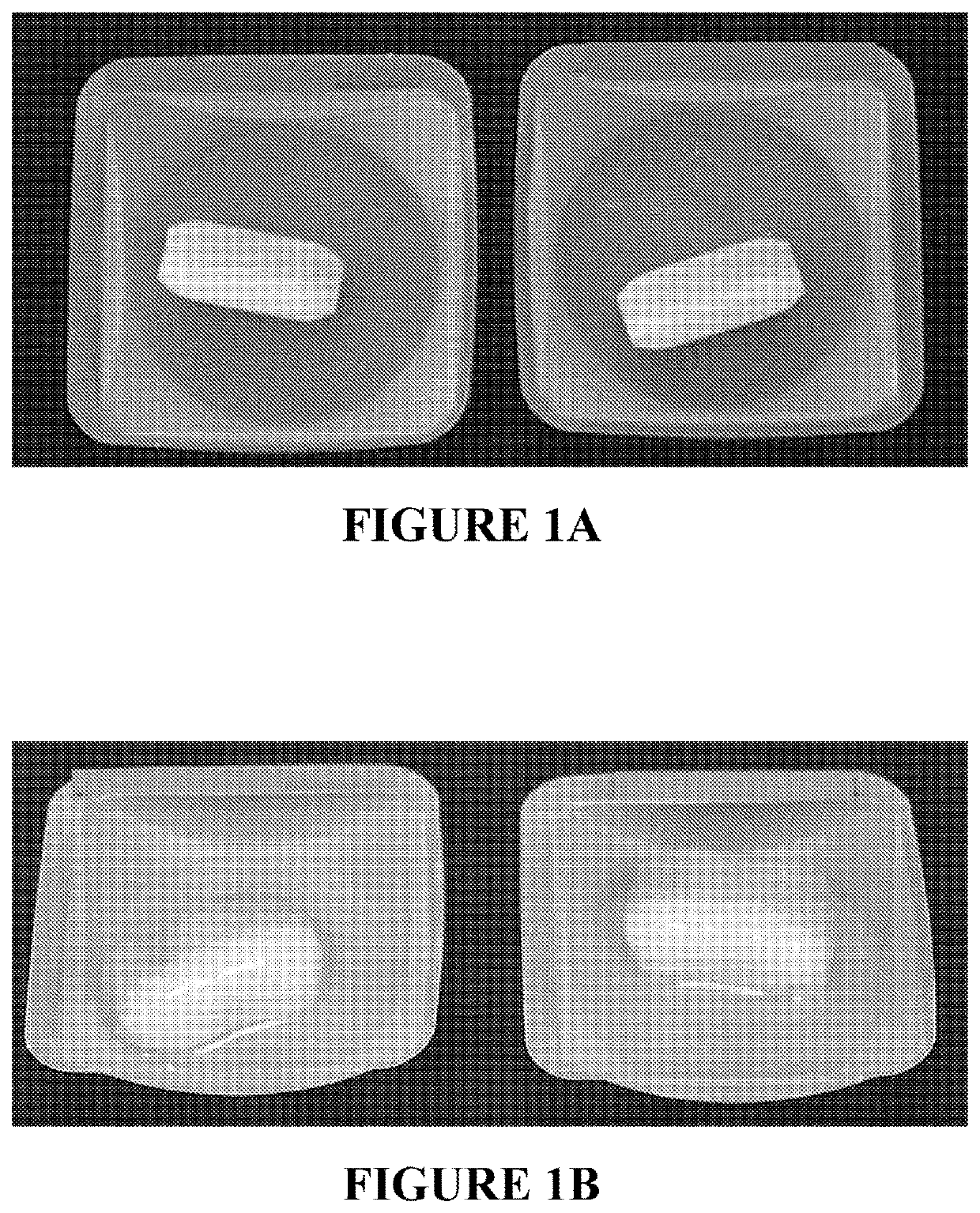

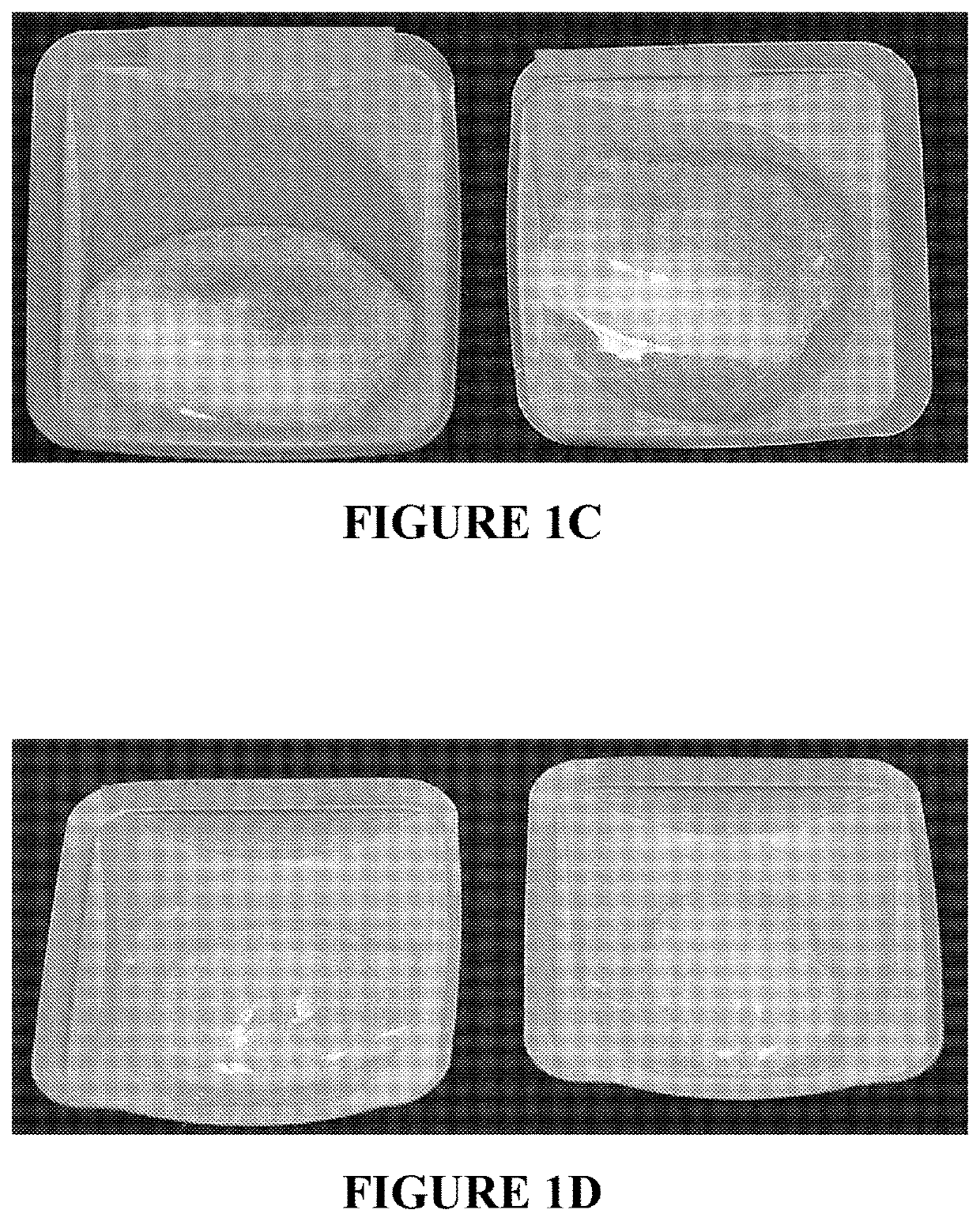

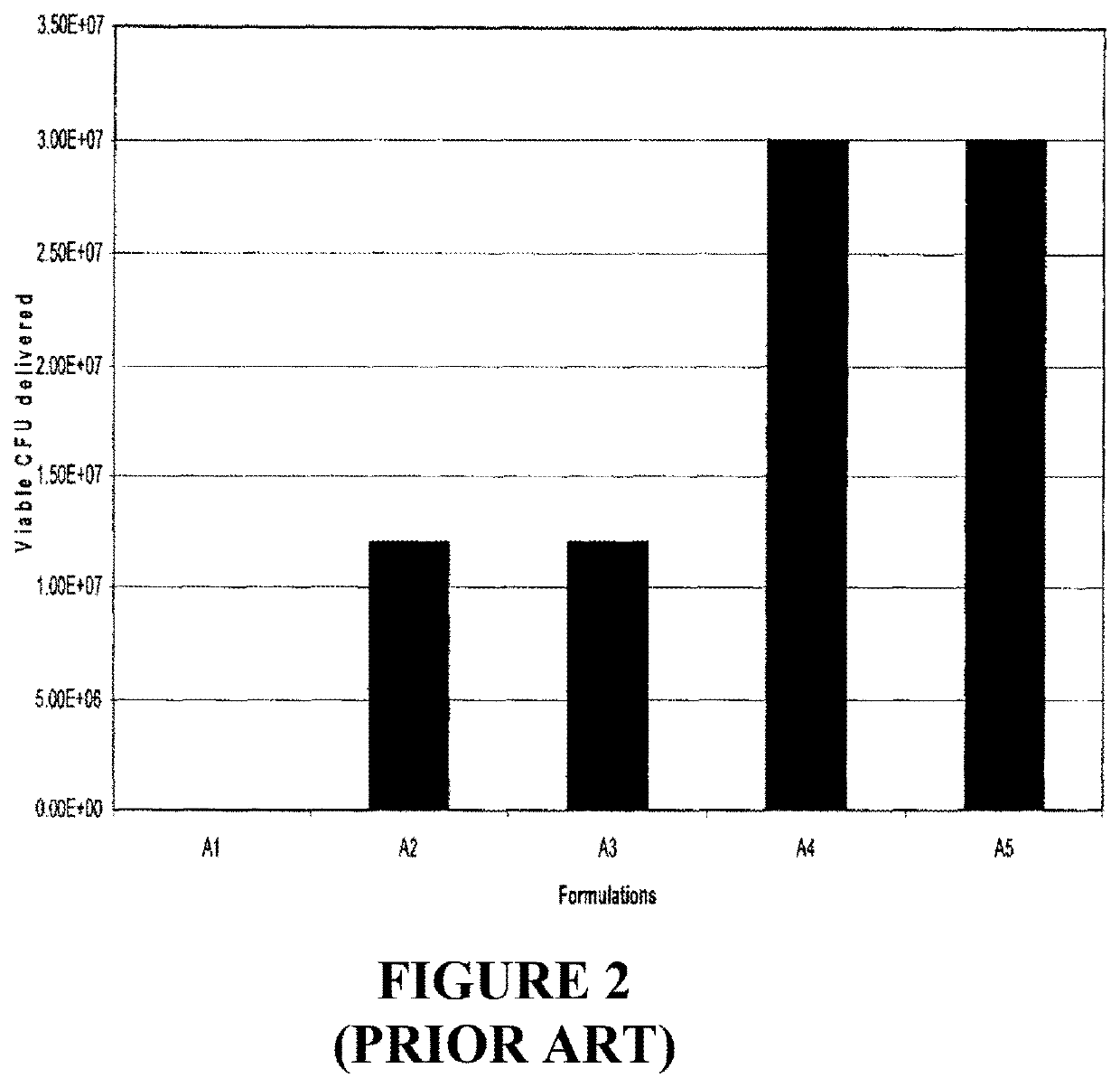

Bi-layer dual release probiotic tablets

ActiveUS20170100442A1Easy to customizeHarsh environmentPeptide/protein ingredientsDigestive systemDosage Form UnitDual release

The present invention generally relates to dietary supplement and pharmaceutical formulations comprising layered acid protective oral dosage formulations comprising probiotics and provided as single unified or cohesive dosage form units. Each individual acid protective layer of the cohesive dosage form provides one of a different probiotic payload, a different release profile to target delivery of probiotic to a particular region in the gastrointestinal tract, or both different probiotic payloads and release pro files to target delivery of different probiotics to particular regions in the gastrointestinal tract.

Owner:PROBI USA INC

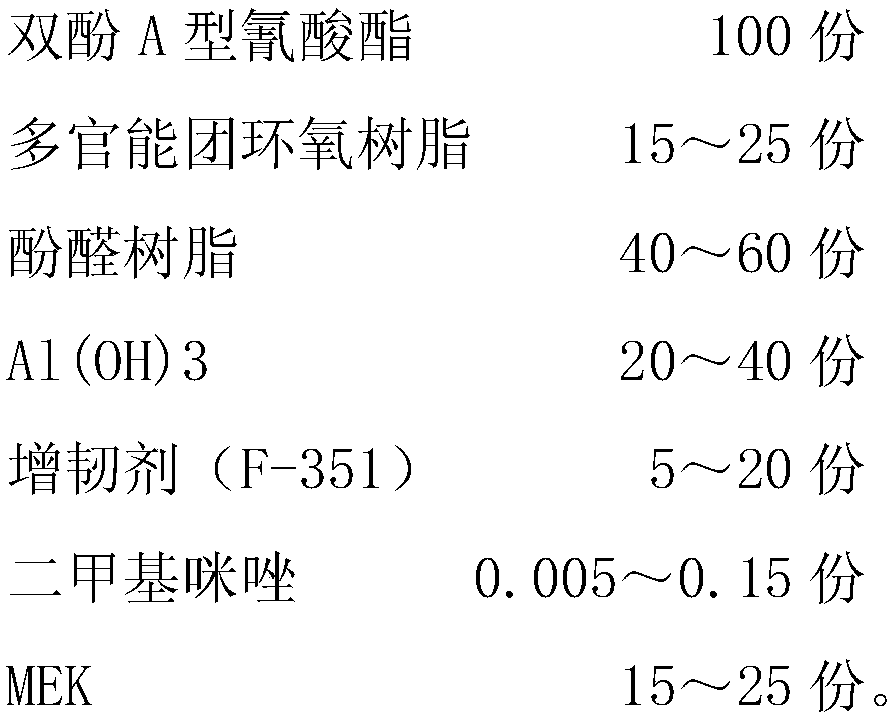

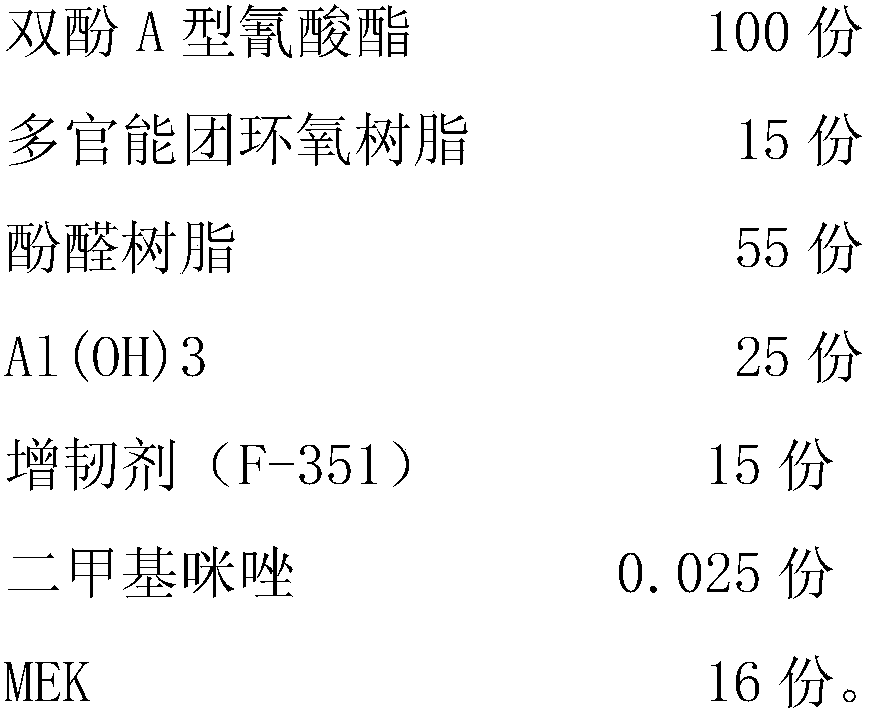

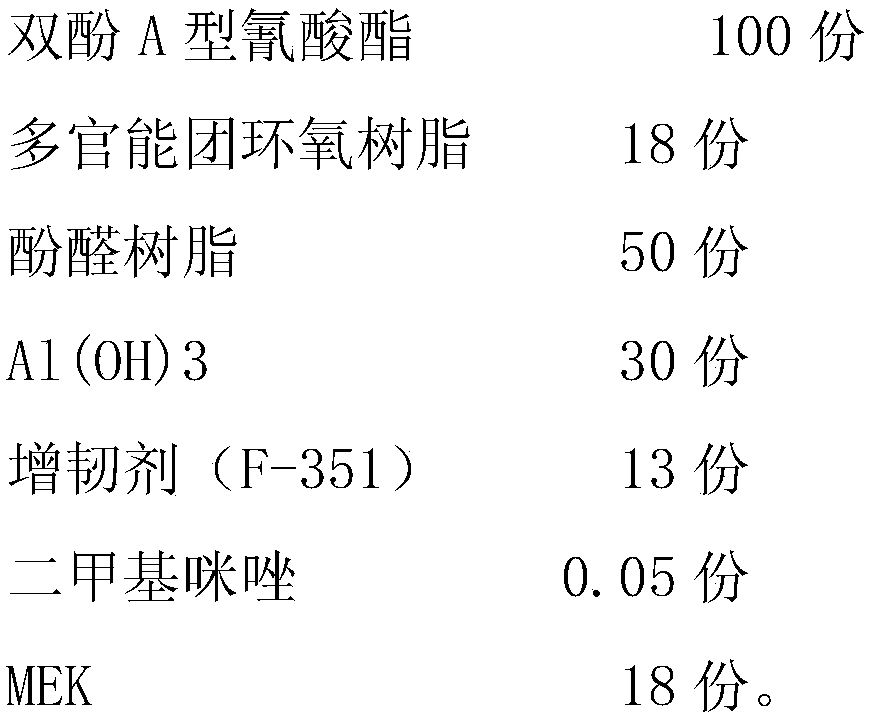

Production technology of high-tenacity copper-clad laminated board with low CTE and high breakage voltage

InactiveCN108099350ALow CTEImprove breakdown voltageLamination ancillary operationsLaminationCopper foilHot pressing

The invention relates to a production technology of a high-tenacity copper-clad laminated board with low CTE and high breakage voltage. The production technology of the copper-clad laminated board comprises the following steps: setting the formula of a resin glue solution, adjusting P sheet production parameters and adjusting a compression molding technology, specifically firstly sufficient and uniformly mixing raw materials of the formula of the resin glue solution used for producing the copper-clad laminated board, then gluing the uniformly mixed resin glue solution onto electronic grad glass fiber cloth, drying the resin glue solution on a vertical gluing machine to obtain prepregs, then laminating two to ten prepregs, then overlapping a copper foil, carrying out compression molding inside a vacuum pressing machine, and finally packaging the prepared copper-clad laminated board for shipment after the testing for the appearance and inner materials of the board is qualified. The boardafter compression molding manufactured through the production technology of the copper-clad laminated board has the characteristics of low CTE and high breakage voltage, and through modification of the formula, the tenacity and durability of the board are greatly improved, so that the PCB processing performance is greatly improved.

Owner:GUANGDE LONGTAI ELECTRONICS SCI TECH

Fiber optic sensor and method for making

InactiveUS7720321B2Increase temperatureHarsh environmentCladded optical fibreMaterial analysis by optical meansOptoelectronicsHigh heat

Owner:GENERAL ELECTRIC CO

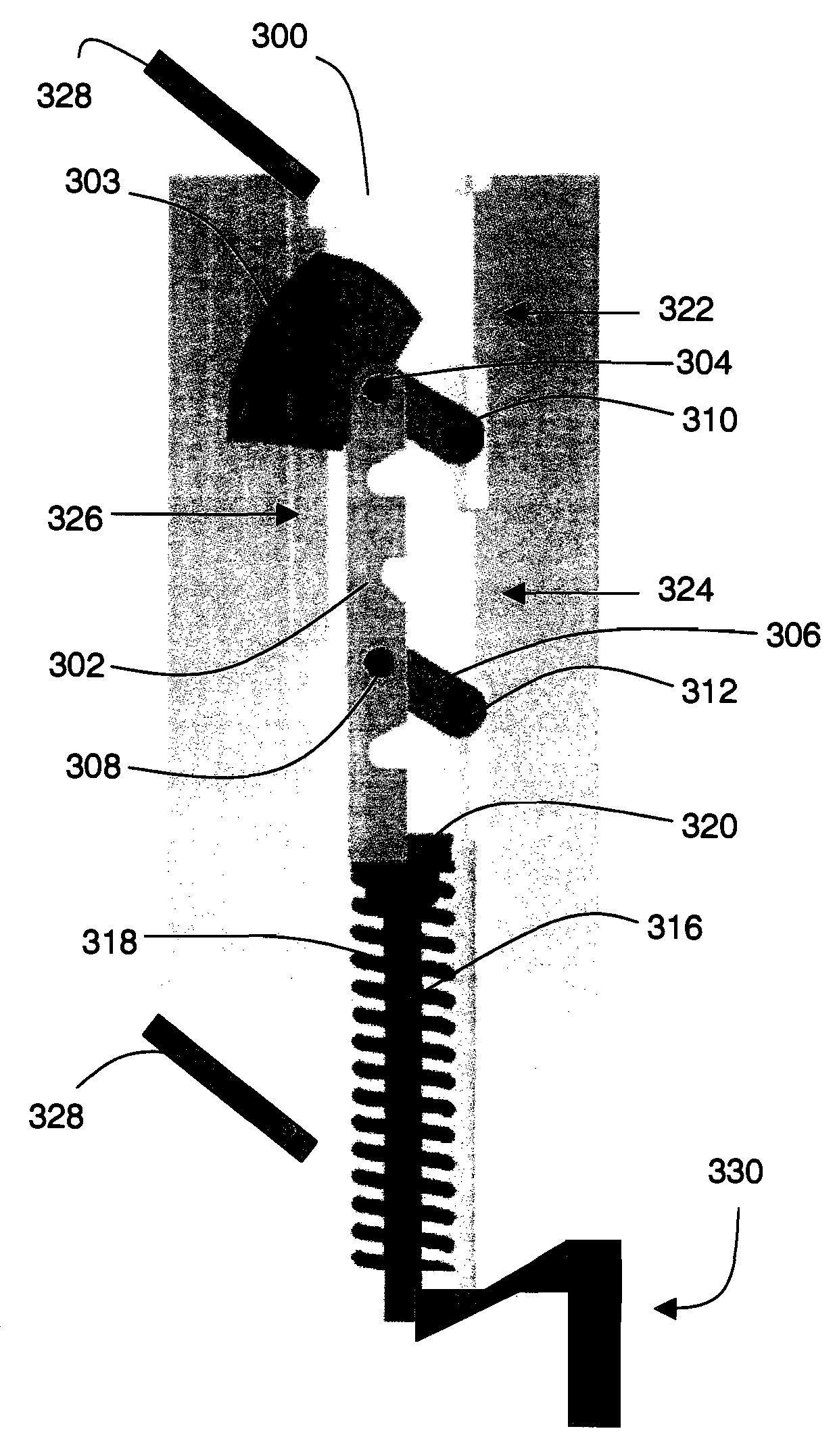

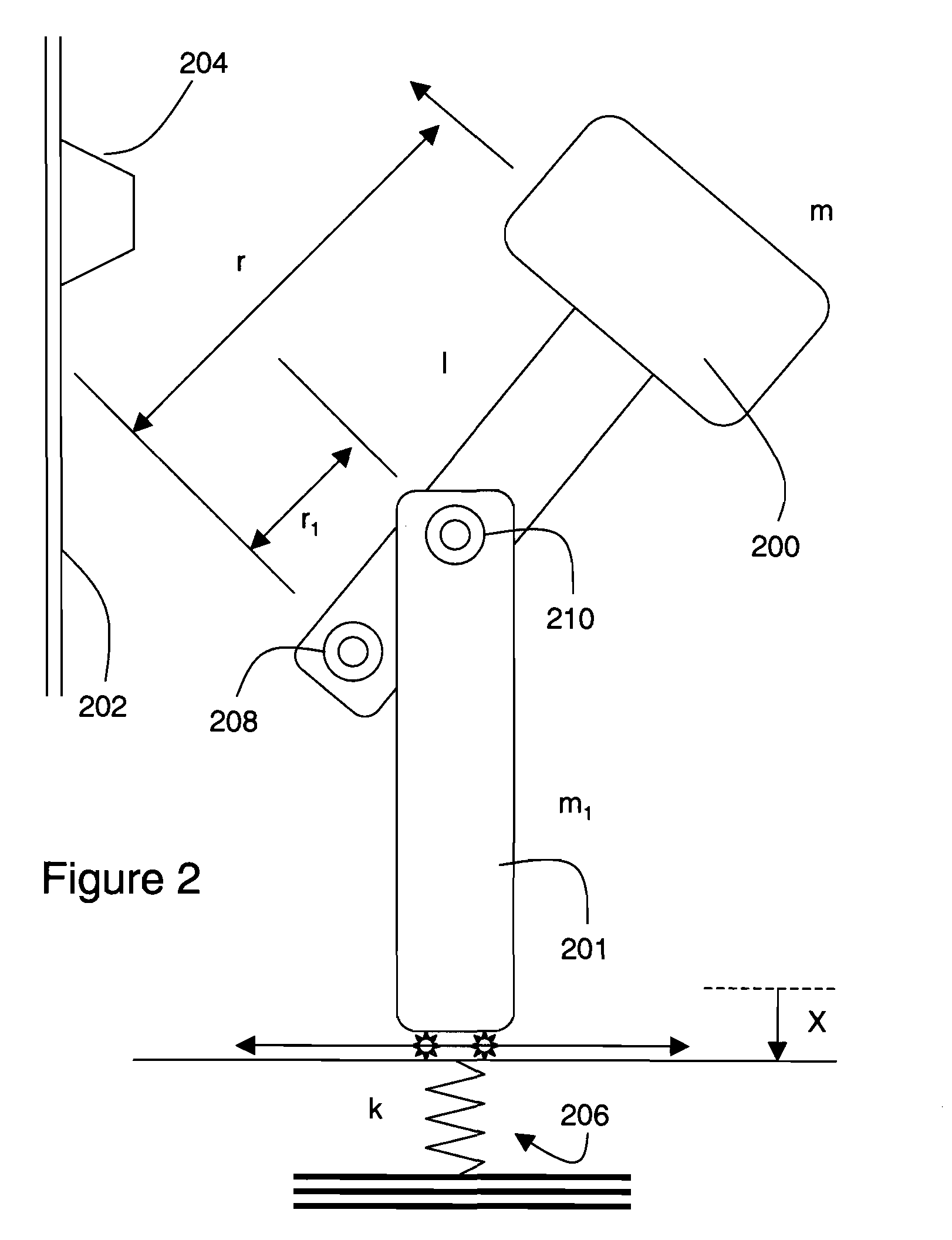

Downhole seismic source

InactiveUS7617908B2Available working volumeSimple and inexpensiveSurveyFluid removalDrive shaftEngineering

Elastodynamic waves are generated by a tool having a hammer rotatably connected with a housing by a first hinge and an actuator arm rotatably connected with the hammer by a second hinge. An axial force applied to the actuator arm by a drive shaft and spring is translated and amplified to a radial impact force by rotation of the hammer around the first hinge. The tool may also include a stabilizer arm connected to the actuator arm by a third hinge, and connected to the housing by a fourth hinge. The housing may be an acoustic wireline tool cylinder having an opening that permits the hammer mass to extend outside the housing when rotated in a first direction. The housing may also include a second opening that permits the hammer mass to extend outside the housing when rotated in a second direction, and a third opening that permits the hammer mass to extend outside the housing when rotated between the first and second openings.

Owner:SCHLUMBERGER TECH CORP

Fiber optic sensor and method for making

InactiveUS20090022449A1Increase temperatureHarsh environmentCladded optical fibreMaterial analysis by optical meansOptoelectronicsFiber optic sensor

A fiber optic sensor including a fiber having a modified surface integral with the fiber wherein the modified surface includes an open pore network with optical agents dispersed within the open pores of the open pore network. Methods for preparing the fiber optic sensor are also provided. The fiber optic sensors can withstand high temperatures and harsh environments.

Owner:GENERAL ELECTRIC CO

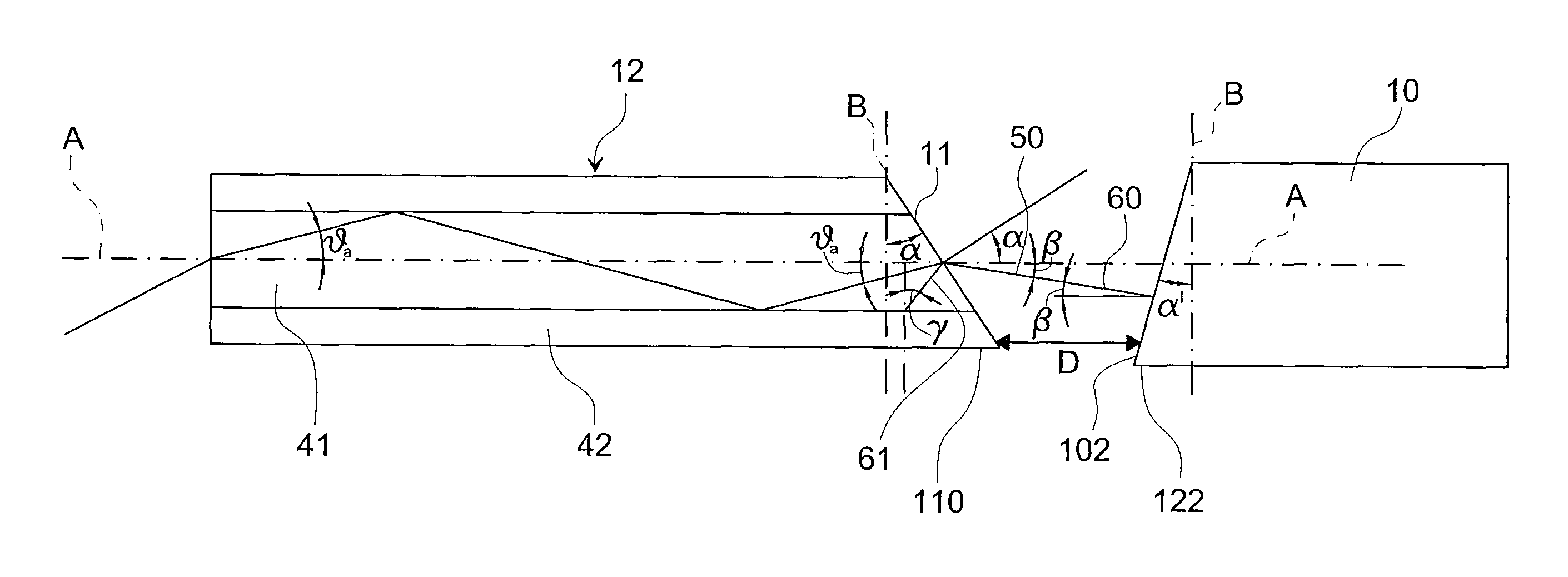

Optical sensor for contactless pressure measurements

ActiveUS9476784B2Improve reliabilityHarsh environmentFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsLight beamEngineering

Owner:LASER POINT SRL

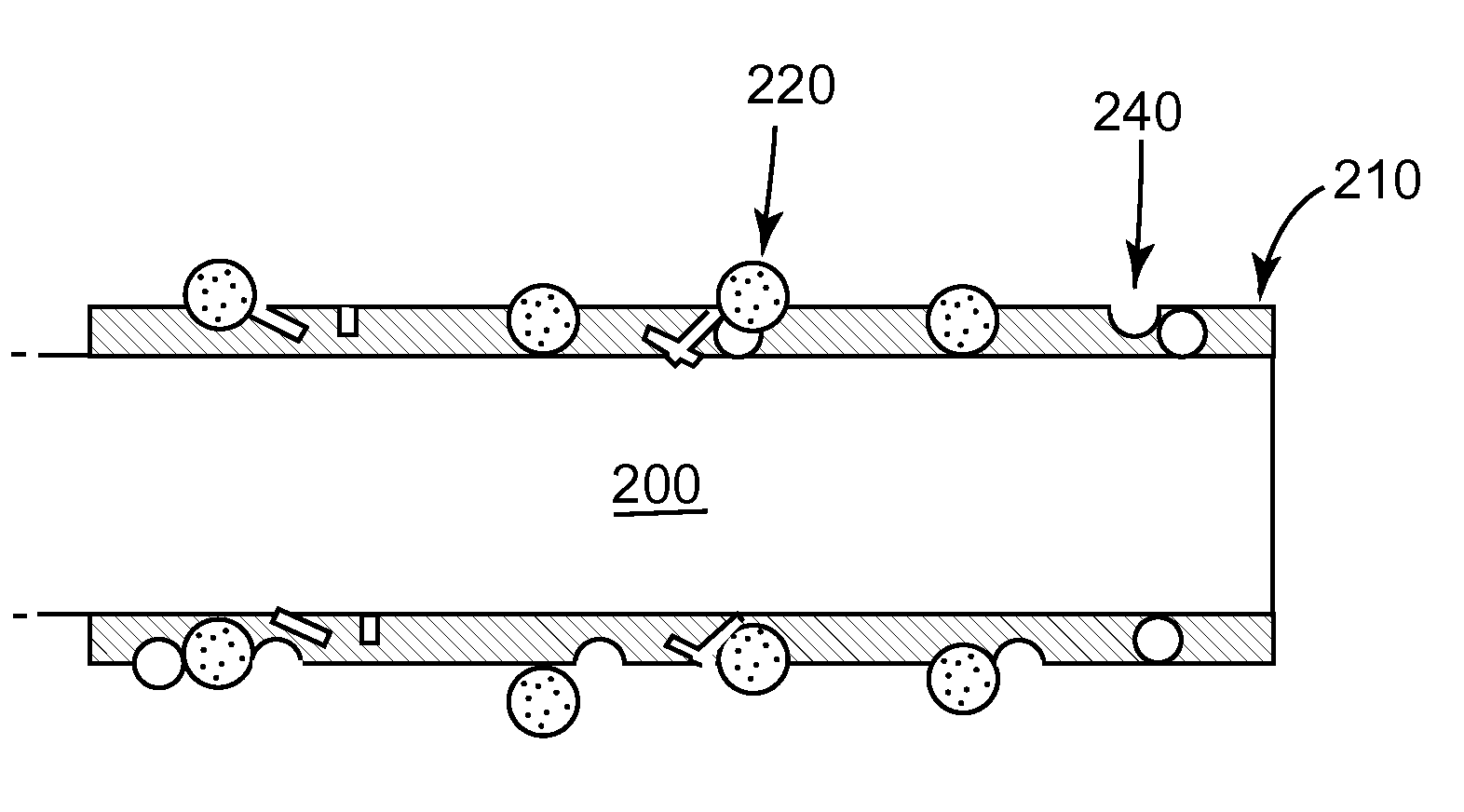

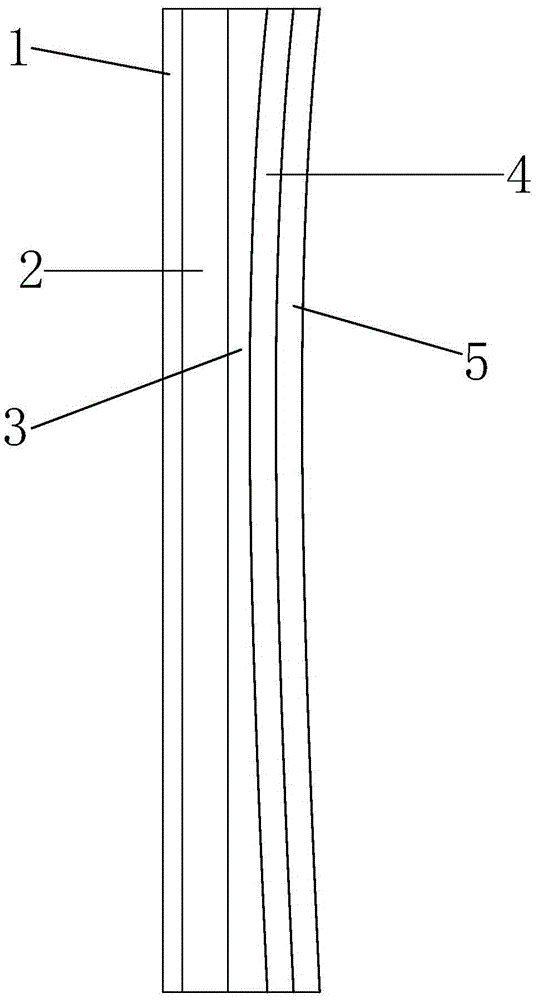

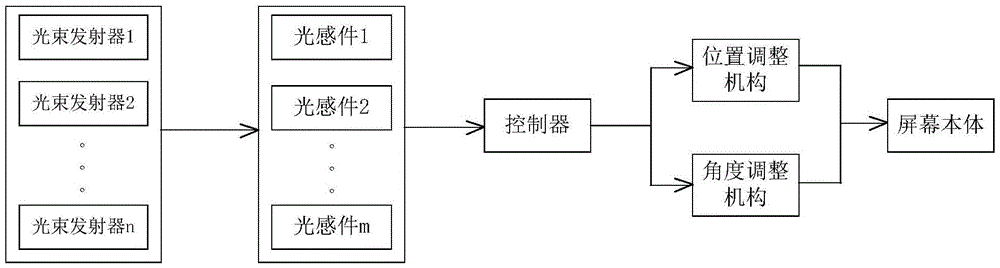

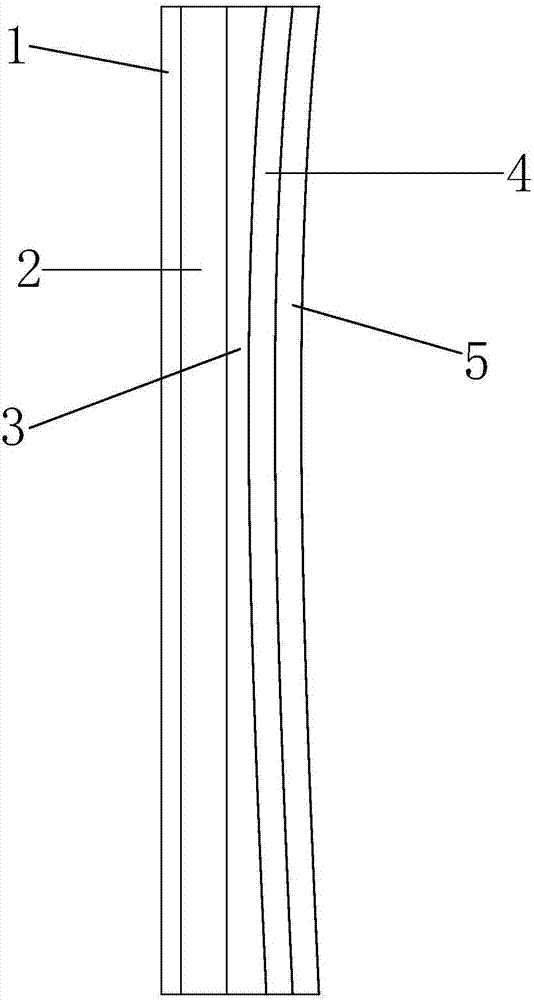

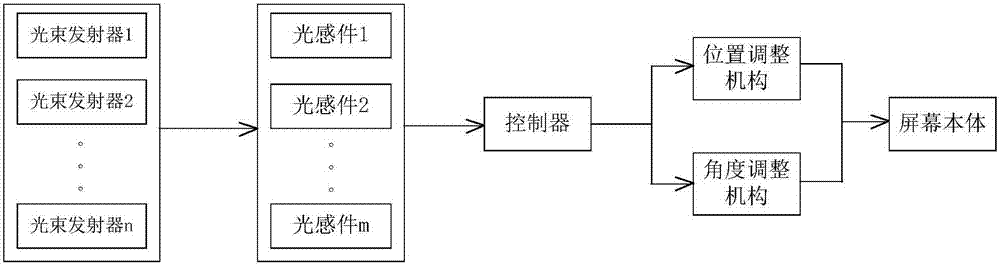

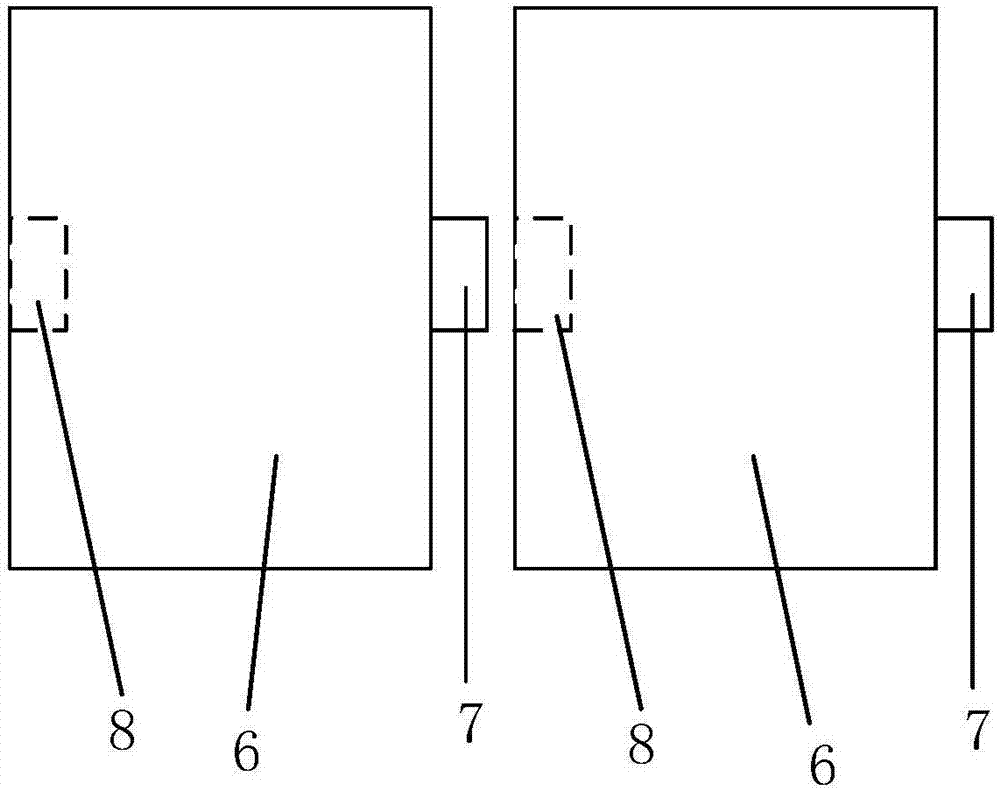

Orthographic projection screen and production method of screen body thereof

ActiveCN105527790AReduce penetrationGood mechanical propertiesProjectorsPolyethylene terephthalateProjection screen

The invention provides an orthographic projection screen and a production method of a screen body thereof. The orthographic projection screen comprises a screen body which comprises a flat curing force layer made of PET (polyethylene terephthalate), an inner arc structure layer, a projection paint layer, a lusterless paint layer and a light absorption layer, the light absorption layer is arranged at the back of the flat curing force layer, the inner arc structure layer is arranged in the front of the flat curing force layer, one side, back to the flat curing force layer, of the inner arc structure layer concaves to form an inner arc, the projection paint layer is arranged on the side, and the lusterless paint layer is arranged on the projection paint layer.

Owner:浙江威赛尼科技有限公司

Self-powered miniature mobile sensing device

ActiveUS10844694B2Reduced Power RequirementsNot easily replicableSurveyPiezoelectric/electrostriction/magnetostriction machinesControl theoryMechanical engineering

Owner:SAUDI ARABIAN OIL CO

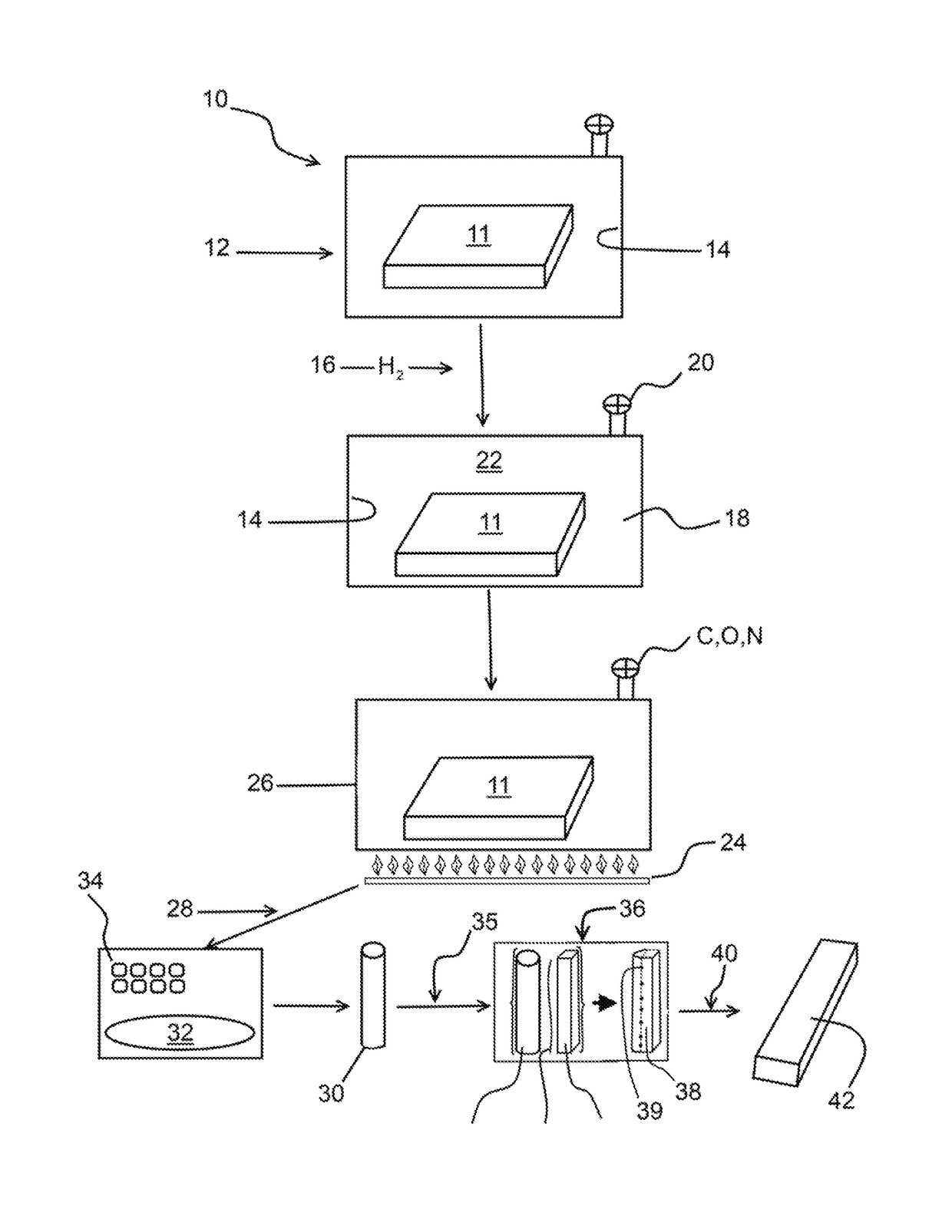

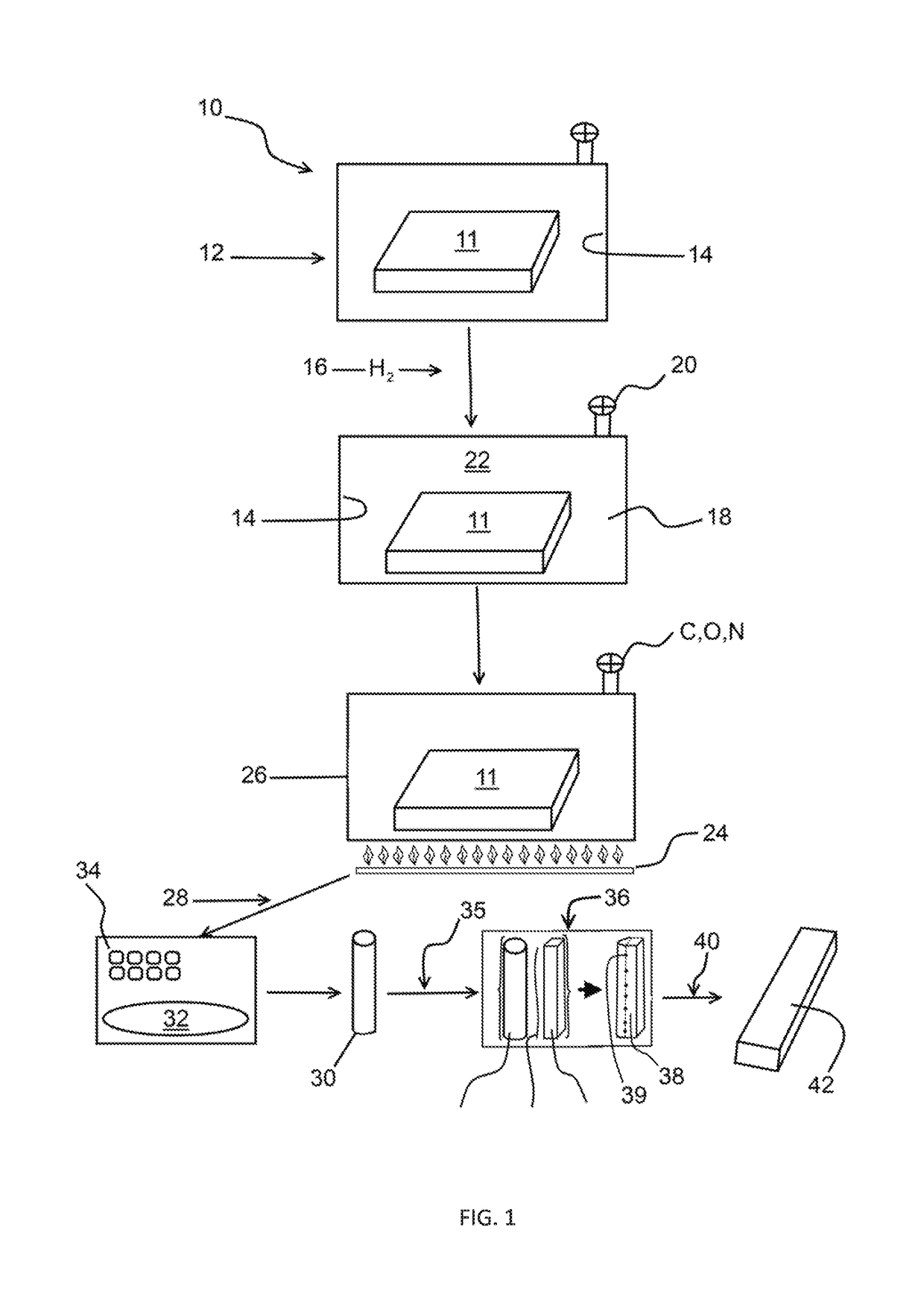

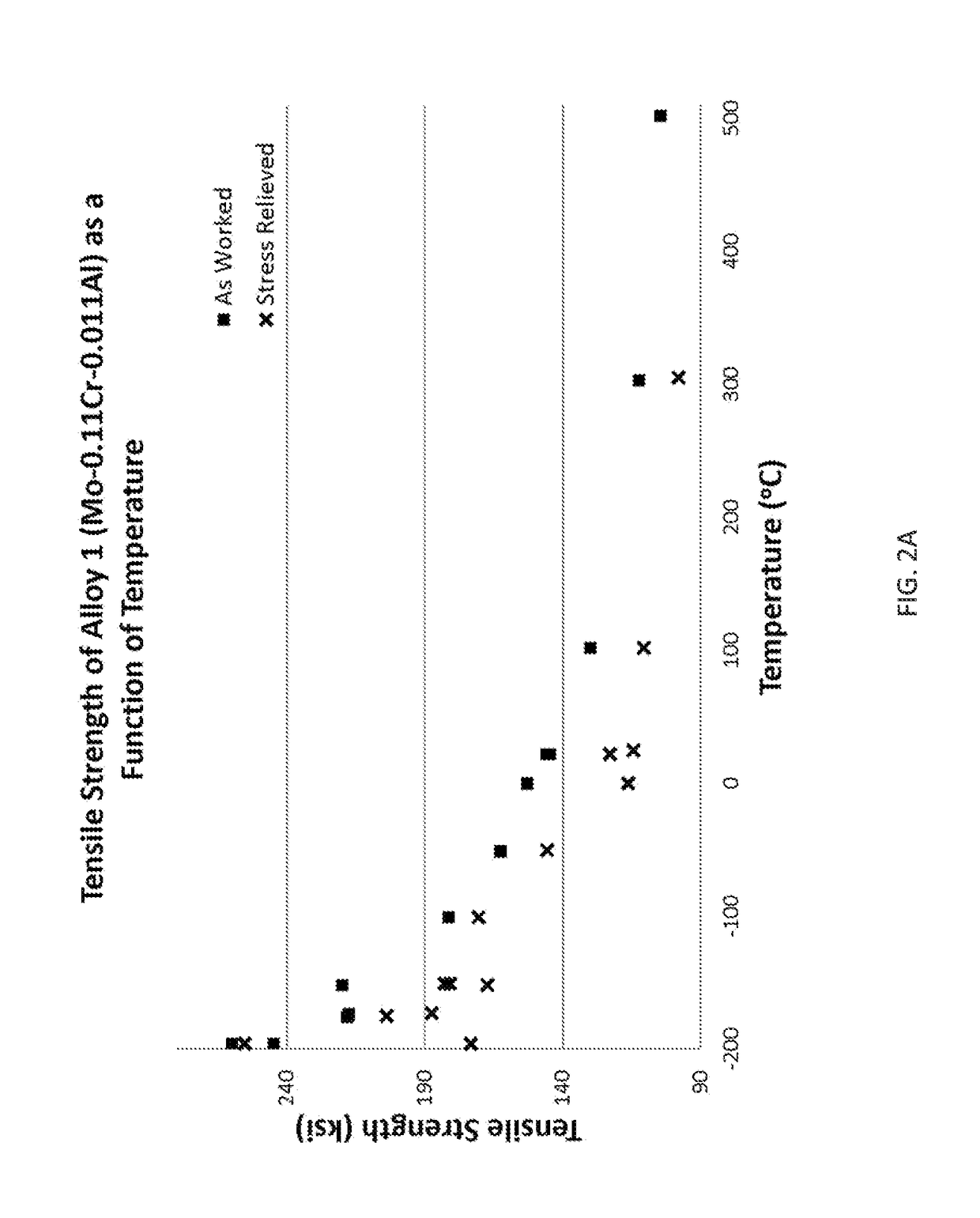

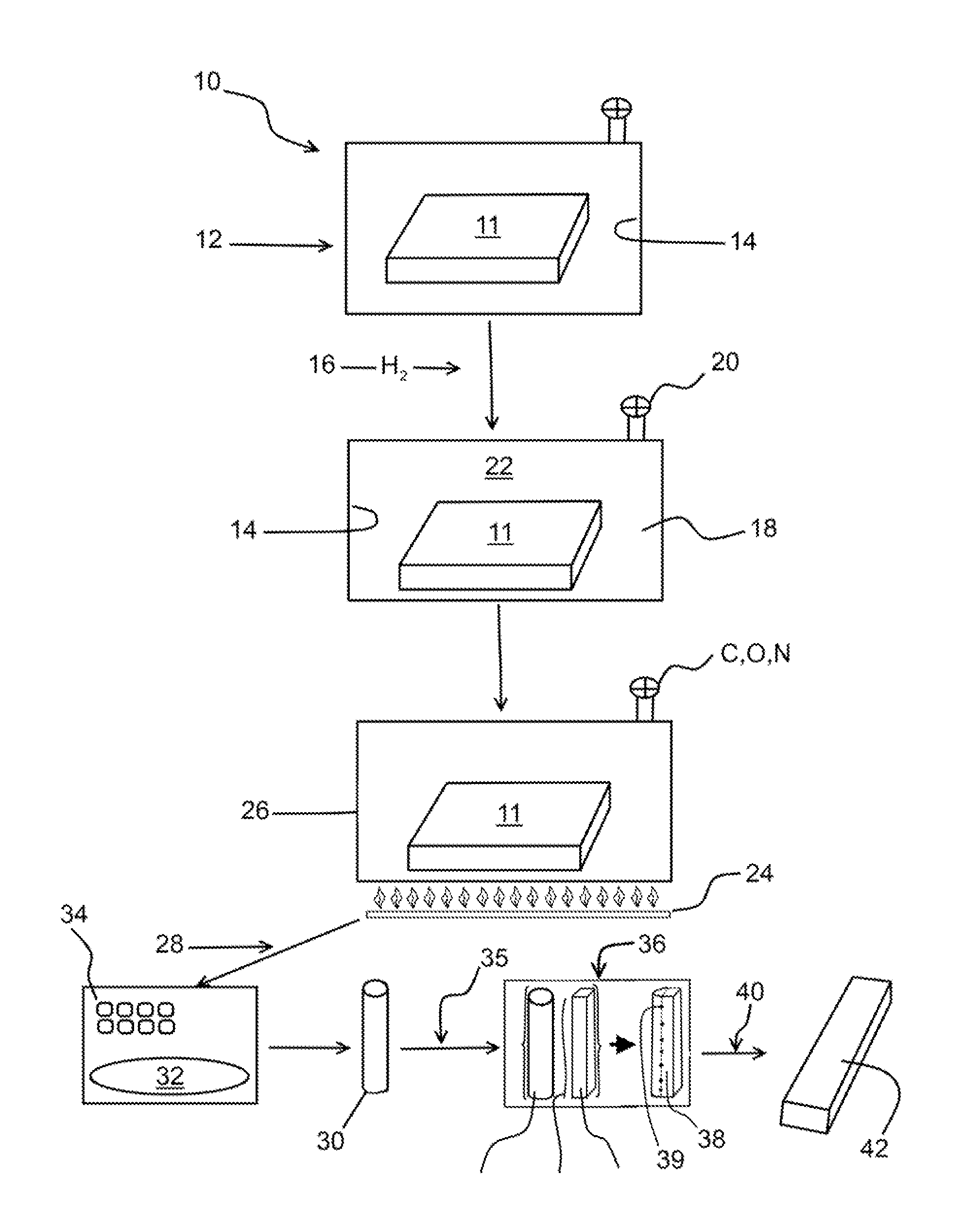

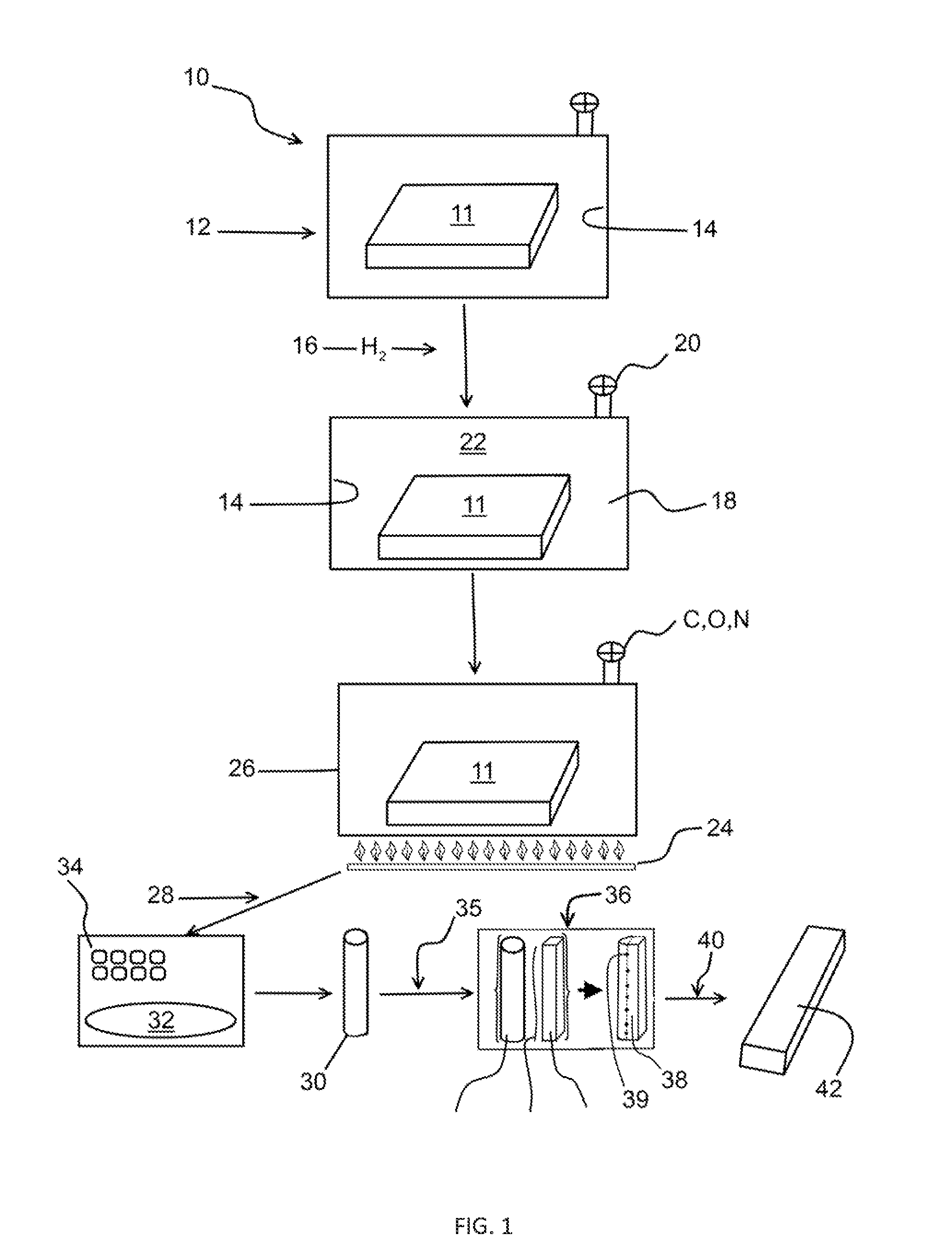

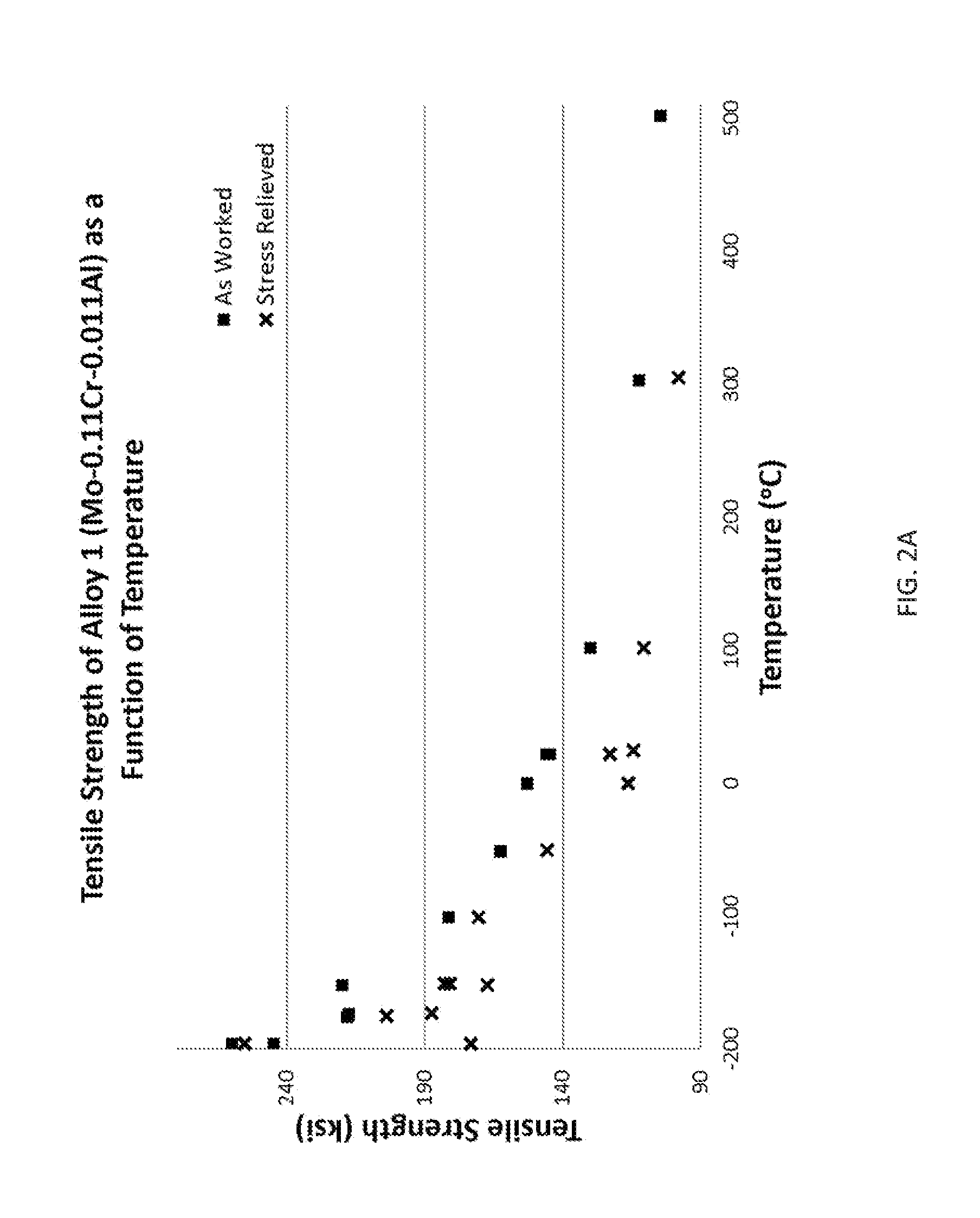

Ductile metal alloys, method for making ductile metal alloys

A ductile alloy is provided comprising molybdenum, chromium and aluminum, wherein the alloy has a ductile to brittle transition temperature of about 300 C after radiation exposure. The invention also provides a method for producing a ductile alloy, the method comprising purifying a base metal defining a lattice; and combining the base metal with chromium and aluminum, whereas the weight percent of chromium is sufficient to provide solute sites within the lattice for point defect annihilation.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

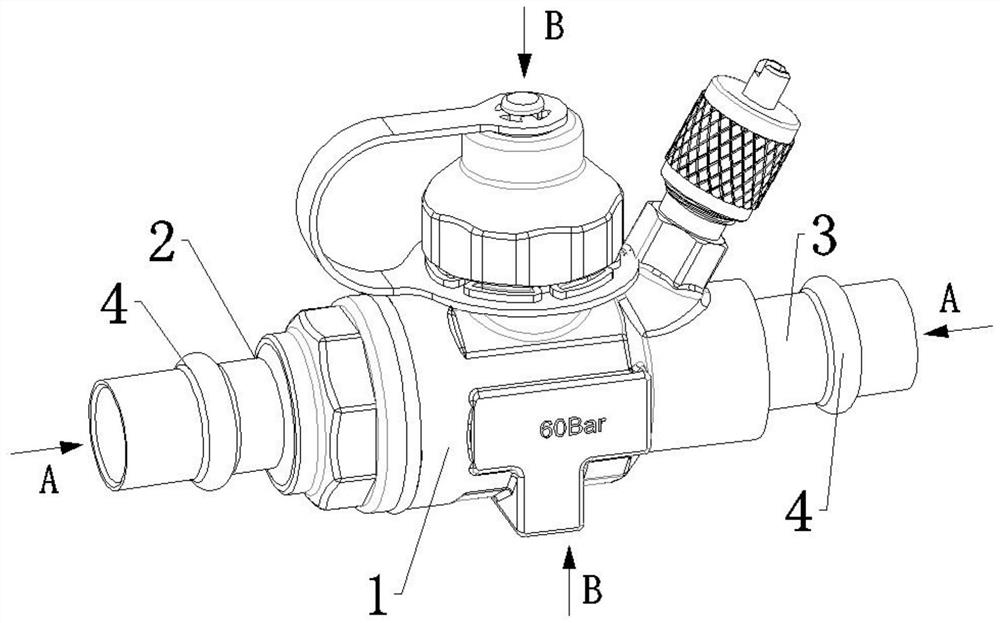

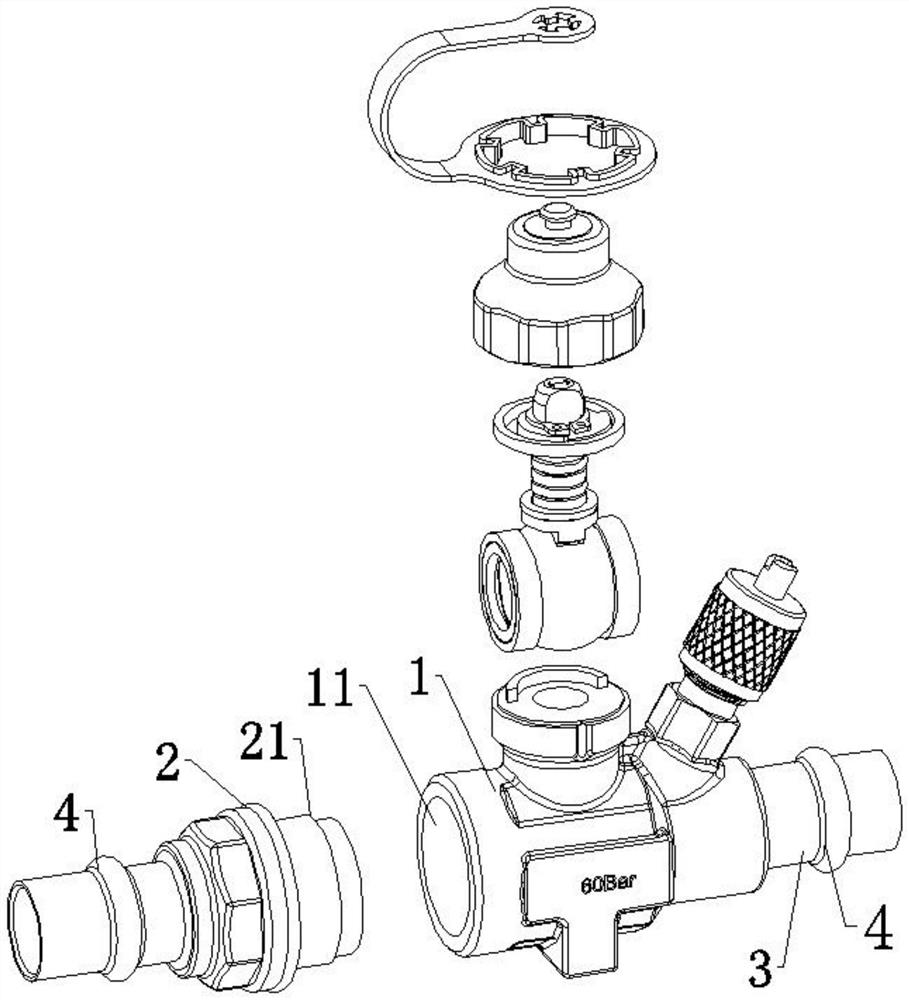

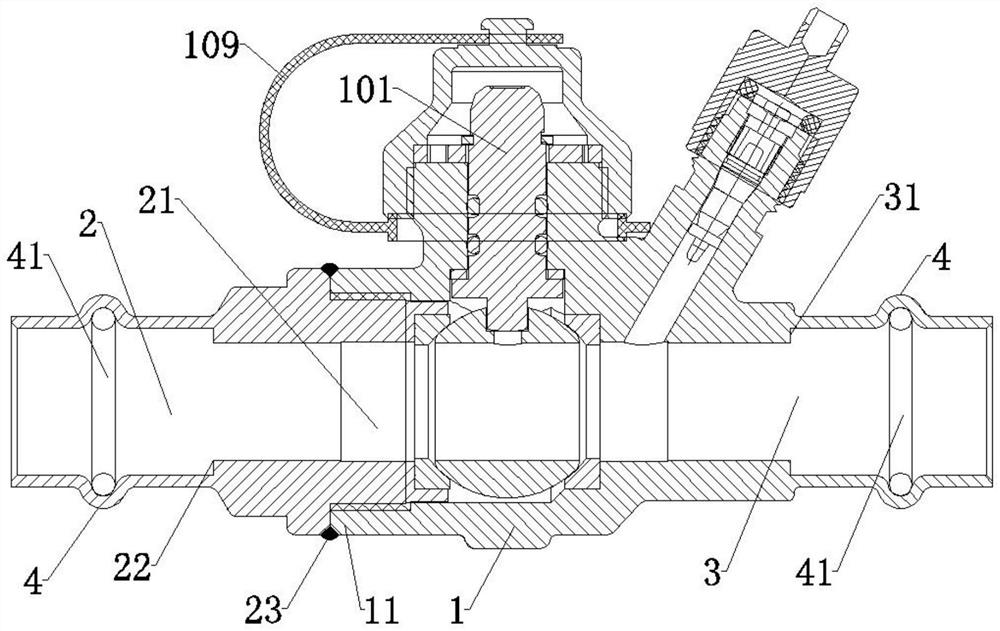

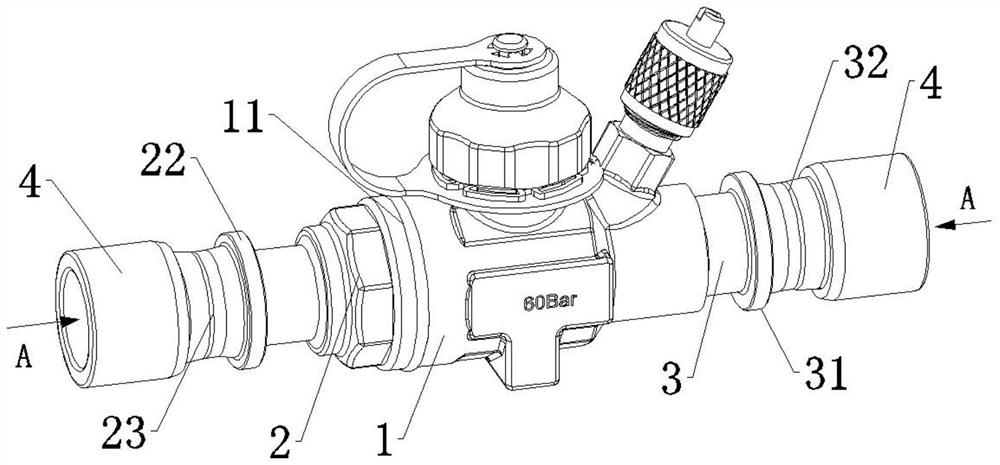

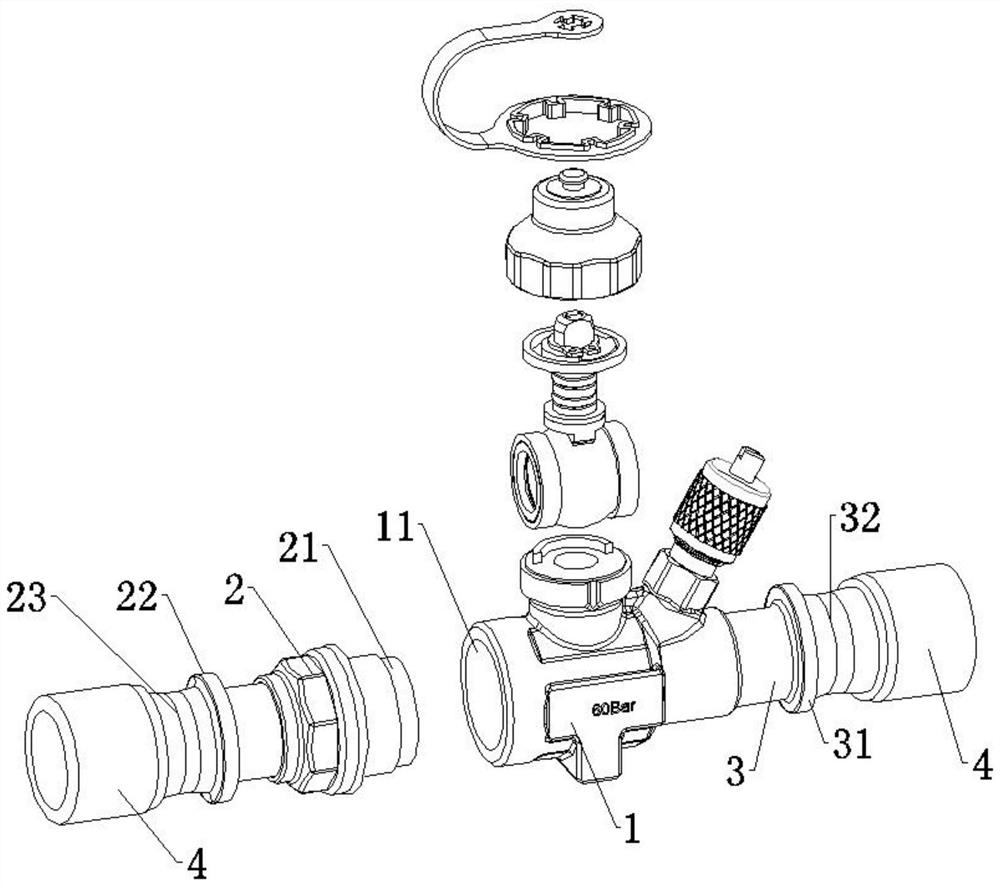

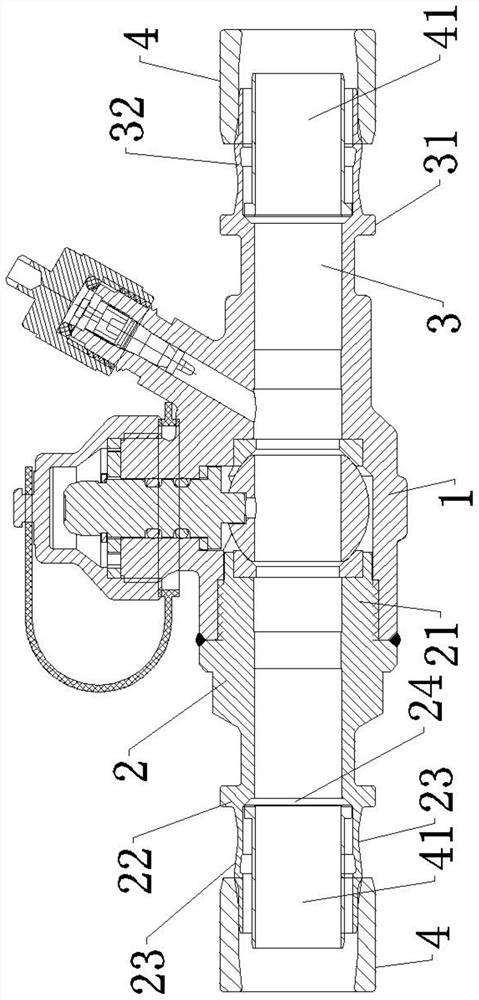

Clamping and pressing type ball valve having integral structure

PendingCN112081943AReduce professional requirementsReduce riskPlug valvesNon-disconnectible pipe-jointsPipe fittingWorking environment

The invention discloses a clamping and pressing type ball valve having an integral structure in the technical field of valves, comprising: a valve body, a socket being arranged at one end, and a valveend clamping and pressing pipe being fixedly arranged at the other end, the valve end clamping and pressing pipe and the valve body being of an integral structure, and an outer convex groove being arranged on the valve end clamping and pressing pipe; and a clamping and pressing pipe fitting, one end being a connecting plug, and the other end being a pipeline port, the clamping and pressing pipe fitting being also provided with an outer convex groove, the connecting plug being inserted into the socket, and the connecting plug and the socket are hermetically fixed by means of full-welding. A clamping and pressing sealing ring is provided in each outer convex groove; the operation can be more convenient; the welding on an installation site is not needed; the open fire connection operation isavoided; the mounting is easier and more convenient; the integral structure is adopted; both pressure and temperature changes are not afraid; the strength is higher; the sealing performance is higher. and leakage is not likely to happen after long-term use in a worse working environment, so that the operation is safer.

Owner:FUZHOU ZHENXIE PIPE

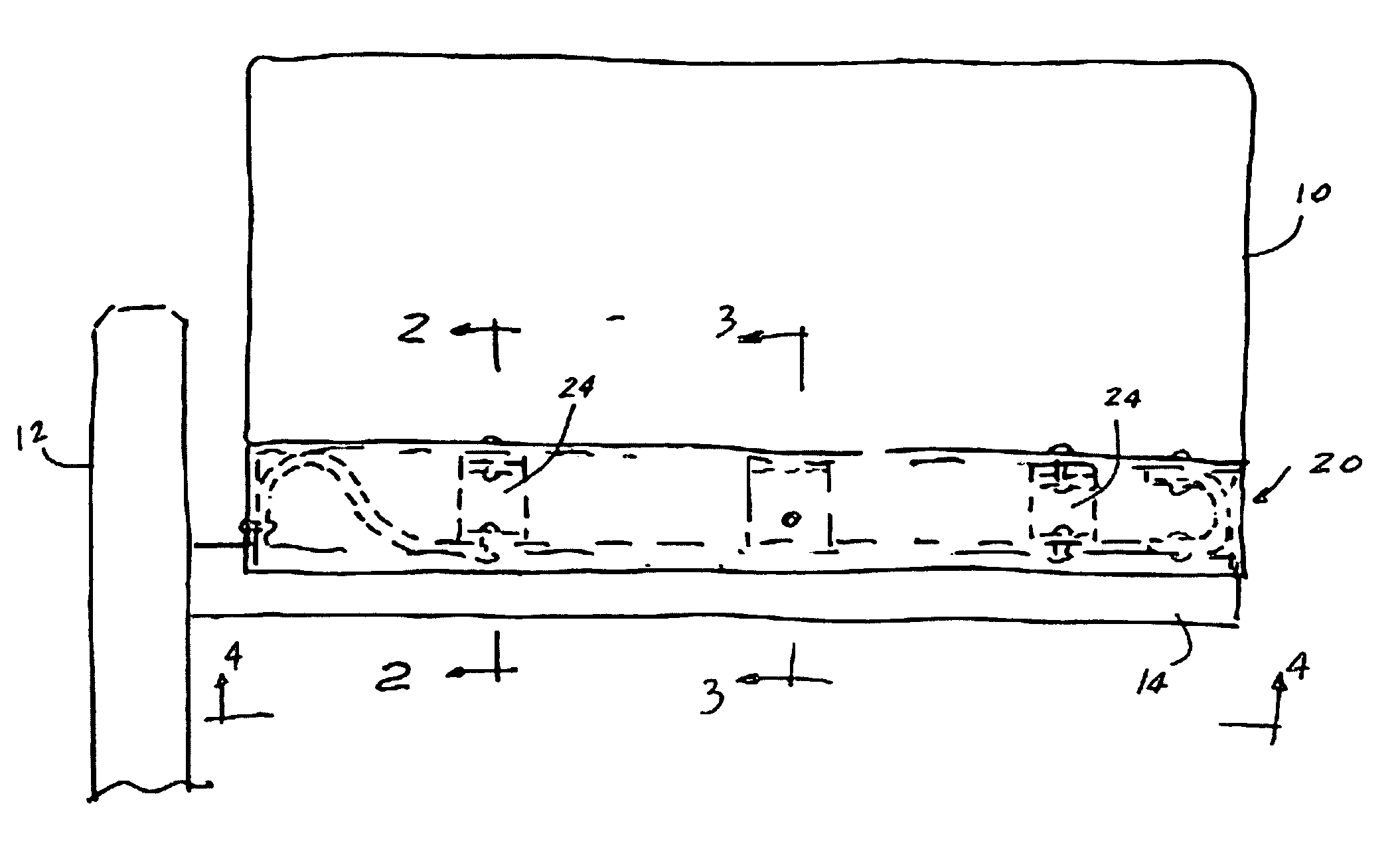

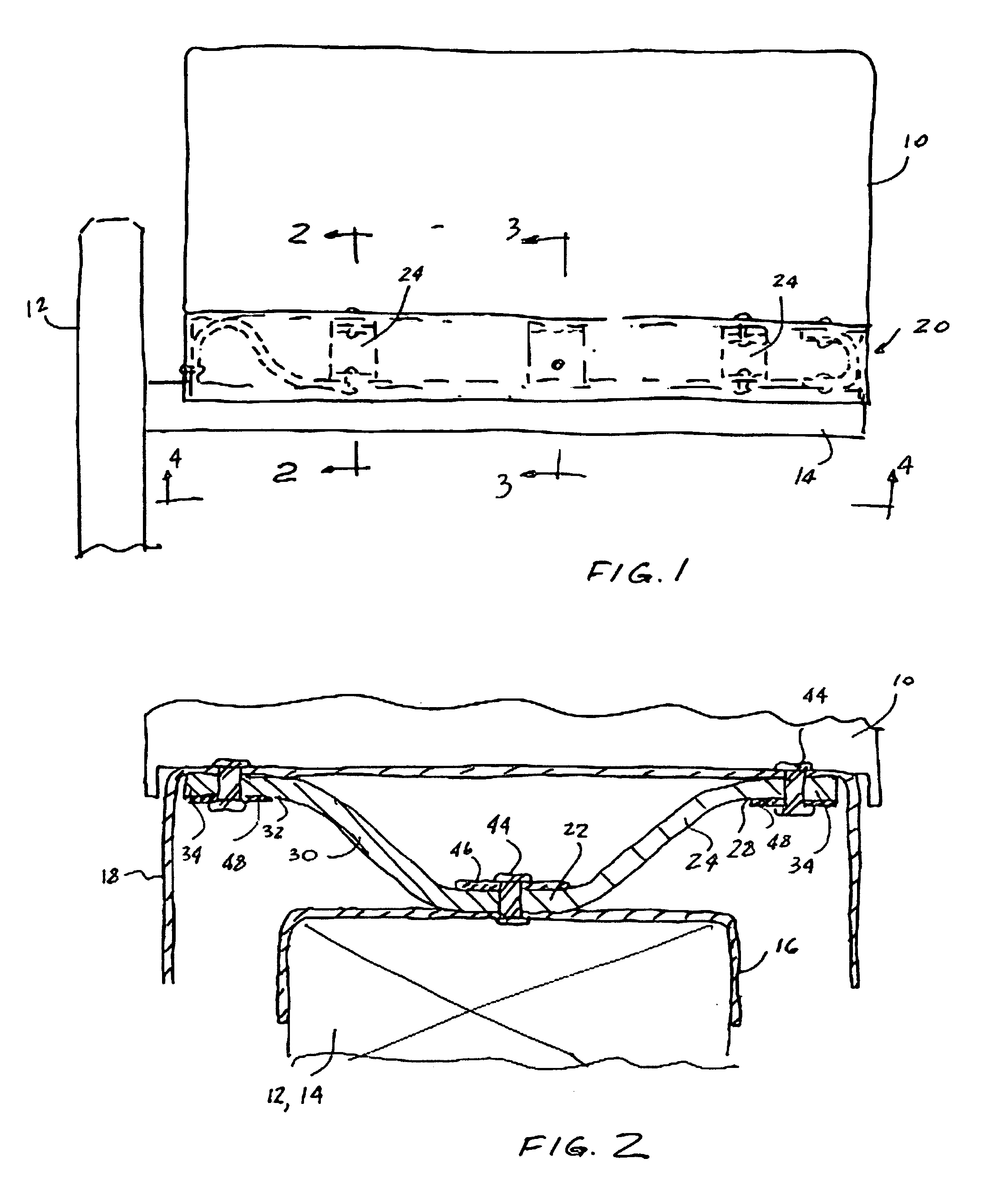

Shock and vibration absorbing device and method

ActiveUS7866540B2Harsh environmentLow production costSpringsStands/trestlesEngineeringVibration absorption

Owner:COX LEONARD R

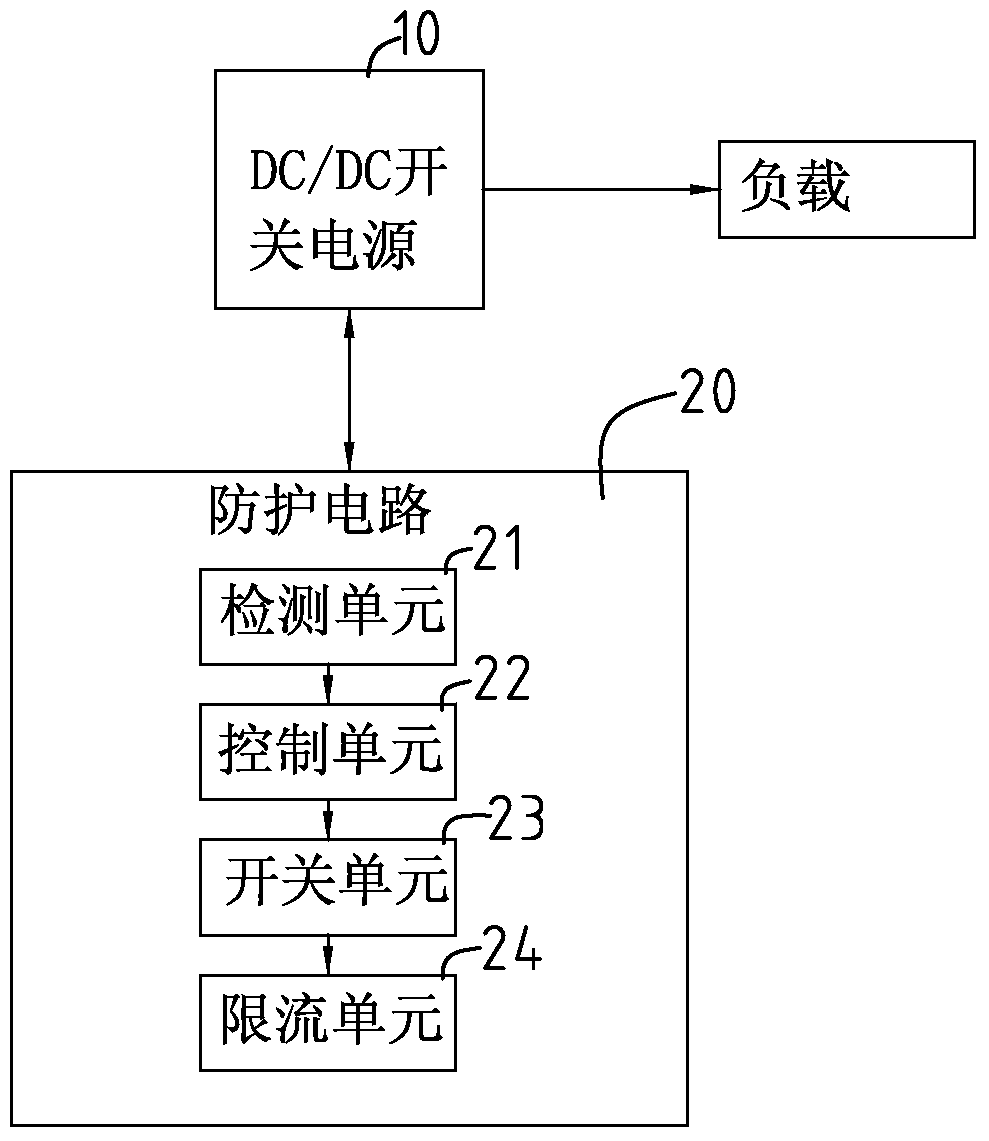

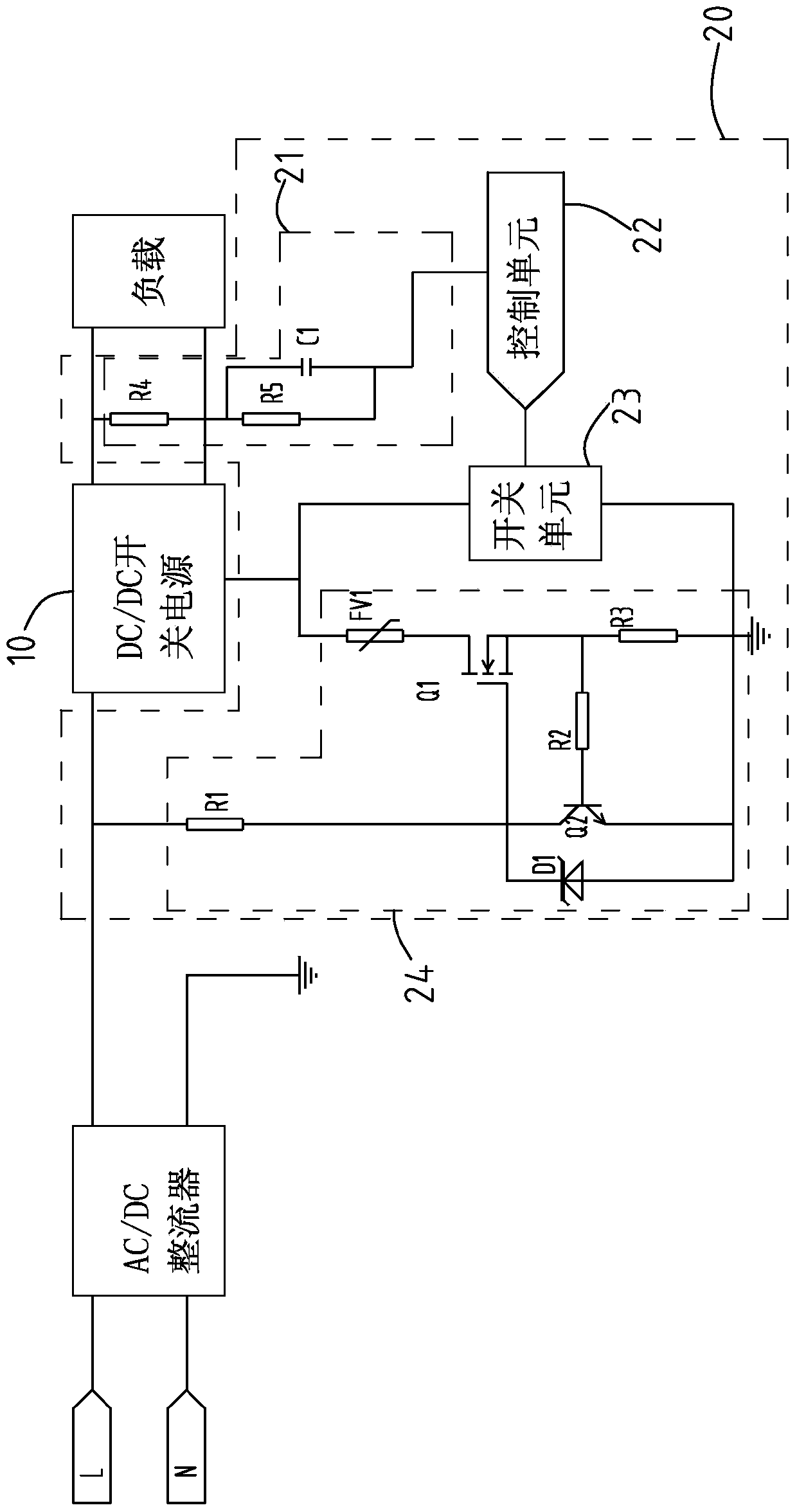

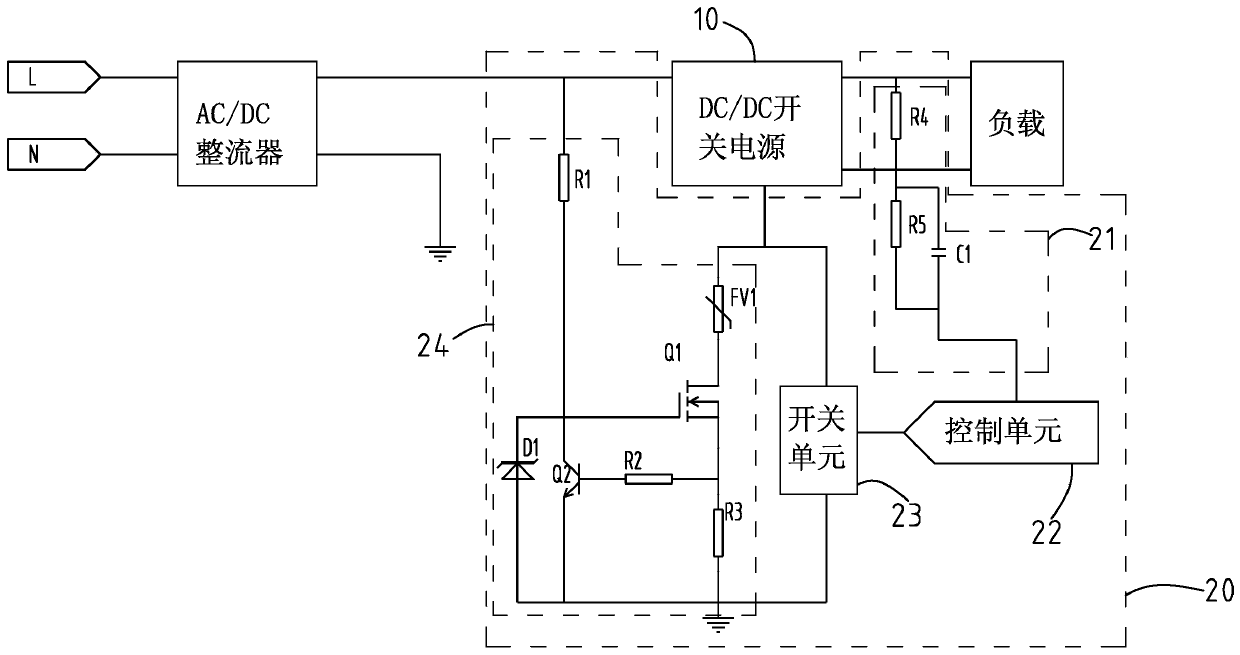

A led power supply with protection circuit

ActiveCN106937436BHarsh environmentElectrical apparatusElectroluminescent light sourcesCapacitanceCurrent limiting

An LED power supply with a protection circuit, the LED power supply includes a DC / DC switching power supply, and the DC / DC switching power supply includes a capacitor. The LED power supply also includes a protection circuit. The protective power supply includes a detection unit for detecting the charging state of the capacitor, a control unit, a switch unit, and a current limiting unit. The current limiting unit is used to limit the magnitude of the current flowing through the capacitor. When the detection unit detects that the capacitor is full, it sends a control signal to the control unit, and the control unit controls the switch unit to turn on after receiving the control signal, so that the LED power supply with the protection circuit enters normal operation state. Because the LED power supply with protection circuit has the current limiting unit, and the current limiting unit can limit the inrush current to a very small value in the early stage when the LED power supply is turned on under the cooperation of the detection unit and the control unit. Below, so that it can meet the more harsh use environment.

Owner:SELF ELECTRONICS CO LTD

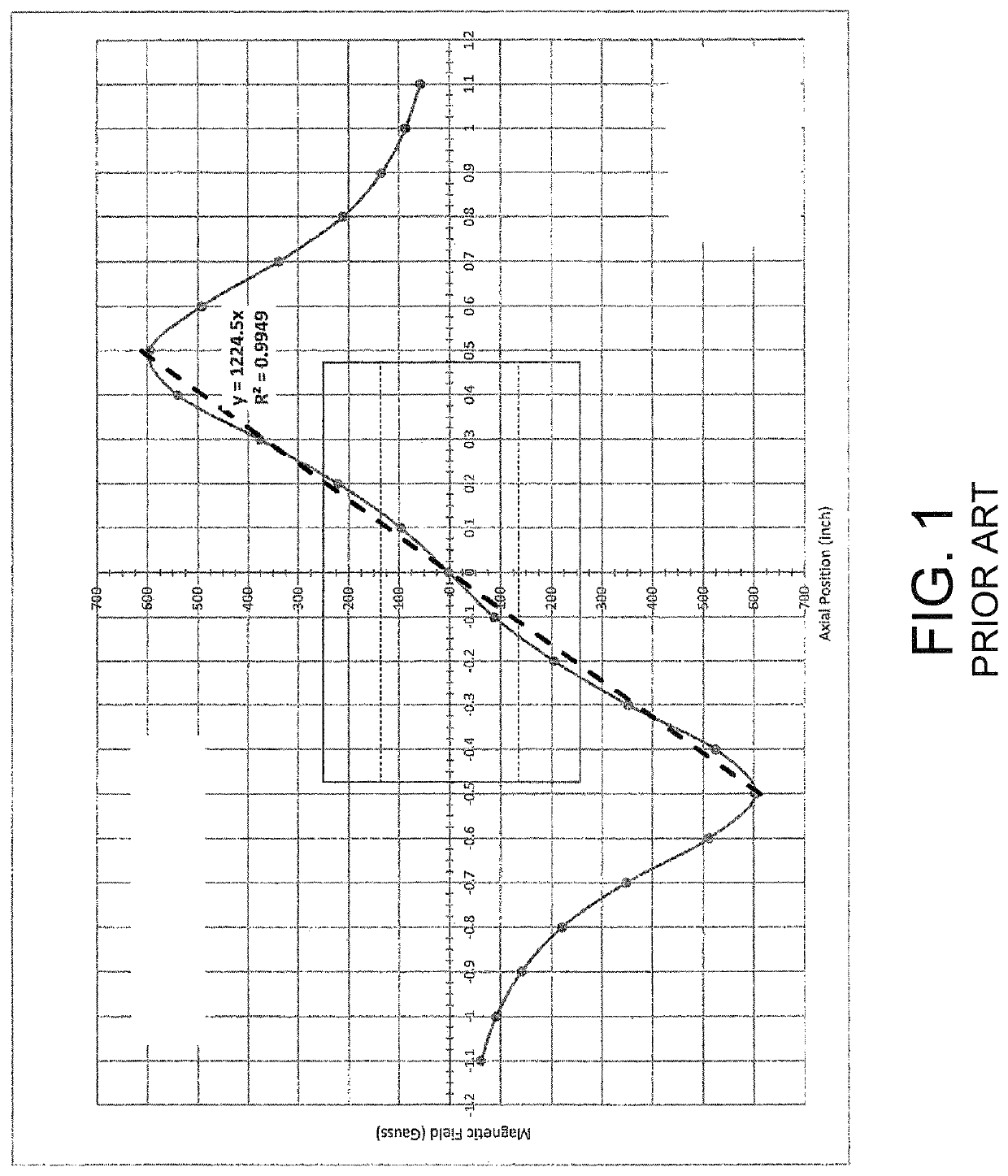

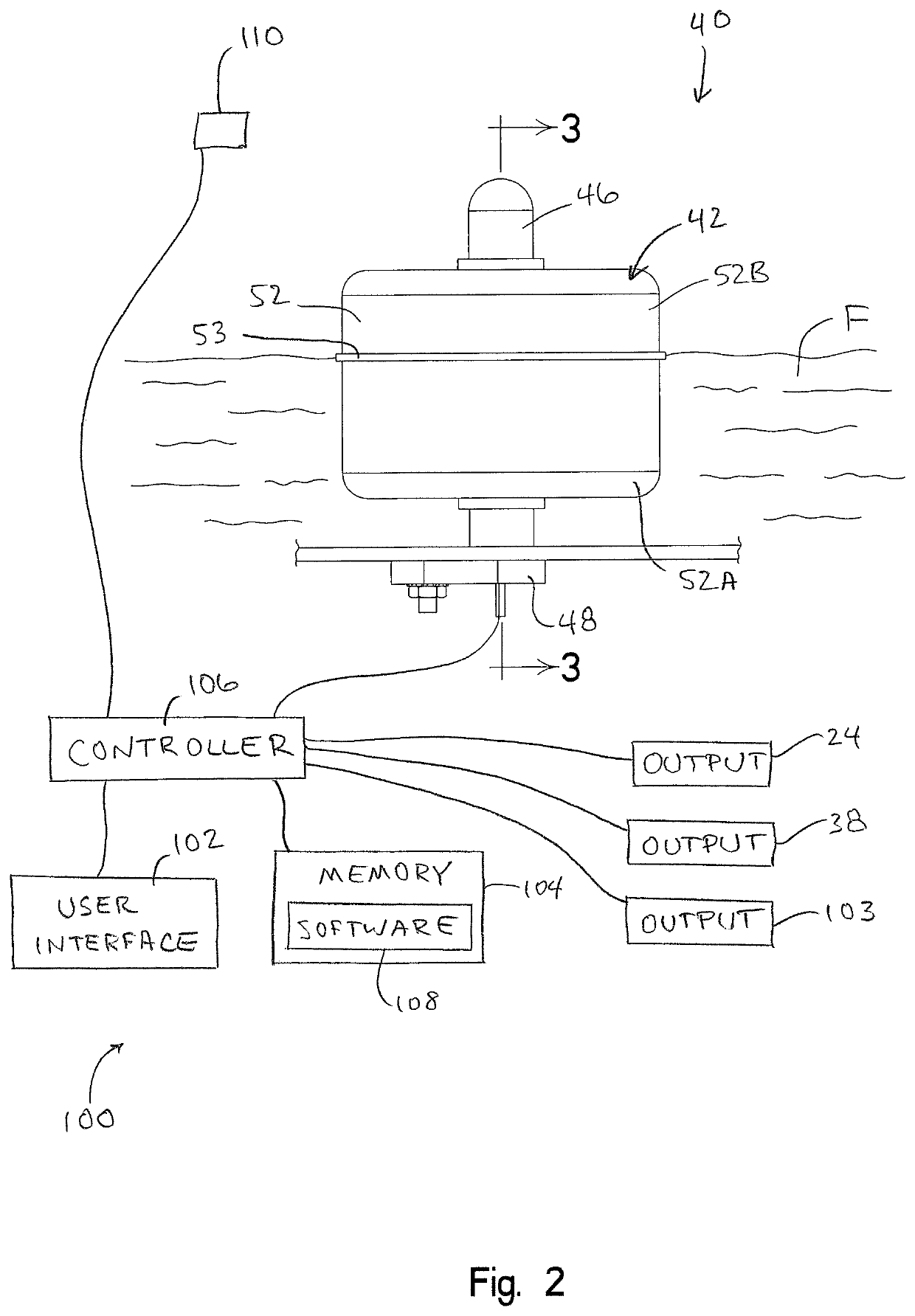

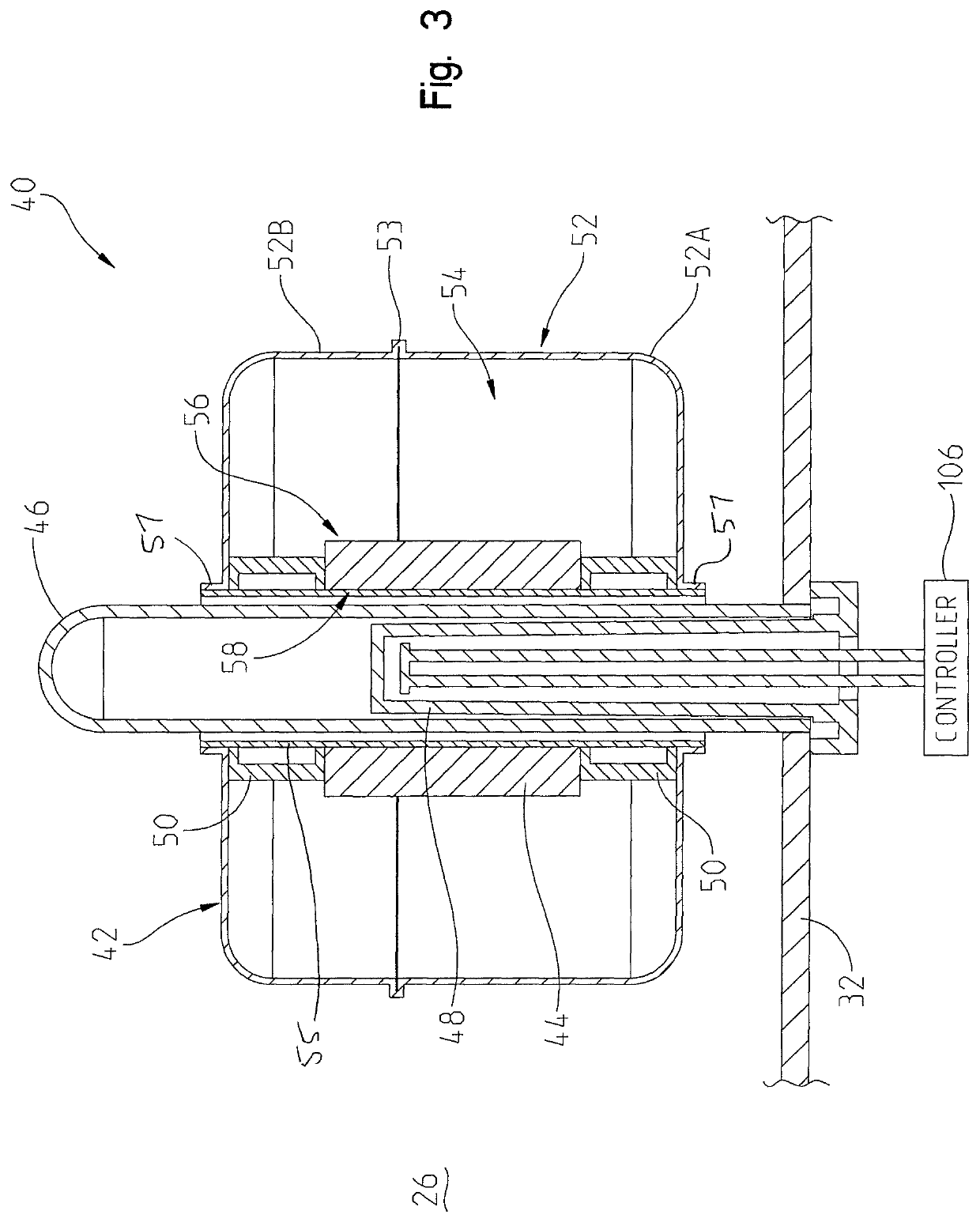

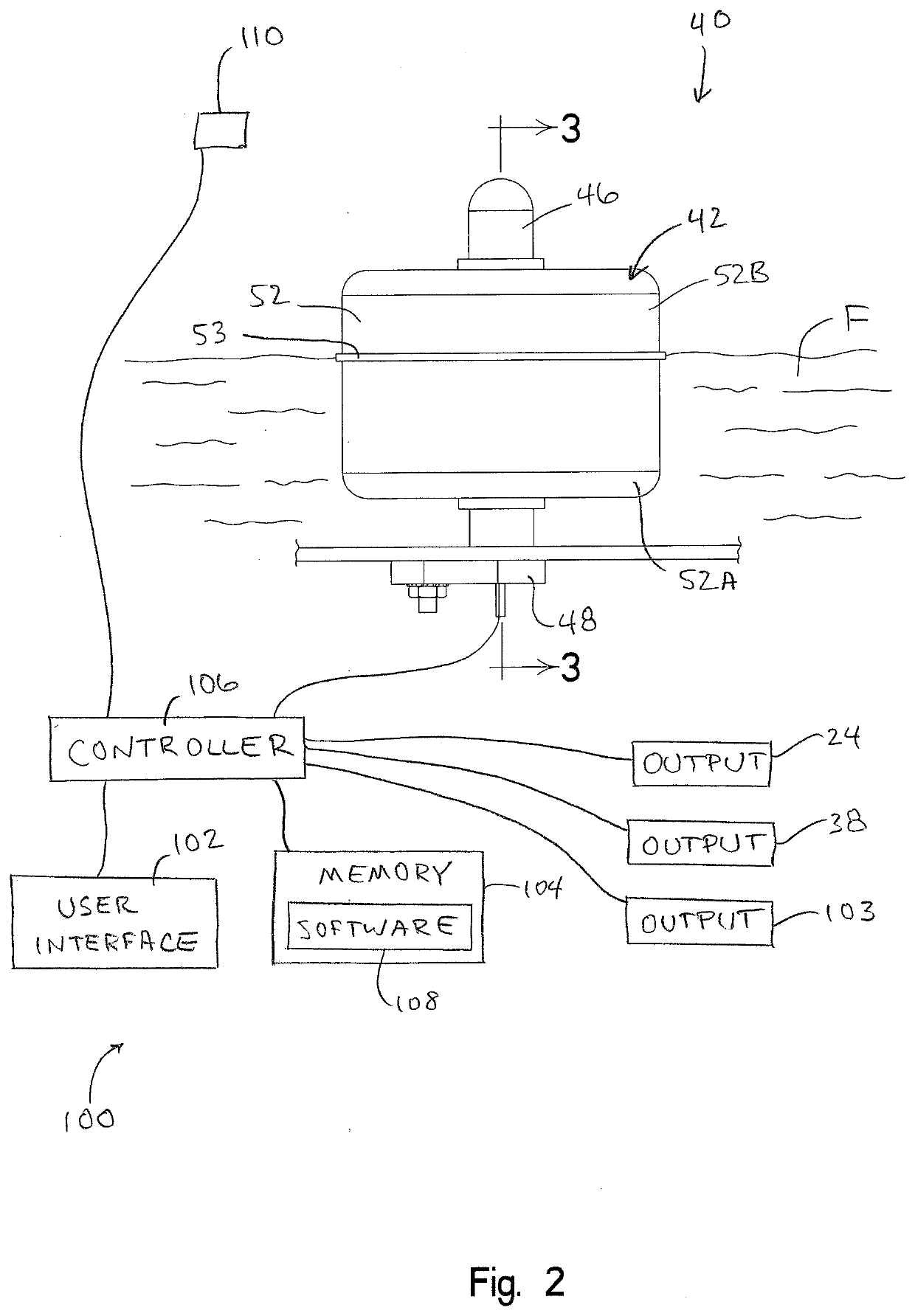

Monitoring with a radially magnetized magnet and hall effect sensor

ActiveUS10955281B1Harsh environmentWater-boiling vesselsSteam cooking vesselsEngineeringLiquid level sensor

An improved fluid level sensor includes a radially magnetized magnet integrated into a float, and a Hall sensor adapted to monitor the magnet field emitted from the magnet. This arrangement provides a continuously variable signal across a range of travel, such that a controller receiving the signal can produce precise fluid level measurements and detect operational states of an associated device based on fluid behavior. In addition, the present fluid level sensor is suitable for use in harsh service environments, both because it is physically resilient to fouling, and because the controller is capable of detecting fouling by sensor behavior. In the context of a steam cooker, the present fluid level sensor can also sense low-water, overfill and fouling conditions, while remaining relatively insensitive to food residue, water scale buildup, corrosion and foaming.

Owner:ACCUTEMP PRODS

Modular sealed portable digital electronic controller

InactiveUS20110017522A1Harsh environmentComponent is quite sensitiveDigital data processing detailsWeighing apparatus detailsElectronic controllerTransceiver

An electronic digital controller, such as a load cell indicator, is disclosed in which a number of components, such as a circuit board, display, and keypad are placed within an enclosure, and the enclosure is bonded closed, such as using an adhesive, to render the enclosure watertight. The keypad is a touch sensitive, capacitive keypad with no moving parts, and it is housed behind a rigid panel. An optoelectronic transceiver allows for data exchange with an electronic memory device housed in the adhesively sealed enclosure and allows for data exchange and for updating or modification of software code housed therein. Other components, such as another circuit board, a power supply, and block connectors, are placed in an adjacent enclosure, and the circuit boards in the two enclosures are electrically connected. The power supply is preferably a potted AC power supply but may also include a battery.

Owner:WEIGH TECH

Sliding extrusion type ball valve having integral structure

PendingCN112082013AReduce professional requirementsReduce riskCorrosion preventionPipe protection against corrosion/incrustationPipe fittingWorking environment

The invention discloses a sliding extrusion type ball valve having an integral structure in the technical field of ball valves, comprising: a valve body, a socket being provided at one end, and a valve end sliding extrusion pipe being fixedly arranged at the other end, the valve end sliding extrusion pipe and the valve body being of an integral structure, a limiting ring being annularly arranged on the outer wall of the valve end sliding extrusion pipe, and a valve end connecting cylinder being fixedly arranged on the outer side of the limiting ring; and a sliding extrusion pipe fitting, one end being a connecting plug, and the other end being a clamping cylinder, a clamping and pressing ring being annularly fixed to the outer wall, and a limiting step being annularly fixed to the inner wall, the clamping and pressing ring being isolated at the outer wall conjunction between the connecting plug and the clamping cylinder, and the limiting step being isolated at the inner wall conjunction between the connecting plug and the clamping cylinder. The operation is more convenient; the welding on an installation site is not needed; the open fire connecting operation is avoided; the mounting is easier and more convenient; the integral structure is adopted; both pressure and temperature changes are not afraid; and leakage is not likely to happen after long-term use in a worse working environment, so that the operation is safer.

Owner:FUZHOU ZHENXIE PIPE

Ductile metal alloys, method for making ductile metal alloys

A ductile alloy is provided comprising molybdenum, chromium and aluminum, wherein the alloy has a ductile to brittle transition temperature of about 300 C after radiation exposure. The invention also provides a method for producing a ductile alloy, the method comprising purifying a base metal defining a lattice; and combining the base metal with chromium and aluminum, whereas the weight percent of chromium is sufficient to provide solute sites within the lattice for point defect annihilation.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Front projection screen device and method for making screen body thereof

ActiveCN105527790BReduce penetrationImprove mechanical propertiesProjectorsPolyethylene terephthalateProjection screen

Owner:浙江威赛尼科技有限公司

Magneto-optical sensor

InactiveUS9133704B2Increase pressureHarsh environmentSurveyConstructionsOptic sensorOptical polarization

A magneto-optic sensor for oilfield application, the sensor (1, 1′, 101, 101′) receives an incident beam IB, IBA, IBB, IBC, IBD and comprises a polarizing element (3, 103) for providing a determined state of polarization beam and a Faraday rotator (4, 104) for providing a response beam having a modified state of polarization. The sensor provides a response beam (RB, RBA, RBB, RBC, RBD having an intensity dependent on an external magnetic field representative of a particular characteristic of a well-bore casing CC, CR applied on the Faraday rotator (4, 104).

Owner:SCHLUMBERGER TECH CORP

Monitoring with a radially magnetized magnet and hall effect sensor

ActiveUS20210348962A1Harsh environmentWater-boiling vesselsSteam cooking vesselsLiquid level sensorCooker

An improved fluid level sensor includes a radially magnetized magnet integrated into a float, and a Hall sensor adapted to monitor the magnet field emitted from the magnet. This arrangement provides a continuously variable signal across a range of travel, such that a controller receiving the signal can produce precise fluid level measurements and detect operational states of an associated device based on fluid behavior. In addition, the present fluid level sensor is suitable for use in harsh service environments, both because it is physically resilient to fouling, and because the controller is capable of detecting fouling by sensor behavior. In the context of a steam cooker, the present fluid level sensor can also sense low-water, overfill and fouling conditions, while remaining relatively insensitive to food residue, water scale buildup, corrosion and foaming.

Owner:ACCUTEMP PRODS

Bi-layer dual release probiotic tablets

ActiveUS10799541B2Easy to customizeHarsh environmentPeptide/protein ingredientsDigestive systemDual releaseDietary supplement

The present invention generally relates to dietary supplement and pharmaceutical formulations comprising layered acid protective oral dosage formulations comprising probiotics and provided as single unified or cohesive dosage form units. Each individual acid protective layer of the cohesive dosage form provides one of a different probiotic payload, a different release profile to target delivery of probiotic to a particular region in the gastrointestinal tract, or both different probiotic payloads and release profiles to target delivery of different probiotics to particular regions in the gastrointestinal tract.

Owner:PROBI USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com