Clamping and pressing type ball valve having integral structure

An integral structure and compression technology, applied in the valve shell structure, valve details, valve device and other directions, can solve the problems of welding seam leakage, limited application and promotion, complicated welding methods and processes, and reduce the risk of leakage and integrity. The effect of reducing the risk of installation work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

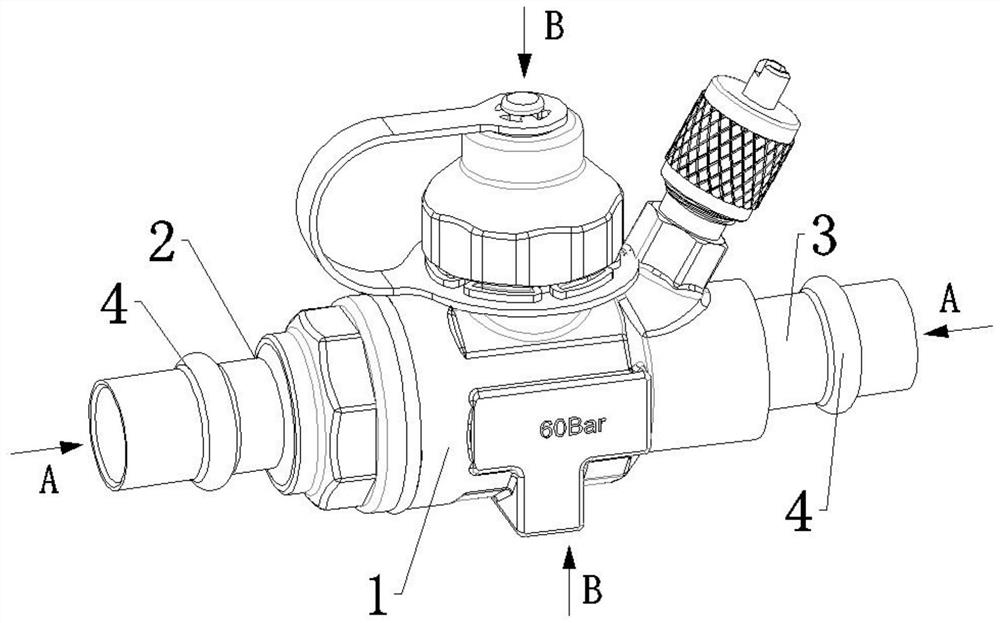

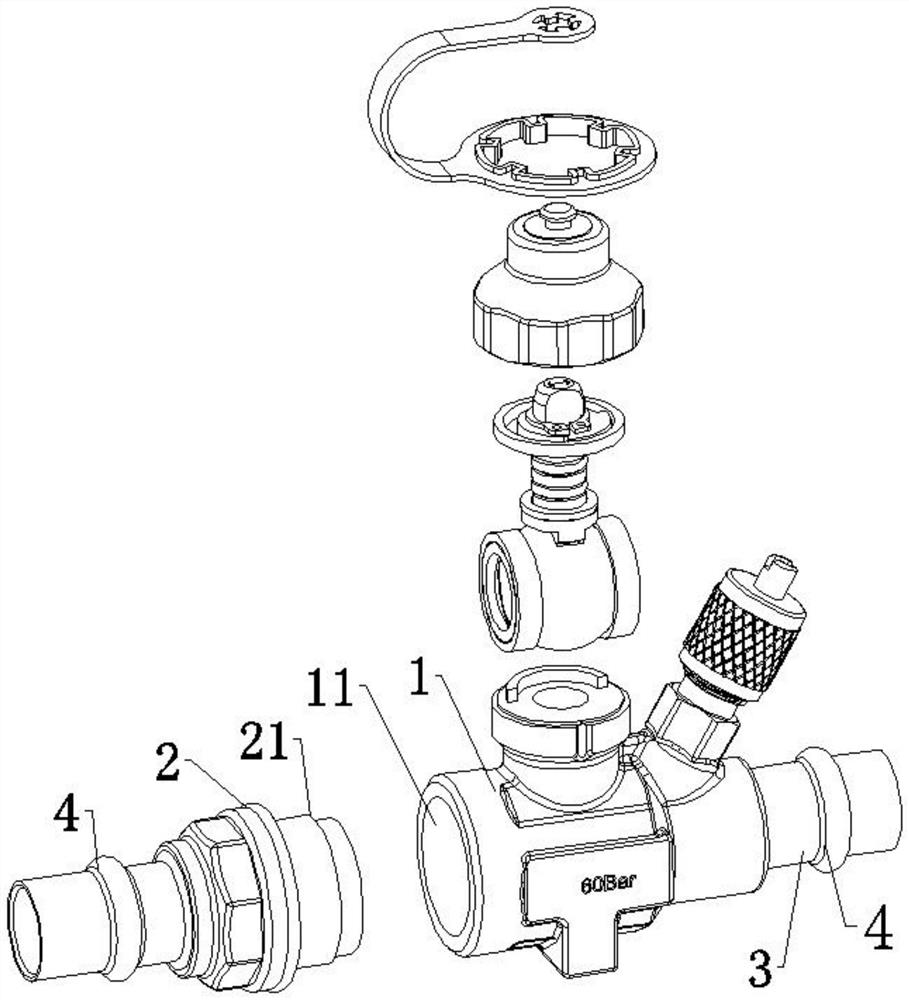

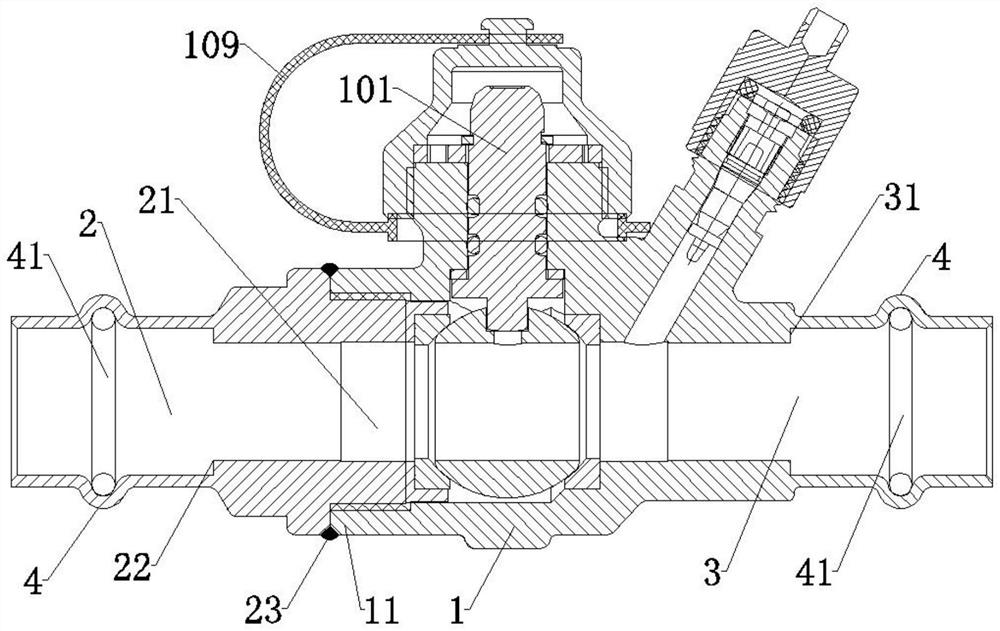

[0033] see Figures 1 to 6 As shown, the present invention provides a technical solution: a compression type ball valve with integral structure, including:

[0034] The valve body 1 is provided with a socket 11 at one end, and a valve end pressing pipe 3 is fixedly installed at the other end. The valve end pressing pipe 3 and the valve body 1 are an integral structure. convex groove 4;

[0035] Press the pipe fitting 2, one end is a plug joint 21, the other end is a pipe interface, and an outer convex groove 4 is also provided on it. The plug joint 21 is inserted in the socket 11, and the plug joint 21 and the socket 11 pass through the whole Sealed and fixed by welding;

[0036] Each of the outer convex grooves 4 is provided with a compression sealing ring 41;

[0037] The outer convex groove 4 is an arc-shaped and outwardly protruding annular groove provided on the inner shaft wall of the clamping pipe 3 and the pressing pipe fitting 2 at the valve end. The shaft wall fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com