Planetary speed reducer specially for roller way

A planetary reducer, roller table technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of limiting the bearing capacity of the reducer, the transmission ratio cannot be reasonably matched, etc., to achieve longevity and bearing capacity. High capacity, compact and reasonable internal structure, and weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

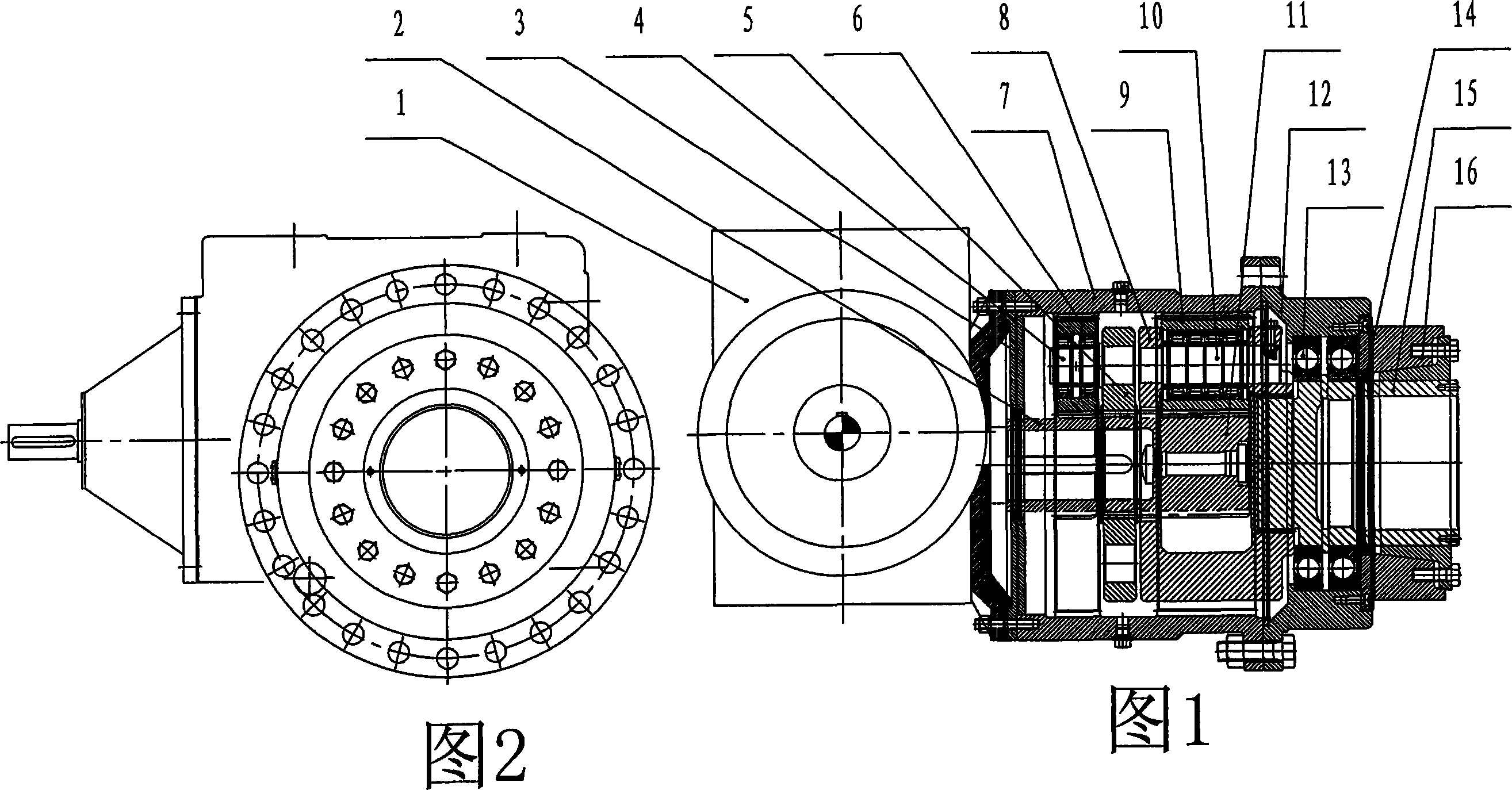

[0015] As shown in Figure 1, 1. Reducer, 2. First-stage sun gear, 3. Flange, 4. First-stage planetary shaft, 5. First-stage planet carrier, 6. First-stage planetary gear, 7. Front Airframe (including the first-stage ring gear and the second-stage ring gear), 8. The second-stage planet carrier, 9. The second-stage planetary gear, 10. The second-stage planetary shaft, 11. The second-stage sun gear, 12, rear body, 13, bearing, 14, oil seal, 15, output hollow shaft, 16, expansion sleeve.

[0016] A specific embodiment of the present invention includes: a special planetary reducer for roller tables, including a flange 3, a box body, a sun gear, a planetary wheel, a planet carrier, and an output hollow shaft 15, and the box body includes a front body 7 and a rear body 12, and the front body 7 is provided with a first-stage ring gear and a second-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com