Self-electroosmosis hydrogel adhesive film

A hydrogel and gel technology, applied in electrotherapy, treatment and other directions, can solve the problems of high cost and limited application, and achieve the effects of stable material properties, simple processing process, and promoting penetration and absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

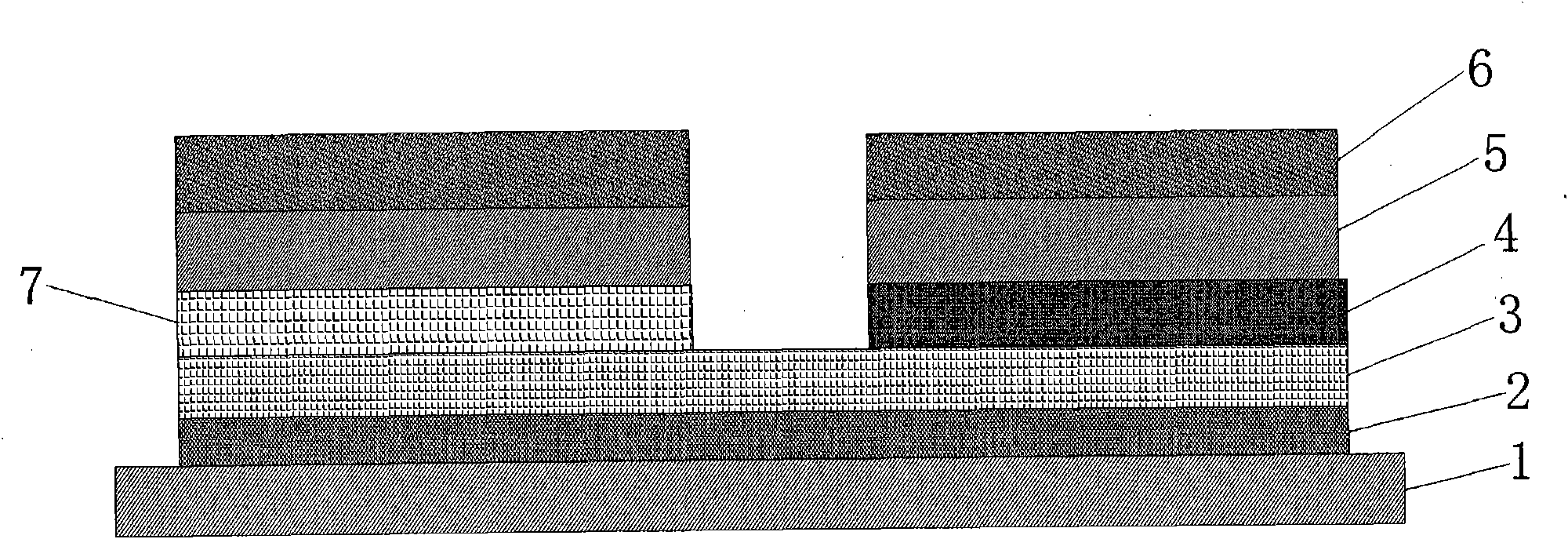

[0039] (1) Preparation of collector material. Mix 1g of graphite and 2g of acetate starch, use lecithin as a dispersing aid, dissolve in 5% polyvinyl alcohol aqueous solution by mass fraction, dry and ball mill for 6 hours to obtain the collector material for use;

[0040] (2) Preparation of negative electrode material. Mix nano-silver powder and neutral polyamide resin at 120°C in a ratio of 1:4 to obtain 2.0 g of a mixture, add 0.1 g of ethyl cellulose to adjust the viscosity, and mix to obtain a negative electrode material for use;

[0041] (3) Preparation of positive electrode material. Mix 1g of activated carbon and 1g of acetate starch, add 0.1g of natural graphite, use lecithin as a dispersing aid, dissolve in 5% polyvinyl alcohol aqueous solution by mass fraction, dry and ball mill for 8 hours to obtain a positive electrode material for use;

[0042] (4) Preparation of conductive adhesive material. Take 0.3 g of chitosan as a gel matrix agent and dissolve it in an org...

Embodiment 2

[0053] (1) Preparation of collector material. Mix 1g SuperP and 2g acetate starch, use lecithin as a dispersing aid, dissolve in 5% polyvinyl alcohol aqueous solution by mass fraction, dry and ball mill for 6 hours to obtain the collector material for use;

[0054] (2) Preparation of negative electrode material. Mix silver powder and neutral polyamide resin at 120°C in a ratio of 1:4 to obtain 2.0 g of a mixture, add 0.1 g of carboxymethyl cellulose to adjust the viscosity, and mix well to obtain a negative electrode material for use;

[0055] (3) Preparation of positive electrode material. Mix 1 g of acetylene black and 1 g of acetate starch, add 0.1 g of natural graphite, use lecithin as a dispersing aid, dissolve in 5% polyvinyl alcohol aqueous solution by mass fraction, dry and ball mill for 8 hours to obtain a positive electrode material for use;

[0056] (4) Preparation of conductive adhesive material. Take 0.3 g of sodium alginate as a gel matrix agent and dissolve i...

Embodiment 3

[0067] (1) Preparation of collector material. Mix 1g of graphite and 2g of acetate starch, use lecithin as a dispersing aid, dissolve in 5% polyvinyl alcohol aqueous solution by mass fraction, dry and ball mill for 6 hours to obtain the collector material for use;

[0068] (2) Preparation of negative electrode material. Mix nano-silver powder and neutral polyamide resin at 120°C in a ratio of 1:4 to obtain 2.0 g of a mixture, add 0.1 g of ethyl cellulose to adjust the viscosity, and mix to obtain a negative electrode material for use;

[0069] (3) Preparation of positive electrode material. Mix 1g of activated carbon and 1g of acetate starch, add 0.1g of natural graphite, use lecithin as a dispersing aid, dissolve in 5% polyvinyl alcohol aqueous solution by mass fraction, dry and ball mill for 8 hours to obtain a positive electrode material for use;

[0070] (4) Preparation of conductive adhesive material. Preparation of hydrogel materials. Take 0.3 g of chitosan as a gel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com