Stacked type battery

A stack type, battery technology, applied in secondary batteries, large flat batteries/batteries, secondary battery manufacturing, etc., can solve the problems of increased manufacturing cost, increased size of deposition equipment, complicated management, etc., and achieves no drop in productivity , the effect of heat dissipation improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described with reference to the drawings. In the drawings referred to below, the same or corresponding members are denoted by the same reference numerals.

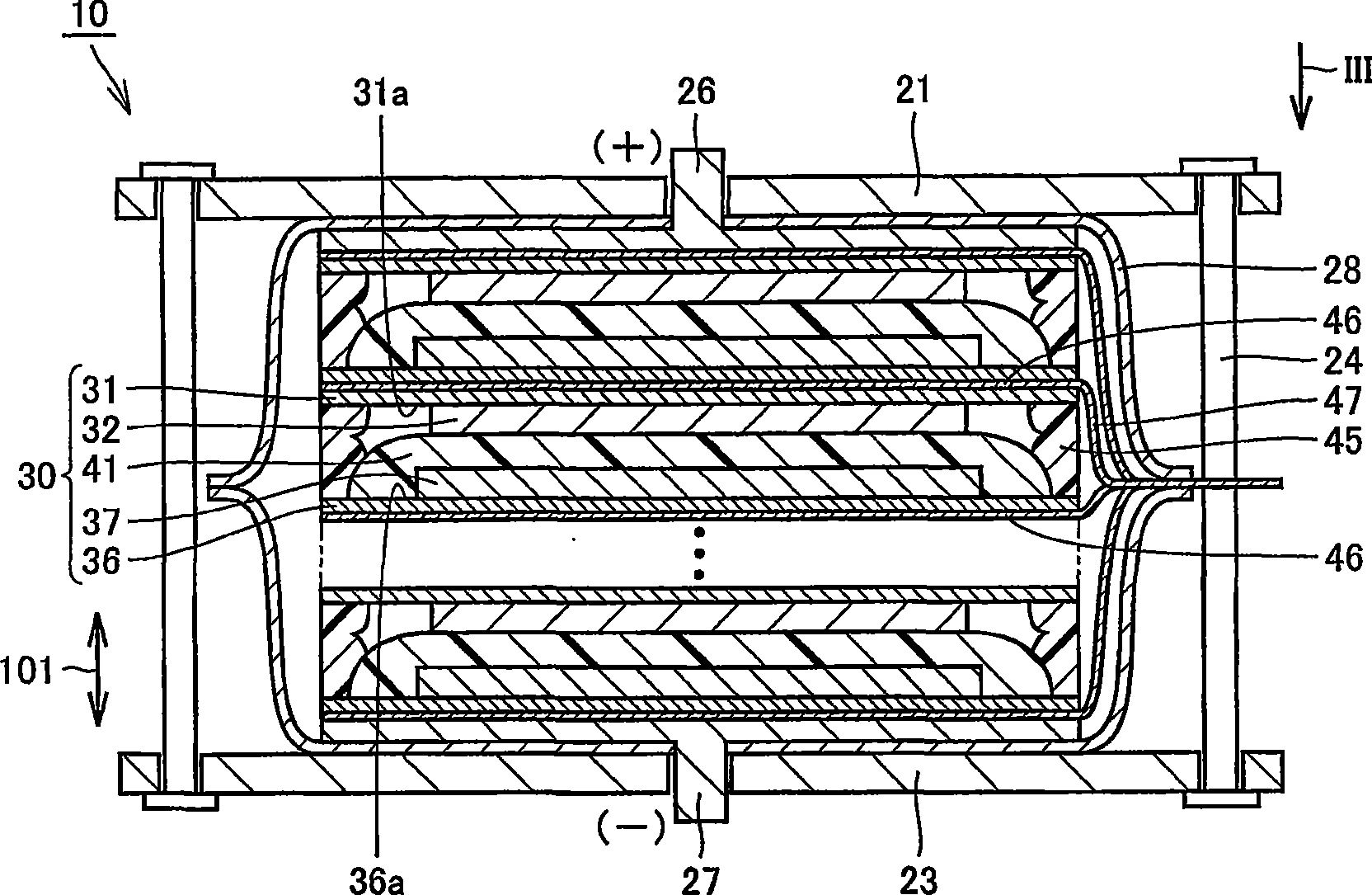

[0031] figure 1 It is a cross-sectional view showing a stacked battery in one embodiment of the present invention. refer to figure 1 , the laminated battery 10 is installed as a power source in a hybrid vehicle including an internal combustion engine (such as a gasoline engine or a diesel engine) and a rechargeable power source as a motive power source. The laminated battery 10 is formed of a lithium ion battery.

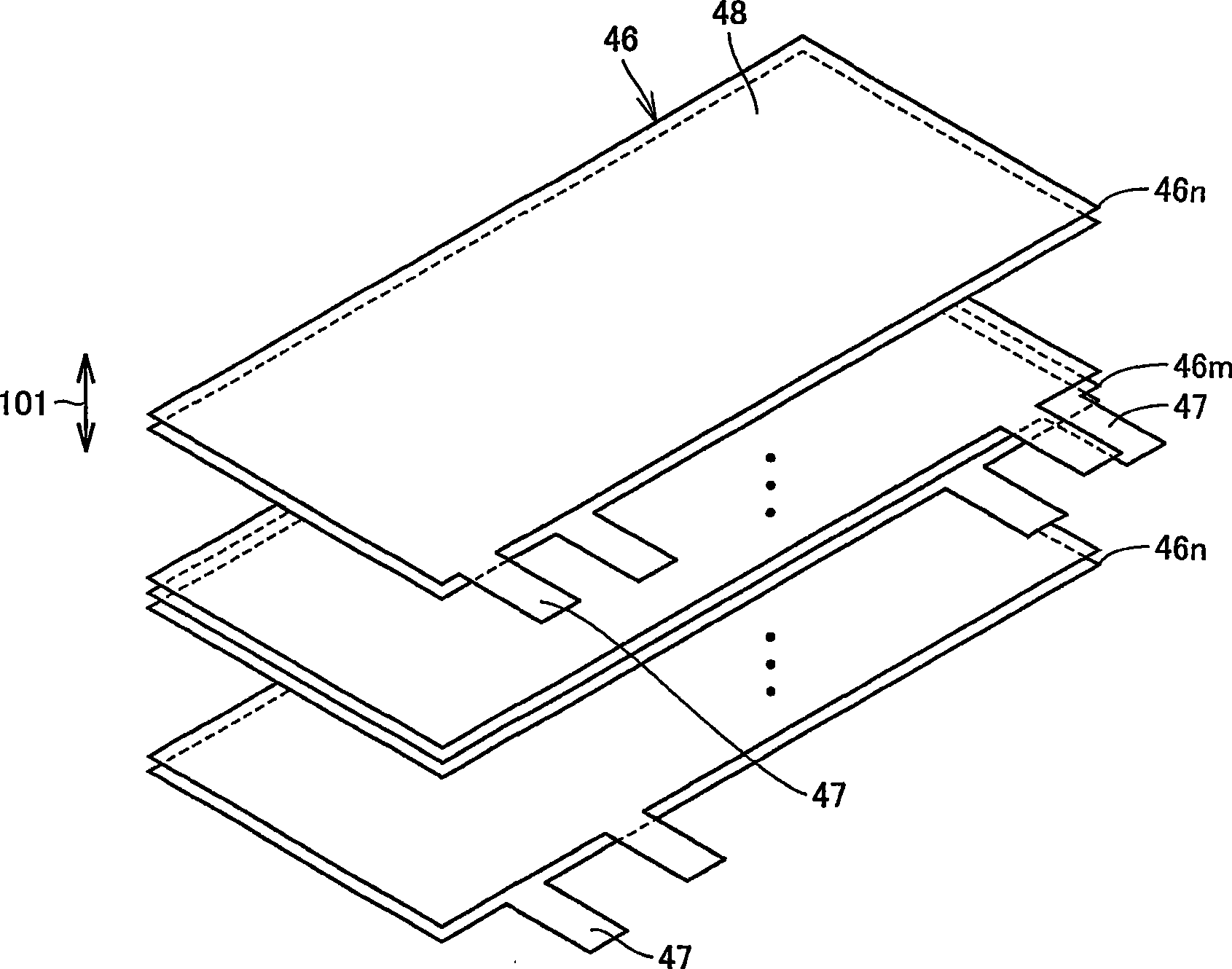

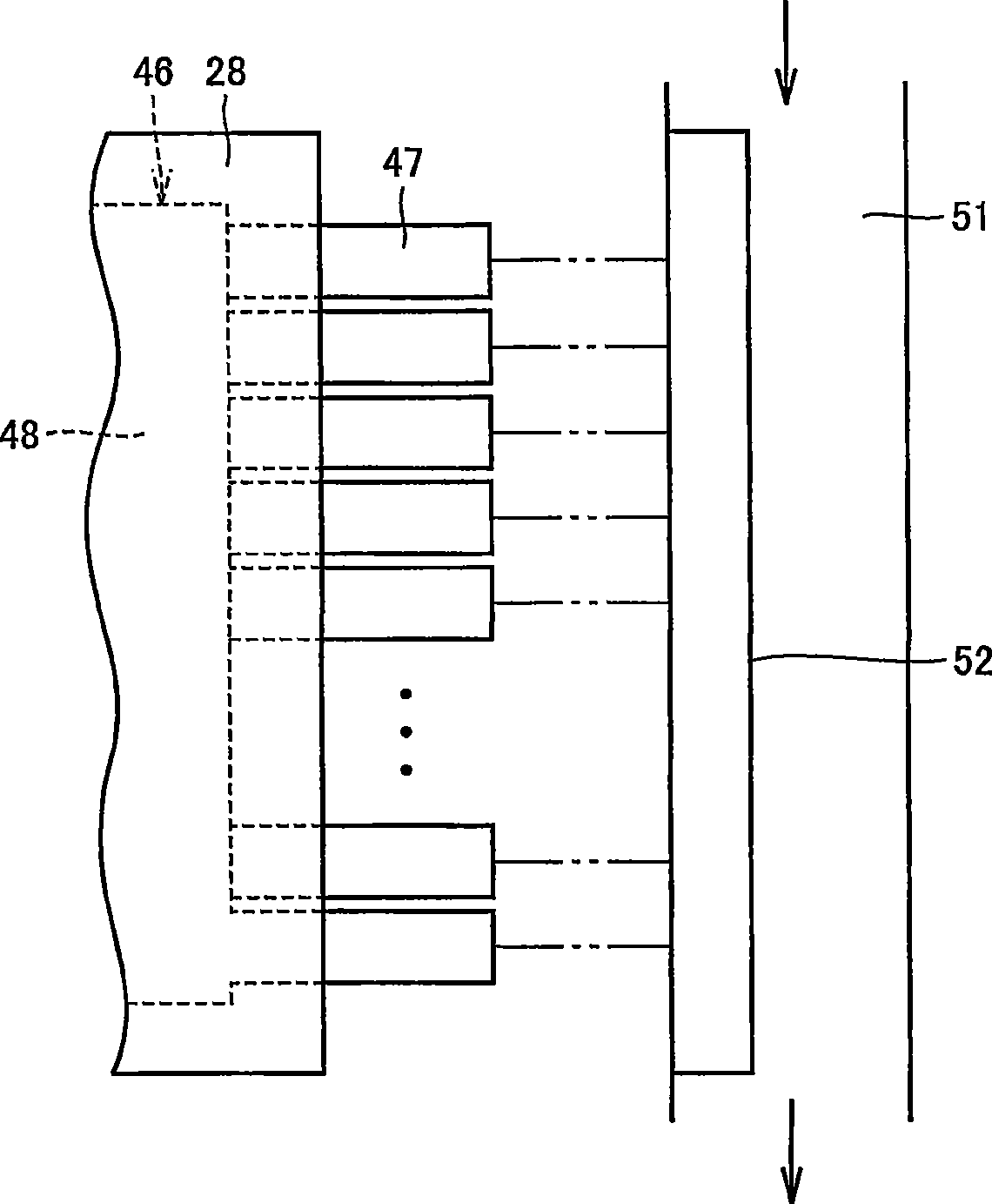

[0032] The laminated battery 10 includes a plurality of unit cells 30 stacked in a direction indicated by an arrow 101 and a plate member 46 arranged between the plurality of unit cells 30 . The laminated battery 10 has a substantially rectangular parallelepiped shape. The laminated battery 10 may have a flat shape in which the length in the stacking direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com