Recycled asphalt concrete processing system

A processing system and technology for reclaiming asphalt, applied in the directions of roads, separation methods, filtration and separation, etc., can solve the problems of inconvenient mixing and stirring production, inconvenience in complete matching of inner ends, inconvenient operation, etc., to improve efficiency, facilitate installation and connection, and realize regeneration. effect of function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

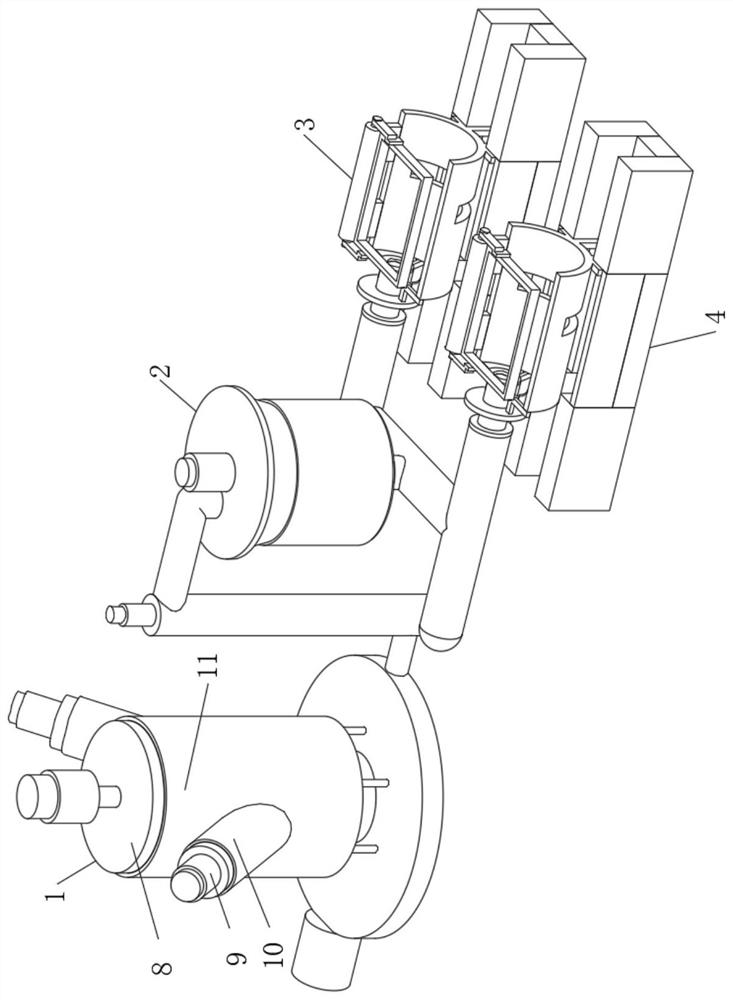

[0032] A regenerative asphalt concrete processing systems, such as figure 1 , Includes a preliminary mixing apparatus 1, the initial end position the mixing device 1 side in communication with a mixing processing means 2, machining end position of the mixing device 2 communicates at the bottom with a first preliminary filtering device 3, the other end of the bottom of the mixing apparatus and processing positions 2 filter means in communication with a second preliminary 4;

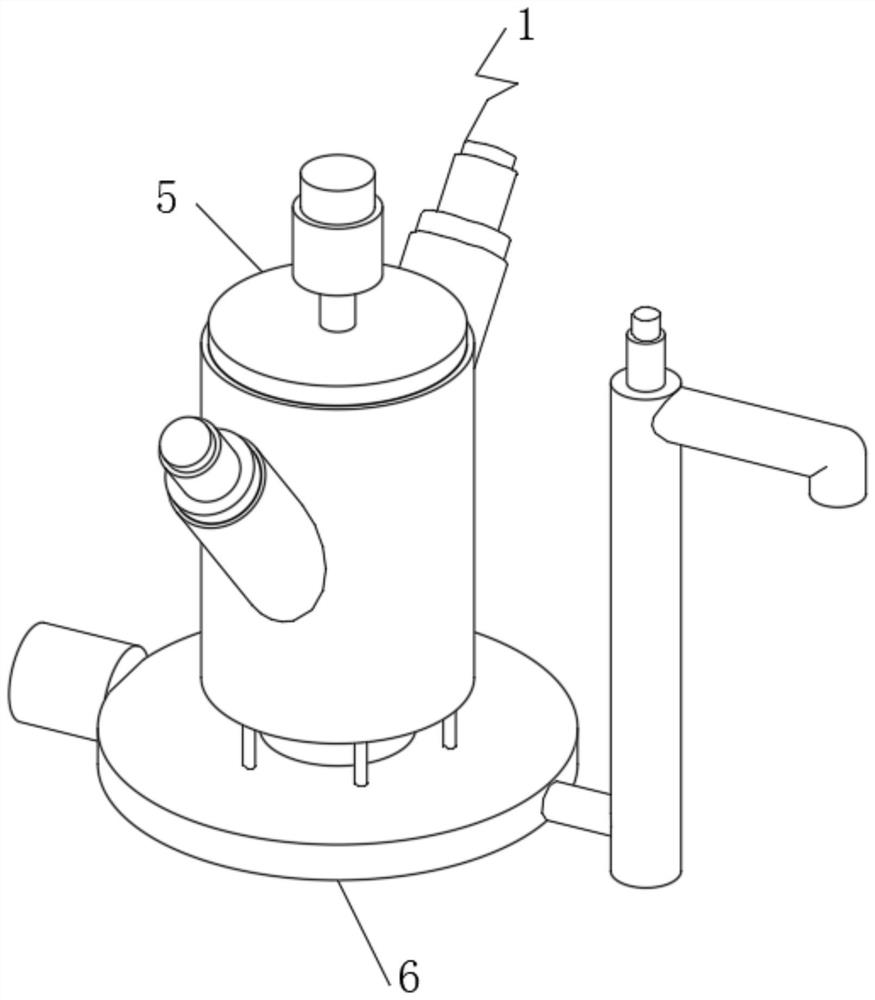

[0033] like figure 2 As shown in the preliminary mixing device 15 and the communication structure comprises a mixed structure 6, 6 communicating structure provided in the bottom end of the initial position of the mixing device 1, the upper end position of the structure 6 in communication with the mixed structure 5 disposed in communication;

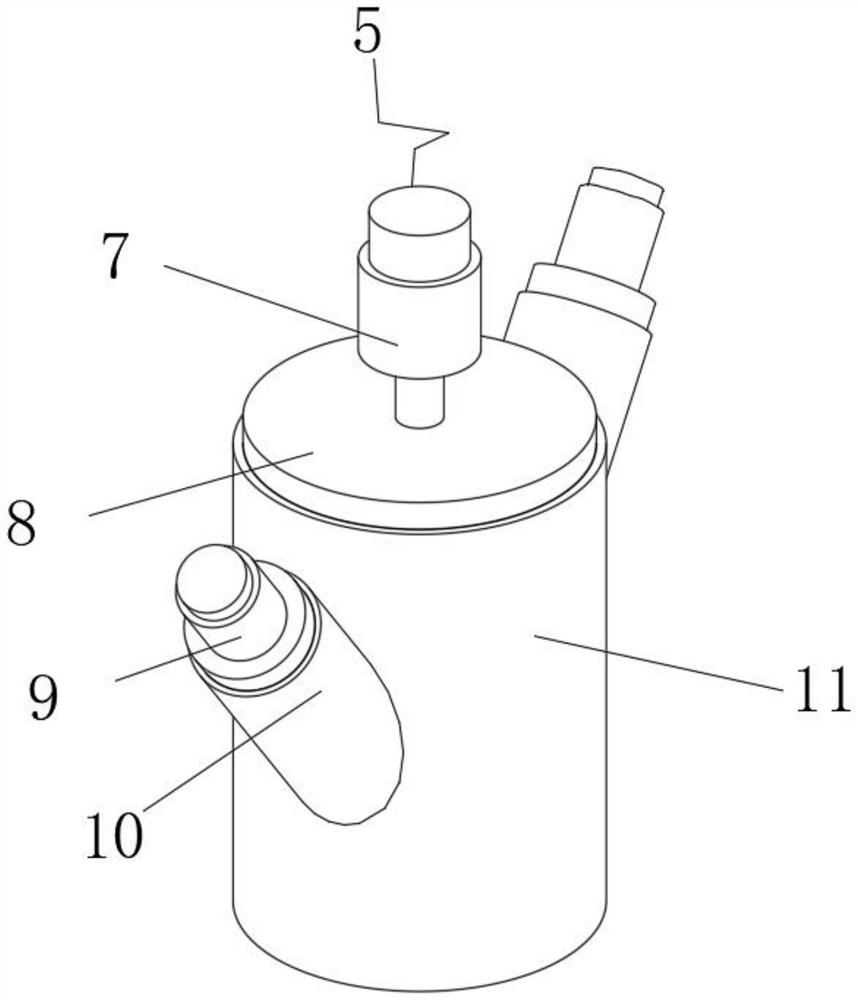

[0034] like image 3 , The hybrid structure 5 comprises a first motor 7, the cover frame 8, the second motor 9, sets of struts 10 and reaction vessel 11, a first motor 7 m...

Embodiment 2

[0044] On the basis of Example 1, if Figure 10 As shown, the first preliminary filter device 3 further includes a connection of the transmission belt 35 and a stable mount 36, and the stabilizing mount 36 is fixedly coupled to the side end position of the curved partition plate 33, and the upper end position of the stabilizing mount 36 is rotated. Connect the transmission belt 35.

[0045] When the present embodiment is used, the stabilizing mount 36 is fixed to the side end position of the arc-shaped partition plate 33 by the arrangement of the conveyance belt 35 and the stabilizing mount 36, and the connection transmission belt 35 is mounted in a solid mounting seat. The upper end surface of 36, the latter drive member is activated, and the connection conveyance belt 35 is activated, so that the filter residue on the upper end of the conveyor belt 35 can be discharged by the connection transmission belt 35.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com