Shielding gas flow controller for a welding apparatus

A technology of flow controller and shielding gas, which is applied in the direction of flow control of electric devices, flow control, welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

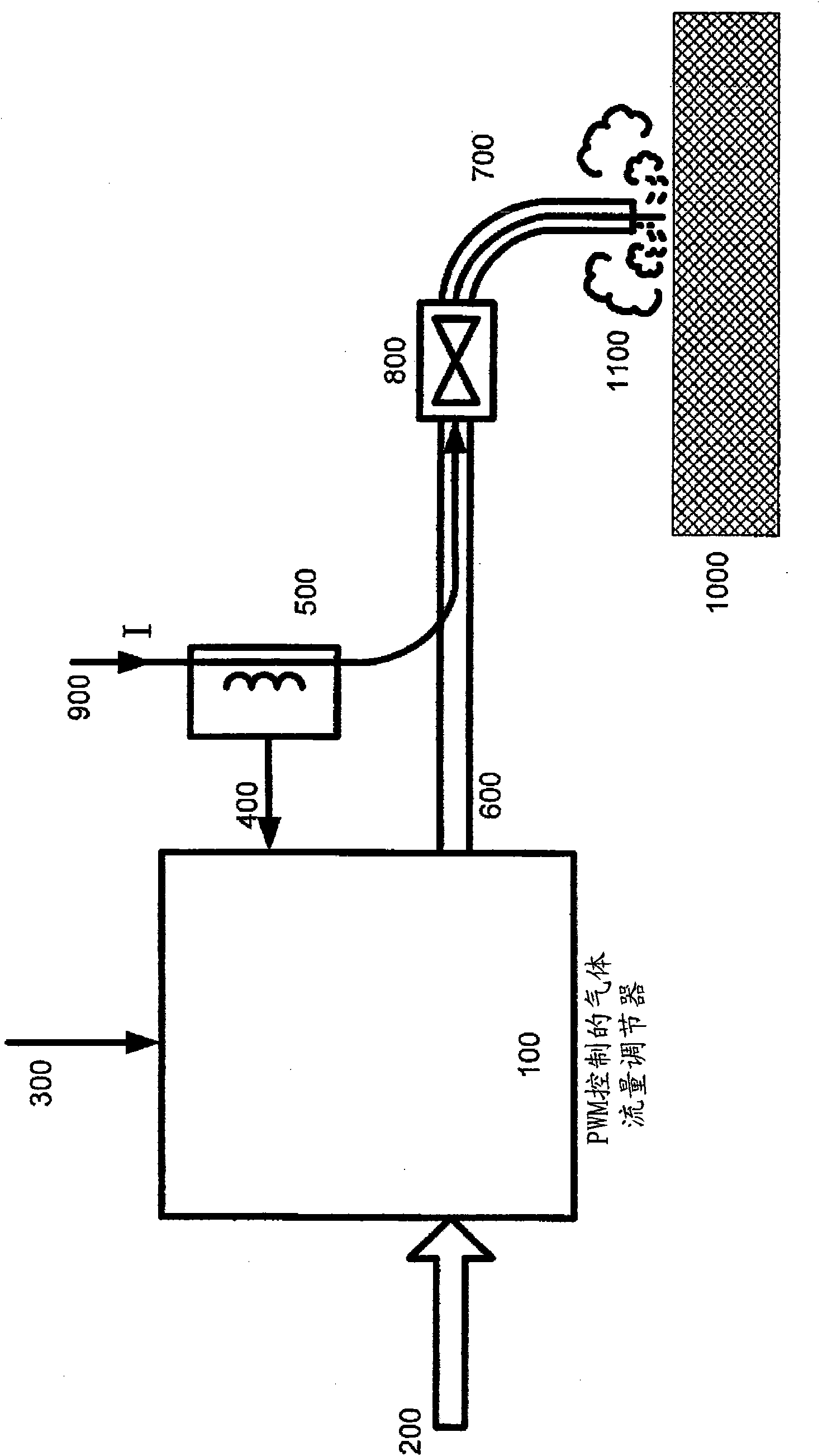

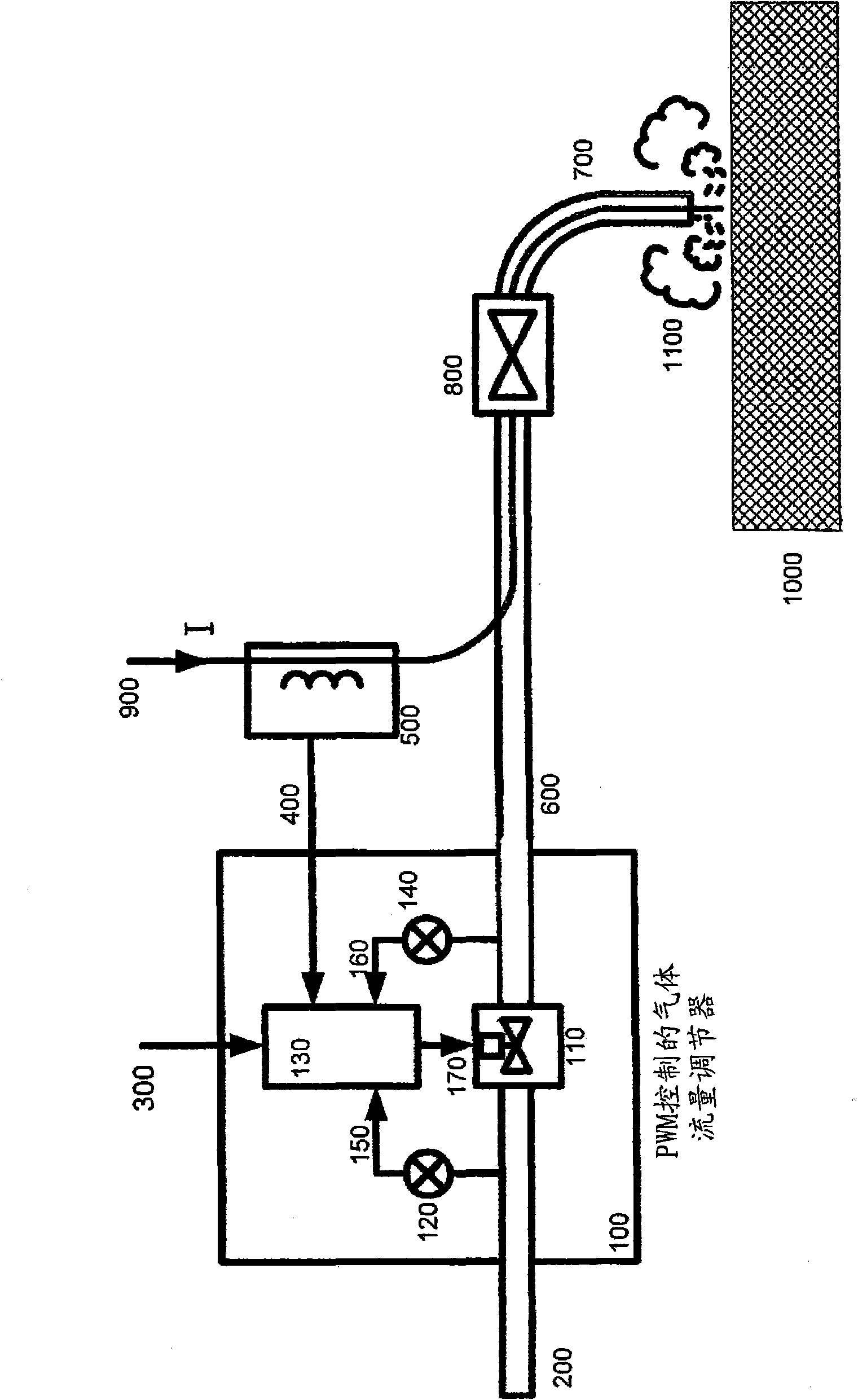

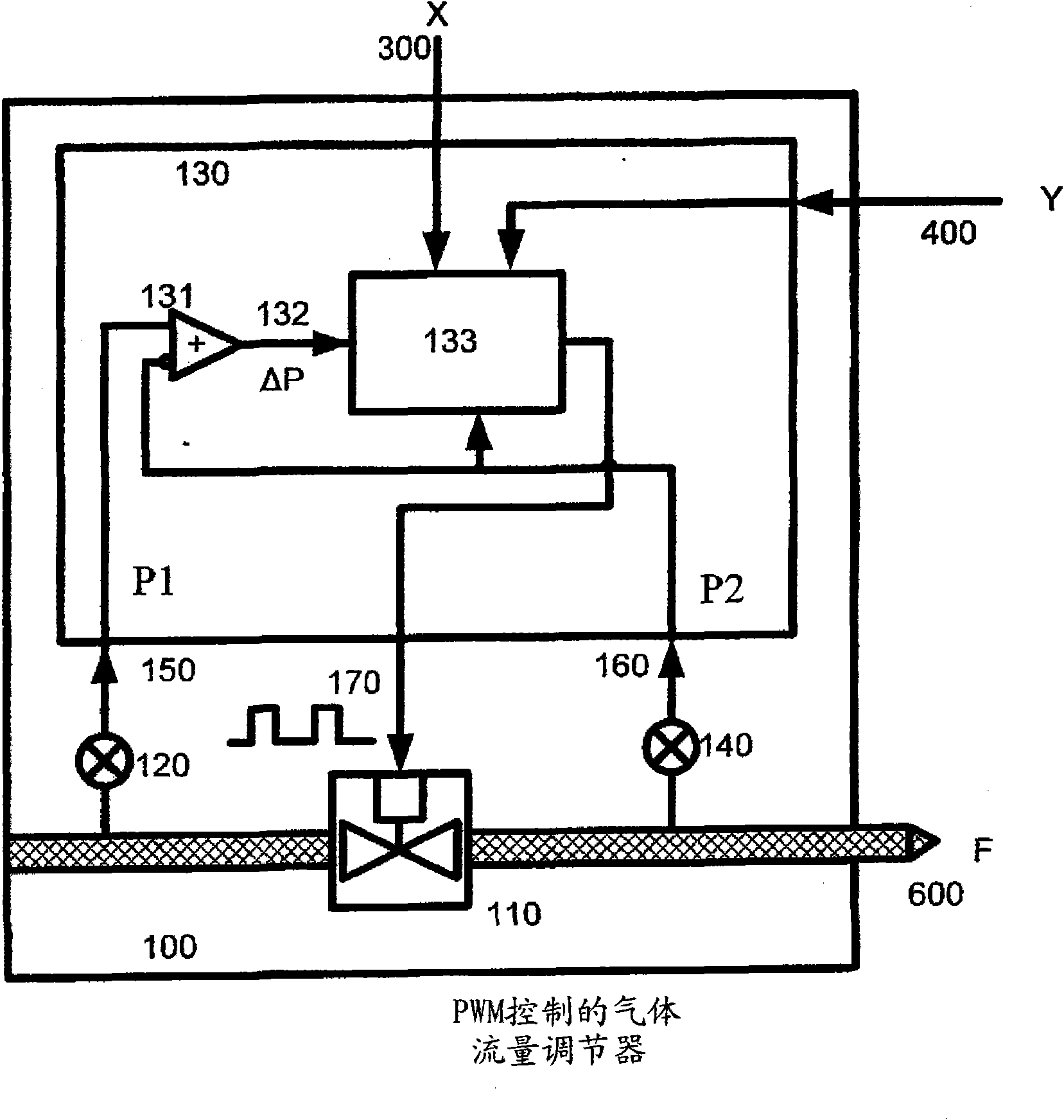

[0022] see figure 1 with figure 2 , the present invention provides an improvement in gas flow stability by automatically controlling the average time the valve remains open, thereby reducing the flow variation typically experienced in prior art welding gas supply installations. In a welding gas supply installation, the gas is supplied from a feed point 200 which will be arranged at a distance from the regulator 100 . In such prior art installations, it is common to locate the regulator 100 at a considerable distance from the gas final exit point 1100 . These distances will generally vary from one facility to another, and the dimensions of supply hoses, pipes, tubing, adapters and connectors will vary, with the result that gas flow levels will be affected, Such as Figure 8 As shown in the measurements performed in , and thus the flow needs to be adjusted in response to pressure changes in order to keep flow levels within acceptable tolerances.

[0023] The gas flow contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com