Method for additive manufacturing of high-entropy alloy part through metal wires

A high-entropy alloy and additive manufacturing technology, used in manufacturing tools, metal processing equipment, welding accessories, etc., can solve the problems of difficult preparation of pre-alloyed powder, waste of alloy raw material powder, and difficulty in real-time control of alloy composition, so as to avoid waste. , low cost, simple and easy preparation of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A robot is used to control the processing path, an electric arc is used as a heat source, and a CoCrFeNi four-principal high-entropy alloy part is manufactured by using a metal argon arc welding technology according to the method disclosed in the present invention. The main implementation steps are as follows:

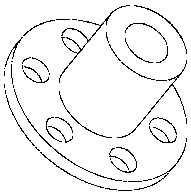

[0031] (1) Establish a three-dimensional model of the high-entropy alloy parts to be manufactured on the computer (such as figure 1 shown), and program the robot machining path according to the 3D model of the part.

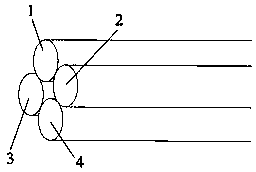

[0032] (2) if figure 2 As shown, select pure metal Co, Cr, Fe and Ni wires with a diameter of 0.5 mm, choose one wire for each type, and combine these four pure metal wires into a wire rope.

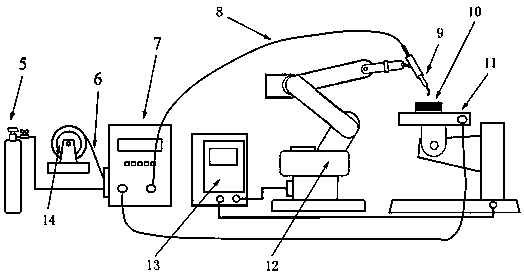

[0033] (3) Schematic diagram of additive manufacturing equipment such as image 3 shown. During additive manufacturing, the wire rope 6 synthesized by metal wire is loaded into the welding wire reel 14, and one end thereof passes through the welding cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com