Weld joint real-time protection cover during welding

A protective cover and gap technology, applied in the direction of welding protection devices, welding accessories, devices for supplying/removing protective gas, etc., can solve the problems of pollution, welding seam pollution, no protection, etc., and achieve the effect of avoiding smoke pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

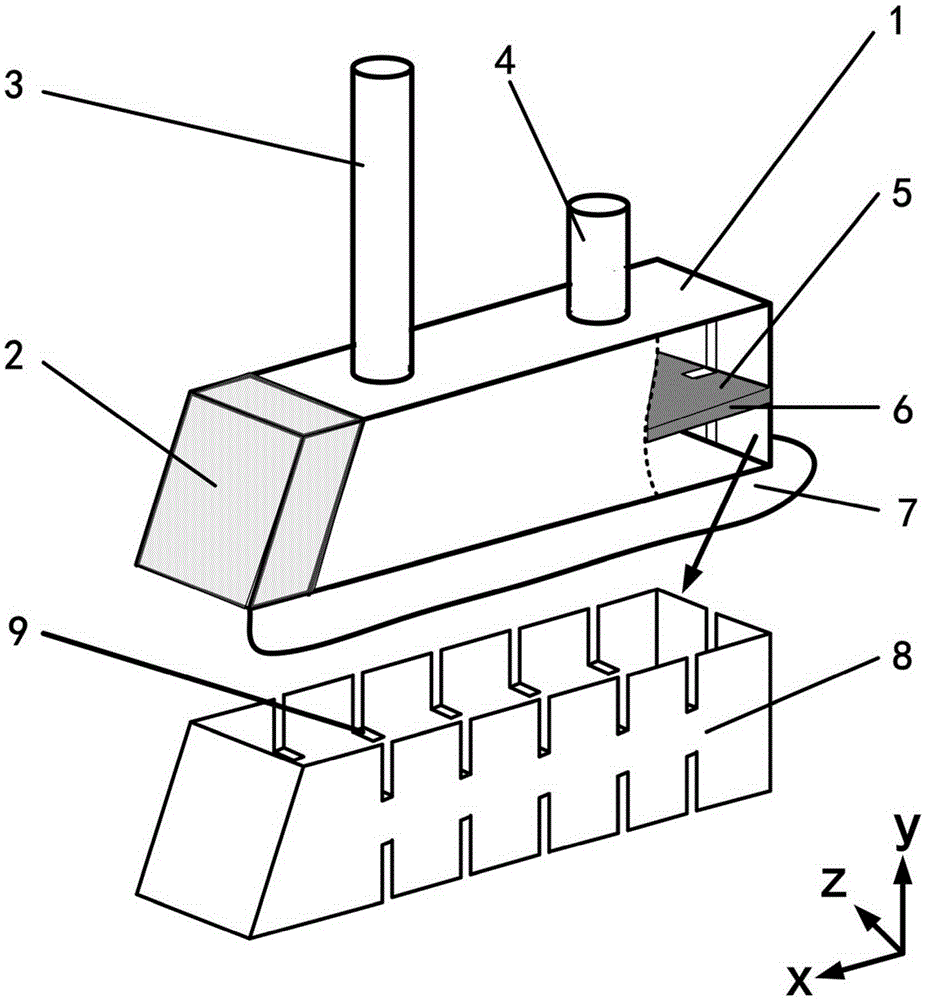

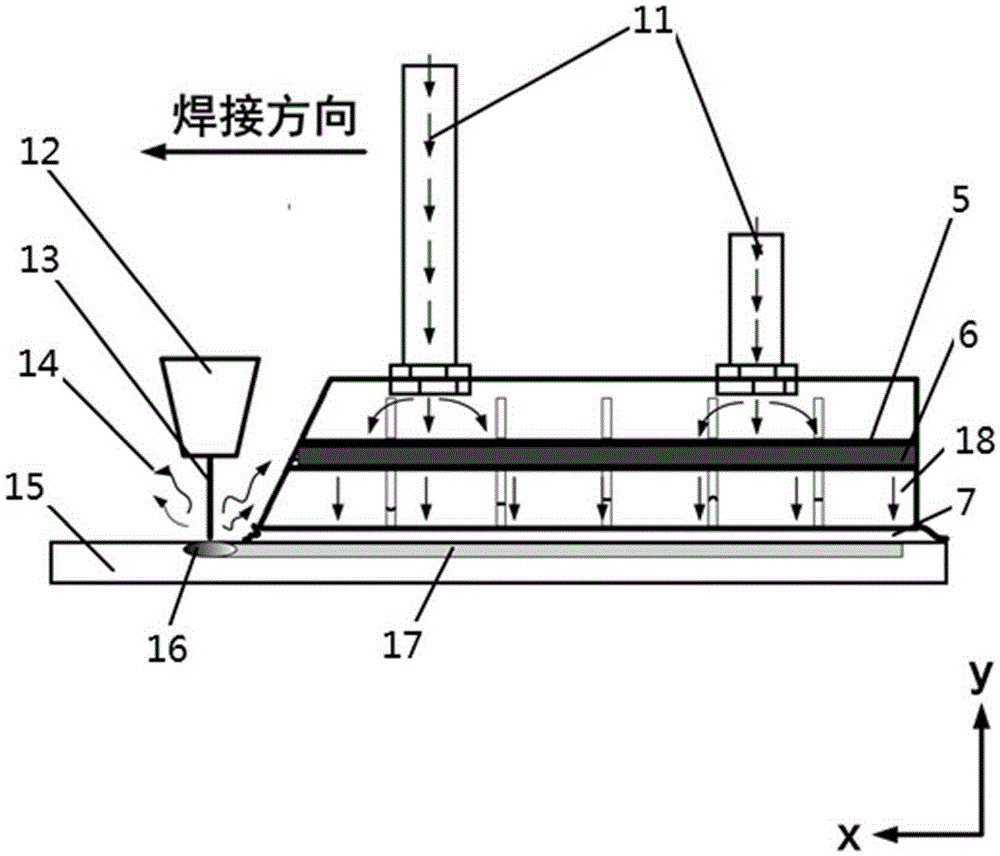

[0019] see figure 1 As shown, a welding seam real-time protective cover during welding of the present invention includes a protective cover shell 1, a smoke baffle 2, a fireproof cotton 7 and a bracket 8 for fixing the metal mesh and clamping the fireproof cotton.

[0020] The protective cover shell 1 is a rectangular box with an open bottom, and the front end of the protective cover shell 1 is provided with a slope. The size of the protective cover shell 1 can be determined by the length and width of the weld to be welded, and generally can be made of 0.8-1mm thick steel plate or copper plate.

[0021] The dust baffle plate 2 is buckled on the front slope of the protective cover shell 1, and as the front baffle plate of the protective cover, it is generally easier to dissipate heat and be made of a metal plate that is difficult to tolerate, such as a copper plate. Thickness comparable to protective cover shell. On the one hand, its function is to push away the smoke generat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com