Butt joint circular seam reverse side gas shielding device for barrel fusion welding

A gas shielding device and technology of gas shielding, applied in the direction of providing/exhausting shielding gas devices, auxiliary devices, welding accessories, etc., can solve problems such as difficulties, reduced joint performance, unsuitable for single-piece or small batch production, etc., to reduce The time required, the reduction of elliptical deformation, the effect of good protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

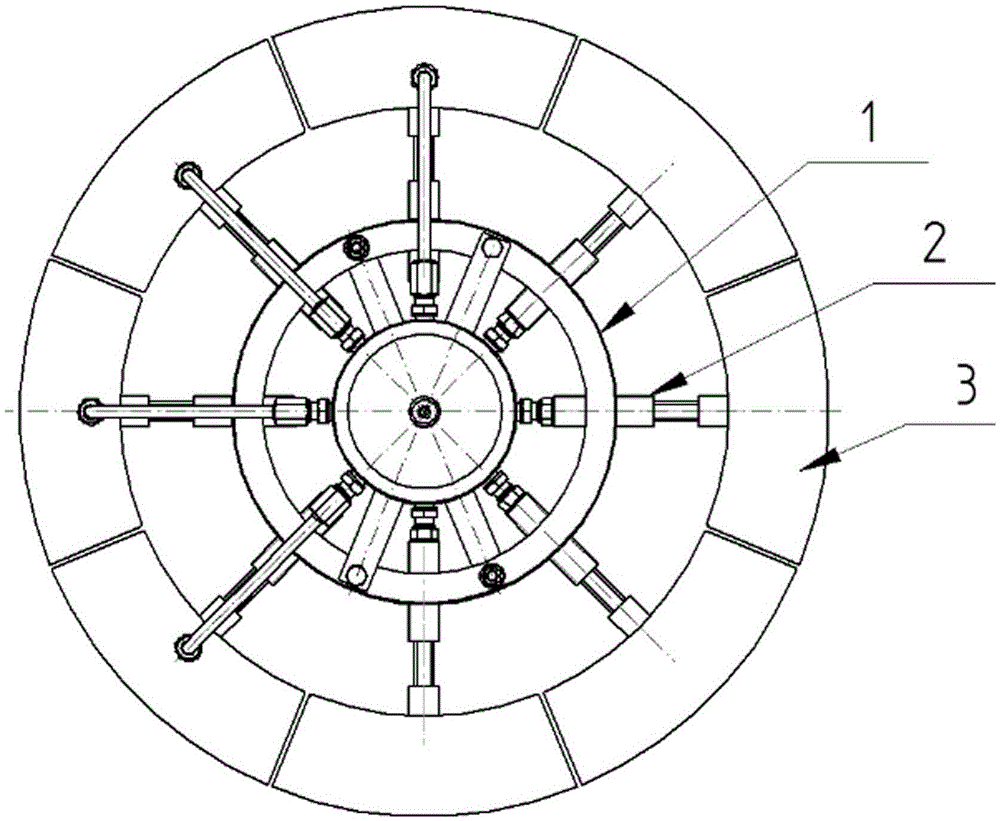

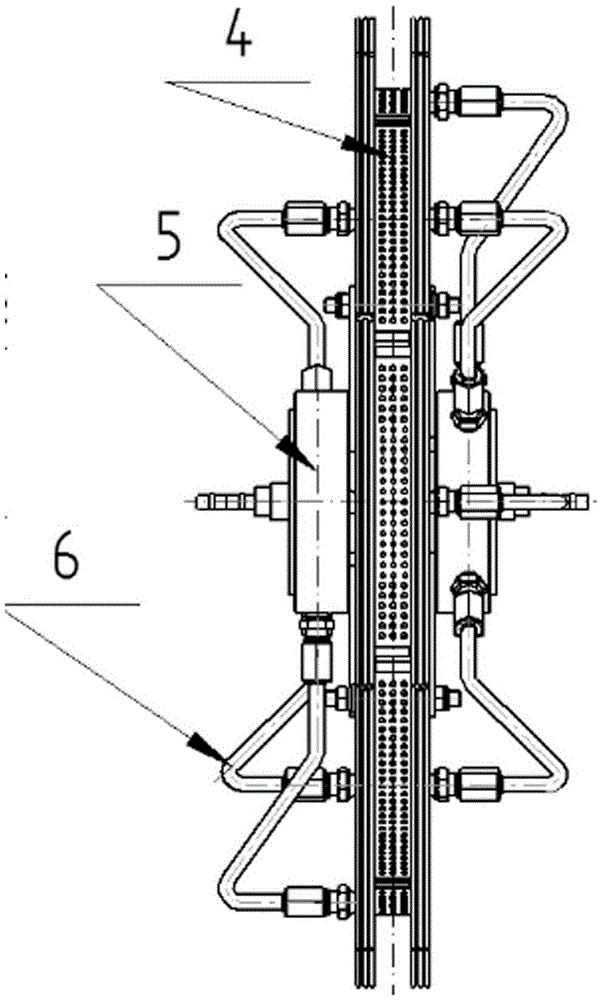

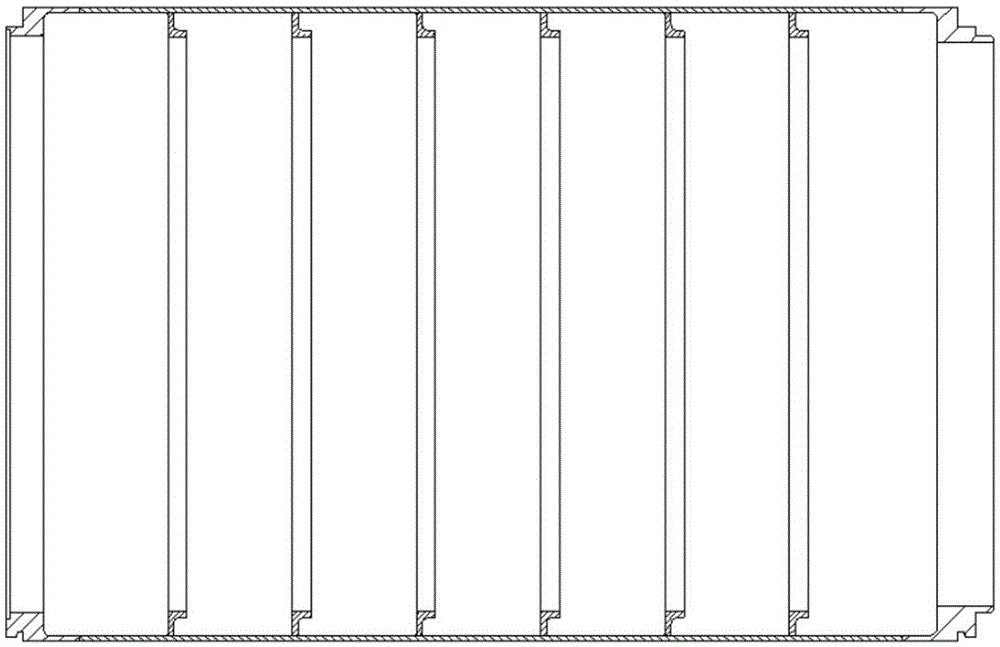

[0017] See figure 1 , figure 2 , a gas protection device for the back side of the cylinder fusion welding butt joint ring seam. The characteristics of the present invention are that it includes two parts: a welding fixture and a gas shielding gas circuit. The welding fixture consists of a supporting ring 1, 8 adjusting screws 2 and 8 arcs The arc-shaped gas protection groove 3 with the same internal diameter of the cylinder is composed of an air-filled hole 7 on the side of the protection groove 3, and a perforated plate 4 for uniform diffusion of auxiliary gas is added in the groove, and the two sides of the protection groove 3 contact the inner wall of the cylinder. For the sealing groove 8, if the elliptical deformation of the cylinder body is relatively large, and the arc surface of the protection groove does not fit tightly with the inner wall of the housing, and the sealing effect is affected, the groove can be filled with asbestos rope. The gas shielding gas path incl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com