Method for preparing phase change asphalt pavement material

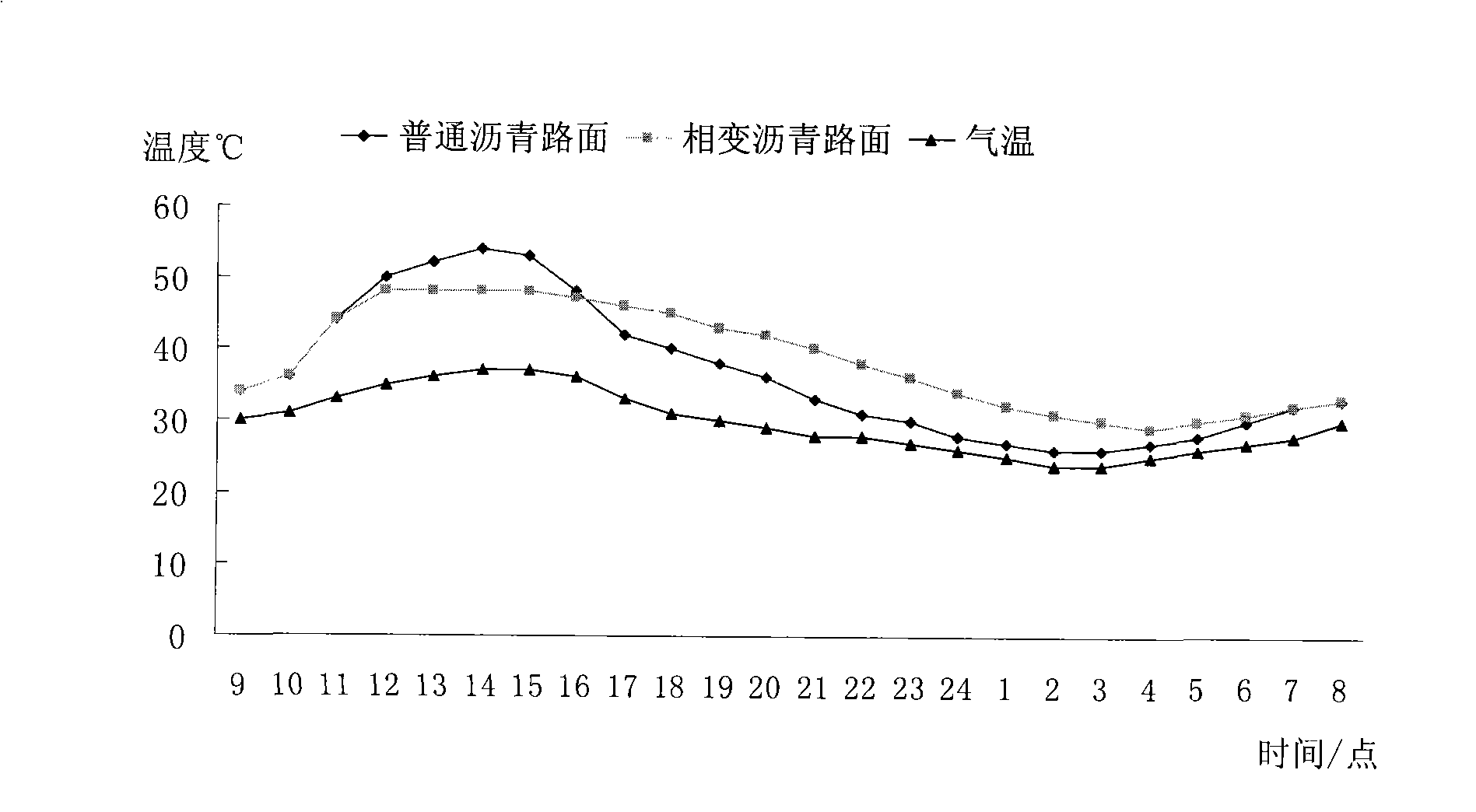

A technology for asphalt pavement and phase change material, which is applied in the field of preparation of phase change asphalt pavement materials, can solve the problems of reducing the service performance of the road surface, endangering the driving safety, pushing the asphalt mixture, etc., to enhance the high temperature resistance performance and improve the high temperature stability. performance, prolonging the life of the pavement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of phase change asphalt pavement material, which includes the following steps:

[0025] 1) Preparation of phase change asphalt modifier: ① According to mass ratio, phase change material: coagulant: support material: coupling agent = 100:2:20:2.4, select phase change material, coagulant, support Material and coupling agent, spare;

[0026] The phase change material is polyethylene glycol (1000, 2000);

[0027] The coagulant is CaCl 2 ;

[0028] The supporting material is polyvinyl alcohol;

[0029] The coupling agent is titanate;

[0030] ② Add the phase change material to the silica sol with a mass concentration of 25%. The mass ratio of the silica sol to the phase change material is 100:12. After the phase change material is completely dissolved, the coagulant is added dropwise, and under strong stirring, It undergoes a gelation reaction and forms a two-dimensional network structure gel after standing; the gel is dried in an oven at 80°C for 30 hours, ...

Embodiment 2

[0039] A preparation method of phase change asphalt pavement material, which includes the following steps:

[0040] 1) Preparation of phase change asphalt modifier: ①According to the mass ratio of phase change material: coagulant: support material: coupling agent = 100:3:20:3.2, select phase change material, coagulant, support Material and coupling agent, spare;

[0041] The phase change material is polyethylene (carbon chain length 20-30);

[0042] The coagulant is MgCl 2 ;

[0043] The supporting material is polyvinyl alcohol;

[0044] The coupling agent is 1,4-butanediol;

[0045] ② Add the phase change material to the silica sol with a mass concentration of 30%. The mass ratio of the silica sol to the phase change material is 100:15. After the phase change material is completely dissolved, the coagulant is added dropwise, and under strong stirring, It undergoes a gelation reaction and forms a two-dimensional network structure gel after standing; the gel is dried in an oven at ...

Embodiment 3

[0054] A preparation method of phase change asphalt pavement material, which includes the following steps:

[0055] 1) Preparation of phase change asphalt modifier: ①According to the mass ratio of phase change material: coagulant: support material: coupling agent = 100:1:10:1, select phase change material, coagulant, support Material and coupling agent, spare;

[0056] The phase change material is paraffin wax (carbon chain length 16-20);

[0057] The coagulant is CaCl 2 ;

[0058] The supporting material is silicon dioxide;

[0059] The coupling agent is 1,4-butanediol;

[0060] ② Add the phase change material to the silica sol with a mass concentration of 20%. The mass ratio of the silica sol to the phase change material is 100:10. After the phase change material is completely dissolved, add the coagulant dropwise, and under strong stirring, It undergoes a gelation reaction and forms a two-dimensional network structure gel after standing; the gel is dried in an oven at 70°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com