Method for preparing graphene from lignin

A technology of lignin and graphene, applied in the direction of graphene, nano-carbon, etc., to achieve the effect of simple equipment and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

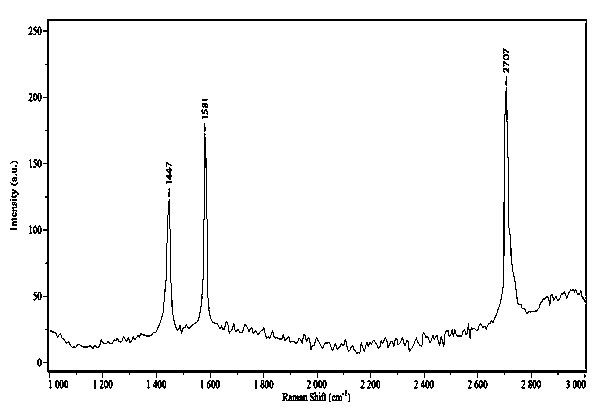

Image

Examples

Embodiment 1

[0023] At room temperature, nickel powder and alkali lignin with a mass ratio of 1:8 were evenly mixed, and then transferred to a porcelain sample boat. Then put the porcelain sample boat into the hinged tube furnace, open the nitrogen valve and feed nitrogen gas at a flow rate of 500ml / min. After 30min, heat the sample to 1500°C at a heating rate of 30°C / min, and keep it at this temperature Keep it for 30 minutes; turn off the heating switch, and when the temperature of the sample drops to around room temperature, take out the sample, wash with deionized water, dilute nitric acid, deionized water, vacuum filter, and dry at low temperature to obtain graphene.

Embodiment 2

[0025] At room temperature, ferric citrate and lignosulfonate with a mass ratio of 1:3 were mixed evenly, and then transferred to a porcelain sample boat. Then put the porcelain sample boat into the hinged tube furnace, open the argon gas valve and feed argon gas at a flow rate of 2000ml / min. After 5min, the sample was heated to 500°C at a heating rate of 5°C / min. Keep at temperature for 120 minutes; turn off the heating switch, and when the temperature of the sample drops to around room temperature, take the sample out, wash with deionized water, vacuum filter, and dry at low temperature to obtain graphene.

Embodiment 3

[0027] At room temperature, nickel acetate and solvent-based lignin with a mass ratio of 1:5 were evenly mixed, and then transferred to a porcelain sample boat. Then put the porcelain sample boat into the hinged tube furnace, open the nitrogen valve and feed nitrogen gas at a flow rate of 1000ml / min. After 20min, heat the sample to 1200°C at a heating rate of 20°C / min, and hold at this temperature Keep it for 45 minutes; turn off the heating switch, and when the temperature of the sample drops to around room temperature, take out the sample, wash with deionized water, vacuum filter, and dry at low temperature to obtain graphene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com