Preparation method for a large-area single-layer or few-layer molybdenum disulfide film

A molybdenum disulfide, large-area technology, applied in the field of preparation of large-area single-layer and few-layer molybdenum disulfide thin films, can solve the problems affecting the generation and film formation of molybdenum disulfide, low sulfur source concentration and vapor pressure, and large airflow reaction etc. to achieve the effect of increasing concentration and vapor pressure, high repetition rate, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

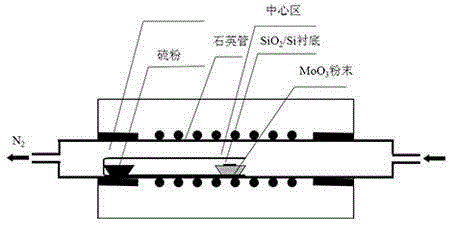

[0020] A quartz test tube with a length of 20 cm and an inner diameter of 25 mm and two quartz boats with a length of 30 mm, a width of 8 mm and a height of 6 mm were ultrasonically cleaned with acetone, absolute ethanol and deionized water, and then dried in a drying oven spare.

[0021] SiO 2 (285nm) / Si substrates were cut into a size of 1cm×1cm, ultrasonicated in absolute ethanol for 5-10min, and then wiped dry with absorbent cotton dipped in absolute ethanol for later use.

[0022] Weigh 500 mg of sulfur powder with a purity of 99.5%, place it evenly in the quartz boat, place the quartz test tube flat, and slowly push the quartz boat containing the sulfur powder to the bottom of the quartz test tube.

[0023] Weigh 10 mg of molybdenum trioxide powder with a purity of 99.9%, place it evenly in another quartz boat, and put the cleaned and dried SiO 2 (285nm) / Si substrate is placed on the quartz boat that contains molybdenum trioxide powder, facing down, about 4mm away from...

Embodiment 2

[0030] A quartz test tube with a length of 30cm and an inner diameter of 30mm and two quartz boats with a length of 40mm, a width of 12mm and a height of 9mm were ultrasonically cleaned with acetone, absolute ethanol and deionized water, and then dried in a drying oven for later use. .

[0031] SiO 2 (285nm) / Si substrate was cut into a size of 1.5cm×1.5cm, ultrasonicated in absolute ethanol for 5-10min, and then dried with absorbent cotton dipped in absolute ethanol for later use.

[0032] Weigh 500 mg of sulfur powder with a purity of 99.5%, place it evenly in the quartz boat, place the quartz test tube flat, and slowly push the quartz boat containing the sulfur powder to the bottom of the quartz test tube.

[0033] Weigh 10 mg of molybdenum trioxide powder with a purity of 99.9%, place it evenly in another quartz boat, and put the cleaned and dried SiO 2 (285nm) / Si substrate is placed on the quartz boat containing molybdenum trioxide powder, face down, about 7mm away from th...

Embodiment 3

[0040] A quartz test tube with a length of 40cm and an inner diameter of 35mm and two quartz boats with a length of 50mm, a width of 15mm and a height of 12mm were ultrasonically cleaned with acetone, absolute ethanol and deionized water, and then dried in a drying oven for later use. .

[0041] SiO 2 (285nm) / Si substrate was cut into a size of 1.8cm×1.8cm, ultrasonicated in absolute ethanol for 5-10min, and then dried with absorbent cotton dipped in absolute ethanol for later use.

[0042] Weigh 500 mg of sulfur powder with a purity of 99.5%, place it evenly in the quartz boat, place the quartz test tube flat, and slowly push the quartz boat containing the sulfur powder to the bottom of the quartz test tube.

[0043] Weigh 10 mg of molybdenum trioxide powder with a purity of 99.9%, place it evenly in another quartz boat, and put the cleaned and dried SiO 2 (285nm) / Si substrate was placed on the quartz boat containing molybdenum trioxide powder, facing down, about 10mm away ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com