Method for improving hot-working performance of Mn18Cr18N steel

A technology of mn18cr18n and thermal processing, which is applied in the field of metallurgy, can solve problems such as easy cracks, and achieve the effects of reducing content, eliminating segregation, and reducing hot embrittlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for improving hot workability of Mn18Cr18N steel, comprising the following steps:

[0043] Step 1, Ingredients:

[0044] According to the mass ratio, electroslag remelting pre-melting slag: rare earth oxide = 4:1, mix evenly, prepare electroslag remelting rare earth slag, dry; rare earth oxide is Ce 2 o 3 ; The drying process is: at 650 ° C, heat preservation for 8 hours, and slowly cool down with the furnace;

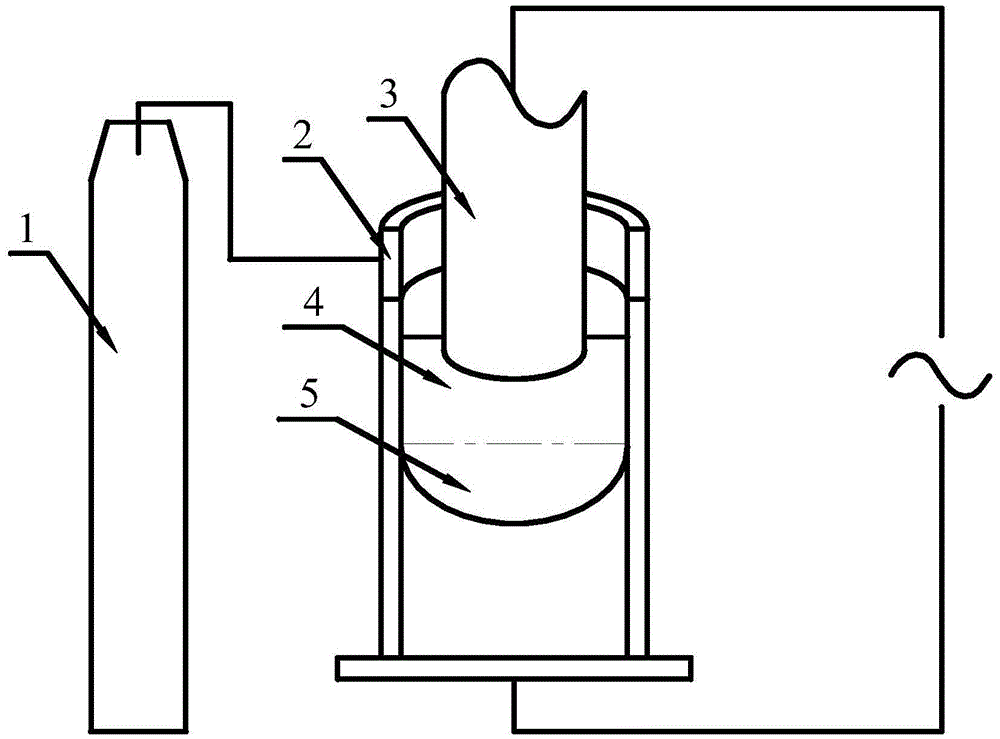

[0045] Step 2, preparation stage for electroslag remelting:

[0046] (1) In the electroslag furnace, place the consumable electrode, crystallizer and arc ignition agent; wherein, the material of the consumable electrode is Mn18Cr18N steel;

[0047] (2) adopt nitrogen protective device, feed in the crystallizer, remove the air in the crystallizer, wherein, the flow rate of nitrogen is 15L / min;

[0048] (3) The quality of electroslag remelting rare earth slag is weighed to be 8kg, and it is configured according to empirical formula (I):

[0049] (4) ...

Embodiment 2

[0056] A method for improving hot workability of Mn18Cr18N steel, comprising the following steps:

[0057] Step 1, Ingredients:

[0058] According to the mass ratio, electroslag remelting pre-melting slag: rare earth oxide = 4:1, mix evenly, prepare electroslag remelting rare earth slag, dry; rare earth oxide is Ce 2 o 3 ; The drying process is: at 750 ° C, heat preservation for 3 hours, and slowly cool down with the furnace;

[0059] Step 2, preparation stage for electroslag remelting:

[0060] (1) In the electroslag furnace, place the consumable electrode, crystallizer and arc ignition agent; wherein, the material of the consumable electrode is Mn18Cr18N steel;

[0061] (2) adopt nitrogen protective device, feed in the crystallizer, remove the air in the crystallizer, wherein, the flow rate of nitrogen is 10L / min;

[0062] (3) The quality of electroslag remelting rare earth slag is weighed to be 8kg, and it is configured according to empirical formula (I):

[0063] (4) ...

Embodiment 3

[0070] A method for improving hot workability of Mn18Cr18N steel, comprising the following steps:

[0071] Step 1, Ingredients:

[0072] According to the mass ratio, electroslag remelting pre-melting slag: rare earth oxide = 3:1, mix evenly, prepare 8kg of electroslag remelting rare earth slag, and dry; the rare earth oxide is La 2 o 3 ; The drying process is: at 700 ° C, keep warm for 4 hours, and slowly cool with the furnace;

[0073] Step 2, preparation stage for electroslag remelting:

[0074] (1) In the electroslag furnace, place the consumable electrode, crystallizer and arc ignition agent; wherein, the material of the consumable electrode is Mn18Cr18N steel;

[0075] (2) adopt nitrogen protective device, feed in the crystallizer, remove the air in the crystallizer, wherein, the flow rate of nitrogen is 10L / min;

[0076] (3) The quality of electroslag remelting rare earth slag is weighed to be 6kg, and it is configured according to empirical formula (I):

[0077] (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com