Preparation method for spherical metal-based rare-earth nano composite powder capable of being used for three-dimensional printing and product prepared through same

A nanocomposite and three-dimensional printing technology, which is applied in metal processing equipment, transportation and packaging, and additive processing, can solve problems such as easy extrusion deformation, increased manufacturing costs, and increased oxygen content of light metal powders to improve comprehensive mechanical properties. Performance, excellent mechanical properties, and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

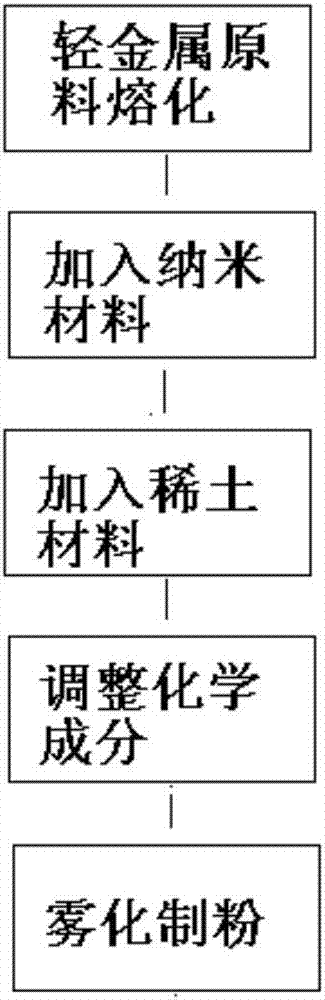

[0034] The preparation method of the spherical light metal-based rare earth nanocomposite powder that can be used for three-dimensional printing is as follows:

[0035] (1) Add aluminum alloy to the crucible of the induction furnace, vacuumize the crucible and fill it with argon gas, adjust the induction current heating to melt the light metal raw material into a liquid melt, control the vacuum degree in the crucible below 6.0×10-3Pa, the argon gas The pressure is 0.05MPa; the intensity of the induced current is 40A;

[0036] (2) Control the temperature of the light metal melt to be 50-100°C higher than its melting point, add 15wt% nanomaterials to the metal melt under electromagnetic stirring and ensure uniform dispersion to form a mixed melt, and adjust the induced current intensity to 20A , the nanomaterial is TiC particles and carbon nanotubes with a mass ratio of 1:1, and the size of the TiC particles and carbon nanotubes is 0.5 to 1.0 nm;

[0037] (3) Add 0.5wt% rare ea...

Embodiment 2

[0041] The preparation method of the spherical light metal-based rare earth nanocomposite powder that can be used for three-dimensional printing is as follows:

[0042](1) Put the titanium alloy into the crucible of the induction furnace, evacuate the crucible and fill it with argon gas, adjust the induction current heating to melt the light metal raw material into a liquid melt, control the vacuum degree in the crucible below 6.0×10-3Pa, and the argon gas The pressure is 0.1MPa; the intensity of the induced current is 5A;

[0043] (2) Control the temperature of the light metal melt to be 50-100°C higher than its melting point, add 20wt% nanomaterials to the metal melt under electromagnetic stirring and ensure uniform dispersion to form a mixed melt, and adjust the induced current intensity to 5A , the nanomaterial is SiC particles and carbon fibers with a mass ratio of 2:1, and the size of the SiC particles and carbon fibers is 0.5-1.0 nm;

[0044] (3) Add 0.5wt% rare earth ...

Embodiment 3

[0048] The preparation method of the spherical light metal-based rare earth nanocomposite powder that can be used for three-dimensional printing is as follows:

[0049] (1) Add aluminum alloy to the crucible of the induction furnace, evacuate the crucible and fill it with argon gas, adjust the induction current heating to melt the light metal raw material into a liquid melt, and control the vacuum degree in the crucible at 6.0×10 -3 Below Pa, the pressure of argon is 0.02MPa; the intensity of induction current is 45A;

[0050] (2) Control the temperature of the light metal melt to be 50-100°C higher than its melting point, add 5wt% nanomaterials to the metal melt under electromagnetic stirring and ensure uniform dispersion to form a mixed melt, and adjust the induced current intensity to 25A , the nanomaterial is SiO with a mass ratio of 1:2 2 particles and graphene, the SiO 2 The size of particles and graphene is 0.5-1.0nm;

[0051] (3) Add 1.0wt% rare earth material to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com