A method and device for preparing nanoparticles

A nanoparticle and erosion technology, applied in the field of nanomaterials, can solve the problem of high energy consumption, achieve the effect of improving the processing speed of ball milling and solving the effect of uneven particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

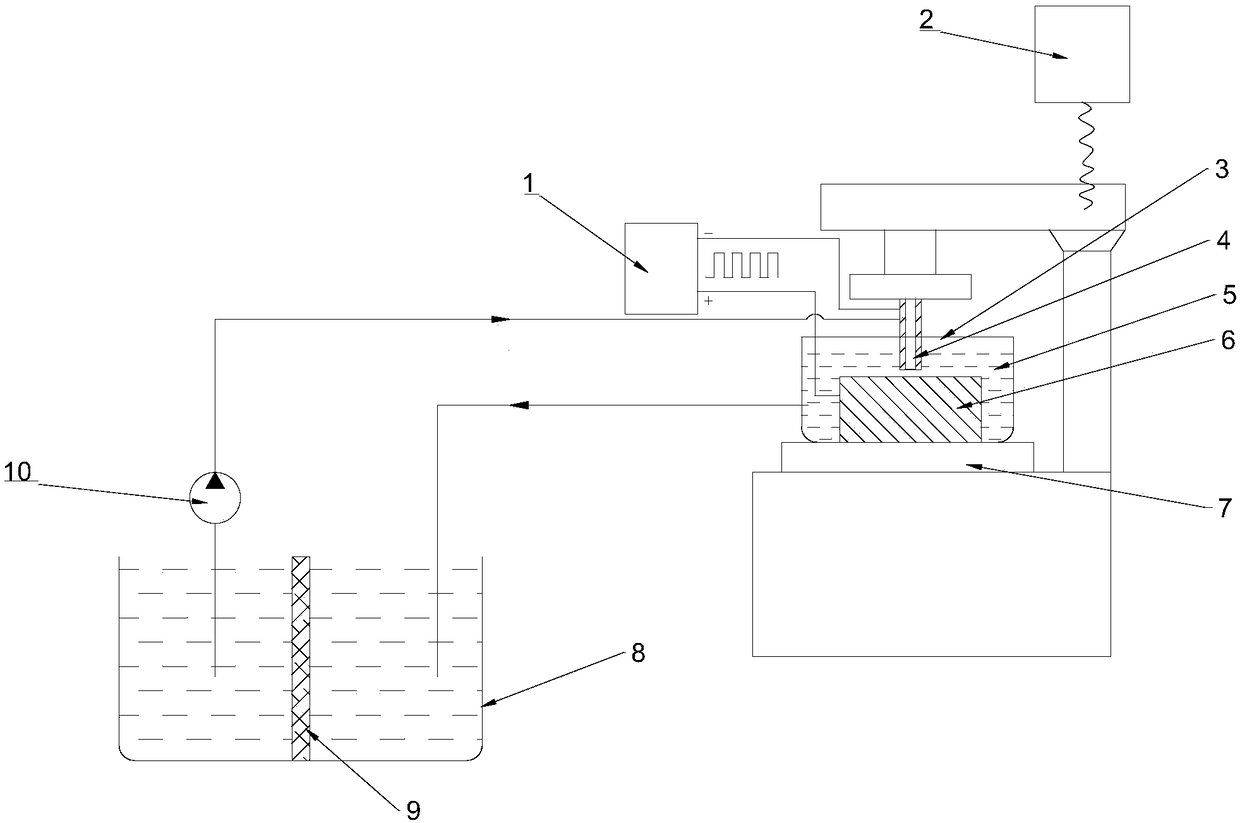

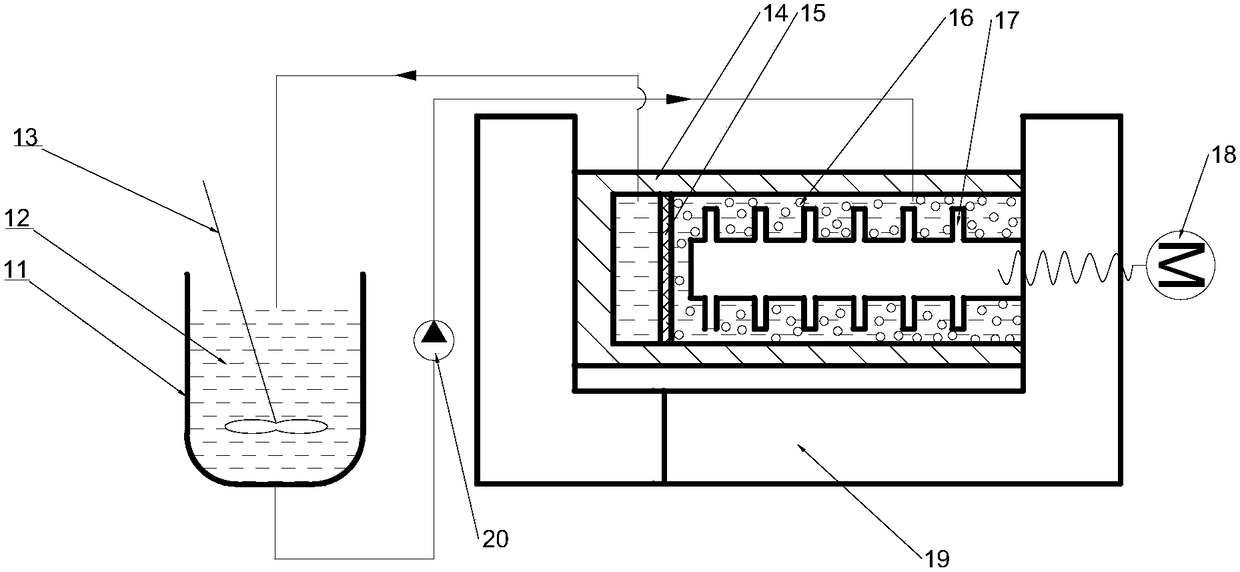

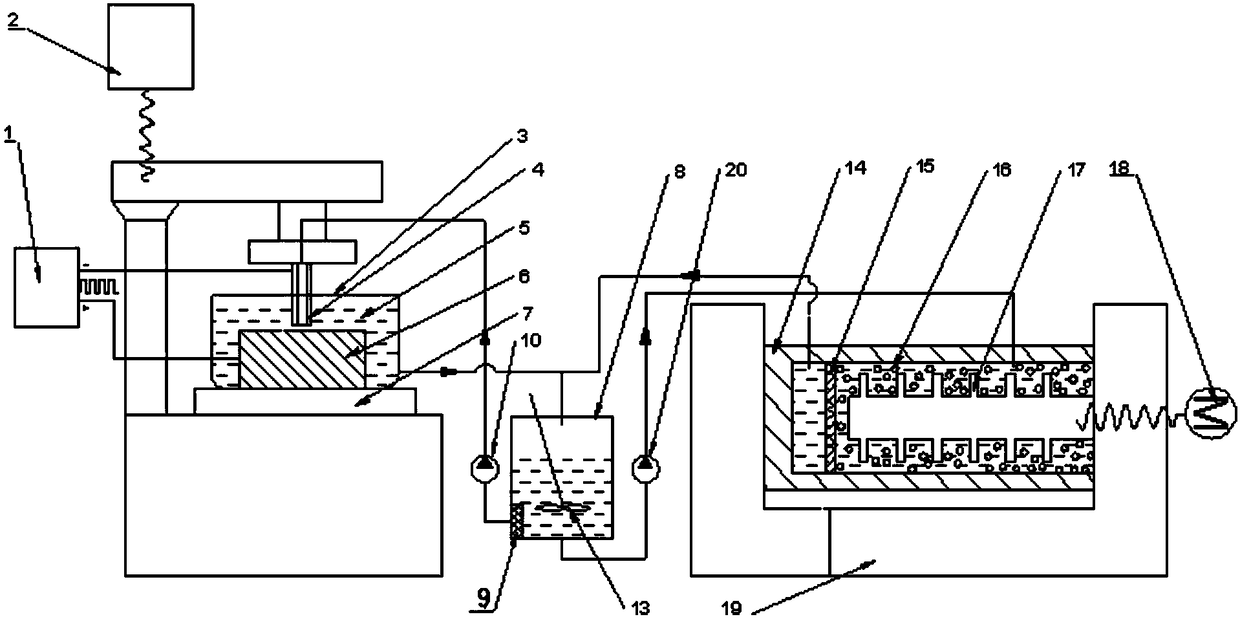

[0055] The structure of a coupling processing device for EDM and high energy ball milling provided by the present invention is as follows: figure 1 and figure 2 shown. A device for preparing micron or submicron particles by spark discharge technology, fixing the working fluid tank 3 on the displacement platform 7, fixing the workpiece electrode 6 in the working fluid tank 3, and realizing the feeding of the workpiece electrode 6 through the numerical control system 2, and the workpiece electrode 6 pass the positive pole of the pulse power supply 1, the tool electrode 4 passes the negative pole of the pulse power supply 1, and the tool electrode 4 is tubular; add the working fluid 5 into the working fluid tank 3, and dip into the gap between the workpiece electrode 6 and the tool electrode 4. A continuous pulsed spark discharge is formed between the tool electrode 4 and the workpiece electrode 6, and the surface of the material is melted and vaporized by the high temperature ...

Embodiment 2

[0069] Such as figure 1 , figure 2 As shown, the device for preparing micron or submicron particles by spark discharge process and the device for preparing micron or submicron particles into nanoparticles by high energy ball milling process are different from Example 1 in that the workpiece material is non-conductive intrinsic silicon, and the working The solution is 10% Na 2 CO 3 solution, the working fluid conducts electricity and acts as an auxiliary electrode.

[0070] The silicon nanoparticles prepared in this example have a purity of 91% as measured by X-ray fluorescence spectrometry (XRF); the particle size D50=80nm is analyzed by a laser particle size analyzer.

Embodiment 3

[0072] Such as figure 1 , figure 2 As shown, the device for preparing micron or submicron particles by spark discharge process and the device for preparing micron or submicron particles into nanoparticles by high energy ball milling process are different from Example 1 in that the grinding aid of ball milling is absolute ethanol, and the ball milling The time is 20h.

[0073] The silicon nanoparticles prepared in this example have a purity of 97% as measured by X-ray fluorescence spectrometry (XRF); the particle size D50=60nm is analyzed by a laser particle size analyzer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com