Method for manufacturing oil casings made of R95-grade steel containing rare earth

A technology of oil casing and production method, applied in the direction of furnace type, furnace, quenching agent, etc., can solve the problems of lack of competitiveness and high cost, and achieve the effects of good high-temperature mechanical properties, low cost, and improved impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

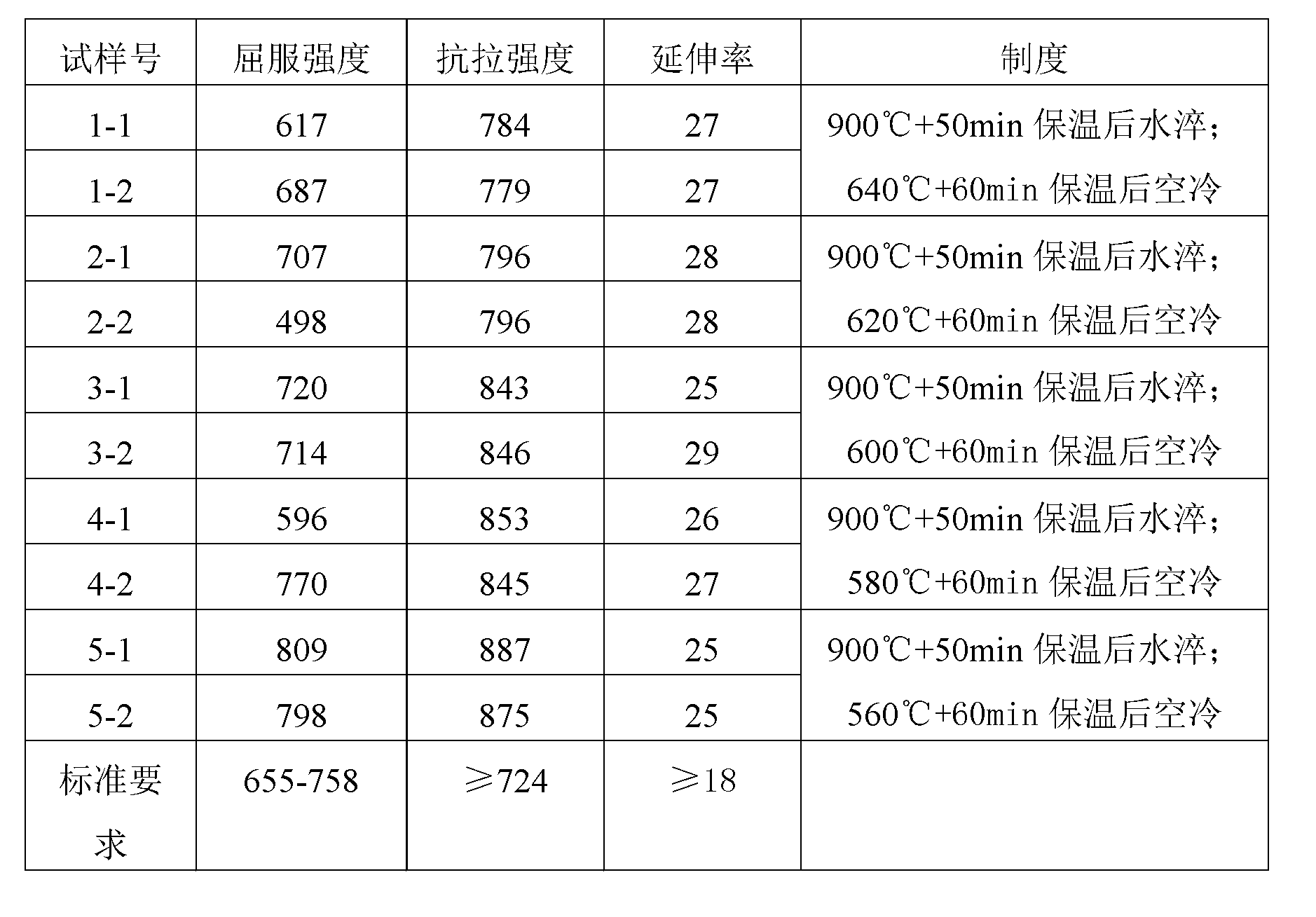

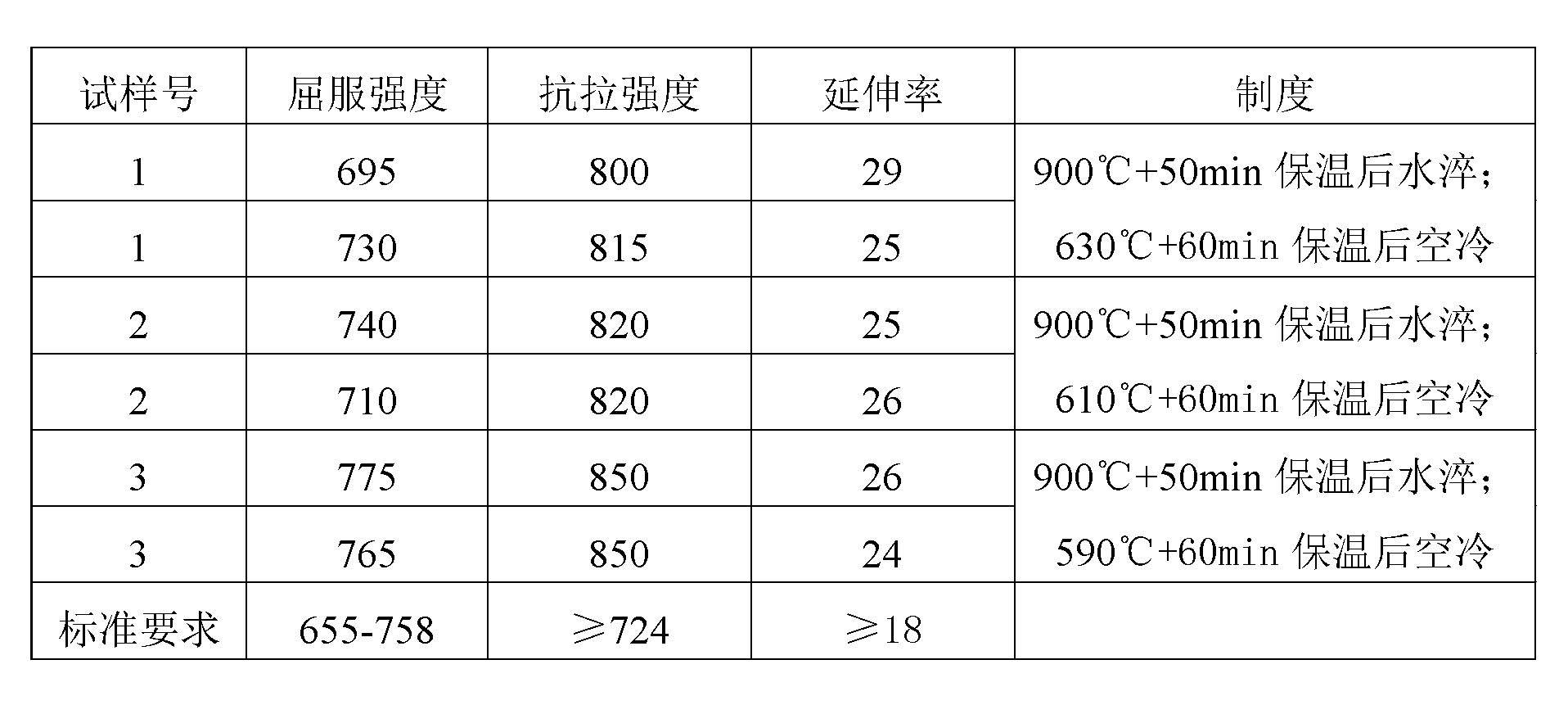

Examples

Embodiment 1

[0030] 1. Smelting test parameters

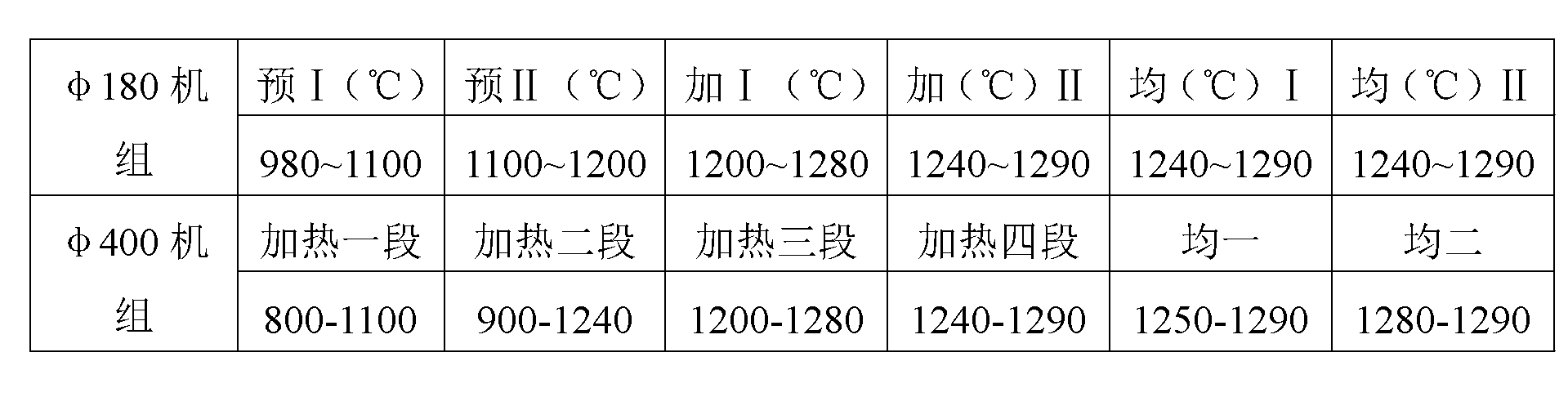

[0031] The following tables 2-5 are the chemical composition of smelting, gas content, control of five harmful elements and inspection results of continuous casting round billet sulfur marks. From the results in the table, it can be seen that the smelting control of steel is very good, creating a good foundation for further production in the next factory. Good raw material condition.

[0032] Table 2 Gas content

[0033] H O N maximum value 1.55 28 48 minimum value 0.38 14 36 average value 1.02 19 40

[0034] Table 3 Chemical Composition of Tube Body

[0035] C Si mn P S Cr Al maximum value 0.30 0.34 1.54 0.019 0.008 0.38 0.038 minimum value 0.25 0.23 1.37 0.012 0.002 0.30 0.020 average value 0.27 0.28 1.42 0.016 0.005 0.33 0.025

[0036] [0036] Table 4 Five harmful elements

[0037] As sn Pb Sb Bi maximum value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com