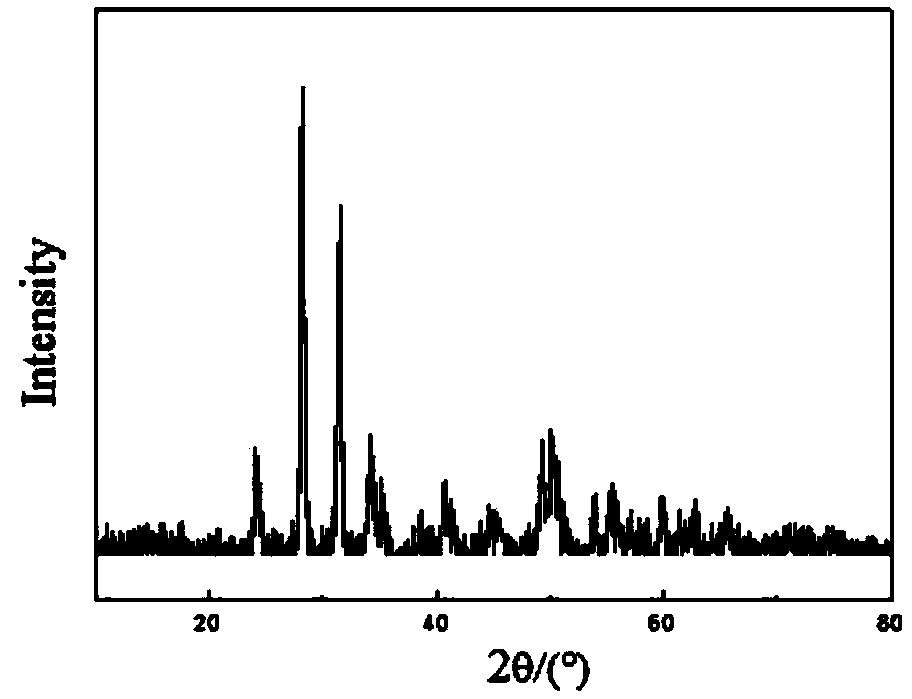

Preparation method for ZrO2 fiber with SiO2 doped

A fiber and continuous fiber technology, which is applied in the field of preparation of ZrO2 polycrystalline continuous fiber, can solve the problems of difficulty in preparation of inorganic polyzirconium solution, insufficient density of zirconia fiber, and decrease in fiber strength, so as to expand the use temperature range and spinning performance Excellent, good high temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 400g basic zirconium carbonate with an electronic scale and pour it into the reaction kettle. Measure 160ml of glacial acetic acid with a graduated cylinder (100g of basic zirconium carbonate is dissolved in 40ml of glacial acetic acid), pour it into the reaction kettle, and add 250ml of distilled water, the reaction produces a lot of bubbles, after a period of time, filter to obtain a colorless and transparent zirconium acetate solution .

[0034] According to ZrO 2 :SiO2 2 The mass ratio of the chemical composition is 95:5. Measure 31ml of tetraethyl orthosilicate (TEOS), add the blend of TEOS and absolute ethanol to the mixed solution of nitric acid and acetic acid, and TEOS will be hydrolyzed rapidly under acidic conditions. , to obtain a silicic acid solution. The volume ratio of TEOS, absolute ethanol, concentrated nitric acid, acetic acid and water is 10:5:1:1:15. At the same time, the silicic acid solution should be used as soon as possible, so as not ...

Embodiment 2

[0039] Weigh 200g basic zirconium carbonate with an electronic scale and pour it into the reaction kettle. Measure 72ml of glacial acetic acid with a graduated cylinder (100g of basic zirconium carbonate is dissolved in 36ml of glacial acetic acid), pour it into the reaction kettle, and add 150ml of distilled water. The reaction produced a large number of bubbles, and after a period of time, a colorless and transparent zirconium acetate solution was obtained by filtration.

[0040] According to ZrO 2 :SiO2 2 The chemical composition of the mass ratio is 92.2:7.8, measure 25ml of tetraethyl orthosilicate (TEOS), add the blend of TEOS and absolute ethanol to the mixed solution of concentrated nitric acid and acetic acid, stir for 0.5h, TEOS Rapid hydrolysis under acidic conditions to obtain silicic acid solution. The volume ratio of TEOS, absolute ethanol, concentrated nitric acid, acetic acid and water is 10:5:1:1:15. Add the obtained silicon solution to the prepared zircon...

Embodiment 3

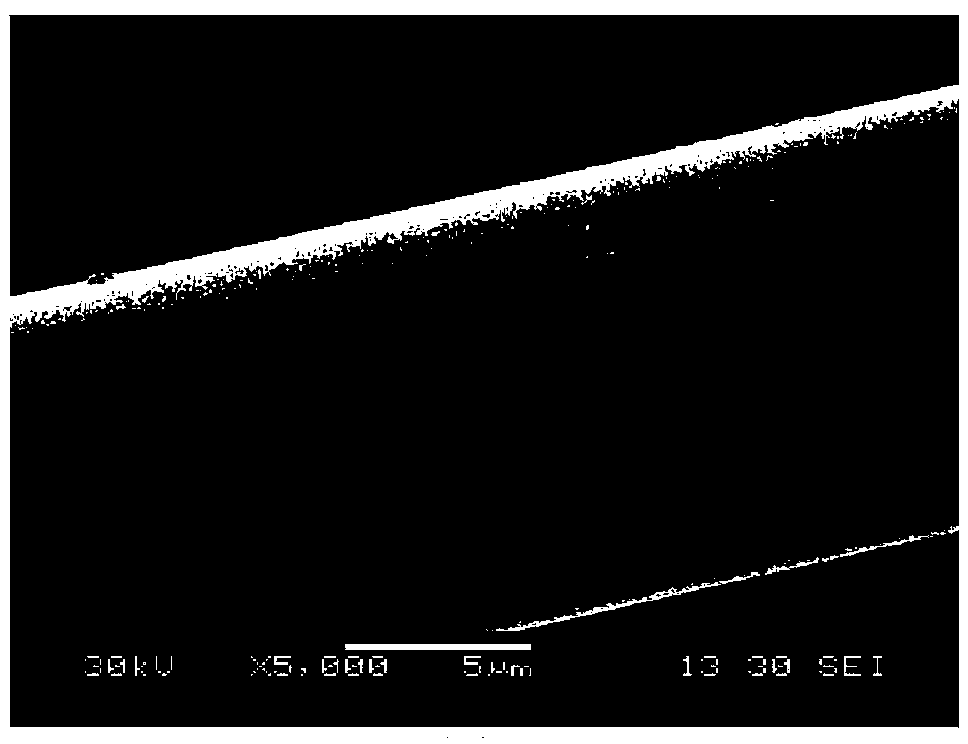

[0044] Prepare colorless and transparent zirconium acetate solution and silicic acid solution according to Example 1. Follow Y 2 o 3 The amount of ZrO 2 2mol% of the content, measure 17.6g of yttrium acetate (molecular formula is Y(Ac) 3 4H 2 O), in ZrO 2 During the phase transition process, using Y 2 o 3 as ZrO 2 stabilizer. Add the silicic acid sol to the prepared zirconium acetate solution, then add yttrium acetate to the mixed solution of the two, and finally add 20ml of glacial acetic acid as a colloidal stabilizer and spinning aid, and stir the acetic acid with a magnetic stirrer. Yttrium dissolves completely. After vacuum concentration at 67°C for 2-2.5 hours, a precursor colloid with a viscosity of about 23-32 Pa.s is produced.

[0045]Centrifugal spinning on a self-made centrifugal spinning machine. Under the action of centrifugal force, the precursor colloid is centrifugally thrown out from a small hole with a diameter of 0.5mm at high speed, and then secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com