Method for preparation of ultra-high temperature ceramic matrix composite material containing boron nitride by in-situ reaction

A technology of ultra-high temperature ceramics and composite materials, applied in the field of ultra-high temperature ceramics, can solve the problems of limited application, easy to cause agglomeration, poor thermal shock resistance, etc., to achieve the effect of improving thermal shock resistance, avoiding agglomeration and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

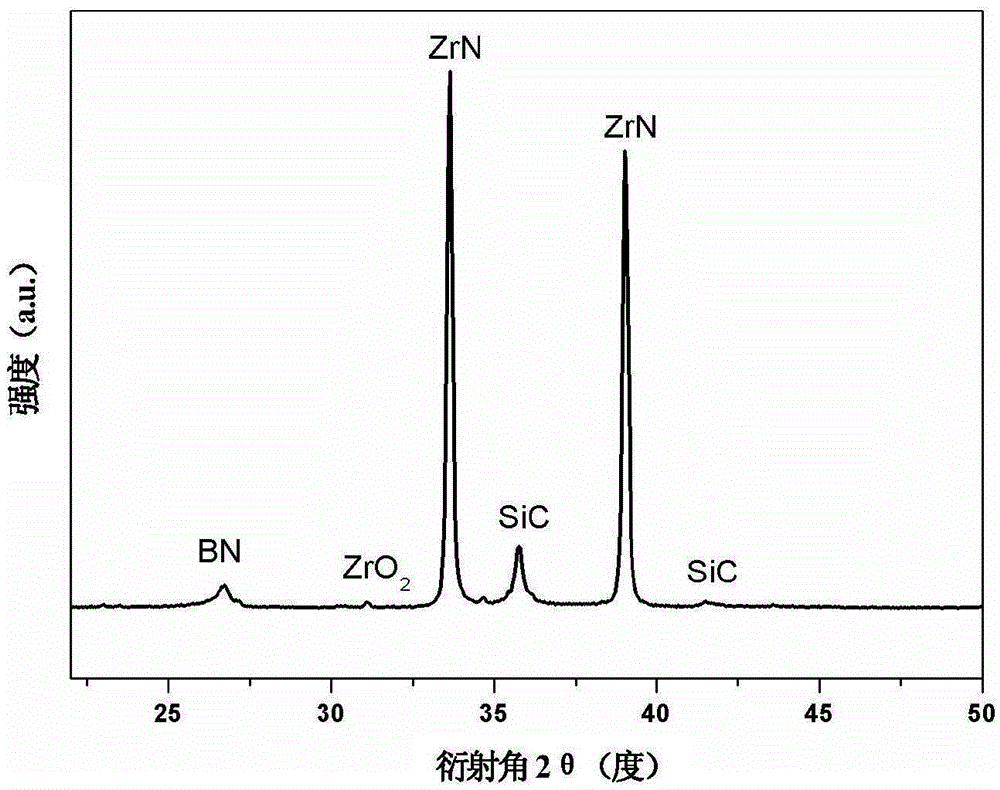

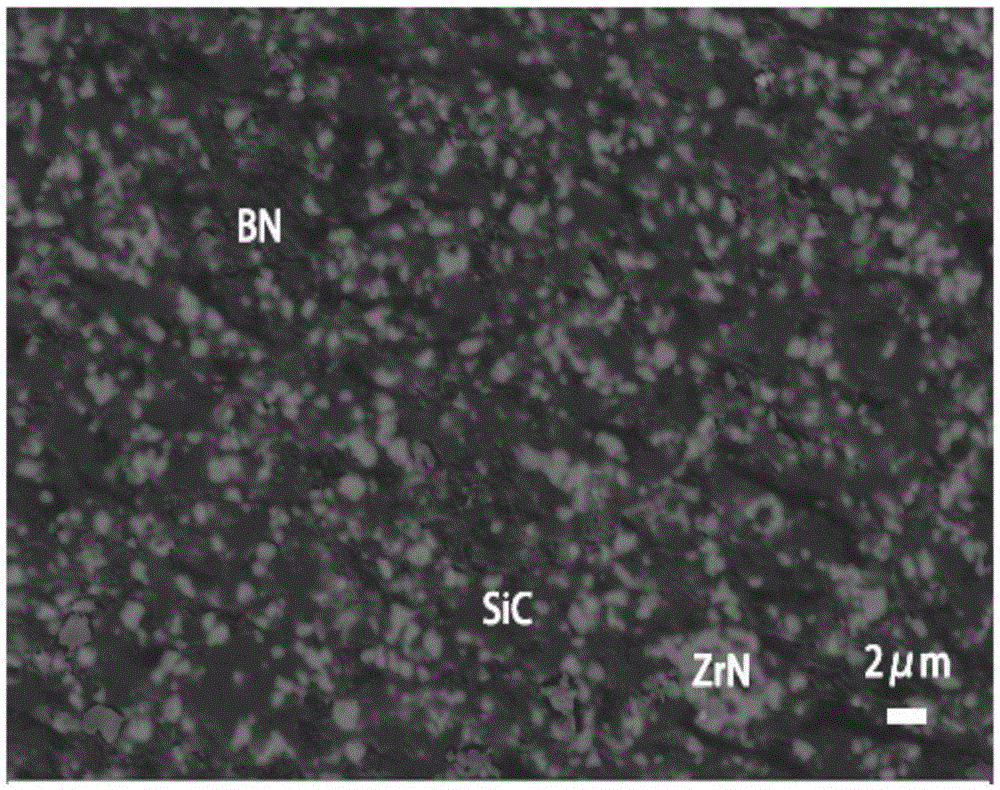

[0036] 46.04 grams of zirconium boride powder with a particle size of 1 micron, 42.93 grams of silicon nitride powder with a particle size of 10 microns and 11.03 grams of graphite powder with a particle size of 400 mesh were ball milled in a ball mill tank for 8 hours, dried and sieved. Then put it into a graphite mould, and cold-press to form it. The applied pressure is 20 MPa. After cold-pressing for 10 minutes, put it into a hot-press furnace for hot-press sintering. The heating rate is 20°C / min, heated to 2100°C and kept for 2 hours, and the pressure is gradually increased to 40MPa while the temperature is rising. The whole sintering process is carried out under nitrogen protection. The obtained reaction product is carried out XRD analysis (see figure 1 ), it can be found that the prepared composite material is mainly composed of zirconium nitride, silicon carbide, boron nitride and a small amount of zirconia, and the phases in the prepared composite material are uniform...

Embodiment 2

[0038]60.21 grams of hafnium boride powder with a particle size of 10 microns, 31.66 grams of silicon nitride powder with a particle size of 1 micron and 8.13 grams of graphite powder with a particle size of 200 mesh were ball milled in a ball mill jar for 24 hours, dried and sieved. Then put it into a graphite mould, and form it by cold pressing, the applied pressure is 10MPa, after cold pressing for 10 minutes, put it into a discharge plasma sintering furnace for sintering. The heating rate is 100°C / min, heated to 1800°C and kept for 10 minutes, and the pressure is gradually increased to 30MPa while the temperature is rising. The whole sintering process is carried out under nitrogen protection. In this example, the prepared composite material is mainly composed of hafnium nitride, silicon carbide, boron nitride and a small amount of hafnium oxide, hafnium nitride accounts for 57.2wt%, silicon carbide accounts for 26.4wt%, and boron nitride accounts for 14.6wt%. Hafnium oxid...

Embodiment 3

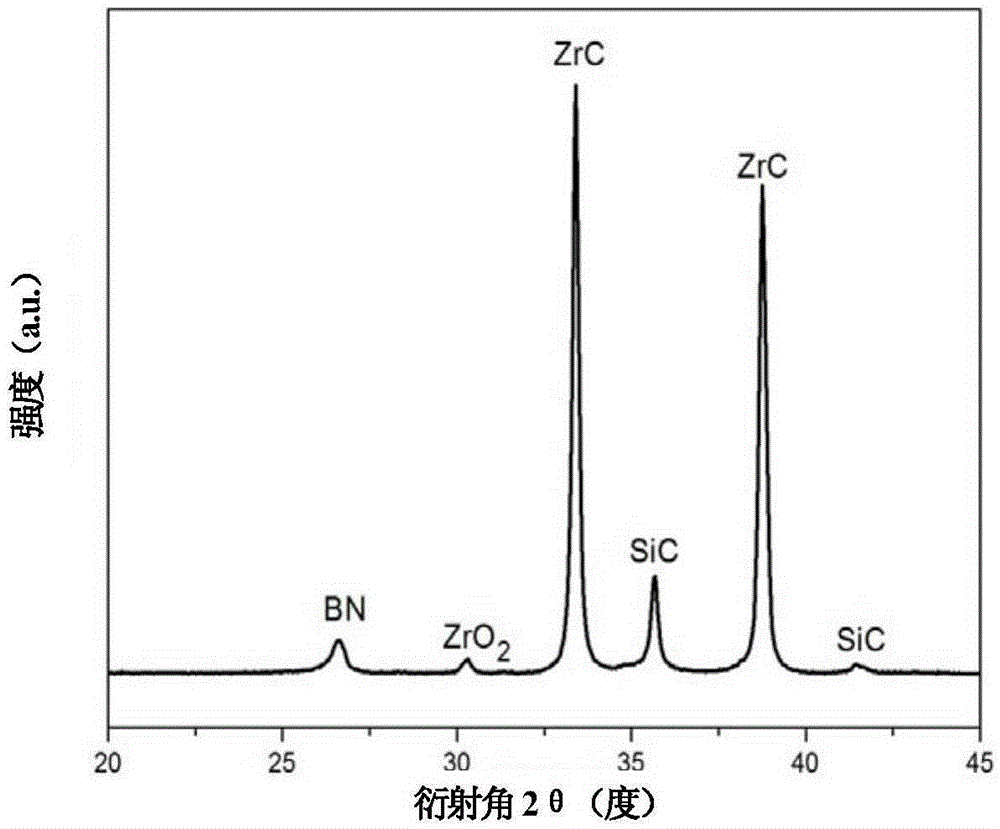

[0040] 52.97 grams of zirconium boride powder with a particle size of 10 microns, 32.97 grams of silicon nitride powder with a particle size of 5 microns and 14.1 grams of graphite powder with a particle size of 300 mesh were milled in a ball mill jar for 16 hours, dried and sieved. Then put it into a graphite mould, and cold-press to form it. The applied pressure is 20 MPa. After cold-pressing for 10 minutes, put it into a hot-press furnace for hot-press sintering. The heating rate is 20°C / min, heated to 2000°C and kept for 1 hour, and the pressure is gradually increased to 40MPa while the temperature is rising. The whole sintering process is carried out under nitrogen protection. The obtained reaction product is carried out XRD analysis (see image 3 ), it can be found that the prepared composite material is mainly composed of zirconium carbide, silicon carbide, boron nitride and a small amount of zirconium oxide, and each phase in the prepared composite material is uniform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com