Method for surface modification of alumina-based ceramic fiber

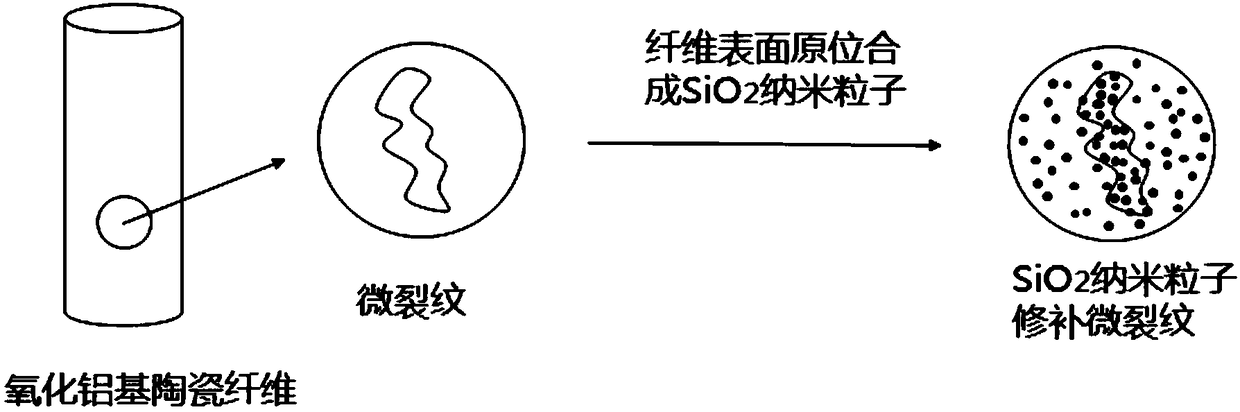

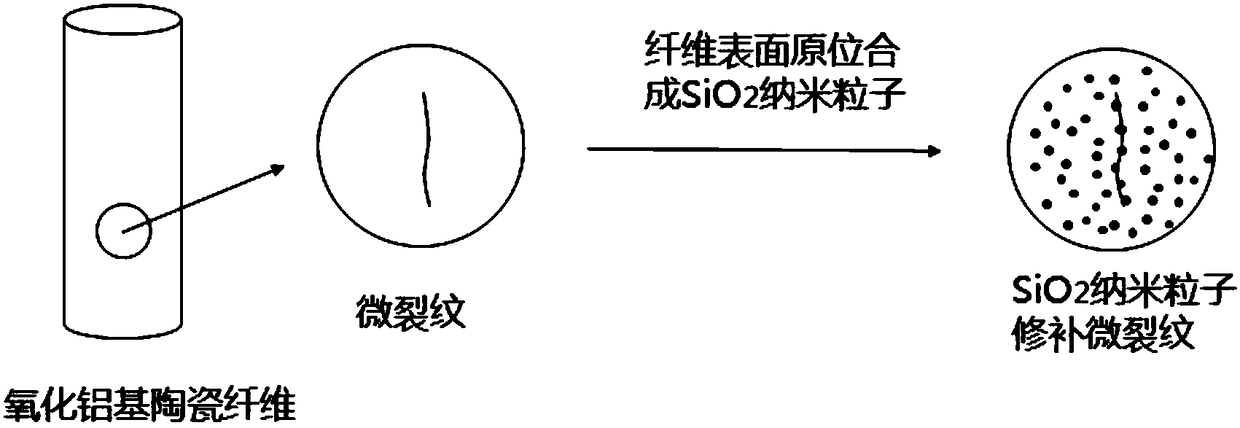

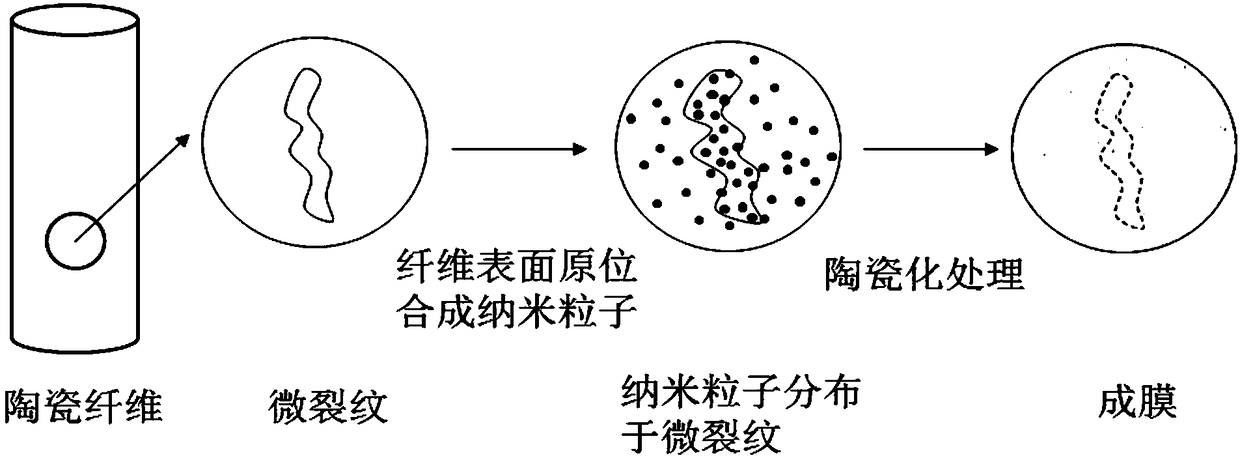

A fiber surface and base ceramic technology, which is used in the surface modification of alumina base ceramic fibers and the surface modification of inorganic ceramic fibers to achieve high mechanical properties, improve surface state, and improve fiber strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A method for surface modification of alumina-based ceramic fibers, specifically implemented according to the following steps:

[0064] (1) Surface purification treatment of alumina-based ceramic fibers: immerse the fibers in deionized water, after ultrasonic treatment for 2 hours, place them in an oven for 1 hour at 110°C, and then take them out for use.

[0065] (2) Prepare the precursor solution: mix tetramethoxysilane and ethanol in a beaker, the tetramethoxysilane content is 60%, and stir evenly for 30 minutes.

[0066] (3) Prepare the reaction solution: mix methanol and deionized water at a mass ratio of 4:1, adjust the pH of the system to 5 with acetic acid, add 1% polyethylene glycol as a dispersant, and keep the temperature in a water bath at 30°C Keep warm and stir evenly for 60min.

[0067] (4) Precursor solution adhered to the fiber surface: immerse the alumina-based ceramic fiber treated in step (1) in the precursor solution in step (2) for 4 hours to fully...

Embodiment 2

[0071] A method for surface modification of alumina-based ceramic fibers, specifically implemented according to the following steps:

[0072] (1) Surface purification treatment of alumina-based ceramic fibers: immerse the fibers in a deionized water-ethanol mixed solution, after ultrasonic treatment for 2 hours, place them in an oven for 1 hour at 110°C, and then take them out for use.

[0073] (2) Prepare the precursor solution: mix tetraethoxysilane and propanol in a beaker, the tetraethoxysilane content is 70%, and stir evenly for 40 minutes.

[0074] (3) Prepare the reaction solution: mix acetone and deionized water at a mass ratio of 5:1, adjust the pH of the system to 4 with hydrochloric acid, add 2% dispersant ethylene glycol, and keep the temperature in a water bath at 40°C And stir evenly for 80min.

[0075](4) Precursor solution adhered to the fiber surface: immerse the alumina-based ceramic fiber treated in step (1) in the precursor solution in step (2) for 5 hours...

Embodiment 3

[0079] A method for surface modification of alumina-based ceramic fibers, specifically implemented according to the following steps:

[0080] (1) Surface purification treatment of alumina-based ceramic fibers: immerse the fibers in an acetone solution, after ultrasonic treatment for 2 hours, place them in an oven for 1 hour at 110°C, and then take them out for use.

[0081] (2) Prepare the precursor solution: mix tetrapropoxysilane and isopropanol in a beaker, the tetrapropoxysilane content is 80%, and stir evenly for 50 minutes.

[0082] (3) Configure the reaction solution: mix ethanol and deionized water at a mass ratio of 6:1, adjust the pH of the system to 6 with acetic acid, add 3% dispersant potassium chloride, and keep the temperature in a water bath at 50°C And stir evenly for 90min.

[0083] (4) Precursor solution adhered to the fiber surface: immerse the alumina-based ceramic fiber treated in step (1) in the precursor solution in step (2) for 6 hours to fully contac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com