Toughened reinforced nylon 6 ternary composite material and preparation method thereof

A composite material and nylon technology, applied in the field of thermoplastic elastomers, can solve problems such as poor dispersion, and achieve the effects of ensuring performance, uniform distribution, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

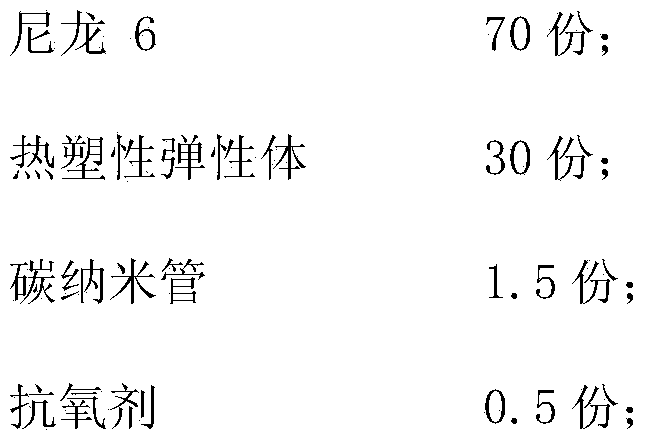

Embodiment 1

[0031]

[0032] (1) Treat 1.5 parts by weight of carbon nanotubes with concentrated sulfuric acid and concentrated nitric acid (weight ratio: 3:1), first ultrasonic at 50°C and 60HZ for 2 hours, and then reflux at 100°C for 2 hours; after acidification Wash with 10 times distilled water, and filter under reduced pressure with a microporous membrane until the pH value of the filtrate reaches 7.

[0033] (2) Add 5 parts by weight of nylon 6 into 100ml of formic acid, mechanically stir and dissolve in an oil bath at 80°C, and at the same time, add the modified carbon nanotubes in step (1) to the formic acid solution for ultrasonication, and after the nylon 6 is completely dissolved, the modified Pour the carbon nanotube formic acid mixture into the formic acid solution dissolved in nylon 6, stir mechanically for 100 minutes, rinse with distilled water, wash several times, and finally blast and dry for 24 hours until the formic acid is completely volatilized, and nylon 6 and mod...

Embodiment 2

[0046]

[0047] (1) Treat 1.5 parts by weight of carbon nanotubes with concentrated sulfuric acid and concentrated nitric acid (3:1), first ultrasonicate at 50°C and 60HZ for 2 hours, and then reflux at 100°C for 2 hours; after acidification, use 10 Wash with distilled water twice, and filter under reduced pressure with a microporous membrane until the pH value of the filtrate reaches 7.

[0048](2) Add 5 parts by weight of nylon 6 into 100ml of formic acid, mechanically stir and dissolve in an oil bath at 80° C., and simultaneously add the modified carbon nanotubes obtained in step (1) into the formic acid solution for ultrasonication. After nylon 6 is completely dissolved, the modified The carbon nanotube formic acid mixture was poured into the formic acid solution dissolved in nylon 6, mechanically stirred for 100 minutes, rinsed with distilled water, washed several times, and finally blown and dried for 24 hours until the formic acid was completely volatilized to obtain ...

Embodiment 3

[0060]

[0061]

[0062] (1) Treat 1.5 parts by weight of carbon nanotubes with concentrated sulfuric acid and concentrated nitric acid (3:1), first ultrasonicate at 50°C, 60HZ for 2 hours, and then reflux at 100°C for 2 hours; after acidification, use 10 times Wash with distilled water, and filter under reduced pressure with a microporous membrane until the pH value of the filtrate reaches 7.

[0063] (2) Add 5 parts by weight of nylon 6 into 100ml of formic acid, mechanically stir and dissolve in an oil bath at 80° C., and simultaneously add the modified carbon nanotubes obtained in step (1) into the formic acid solution for ultrasonication. After nylon 6 is completely dissolved, the modified The carbon nanotube formic acid mixture was poured into the formic acid solution dissolved in nylon 6, mechanically stirred for 100 minutes, rinsed with distilled water, washed several times, and finally blasted and dried for 24 hours until the formic acid was completely volatilize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com