Preparation method of full water electrolysis catalyst with heterojunction structure

A catalyst and heterojunction technology, applied in the field of nanomaterials, can solve the problems of low reserves, strict catalytic environment requirements, unstable catalysts, etc., to achieve improved stability, excellent total water splitting performance, excellent alkali resistance and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

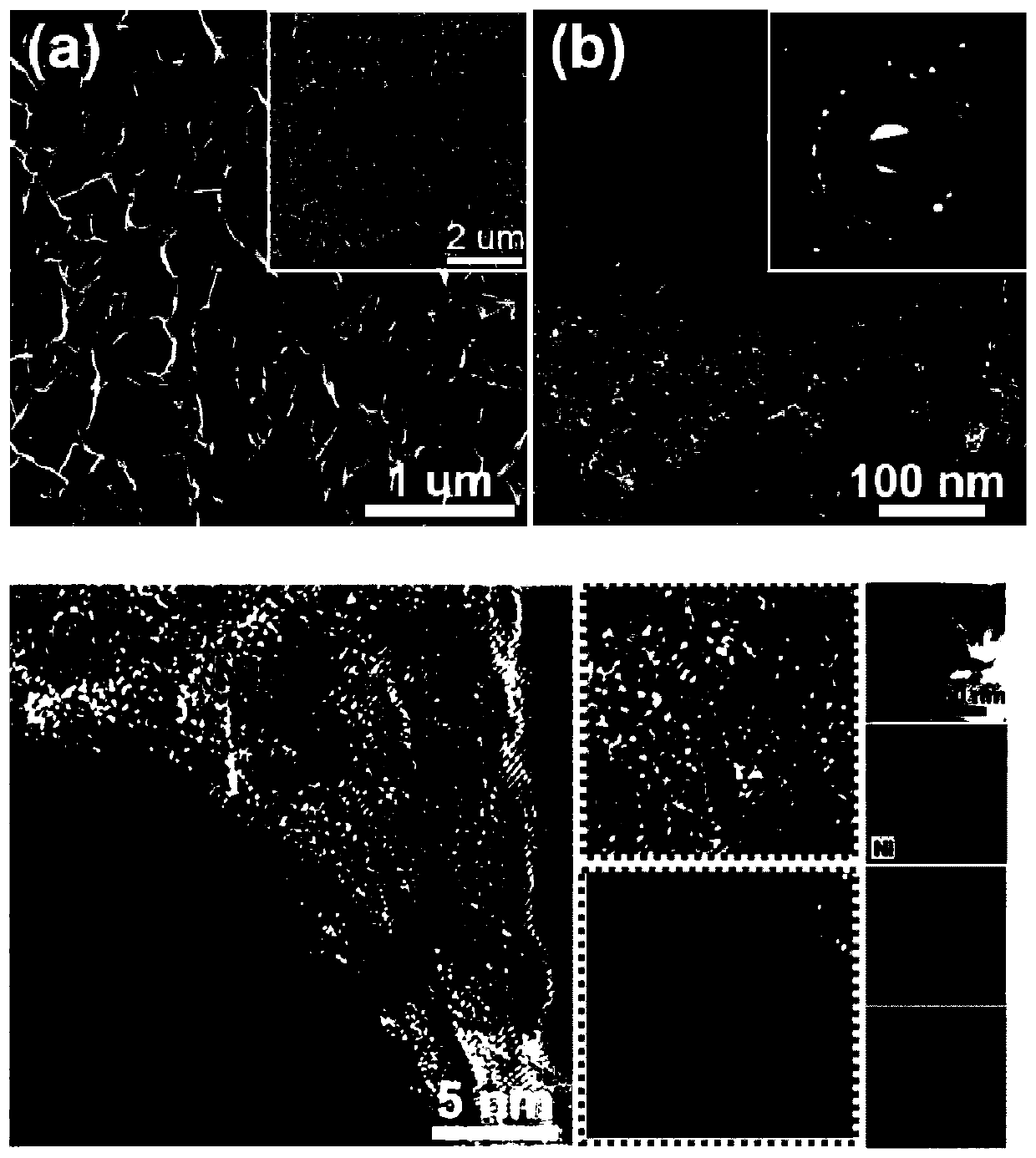

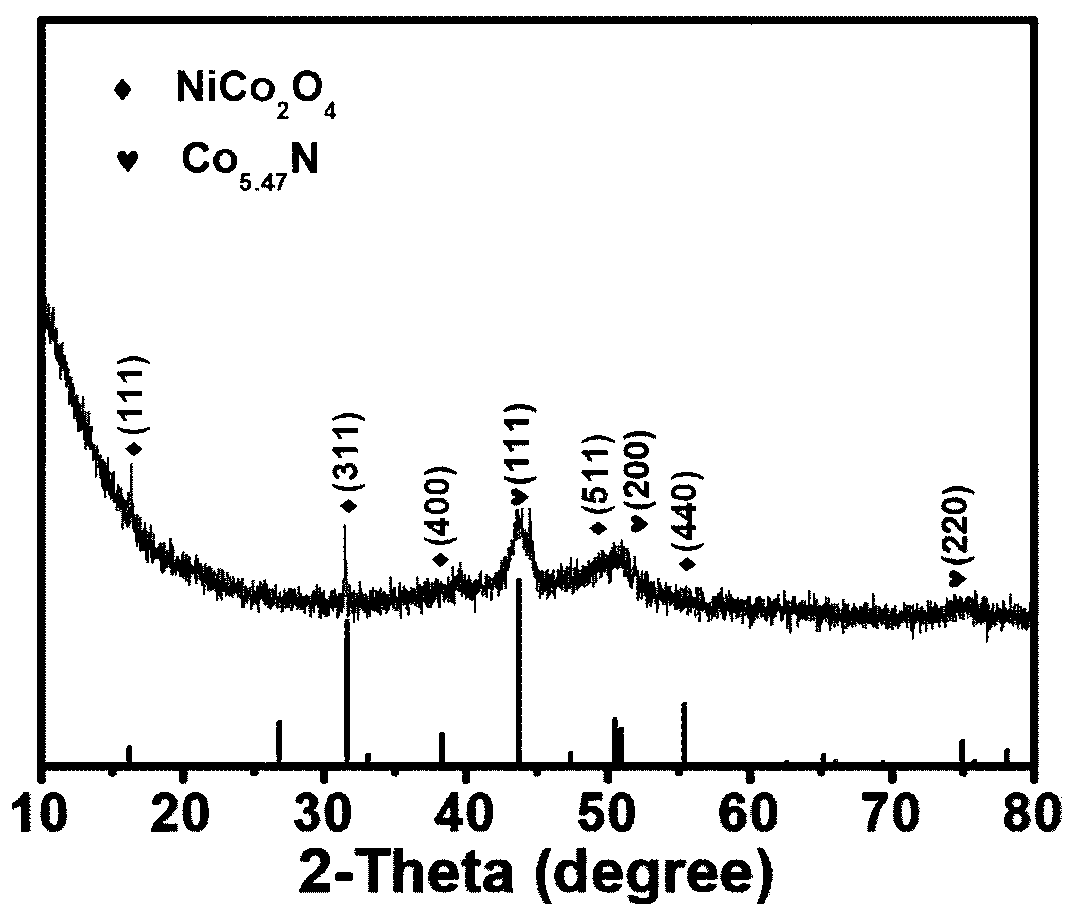

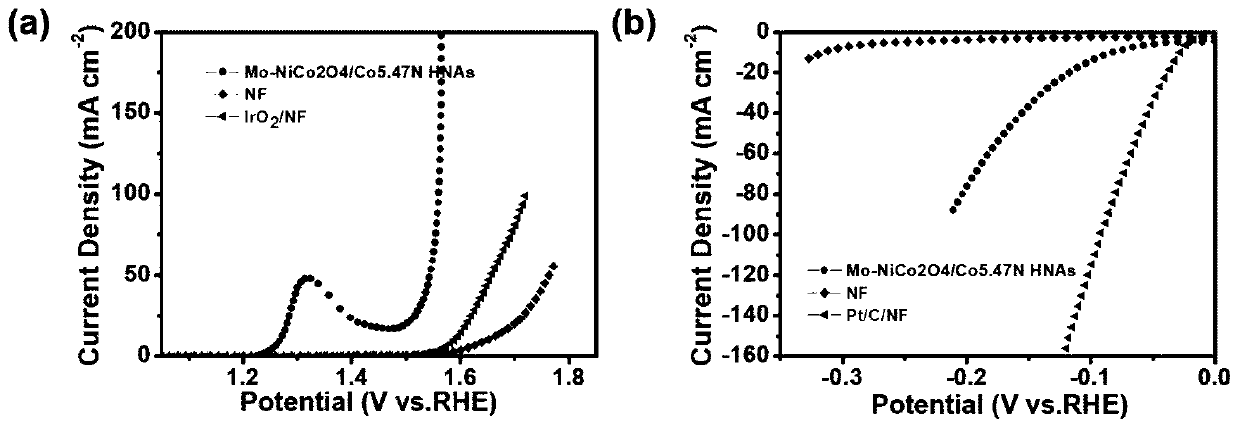

Image

Examples

Embodiment 1

[0054] A preparation method of a total water splitting catalyst with a heterojunction structure, the preparation method comprising the following preparation steps:

[0055] 1) Weigh 0.5g MoO 3 , 0.5g Mn(NO 3 ) 2 ·6H 2 O, 0.2248g Ni(NO 3 ) 2 ·6H 2 O and 0.475g 2-methylimidazole were dissolved in 50mL deionized water to prepare a precursor solution. The foamed nickel was placed in hydrofluoric acid, ethanol, and deionized water for ultrasonic cleaning for 5 minutes, and then the pretreated foamed nickel was Put it together with the precursor solution in the reactor for 120°C hydrothermal reaction for 8 hours, and obtain the trimetallic precursor after the hydrothermal reaction;

[0056] 2) After the trimetallic precursor was naturally cooled to room temperature, the trimetallic precursor was placed in a hydrogen / nitrogen gas mixture with a hydrogen content of 10% VOL, and the temperature was raised in one step at a heating rate of 10°C / min to a temperature of 280 °C in the...

Embodiment 2

[0073] Concrete steps are identical with embodiment 1, difference is: MoO 3 The dosage is 0.2768g, Mn(NO 3 ) 2 ·6H 2 O dosage is 0.1288g, Ni(NO 3 ) 2 ·6H 2 The amount of O was 0.0373 g, and the amount of 2-methylimidazole was 0.2503 g; the hydrothermal reaction temperature was 150° C., and the reaction time was 4 h. The same characterization and test as in Example 1 were performed on the total water splitting catalyst with a heterojunction structure prepared in Example 2, and the results showed that its microstructure was complete and its performance was stable.

Embodiment 3

[0075] Concrete steps are identical with embodiment 1, difference is: MoO 3 The dosage is 2.670g, Mn(NO 3 ) 2 ·6H 2 O dosage is 1.329g, Ni(NO 3 ) 2 ·6H 2 The amount of O was 0.5385 g, and the amount of 2-methylimidazole was 0.4105 g; the hydrothermal reaction temperature was 100° C., and the reaction time was 36 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com