Cobalt diselenide/nitrogen-doped carbon nanomaterial composite electrode catalytic material, preparation method and application thereof

A technology of nitrogen-doped carbon and nanomaterials, applied in chemical instruments and methods, physical/chemical process catalysts, battery electrodes, etc., can solve the problems of high price and low catalytic activity, achieve increased specific surface area, good application prospects, Favorable effect of electrocatalytic reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Soak the carbon cloth in acetone (99.5%), 10% hydrochloric acid, and ethanol (99.7%) in sequence, rinse it with deionized water until neutral, dry it in vacuum at 60°C for 24 hours, and undergo plasma hydrophilization treatment to obtain The hydrophilized carbon cloth is ready for use; at room temperature, add 40mL aqueous solution containing 1.3g dimethylimidazole to 40mL aqueous solution containing 0.5821g cobalt nitrate hexahydrate, mix well under magnetic stirring, add the above carbon cloth at room temperature Under the reaction 4h. After the reaction, rinse 3 times with deionized water. After the obtained product was vacuum-dried at 60°C for 24 hours, Co-MOF was grown in situ on the carbon cloth;

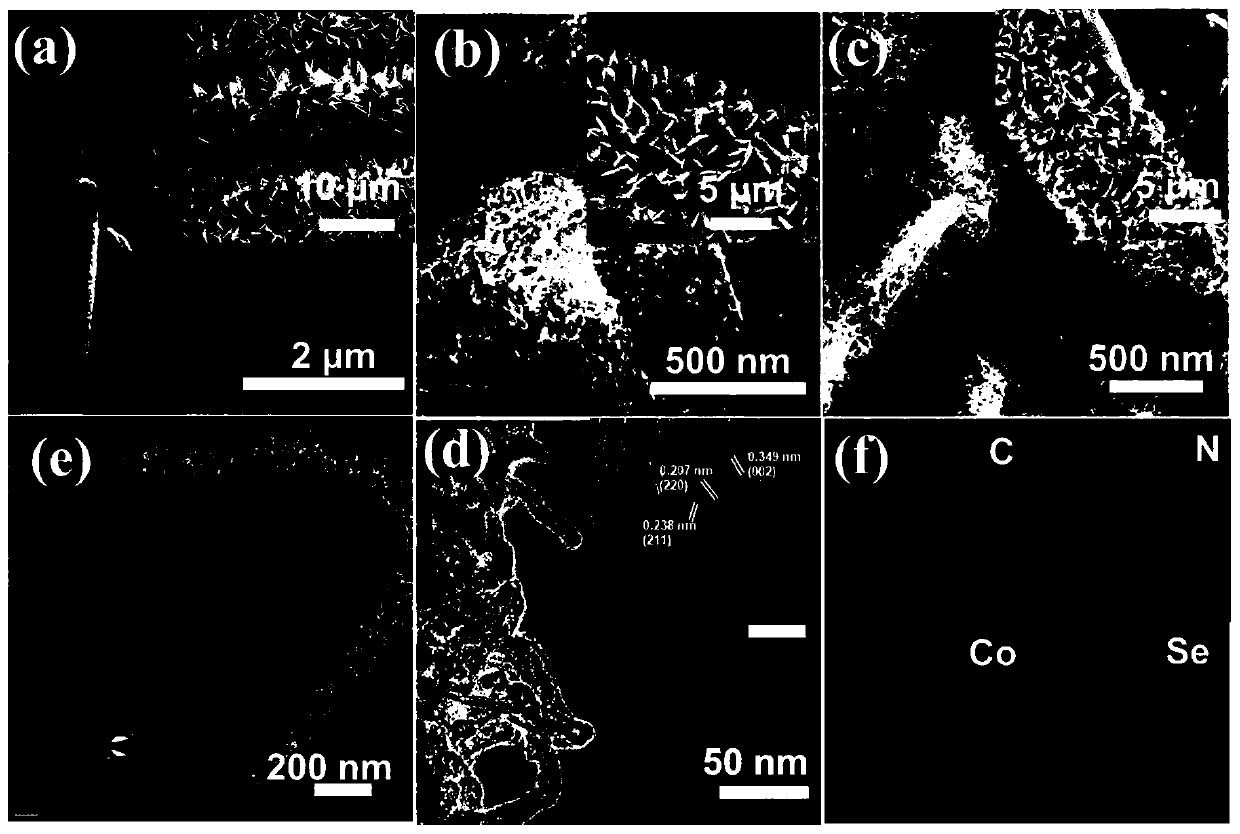

[0039] (2) Grow nitrogen-doped carbon nanotubes / nitrogen-doped carbon nanosheets on the carbon cloth treated in step (1) by CVD, first pass nitrogen gas, and then heat up to 500 degrees Celsius at a rate of 3°C / min, then pass hydrogen gas, Ethanol, calcined for 10...

Embodiment 2

[0045] (1) After soaking the carbon cloth in acetone (99.5%), 10% hydrochloric acid, and ethanol (99.7%) in sequence, rinse it with deionized water until it becomes neutral, dry it in vacuum at 60°C for 24 hours, and make it hydrophilized by plasma for later use. At room temperature, add 40mL aqueous solution containing 1.3g dimethylimidazole to 40mL aqueous solution containing 0.5821g cobalt nitrate hexahydrate, mix well under magnetic stirring, add the above carbon cloth and react at room temperature for 4h. After the reaction, rinse 3 times with deionized water. After the obtained product was vacuum-dried at 60°C for 24 hours, Co-MOF was grown in situ on the carbon cloth;

[0046] (2) Grow nitrogen-doped carbon nanotubes / nitrogen-doped carbon nanosheets on the carbon cloth treated in step (1) by CVD: first pass nitrogen gas, heat up to 500 degrees Celsius at a rate of 3°C / min, then pass hydrogen gas, Ethanol, calcined for 30 minutes, passed nitrogen, kept at 500 degrees fo...

Embodiment 3

[0050] (1) After soaking the carbon cloth in acetone (99.5%), 10% hydrochloric acid, and ethanol (99.7%) in sequence, rinse it with deionized water until it becomes neutral, dry it in vacuum at 60°C for 24 hours, and make it hydrophilized by plasma for later use. At room temperature, add 40mL aqueous solution containing 1.3g dimethylimidazole to 40mL aqueous solution containing 0.5821g cobalt nitrate hexahydrate, mix well under magnetic stirring, add the above carbon cloth and react at room temperature for 4h. After the reaction, rinse 3 times with deionized water. After the obtained product was vacuum-dried at 60°C for 24 hours, Co-MOF was finally grown in situ on carbon cloth;

[0051] (2) Grow nitrogen-doped carbon nanotubes / nitrogen-doped carbon nanosheets on the carbon cloth treated in step (1) by CVD, first pass nitrogen gas, and then heat up to 500 degrees Celsius at a rate of 3°C / min, then pass hydrogen gas, Ethanol, calcined for 10 minutes, passed nitrogen, kept at 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com