Method for preparing fluorinated hydroxyapatite/ zirconium oxide (FHA/ZrO2) composite ceramic powder with good heat stability by hydrothermal synthesis

A composite ceramic and thermal stability technology, applied in the field of composite ceramic powder preparation, can solve the problems of uneven dispersion and mixing of components, poor thermal stability, etc., achieve uniform distribution of components, improve thermal stability, and improve thermal stability. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

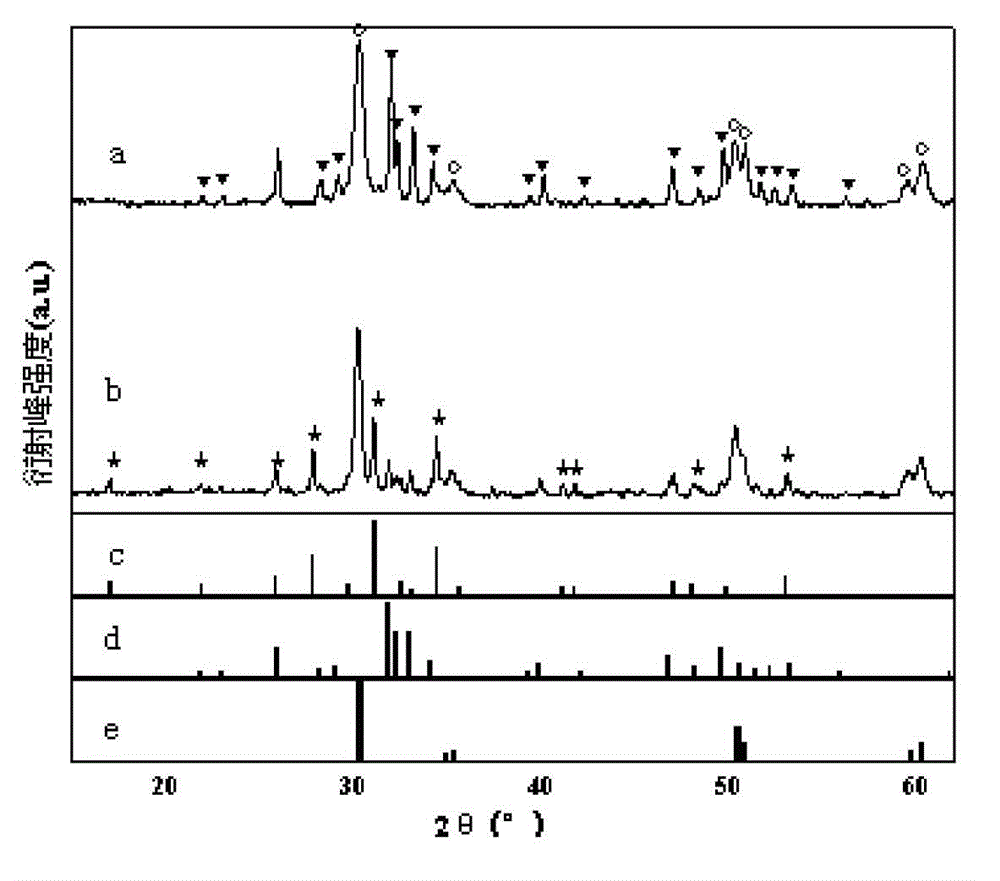

Image

Examples

specific Embodiment approach 1

[0023] Specific embodiment one: the FHA / ZrO with good thermal stability of this embodiment 2 The hydrothermal synthesis preparation method of composite ceramic powder is realized according to the following steps:

[0024] 1. Yttrium stabilized hydrated zirconia powder Y 2 o 3 -Zr(OH) 4 Preparation: ZrOCl 2 ·8H 2 O and Y (NO 3 ) 3 ·8H 2 O is dissolved in distilled water to make a mixed solution, and ammonia water with a mass percentage concentration of 25% to 28% is added dropwise to the mixed solution, and after aging for 1.5 to 2 hours, the precipitate obtained after aging is centrifuged and washed to obtain yttrium Stabilized hydrated zirconia powder Y 2 o 3 -Zr(OH) 4 ; Wherein, ZrOCl in the mixed solution 2 The concentration is 0.19~0.21mol·L -1 ,, the molar ratio of Zr and Y in the mixed solution is 100:6;

[0025] 2. Hydrothermal synthesis of FHA / ZrO 2 Composite precursor powder

[0026] a. According to Ca / P molar ratio (1.67~1.68): 1, calcium nitrate aqueo...

specific Embodiment approach 2

[0037] Embodiment 2: This embodiment differs from Embodiment 1 in that: the centrifugation in step 1 is performed at 5000-8000 r / min for 3-5 minutes. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0038] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the washing in step 1 uses distilled water for washing. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com