Tungsten-doped alloy powder and preparing method thereof

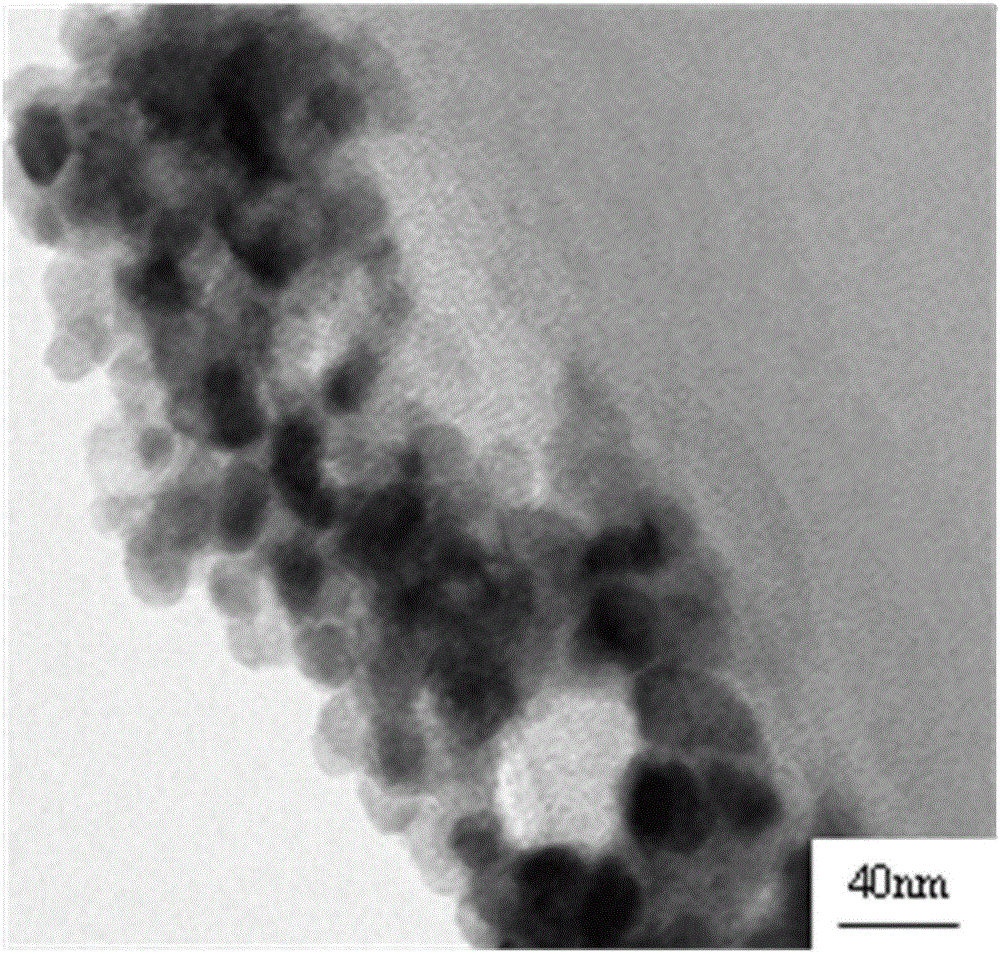

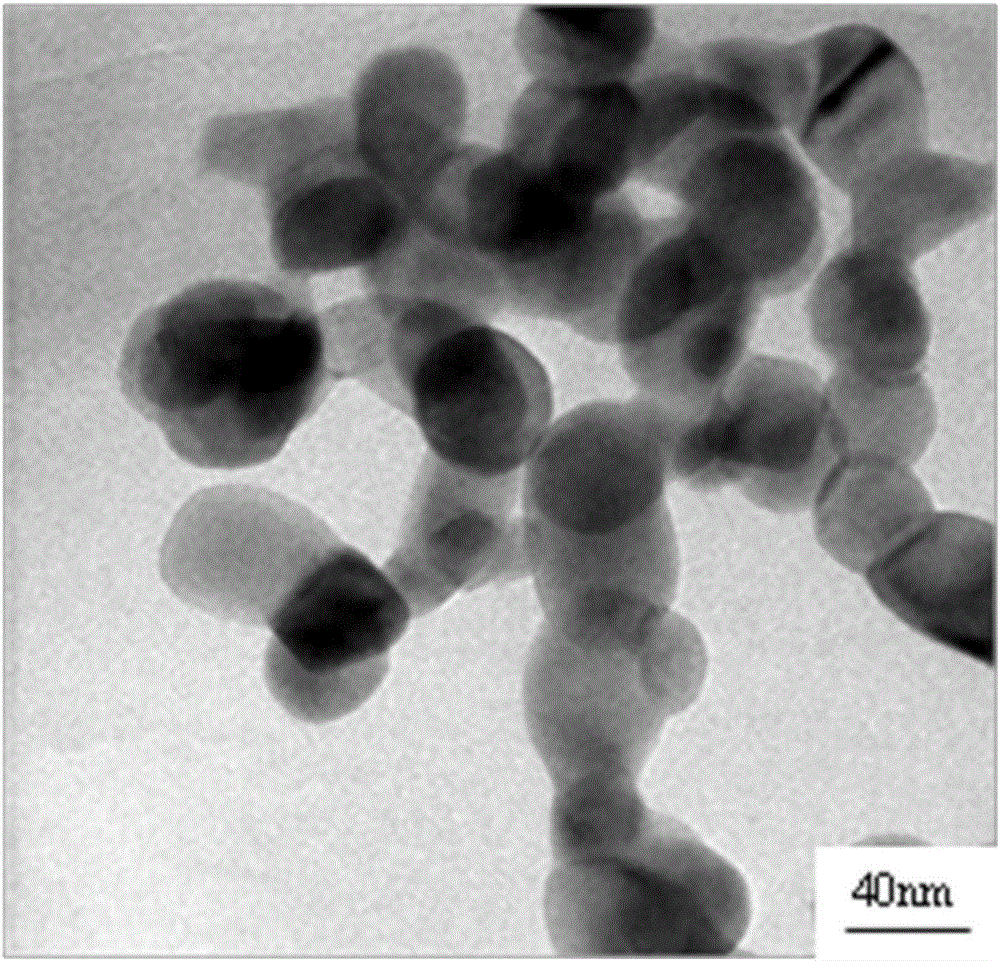

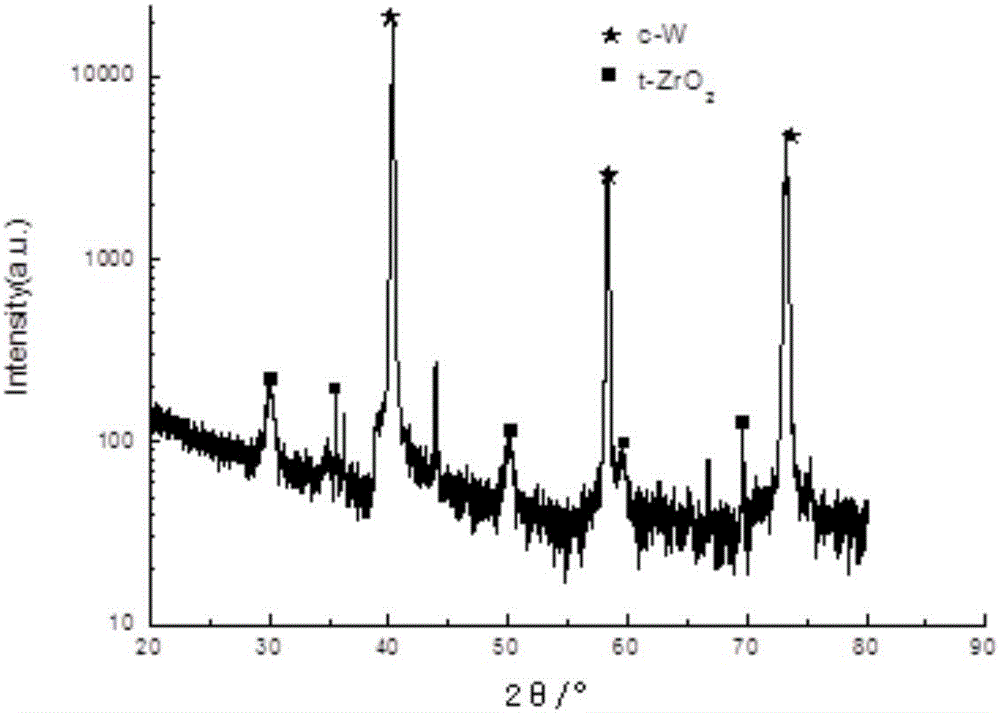

A tungsten alloy and powder technology, applied in the field of doped tungsten alloy powder and its preparation, can solve the problem of difficult to meet high-performance tungsten alloy, and achieve the effect of uniform distribution of components, uniform distribution and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of the doped tungsten alloy powder of the present embodiment comprises the following steps:

[0037] 1) Prepare suspension A and suspension B:

[0038] A) Take 61.0g of ammonium paratungstate, mix 13ml of concentrated nitric acid and ammonium paratungstate in beaker 1, add distilled water to adjust the pH to 1, pour it into autoclave 1 after stirring, put it in a vacuum drying oven and react at 180°C for 15h, After the reaction, pour out the supernatant in the autoclave 1, then pour it into the beaker 2, add distilled water to wash the precipitate 5 times, then add distilled water, and stir to obtain a suspension A;

[0039]B) Get 4.10g of zirconium nitrate and dissolve it in distilled water. According to the ratio of ammonia and zirconium nitrate molar ratio in ammonia water to 4:1, drip ammonia water into the zirconium nitrate solution to form a precipitate to obtain suspension B1; take 1.09 g of yttrium nitrate g is dissolved in distilled wate...

Embodiment 2

[0044] The preparation method of the doped tungsten alloy powder of the present embodiment comprises the following steps:

[0045] 1) Prepare suspension A and suspension B:

[0046] A) Take 398.56g of ammonium paratungstate, mix 85ml of concentrated nitric acid and ammonium paratungstate in beaker 1, add distilled water to adjust the pH to 1.2, pour it into autoclave 1 after stirring, put it in a vacuum drying oven and react at 180°C for 17h, After the reaction, pour out the supernatant in the autoclave 1, then pour it into the beaker 2, add distilled water to wash the precipitate 8 times, then add distilled water, and stir to obtain a suspension A;

[0047] B) Dissolve 14.19 g of zirconium nitrate in distilled water. According to the ratio of ammonia and zirconium nitrate molar ratio of 4:1 in the ammonia water, drip ammonia water into the zirconium nitrate solution to form a precipitate to obtain suspension B1; take 5.05 g of yttrium nitrate g is dissolved in distilled wate...

Embodiment 3

[0052] The preparation method of the doped tungsten alloy powder of the present embodiment comprises the following steps:

[0053] 1) Prepare suspension A and suspension B:

[0054] A) Take 238.38g of ammonium paratungstate, add 50ml of concentrated nitric acid into distilled water to make a nitric acid solution with a pH of 1.1, mix it with ammonium paratungstate in beaker 1, pour it into autoclave 1 after stirring, put it in a vacuum drying oven at 180°C The reaction was carried out for 20 hours. After the reaction, the supernatant in the autoclave 1 was poured out, then poured into the beaker 2, and the precipitate was washed with distilled water for 6 times, then added with distilled water, and stirred to obtain a suspension A;

[0055] B) Get 21.89g of zirconium nitrate and dissolve it in distilled water. According to the ratio of ammonia and zirconium nitrate molar ratio in ammonia water to 4:1, drip ammonia water into the zirconium nitrate solution to form a precipitate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com