Composite thin film for flexible electrode and preparation method thereof

A composite film and flexible graphite technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of unsatisfactory energy storage characteristics, low energy density, and poor rate performance of all-solid-state flexible supercapacitors. problem, to achieve the effect of no aggregation, excellent electrical conductivity, and good rate performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

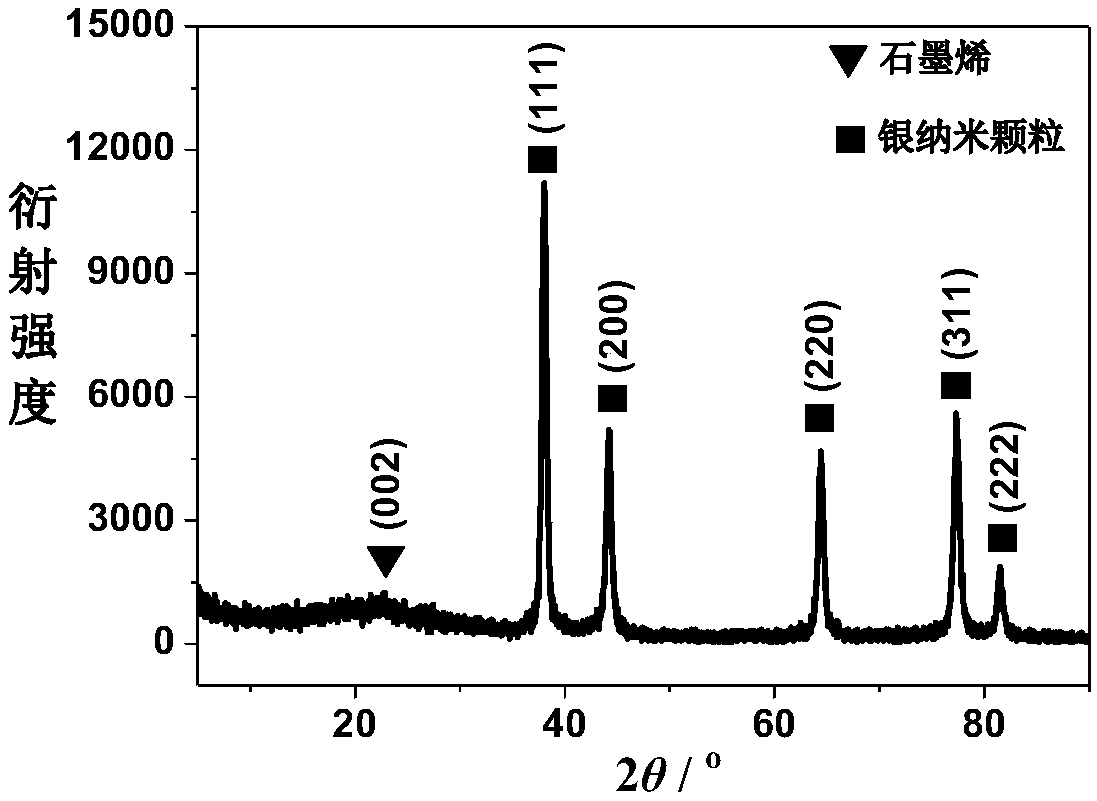

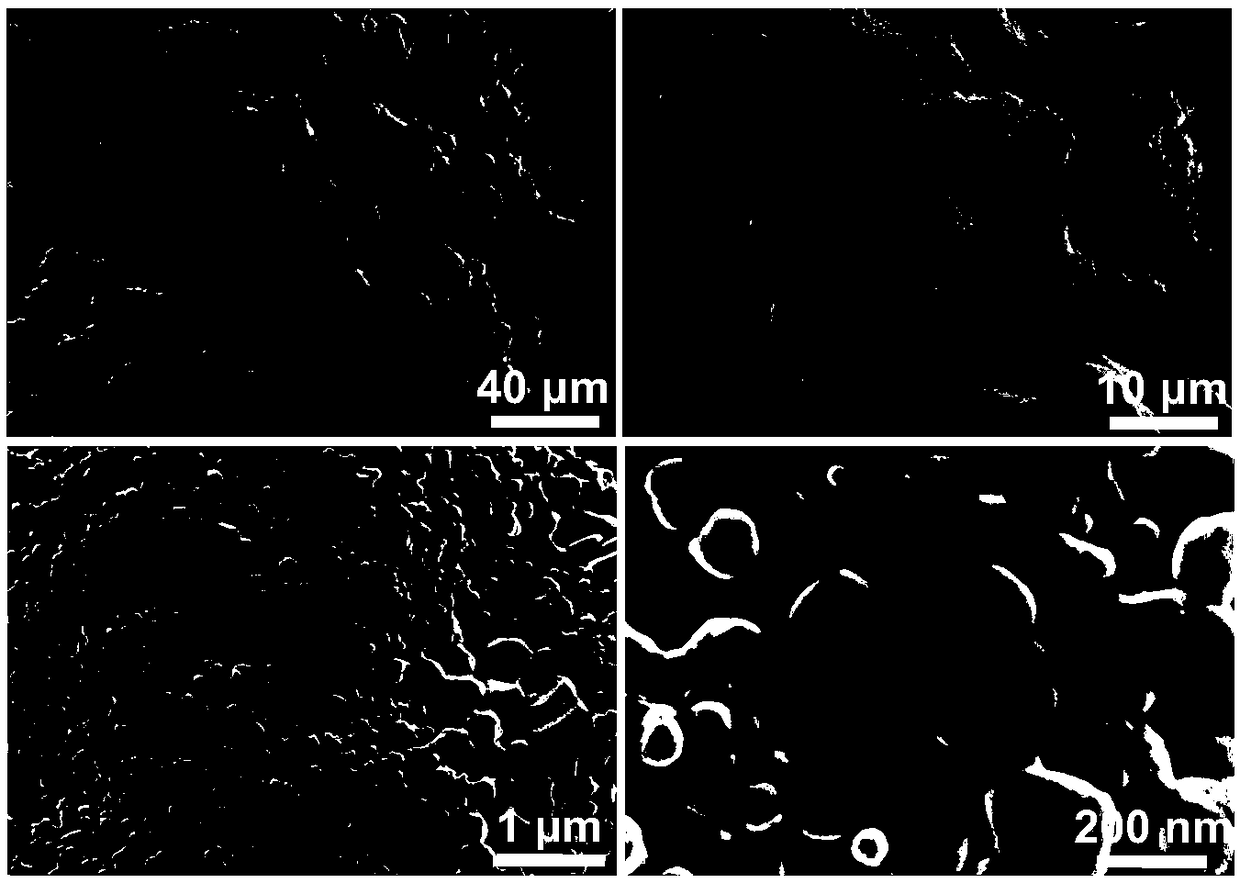

[0060] The method provided by the invention is used to prepare cellulose / graphene / silver nanoparticle composite film:

[0061] (1) Cut 180mg filter paper into pieces and mix with 300mL 0.6mg mL -1 Add the graphene oxide aqueous dispersion to the cooking machine together, start the cooking machine, make the rotor rotate at a speed of about 30,000 rpm and stir for 4 minutes, and then break the filter paper to make cellulose fiber + graphene oxide slurry material.

[0062] (2) Transfer the mixed slurry in step (1) to a beaker, add 60 mL of freshly prepared silver ammonia solution with a concentration of 0.15 M under rapid magnetic stirring, then raise the temperature to 85° C. and react for 30 min. During this process, the silver-ammonia complex was reduced by graphene oxide into silver nanoparticles, and at the same time, the recombination of each component was induced to generate a cellulose / graphene oxide / silver nanoparticle composite.

[0063] (3) The product of step (2) is...

Embodiment 2

[0069] The method provided by the present invention is used to construct a symmetrical all-solid-state flexible supercapacitor [cellulose / graphene / silver nanoparticles / / cellulose / graphene / silver nanoparticles]:

[0070] (1) Add 5g of polyvinyl alcohol to 50mL of water, raise the temperature to 90°C, and stir to dissolve it at the same time. Then slowly drop 2mL 1g mL under stirring -1 The aqueous solution of potassium chloride was naturally cooled to room temperature to obtain a clear and transparent polyvinyl alcohol / potassium chloride gel electrolyte.

[0071] (2) The cellulose / graphene / silver nanoparticle composite film synthesized in embodiment 1 is cut into 0.5cm * 3cm rectangular strip, placed on the glass slide, then a small amount of polyvinyl alcohol / graphene in step (1) / Potassium chloride gel electrolyte is poured on its surface, covering an area of 0.5cm×2cm, that is, leaving a blank area of 0.5cm×1cm for connecting with the electrode clip, and then letting th...

Embodiment 3-5

[0078] Embodiment 3-5: Carried out according to the steps and parameters in Table 1 below, and the others are the same as in Embodiment 1.

[0079]

[0080] The composite film and the flexible capacitor obtained by the above embodiments 3-5 still have the above-mentioned technical effects of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com