Preparation method of ordered solid oxide membrane electrode

A solid oxide, membrane electrode technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of reducing electrochemical performance, affecting long-term stability and life, and reducing electrode polarization loss and concentration polarization loss, increasing the three-phase reaction interface, and improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention provides a method for preparing an ordered solid oxide membrane electrode. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

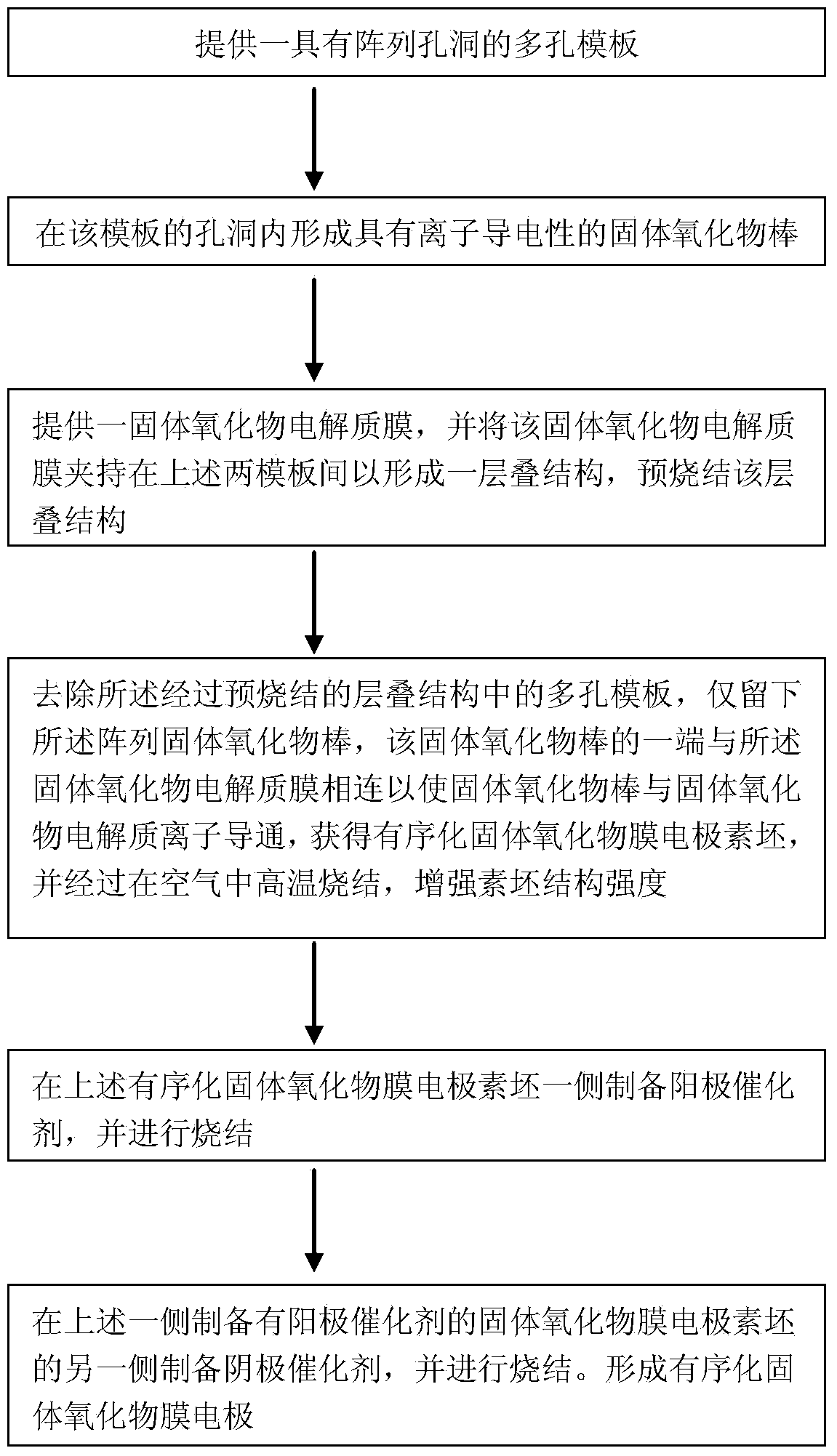

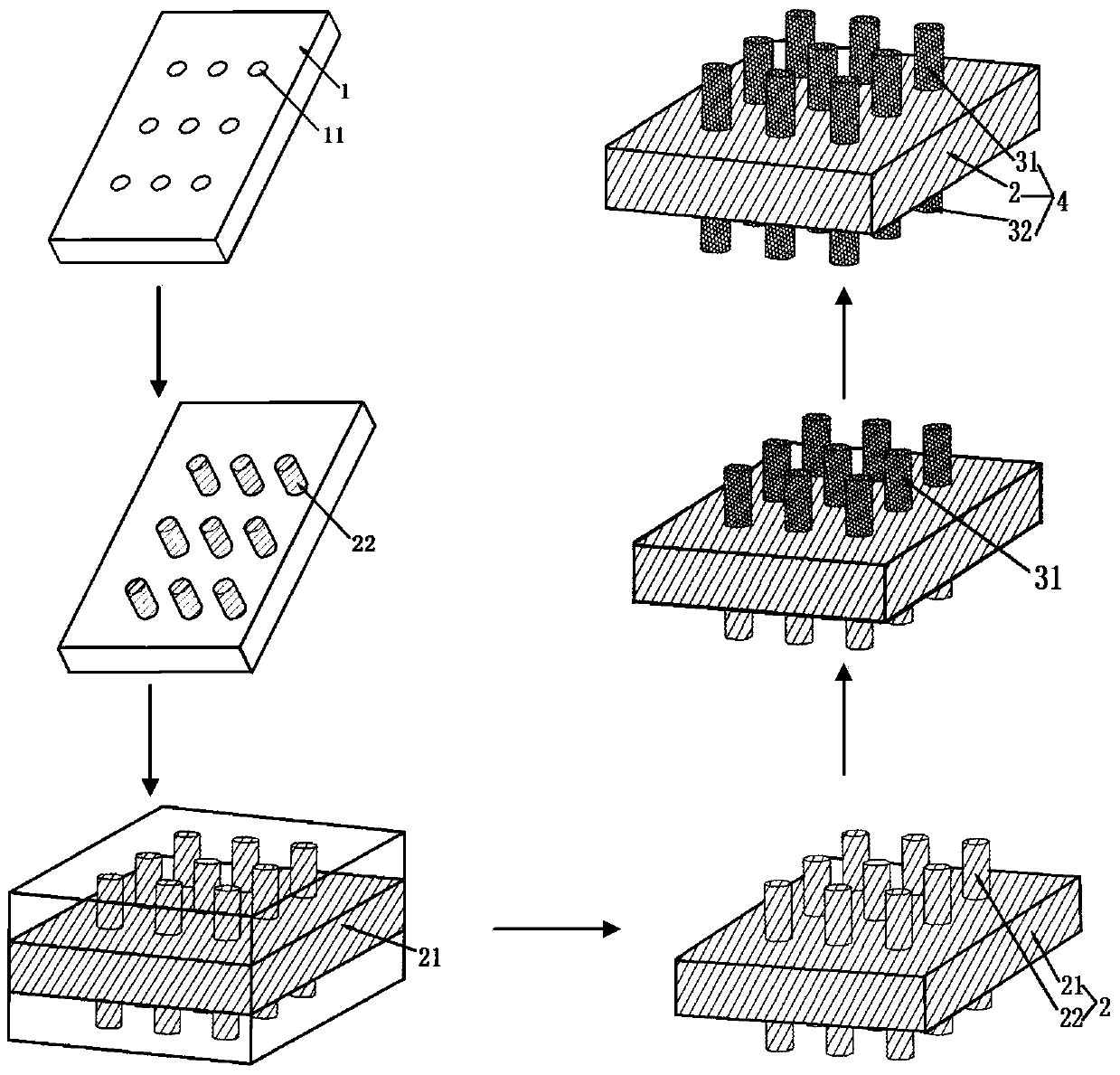

[0031] see figure 1 and figure 2 The method for preparing an ordered solid oxide membrane electrode provided in this embodiment specifically includes the following steps:

[0032] Step 1: providing a porous template with an array of holes;

[0033] Step 2: forming ion-conductive solid oxide rods in the pores of the template;

[0034] Step 3: providing a solid oxide electrolyte membrane, and sandwiching the solid oxide electrolyte membrane between the above two templates to form a laminated structure, and pre-sintering the laminated structure;

[0035] Step 4: removing the porous template in the pre-sintered laminated structure, leaving only the array of solid oxide rods, one end of which is connected to the solid oxide electrolyte membrane so th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com