Medium-low-temperature solid oxide fuel cell negative electrode material and preparation method thereof

A fuel cell cathode and solid oxide technology, which is applied in the direction of fuel cells, battery electrodes, chemical instruments and methods, etc., can solve problems such as structural instability, and achieve the effect of improving electrical conductivity and fine powder particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

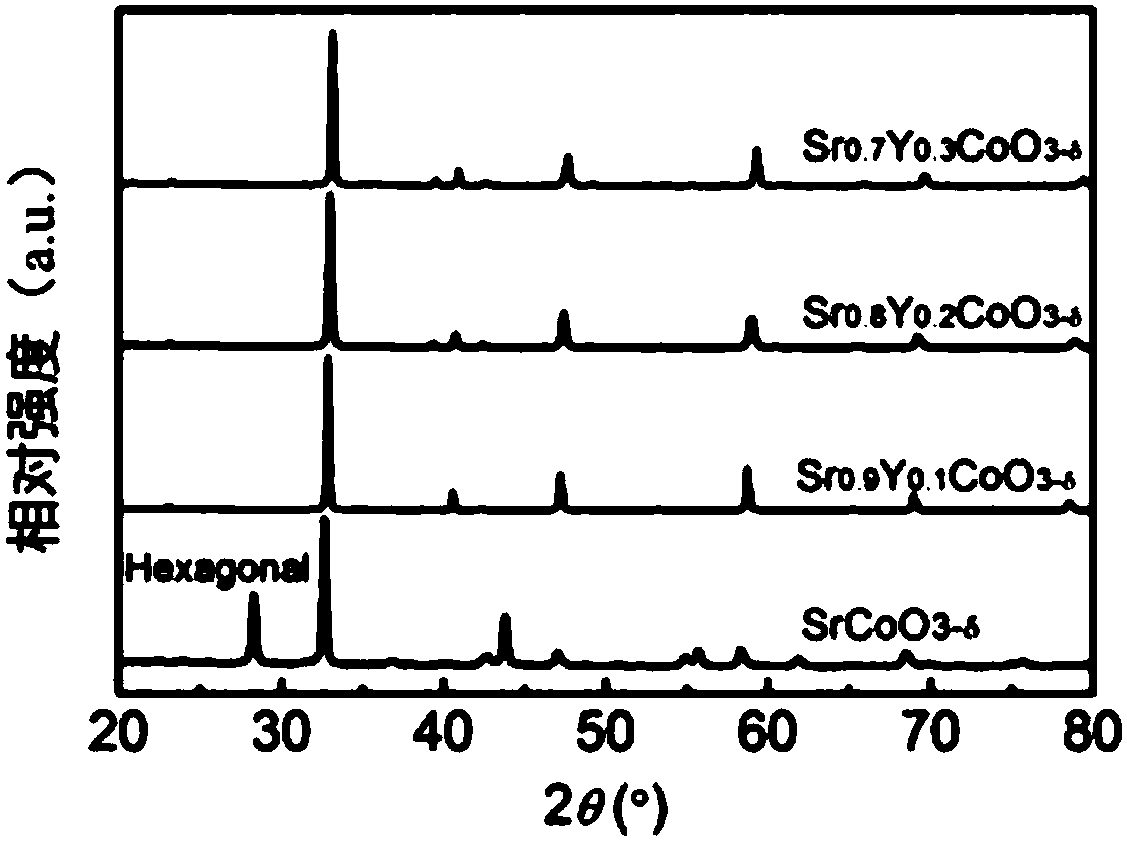

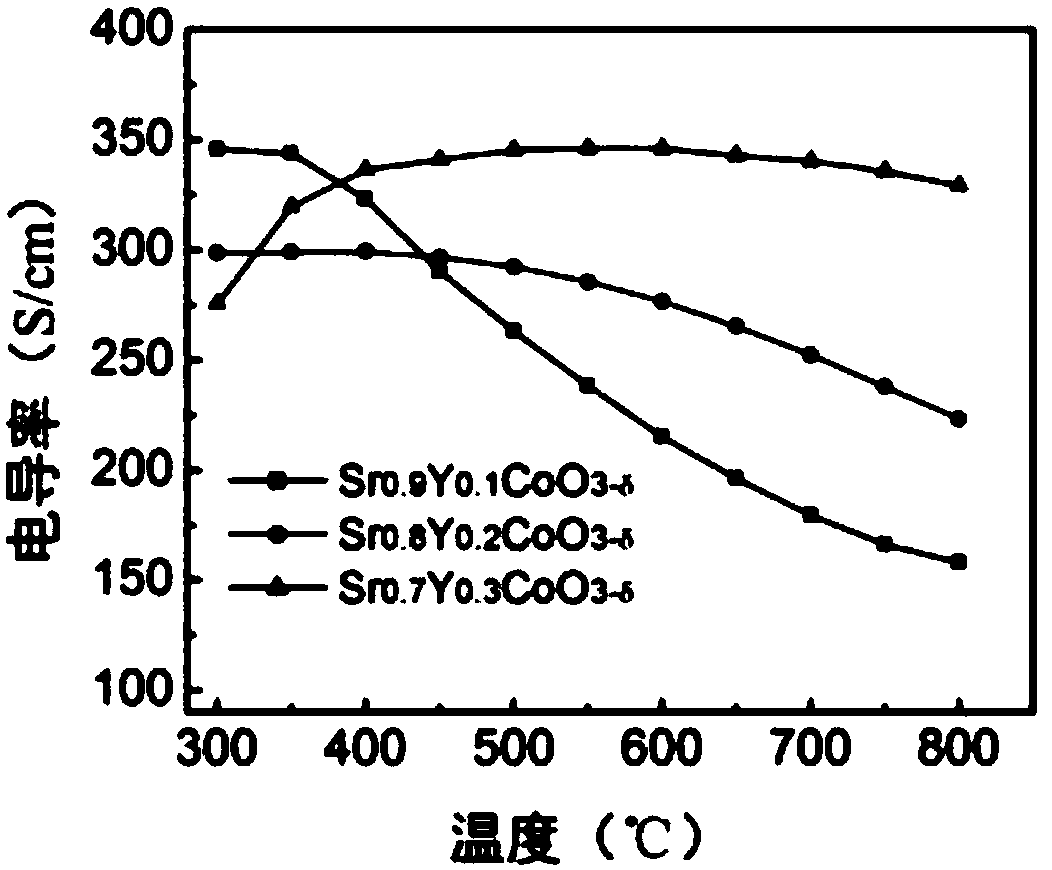

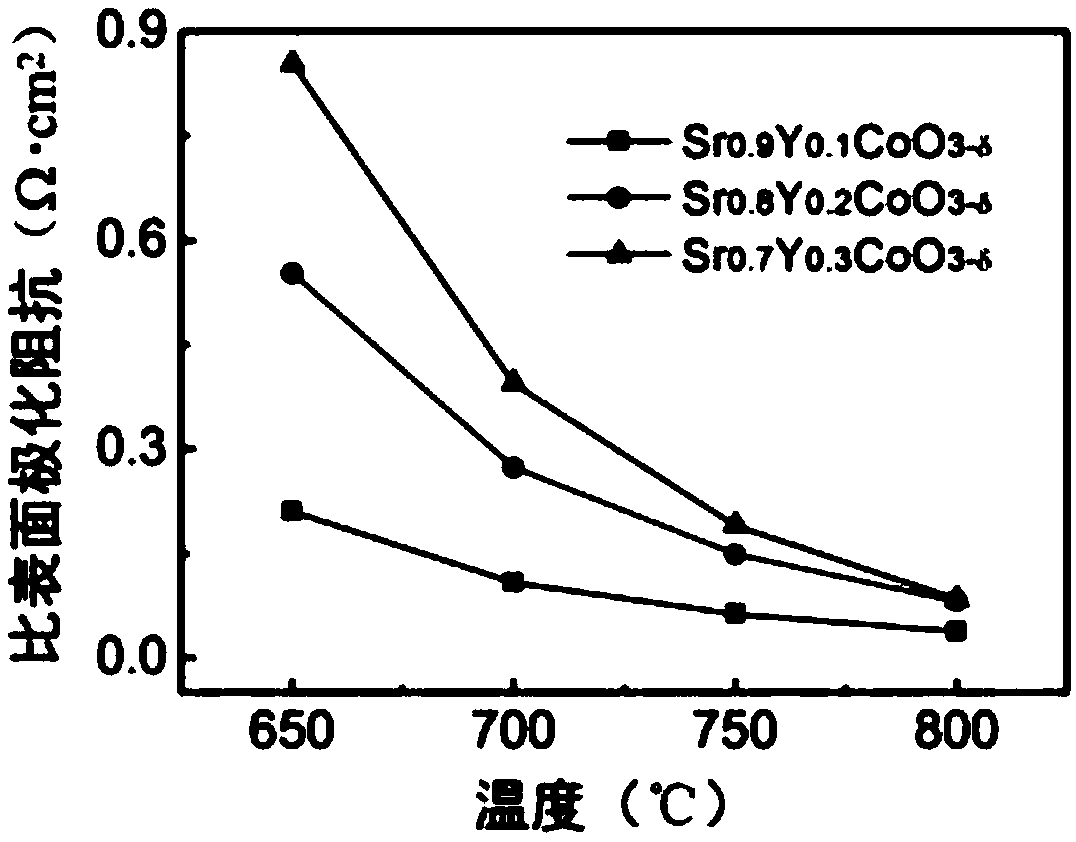

[0024] Low temperature solid oxide fuel cell cathode material Sr in embodiment 1 0.9 Y 0.1 CoO 3-δ Synthesis

[0025] 1. The cathode material has the general formula Sr 1-x R x CoO 3-δ Among them, when R is Y and when x=0.1, it is Sr 0.9 Y 0.1 CoO 3-δ , according to 0.05mol Sr 0.9 Y 0.1 CoO 3-δ Proportion, weigh 9.523g Sr(NO 3 ) 2 (analytical pure), 1.915gY (NO 3 ) 3 ·6H 2 O (analytically pure), 14.554g Co(NO 3 ) 2 ·6H 2 O (analytical pure);

[0026] 2. Slowly add the above-mentioned materials into a beaker filled with 200mL deionized water, dissolve them completely, stir evenly, add 58.446g EDTA (analytical pure) and 19.214g citric acid (analytical pure) into the mixed solution in turn and stir fully, Add NH dropwise to the mixed solution 3 ·H 2 O solution until the solution becomes transparent and the pH value is adjusted to 8, then add deionized water to 500mL;

[0027] 3. Put the above beaker containing the solution on a magnetic stirrer to heat and s...

Embodiment 2

[0031] Low temperature solid oxide fuel cell cathode material Sr in embodiment 2 0.8 Y 0.2 CoO 3-δ Synthesis

[0032] 1. The cathode material has the general formula Sr 1-x R x CoO 3-δ Among them, when R is Y and when x=0.2, it is Sr 0.8 Y 0.2 CoO 3-δ , according to 0.05mol Sr 0.8 Y 0.2 CoO 3-δ Proportioning, weigh 8.465g Sr(NO 3 ) 2 (analytical pure), 3.829gY (NO 3 ) 3 ·6H 2 O (analytically pure), 14.554g Co(NO 3 ) 2 ·6H 2 O (analytical pure);

[0033] 2. Slowly add the above-mentioned materials into a beaker filled with 200mL deionized water, dissolve them completely, stir evenly, add 58.446g EDTA (analytical pure) and 19.214g citric acid (analytical pure) into the mixed solution in turn and stir fully, Add NH dropwise to the mixed solution 3 ·H 2 O solution until the solution becomes transparent and the pH value is adjusted to 8, then add deionized water to 500mL;

[0034] 3. Put the above beaker containing the solution on a magnetic stirrer to heat an...

Embodiment 3

[0038] Low temperature solid oxide fuel cell cathode material Sr in embodiment 3 0.7 Y 0.3 CoO 3-δ Synthesis

[0039] 1. The cathode material has the general formula Sr 1-x R x CoO 3-δ Among them, when R is Y and when x=0.3, it is Sr 0.7 Y 0.3 CoO 3-δ , according to 0.05mol Sr 0.7 Y 0.3 CoO 3-δ Proportioning, weigh 7.407g Sr(NO 3 ) 2 (analytical pure), 5.738gY (NO 3 ) 3 ·6H 2 O (analytically pure), 14.554g Co(NO 3 ) 2 ·6H 2 O (analytical pure);

[0040] 2. Slowly add the above-mentioned materials into a beaker filled with 200mL deionized water, dissolve them completely, stir evenly, add 58.446g EDTA (analytical pure) and 19.214g citric acid (analytical pure) into the mixed solution in turn and stir fully, Add NH dropwise to the mixed solution 3 ·H 2 O solution until the solution becomes transparent and the pH value is adjusted to 8, then add deionized water to 500mL;

[0041] 3. Put the above beaker containing the solution on a magnetic stirrer to heat an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com