Ordered solid oxide membrane electrode

A solid oxide and membrane electrode technology, applied in battery electrodes, circuits, fuel cells, etc., can solve problems affecting long-term stability and life, and reducing electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

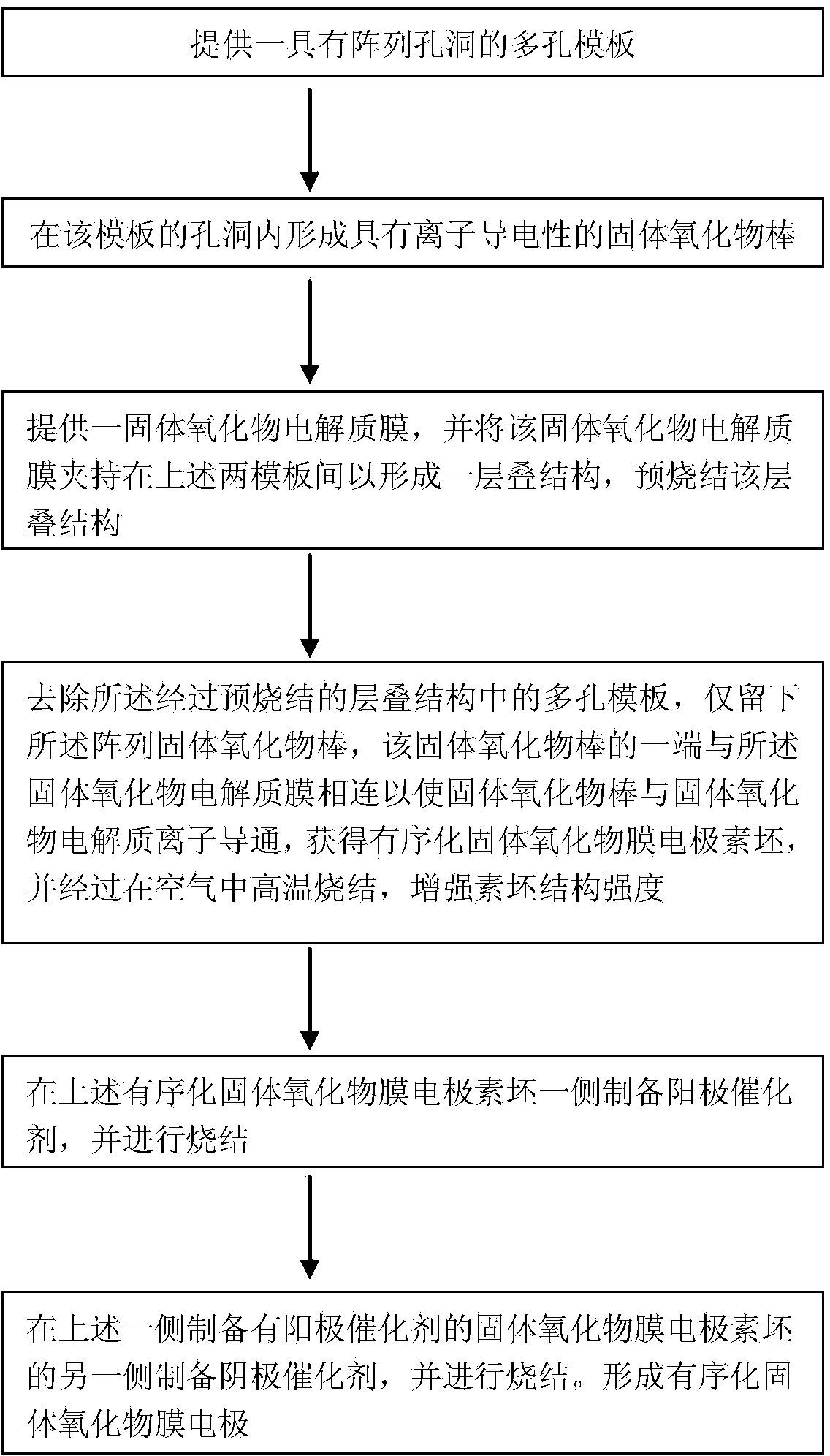

[0023] The present invention provides an ordered solid oxide membrane electrode. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

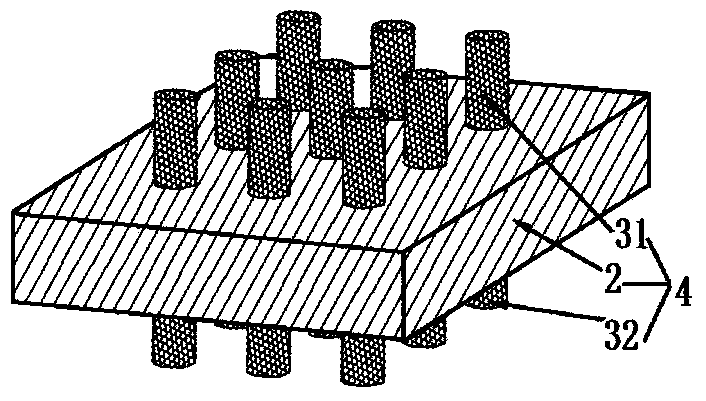

[0024] This embodiment provides an ordered solid oxide membrane electrode 4, the ordered solid oxide membrane electrode 4 is composed of an ion conductor 2, an anode 31 and a cathode 32; the ion conductor 2 is composed of a solid oxide electrolyte membrane 21 and a plurality of solid oxide rods 22 arranged on both sides of the surface; the anode 31 is composed of multiple solid oxide rods 22 arranged on the surface of the solid oxide electrolyte membrane A plurality of anode catalyst particles are closely connected, and the cathode 32 is composed of a plurality of cathode catalyst particles closely connected on the surface of a plurality of solid oxide rods 22 arranged on the surface of the other side of the solid oxide electrolyte membrane 21 .

[0025] The solid oxide r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com