Intermediate-temperature solid oxide fuel cell one-dimensional nano composite cathode and preparation method thereof

A solid oxide, fuel cell technology, applied in battery electrodes, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of high cathode polarization resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

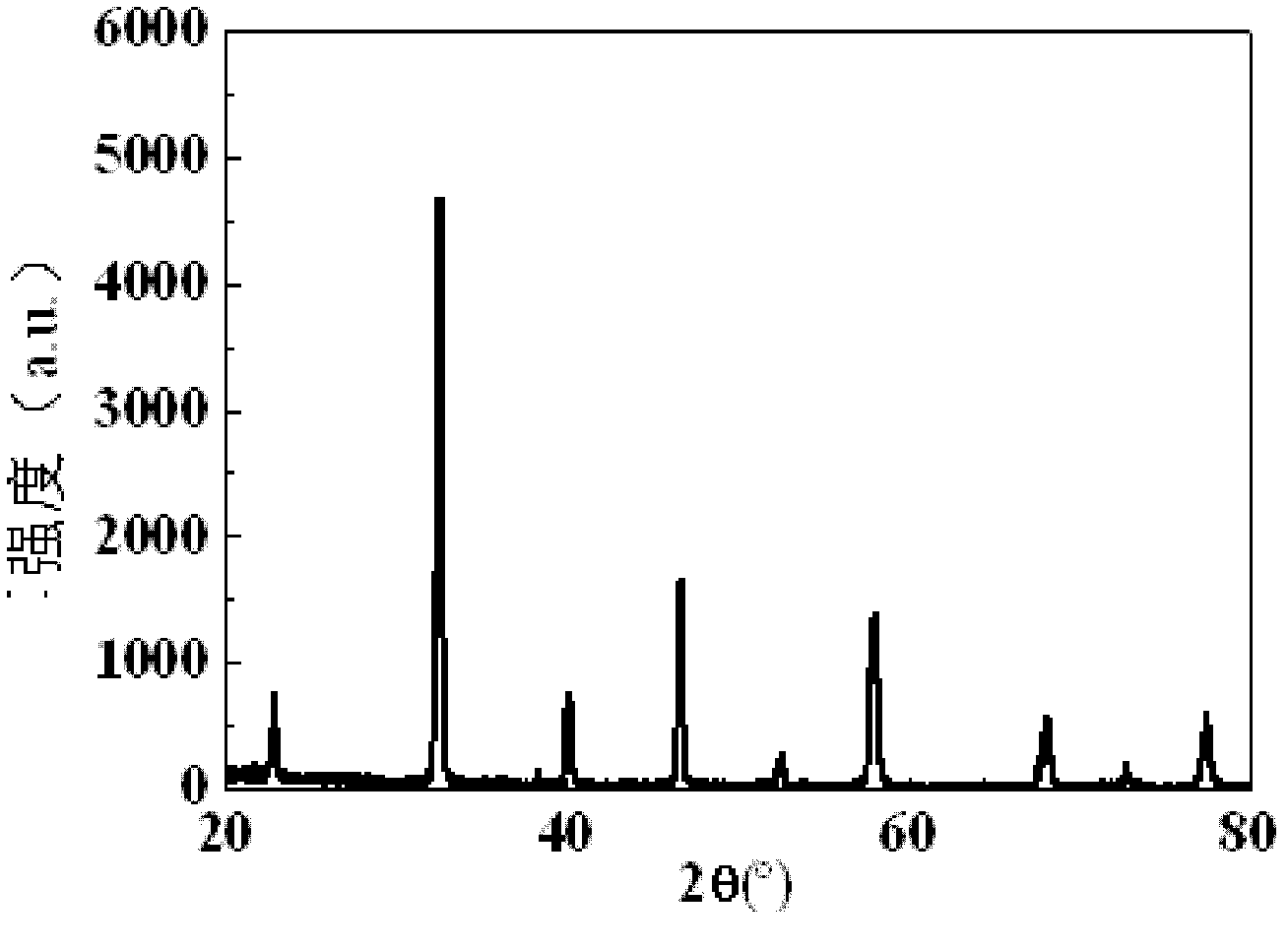

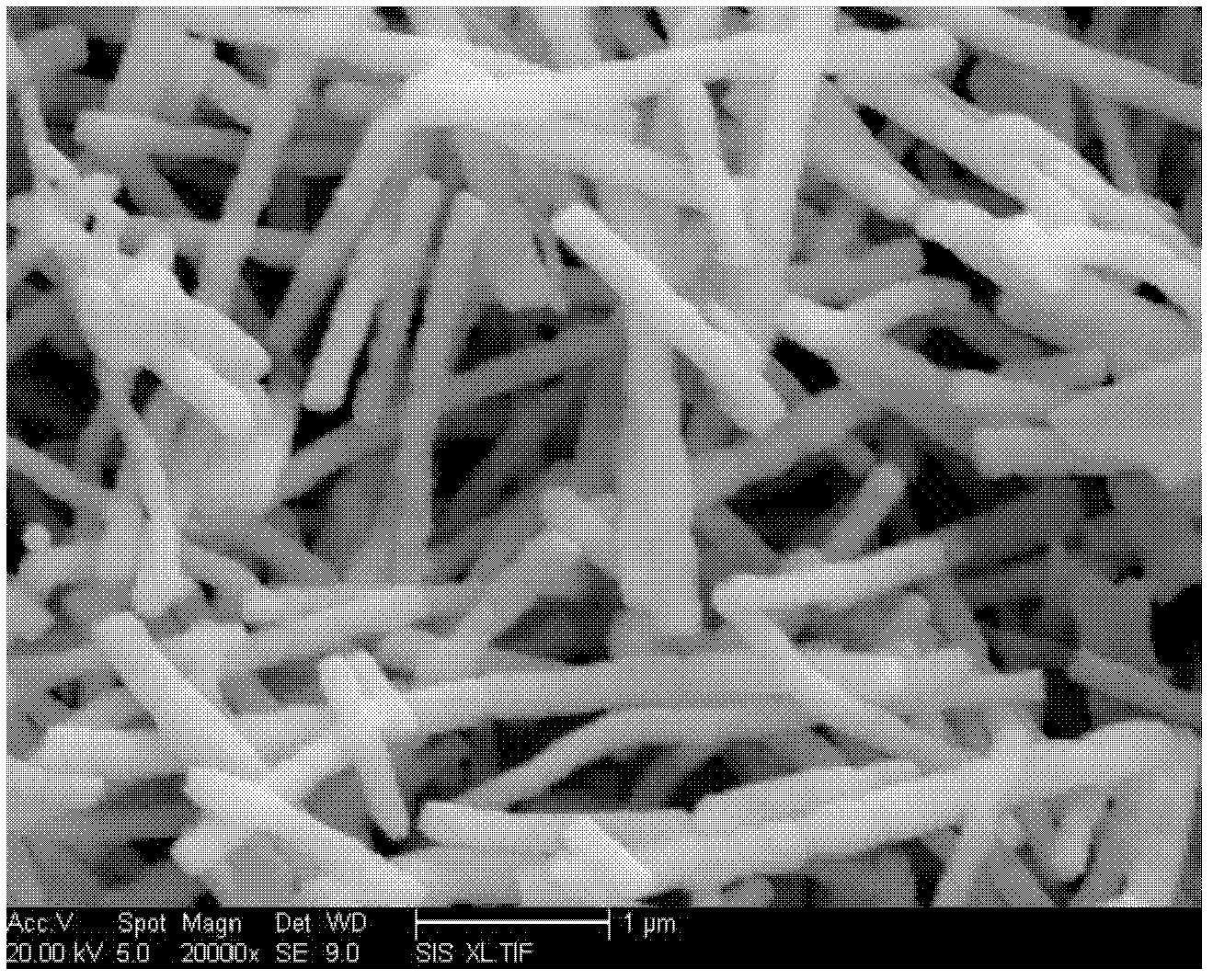

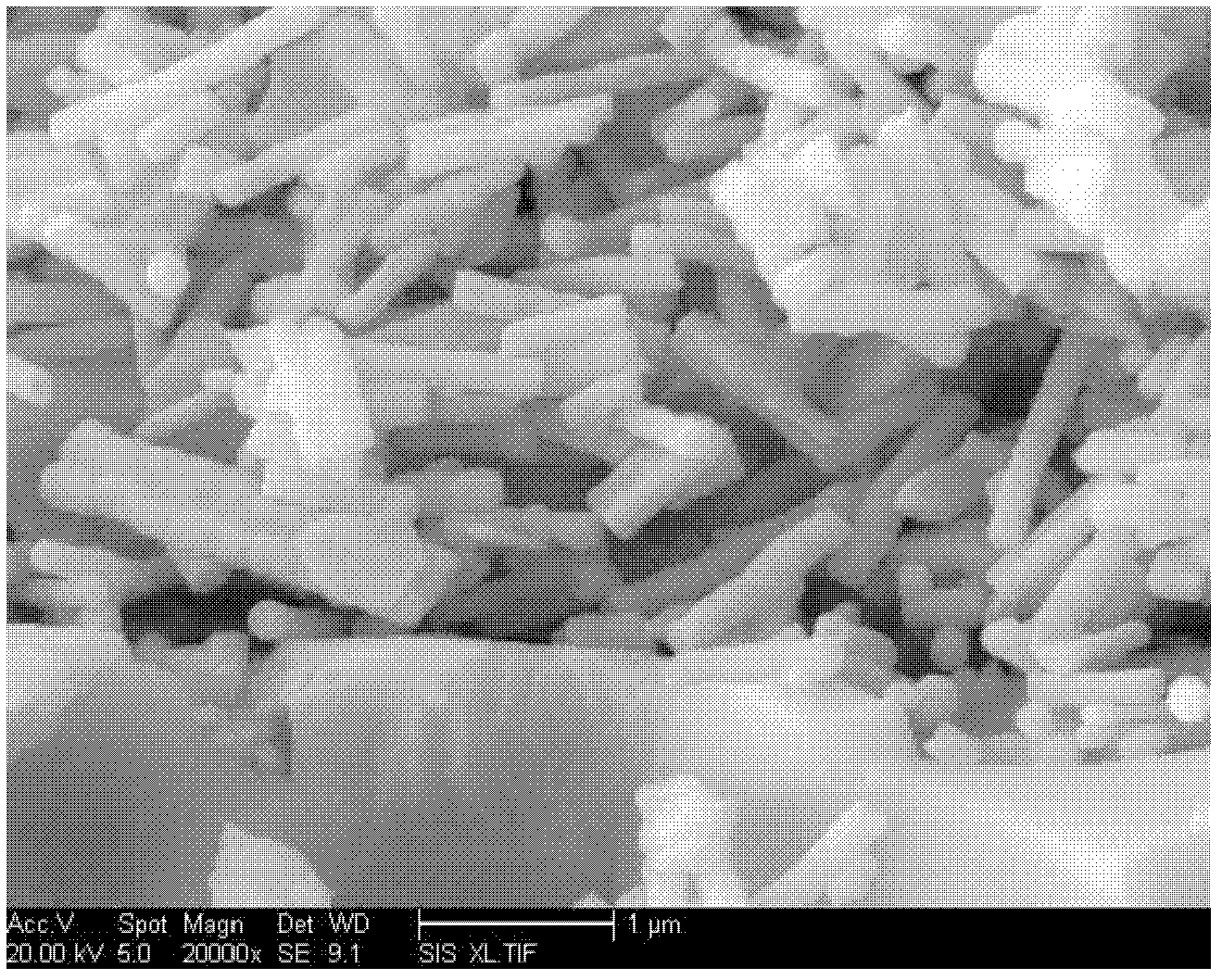

[0027] Specific embodiment 1: The one-dimensional nanocomposite cathode of a medium temperature solid oxide fuel cell in this embodiment is based on Ce 0.8 Gd 0.2 O 1.9 (GDC) The electrolyte sheet is the substrate, and the surface of the substrate is coated with nanorod-like La 0.8 Sr 0.2 Co 0.2 Fe 0.8 O 3 Powder, and La 0.8 Sr 0.2 Co 0.2 Fe 0.8 O 3 Ce attached to nanorods 0.8 Gd 0.2 O 1.9 Nano particles.

[0028] The one-dimensional nanocomposite cathode of the intermediate temperature solid oxide fuel cell of this embodiment is to prepare nanofibers by electrospinning. After the fibers are sintered, a rod-like structure powder is obtained, and the rod-like structure powder is mixed with GDC nanopowders Then, a slurry is prepared and coated on the GDC electrolyte sheet, and after sintering, a one-dimensional nanocomposite cathode of a medium temperature solid oxide fuel cell is obtained. On the cathode, the one-dimensional rod-shaped LSCF and GDC nano-combination extend the elect...

specific Embodiment approach 2

[0029] Specific implementation manner 2: The preparation method of a one-dimensional nanocomposite cathode of an intermediate temperature solid oxide fuel cell of this embodiment is carried out in the following steps:

[0030] 1. Electrospinning precursor liquid preparation: According to the molar ratio of lanthanum nitrate, iron nitrate, cobalt nitrate and strontium nitrate of 4:4:1:1, weigh lanthanum nitrate, iron nitrate, cobalt nitrate and strontium nitrate respectively. Add to N,N-dimethylformamide, magnetically stir until the nitrate is completely dissolved, then add polyvinylpyrrolidone, and stir at room temperature for 4h-6h to obtain an electrospinning precursor solution; among them, the electrospinning precursor solution The mass percentage of nitrate is 15%-25%, and the mass percentage of polyvinylpyrrolidone is 8%-12%;

[0031] 2. Electrospinning to prepare nanofibers: the electrospinning precursor obtained in step 1 is added to the syringe, and a flat stainless steel i...

specific Embodiment approach 3

[0036] Specific embodiment three: This embodiment is different from the specific embodiment two in that the mass ratio of the terpineol solution of LSCF nanorod powder and ethyl cellulose in step four is 1:1. Others are the same as the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com