Synthetic method for lithium nickel manganese oxygen covered with lithium titanate

A technology of lithium titanate coating and lithium nickel manganese oxide, which is applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of poor electrical performance of lithium nickel manganese oxide, and achieve improved rate performance and cycle performance And rate performance, the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

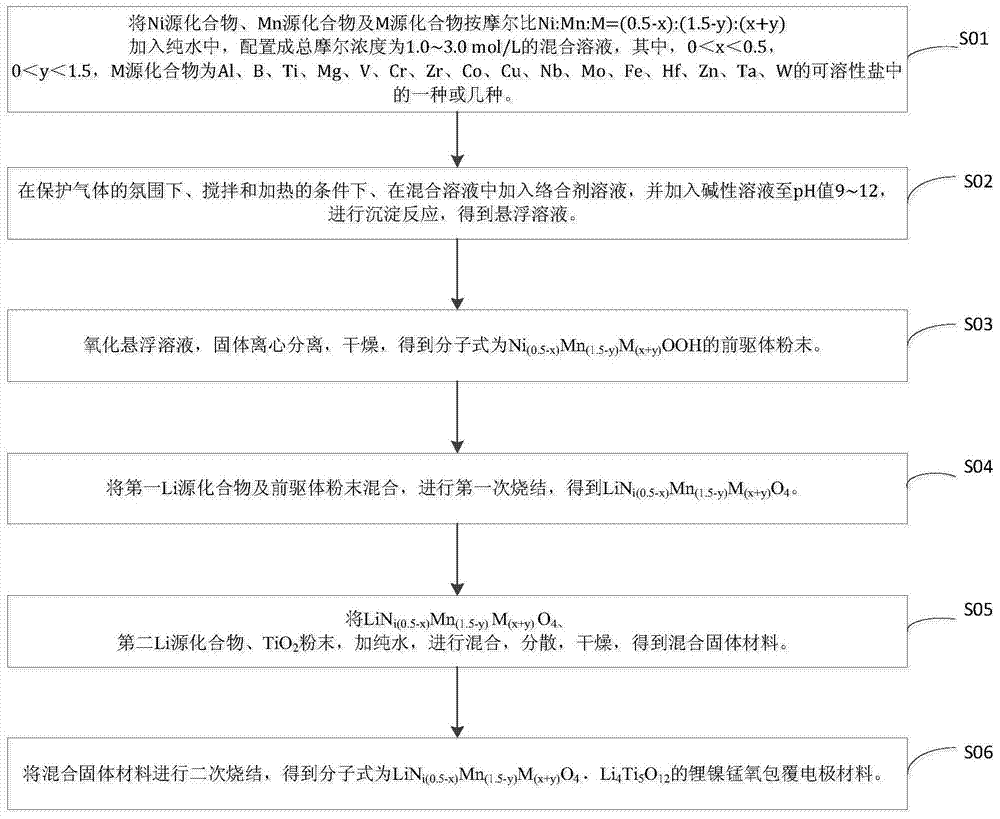

Method used

Image

Examples

Embodiment 1

[0056] 1) NiSO 4 , MnSO 4 and Cr(NO 3 ) 3 Add Ni:Mn:Cr=1:3:1 into distilled water at a molar ratio to form a mixed solution with a total molar concentration of 2.5mol / L.

[0057] 2) Under the conditions of a protective gas atmosphere, a stirring speed of 400rpm and 30°C, the ratio of EDTA to the mixed solution is mixed according to the molar ratio of EDTA:(Mn+Ni+Cr)=0.1, And add NaOH solution to adjust the pH value to 9, carry out the precipitation reaction, and obtain the suspension solution.

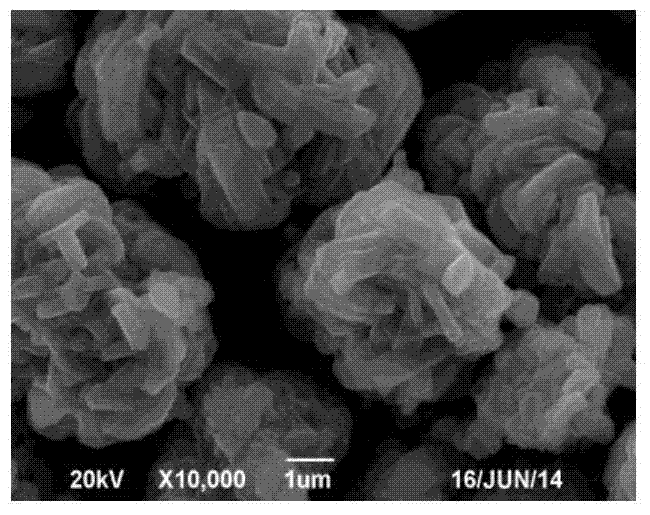

[0058] 3) Oxidize the suspended solution, centrifuge the solid, and dry to obtain a molecular formula of Ni 0.4 mn 1.2 Cr 0.4 OOH precursor powder.

[0059] 4) will Li 2 CO 3 and precursor powder by Li 2 CO 3 : (Ni+Mn+Cr) = 0.2 mixed, sintered at 700 ° C for 15 hours for the first sintering to obtain LiNi 0.4 mn 1.2 Cr 0.4 o 4 .

[0060] 5) LiNi 0.4 mn 1.2 Cr 0.4 o 4 , Li 2 CO 3 、TiO 2 powder, add pure water, mix, disperse, and dry to obtain a mixed solid materia...

Embodiment 2

[0063] 1) NiCl 2 , MnSO 4 and AlCl 3 Add Ni:Mn:Al=6:18:1 into distilled water at a molar ratio to form a mixed solution with a total molar concentration of 2.5mol / L.

[0064] 2) Under the conditions of a protective gas atmosphere, a stirring speed of 450rpm and 40°C, the ratio of disodium edetate to the mixed solution is based on disodium edetate: (Mn+Ni+Al)=0.3 The molar ratio was mixed, and KOH solution was added to adjust the pH value to 9.5, and a precipitation reaction was carried out to obtain a suspension solution.

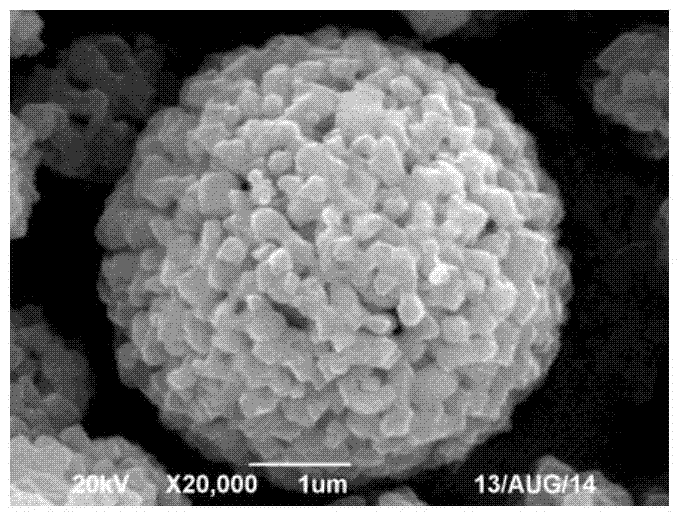

[0065] 3) Oxidize the suspended solution, centrifuge the solid, and dry to obtain a molecular formula of Ni 0.48 mn 1.44 Al 0.08 OOH precursor powder.

[0066] 4) Mix LiCl and precursor powder according to LiCl: (Ni+Mn+Al)=0.6, and sinter at 750°C for 20 hours for the first sintering to obtain LiNi 0.48 mn 1.44 Al 0.08 o 4 .

[0067] 5) LiNi 0.48 mn 1.44 Al 0.08 o 4 , LiF, TiO 2 powder, add pure water, mix, disperse, and dry to obtain a mixe...

Embodiment 3

[0070] 1) Ni(NO 3 ) 2 、C 4 h 6 o 4 Ni, Mn(NO 3 ) 2 and B 2 o 3 Add in pure water at a molar ratio of Ni:Mn:B=6:18:1 to form a mixed solution with a total molar concentration of 1.5mol / L. where Ni(NO 3 ) 2 and C 4 h 6 o 4 The molar ratio of Ni is 1:1.

[0071] 2) Under the conditions of a protective gas atmosphere, a stirring speed of 500rpm and 50°C, the ratio of the mixed complexing agent solution of ethylenediamine and ammonium sulfate to the mixed solution is according to the mixed complexing agent solution: (Mn+Ni+B) = 0.7 molar ratio, and adding KOH solution to adjust the pH value to 10, and carry out precipitation reaction to obtain a suspension solution. Wherein the molar ratio of ethylenediamine to ammonium sulfate is 2:1.

[0072] 3) Oxidize the suspended solution, centrifuge the solid, and dry to obtain a molecular formula of Ni 0.48 mn 1.44 B 0.08 OOH precursor powder.

[0073] 4) will Li 2 SO 4 and precursor powder by Li 2 SO 4 : (Ni+Mn+B) = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com