Fluconazole tablet composition, tablet and preparation method

A fluconazole tablet and composition technology, applied in the field of pharmaceutical preparations, can solve the problems of unstable fluconazole crystal form, low dissolution rate of ordinary tablets, and crystal form transformation, and achieve fast disintegration speed and dissolution The effect of high speed, good compressibility and low friability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

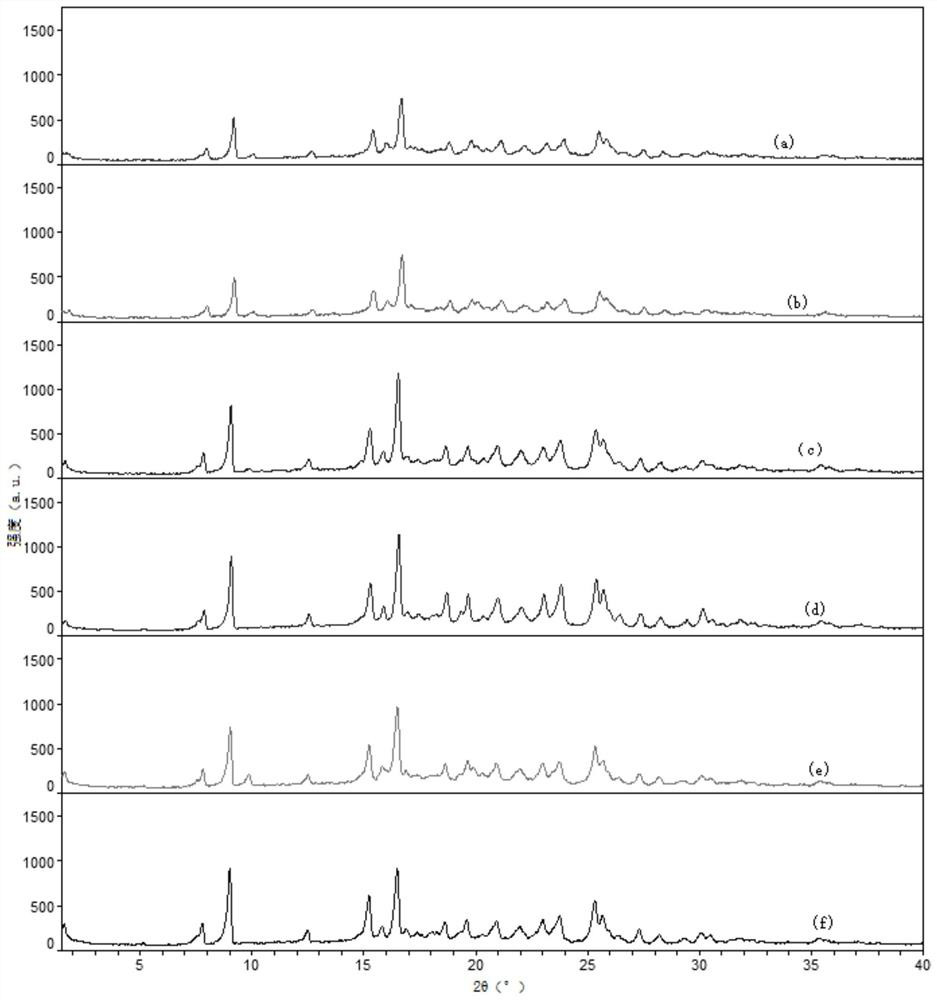

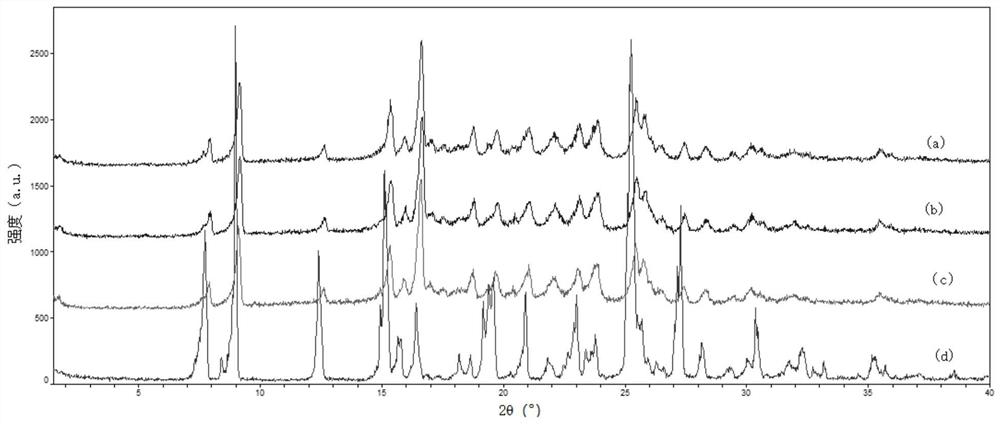

Image

Examples

Embodiment 1

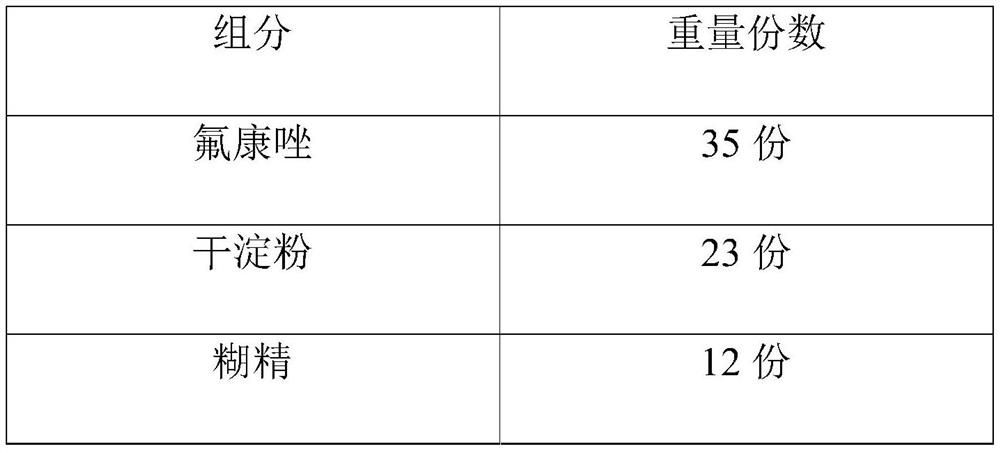

[0034] The present embodiment provides a kind of fluconazole tablet, and prescription consumption is as shown in the table below:

[0035]

[0036]

[0037] The preparation method of above-mentioned fluconazole tablet is as follows:

[0038] Step 1, pulverizing the fluconazole raw material through an 80-mesh sieve for subsequent use, and passing other auxiliary materials through a 60-mesh sieve for subsequent use;

[0039] Step 2: Take corn starch, add it to purified water at 40°C, stir and disperse evenly, then add purified water at 90°C to make slurry, cool down, and prepare starch slurry with a mass concentration of 5 wt%.

[0040] Step 3. Weigh each component according to the prescription amount, mix the weighed fluconazole, dry starch, dextrin, and low-substituted hydroxypropyl cellulose evenly, add the prepared starch slurry, and make a soft material. Soft materials are granulated with a 24-mesh sieve, and the wet granules are dried to control the moisture between...

Embodiment 2

[0042] The present embodiment provides a kind of fluconazole tablet, and prescription consumption is as shown in the table below:

[0043] components parts by weight Fluconazole 40 copies dry starch 25 copies dextrin 15 copies Low-substituted hydroxypropyl cellulose 6 servings Magnesium stearate 1.0 copies 7wt% starch slurry 17 copies

[0044] The preparation method of above-mentioned fluconazole tablet is as follows:

[0045] Step 1, pulverizing the fluconazole raw material through a 60-mesh sieve for subsequent use, and passing other auxiliary materials through a 100-mesh sieve for subsequent use;

[0046] Step 2: Take cornstarch, add it to purified water at 50°C, stir and disperse evenly, then add purified water at 100°C to make slurry, cool down, and prepare starch slurry with a mass concentration of 7wt%;

[0047] Step 3. Weigh each component according to the prescription amount, mix the weighed fluconazole, dry s...

Embodiment 3

[0049] The present embodiment provides a kind of fluconazole tablet, and prescription consumption is as shown in the table below:

[0050] components parts by weight Fluconazole 45 copies dry starch 20 copies dextrin 10 copies Low-substituted hydroxypropyl cellulose 8 servings Magnesium stearate 0.8 parts 6wt% starch slurry 18 copies

[0051] The preparation method of above-mentioned fluconazole tablet is as follows:

[0052] Step 1, pulverizing the fluconazole raw material through a 100-mesh sieve for subsequent use, and passing other auxiliary materials through an 80-mesh sieve for subsequent use;

[0053]Step 2: Take cornstarch, add it to purified water at 45°C, stir and disperse evenly, then add purified water at 80°C to make slurry, cool down, and prepare starch slurry with a mass concentration of 6 wt%.

[0054] Step 3. Weigh each component according to the prescription amount, mix the weighed fluconazole, dry st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com